ISO/DIS 18531

(Main)Implants for surgery -- Calcium phosphate bioceramics -- Characterization of hardening bone paste materials

Implants for surgery -- Calcium phosphate bioceramics -- Characterization of hardening bone paste materials

Implants chirurgicaux -- Biocéramiques à base de phosphate de calcium -- Caractérisation du durcissement des matériaux osseux sous forme de pâte

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 18531

ISO/TC 150/SC 1 Secretariat: DIN

Voting begins on: Voting terminates on:

2015-06-22 2015-09-22

Implants for surgery — Calcium phosphate bioceramics —

Characterization of hardening bone paste materials

Titre manque

ICS: 11.040.40

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 18531:2015(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2015

---------------------- Page: 1 ----------------------

ISO/DIS 18531:2015(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 18531:2015(E)

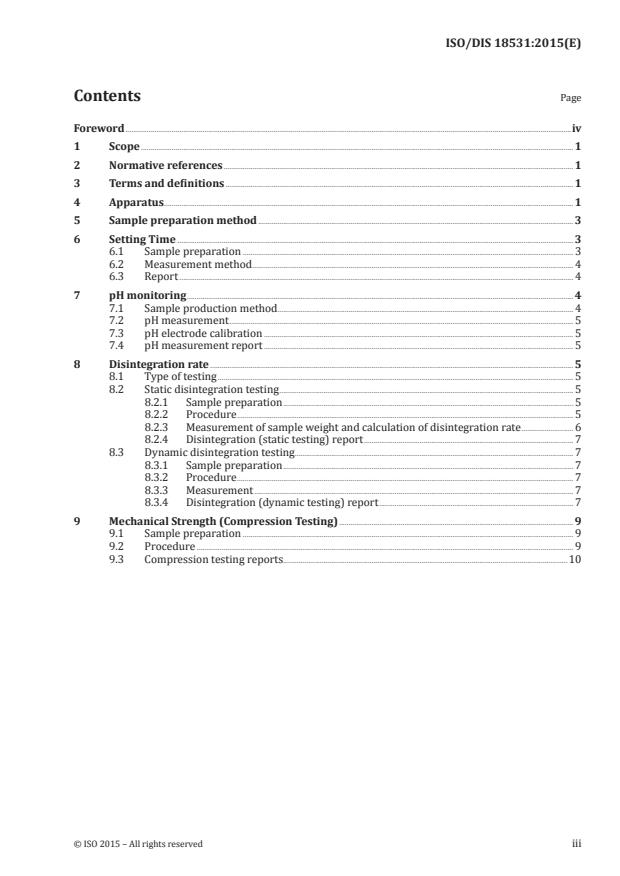

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Apparatus ..................................................................................................................................................................................................................... 1

5 Sample preparation method .................................................................................................................................................................... 3

6 Setting Time .............................................................................................................................................................................................................. 3

6.1 Sample preparation ............................................................................................................................................................................ 3

6.2 Measurement method ....................................................................................................................................................................... 4

6.3 Report ............................................................................................................................................................................................................. 4

7 pH monitoring ......................................................................................................................................................................................................... 4

7.1 Sample production method.......................................................................................................................................................... 4

7.2 pH measurement ................................................................................................................................................................................... 5

7.3 pH electrode calibration ................................................................................................................................................................. 5

7.4 pH measurement report ................................................................................................................................................................. 5

8 Disintegration rate ............................................................................................................................................................................................. 5

8.1 Type of testing ......................................................................................................................................................................................... 5

8.2 Static disintegration testing ......................................................................................................................................................... 5

8.2.1 Sample preparation ....................................................................................................................................................... 5

8.2.2 Procedure ............................................................................................................................................................................... 5

8.2.3 Measurement of sample weight and calculation of disintegration rate ........................... 6

8.2.4 Disintegration (static testing) report ............................................................................................................. 7

8.3 Dynamic disintegration testing................................................................................................................................................. 7

8.3.1 Sample preparation ....................................................................................................................................................... 7

8.3.2 Procedure ............................................................................................................................................................................... 7

8.3.3 Measurement ...................................................................................................................................................................... 7

8.3.4 Disintegration (dynamic testing) report ..................................................................................................... 7

9 Mechanical Strength (Compression Testing) .......................................................................................................................... 9

9.1 Sample preparation ............................................................................................................................................................................ 9

9.2 Procedure .................................................................................................................................................................................................... 9

9.3 Compression testing reports....................................................................................................................................................10

© ISO 2015 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 18531:2015(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directivesAttention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received. www.iso.org/patentsAny trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT), see the following URL: Foreword - Supplementary informationThe committee responsible for this document is ISO/TC 150, Implants for surgery, Subcommittee

SC 1, Materials.iv © ISO 2015 – All rights reserved

---------------------- Page: 4 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 18531:2015(E)

Implants for surgery — Calcium phosphate bioceramics —

Characterization of hardening bone paste materials

1 Scope

This International Standard specifies methods for measuring the physicochemical characteristics of

calcium phosphate ceramic bone cement materials, prepared from mixing powder and liquid agents as

supplied by the manufacturer and used in artificial bones and similar applications.

2 Normative referencesThe following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 7500-1, Metallic materials — Verification of static uniaxial testing machines — Part 1: Tension/compression

testing machines — Verification and calibration of the force-measuring systemISO 80000-1, Quantities and units — Part 1: General

3 Terms and definitions

For the purposes of this standard, the following terms and definitions apply.

