ASTM B214-07

(Test Method)Standard Test Method for Sieve Analysis of Metal Powders

Standard Test Method for Sieve Analysis of Metal Powders

SIGNIFICANCE AND USE

The particle size distribution of a metal powder affects its behavior in P/M processing and other applications of these materials. The test method may be part of the purchase agreement between powder supplier and user, or it may be an internal quality control test for either.

SCOPE

1.1 This test method covers the dry sieve analysis of metal powders or mixed powders, using sieves with openings ranging from 45 to 1000 micrometers.

1.2 This test method is based on a particular type of mechanical sieve shaker (see 5.2). Other types of sieve shakers are also available, but their precision and reproducibility have not been determined.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B214–07

Standard Test Method for

1

Sieve Analysis of Metal Powders

This standard is issued under the fixed designation B214; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the dry sieve analysis of metal

E1638 Terminology Relating to Sieves, Sieving Methods

powdersormixedpowders,usingsieveswithopeningsranging

and Screening Media

from 45 to 1000 micrometers.

2.2 MPIF Standard:

1.2 This test method is based on a particular type of

MPIF 05 Determination of Sieve Analysis of Metal Pow-

mechanical sieve shaker (see 5.2). Other types of sieve shakers

3

ders

are also available, but their precision and reproducibility have

not been determined.

3. Terminology

1.3 The values stated in SI units are to be regarded as the

3.1 Definitions—Useful definitions of terms relating to

standard. The values given in parentheses are for information

powder metallurgy are found in B243 and those relating to

only.

sieve analysis are found in E1638.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 The particle size distribution of a metal powder affects

priate safety and health practices and determine the applica-

its behavior in P/M processing and other applications of these

bility of regulatory limitations prior to use.

materials. The test method may be part of the purchase

agreement between powder supplier and user, or it may be an

2. Referenced Documents

2

internal quality control test for either.

2.1 ASTM Standards:

B212 Test Method for Apparent Density of Free-Flowing

5. Apparatus

Metal Powders Using the Hall Flowmeter Funnel

5.1 Sieves—Select a set of standard sieves from the table

B215 Practices for Sampling Metal Powders

entitled, “Nominal Dimensions, Permissible Variations for

B243 Terminology of Powder Metallurgy

Wire Cloth of Standard Test Sieves (U.S.A.) Standard Sieves,”

B329 Test Method for Apparent Density of Metal Powders

of Specification E11, or the equivalent Tyler standard sieves.

and Compounds Using the Scott Volumeter

The sieves shall be 200 mm (8 in.) in diameter and either 25 or

B417 Test Method for Apparent Density of Non-Free-

50 mm (1 or 2 in.) in depth, and fitted with bronze, brass,

Flowing Metal Powders Using the Carney Funnel

stainless steel, or other suitable wire cloth. The U.S. sieves

B703 Test Method for Apparent Density of Powders Using

given in the table entitled, “U.S. Standard Series Test Sieves

Arnold Meter

and Equivalent Tyler Standard Sieves,” of this test method

E11 SpecificationforWovenWireTestSieveClothandTest

shall conform to Specification E11. If Tyler standard sieves are

Sieves

substituted, they shall conform to the permissible variations

given in the table entitled, “Nominal Dimensions, Permissible

1

Variations for Wire Cloth of Standard Test Sieves (U.S.A.)

This test method is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

Standard Sieves” of Specification E11.

mittee B09.02 on Base Metal Powders.

NOTE 1—The new U.S. Series standard sieves, adopted in 1970, are the

Current edition approved Jan. 1, 2007. Published January 2007. Originally

approved in 1946. Last previous edition approved in 1999 as B214 – 99. DOI: preferred sieves to use.The old U.S. Series standard sieves and equivalent

10.1520/B0214-07.

sieves manufactured by other companies, such as Tyler, may also be used

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Metal Powder Industries Federation (MPIF), 105 College Road

the ASTM website. East, Princeton, NJ 08540, http://www.mpif.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B214–07

if the new U.S. Series is not available. Care should be taken to make sure

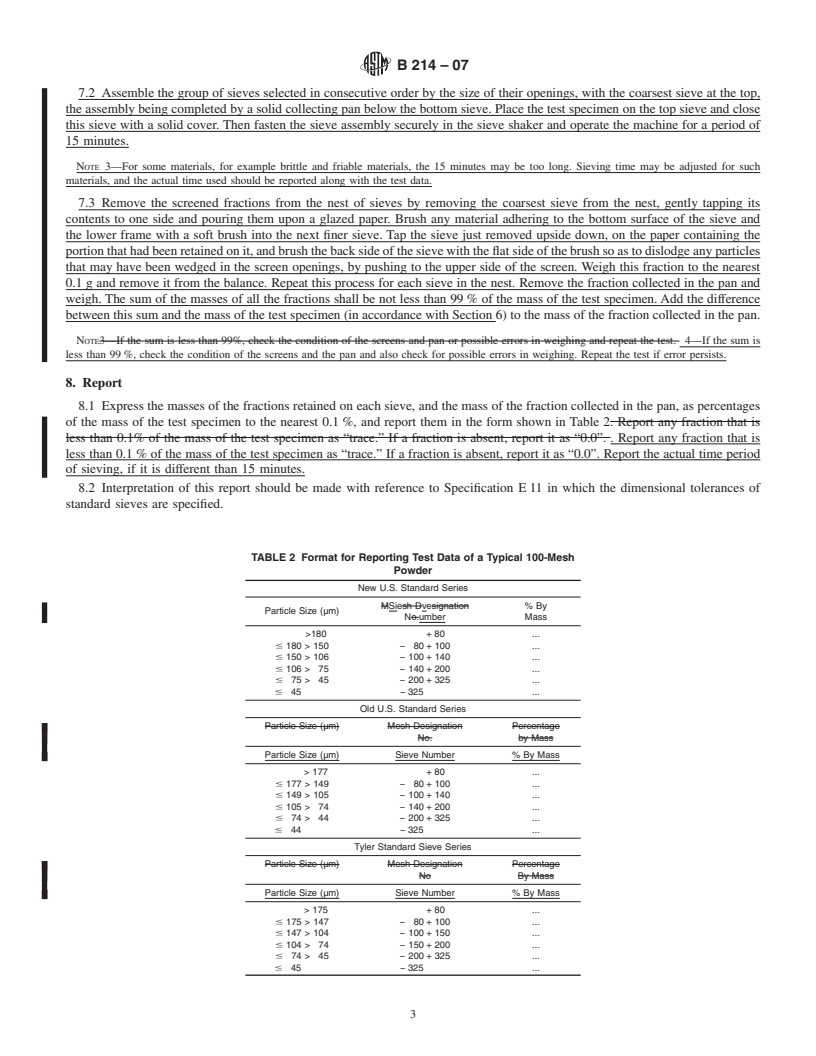

7.3 Remove the screened fractions from the nest of sieves

that sieve opening sizes are correct when performing standardization

by removing the coarsest sieve from the nest, gently tapping its

work.

contents to one side and pouring

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B214–99 Designation:B214–07

Standard Test Method for

1

Sieve Analysis of Metal Powders

This standard is issued under the fixed designation B 214; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1This test method covers the determination of the dry sieve analysis of metal powders.

1.2

1.1 Thistestmethodcoversthedrysieveanalysisofmetalpowdersormixedpowders,usingsieveswithopeningsrangingfrom

45 to 1000 micrometers.

1.2 This test method is based on a particular type of mechanical sieve shaker (see 5.2). Other types of sieve shakers are also

available, but their precision and reproducibility have not been determined.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B 212 Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel

2

B 215Practices for Sampling Finished Lots of Metal Powders Practices for Sampling Metal Powders

2

B 243Terminology of Powder Metallurgy Terminology of Powder Metallurgy

B 329 Test Method for Apparent Density of Metal Powders and Compounds Using the Scott Volumeter

B 417 Test Method for Apparent Density of Non-Free-Flowing Metal Powders Using the Carney Funnel

B 703 Test Method for Apparent Density of Powders Using Arnold Meter

E 11Specification for Wire-Cloth Sieves for Testing Purposes Specification for Wire Cloth and Sieves for Testing Purposes

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E 1638 Terminology Relating to Sieves, Sieving Methods and Screening Media

2.2 MPIF Standard:

3

MPIF 05 Determination of Sieve Analysis of Metal Powders

3. Terminology

3.1 Definitions—Useful definitions of terms for metal powders and powder metallurgy are found inTerminology B243—Useful

definitions of terms relating to powder metallurgy are found in B 243 and those relating to sieve analysis are found in E 1638.

4. Significance and Use

4.1 The particle size distribution of a metal powder affects its behavior in P/M processing and other applications of these

materials. The test method may be part of the purchase agreement between powder manufacturersupplier and user, or it may be

an internal quality control test for either. This test method is appropriate for materials with size distributions typified by metal

powders used in powder metallurgy.

1

This test method is under the jurisdiction of ASTM Committee B-9B09 on Metal Powders and Metal Powder Products,Products and is the direct responsibility of

Subcommittee B09.02 on Base Metal Powders.

Current edition approved April 10, 1999.Jan. 1, 2007. Published August 1999.January 2007. Originally published as B214–46T.approved in 1946. Last previous edition

approved in 1999 as B 214 – 929.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.05volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards , Vol 14.02.

3

Available from Metal Powder Industries Federation (MPIF), 105 College Road East, Princeton, NJ 08540, http://www.mpif.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B214–07

5. Apparatus

5.1 Sieves—A set of standard sieves selected from Table 1 of Specification E11, or the equivalent Tyler standard sieves. The

sieves shall be 8 in. (203.2 mm) in diameter and either 1 or 2 in. (25 or 50 mm) in depth and fitted with bronze, brass, stainless

steel, or other suitable wire cloth. The U.S. sieves given in Table 1 of this method shall conform to Specification E11. If Tyler

standard sieves are substituted, they shall conform to the permissible variations given in Table 1 of Specificatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.