3.1

calcium phosphate bone cement

mixture of calcium phosphate powder and a liquid agent that after hardening becomes artificial bone

3.2setting

loss of fluidity and hardening of a bone cement produced by a chemical reaction

3.3

setting time

time required from the start of powdered agent and liquid agent blending until hardening of the cement

3.4disintegration rate

weight ratio of the disintegrated portion of the cylinder to that of the whole cylinder of the bone cement,

when the cylinder is immersed in the physiological saline before hardening4 Apparatus

4.1 Analytical eletronic balance, with 1 mg, or greater resolution.

4.2 Plastic spatula, with a flat tip for kneading the bone paste. To ensure uniform kneading of bone

paste, a plastic spatula used primarily in dentistry is recommended.4.3 Cement mixing tablet, for kneading the bone paste. To ensure uniform kneading of bone paste, a

cement mixing tablet used primarily in dentistry is recommended. General purpose kneading tools, such

as knife or spatula are also required.© ISO 2015 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/DIS 18531:2015(E)

4.4 Adjustable incubator or thermostatic bath, with a capacity of mantaining the material at a

controlled temperature of (37 ± 2) °C and a controlled humidity of 95 % and 100 %, used for hardening

measurements (see Clause 6), for disintegration tests (see Clause 8) and for compression test (see

Clause 9). Alternatively, for the dynamic compression test (see 8.3), a thermostatic jacket, with capacity

of mantaining the container temperature at (37 ± 0,5) °C during testing can be used.

To create 95 % to 100 % relative humidity in the incubator, attach an auxiliary tray such that water

extends into the bottom of the opening/closing apparatus. Place a mould packed with bone paste onto

the auxiliary tray; any water submerging the bottom surface of the tray presents a problem. To maintain

a state of elevated humidity, the entire incubator may also be placed in a thermostatic chamber.

4.5 Specimen mould, for hardening measurements (see Clause 6), with diameter between 7 mm

and 15 mm, and height between 3 mm and 5 mm. The mould used may be a vinyl chloride, acrylic,

Polytetrafluoroethylene (PTFE), or other such pipe cut to an appropriate size.4.6 Gillmore needle apparatus, for hardening measurements (see Clause 6). Setting time shall be

measured with a light needle arm.NOTE 1 This selection is a criterion for the recommended time elapsed in bone paste kneading and filling

procedures.NOTE 2 There are two needle arms in the apparatus, light and heavy - the first, with a 2,12 mm diameter and

113,4 g mass, and the other, with a 1,06 mm diameter and 453,6 g mass. The light needle arm is intended to show

early hardening behaviour, and the heavy type to show subsequent hardening behaviour.

4.7 Specimen preparing device for pH monitoring, plastic tube with inner diameter 8 mm to 9 mm

and a piston extruder, as presented in Figure 1, for pH-monitoring (see Clause 7).

4.8 Separating sheet or plastic sheet, e.g. a vinyl sheet, approx. 0,2 mm thickness, allowing ready

separation of the bone paste and extruders. For pH-monitoring (see Clause 7), with approximately from

7,5 mm to 8,5 mm diameter, according to the diameter of the piston producing specimens. For static

disintegration test (see 8.2), with approximately 4 mm.4.9 Sample moulding tool, with inner diameter 4,8 mm, comprising an outer tube and an extruder which

produce a bone paste sample with dimensions of 4,8 mm diameter, 16,5 mm length, and approximately

0,3 mL volume, used for static disintegration test (see 8.2).4.10 Plastic container, with a volume of approximately 50 mL and a 50 mm inner diameter, for sample

immersion in static disintegration test (see 8.1).4.11 Physiological saline, isotonic solution containing 9,0 g of NaCl per litre.

4.12 Stainless steel wire rack, with 0,5 mm wire diameter, 10 mesh, 2,0 mm grid, 2 mm to 4 mm height,

for supporting sample in the plastic container bath (see 8.2).4.13 Dryer or incubator, with capacity of mantaining the material at a controlled temperature of

(65 ± 5) °C, used for disintegration tests (see Clause 8).4.14 Sample mould, a cylindrical tube with an inner diameter of 8 mm to 9 mm and a length of 16 mm

to 18 mm, used for dynamic disintegration tests (see 8.3).NOTE A volumetric disposable syringe with the outer tube tip cut off may be used.

4.15 Dynamic disintegration device, comprising a closable container of glass or other such inert

material, a motor, and a rotating axis and circular basket and a rotation adjuster. The container is a

cylinder with a lip at the top and a semi-circular bottom, capacity of 1 L, height of 160 mm to 210 mm, and

2 © ISO 2015 – All rights reserved---------------------- Page: 6 ----------------------

ISO/DIS 18531:2015(E)

inner diameter of 98 mm to 106 mm. The rotating axis and cylindrical bath shall be made from stainless

steel (SUS316) or an equivalent inert material. Figure 4 presents an example of a rotating axis and basket.

The rotation adjuster shall allow adjustment in a range of the specified rpm ± 4 %. In addition to smooth

rotation of the rotating axis, shall be ensured that no shaking or vibration by the apparatus or from its

environs develops. To prevent the sample from contacting the basket, a sinker made from acid-resistant

wire or other mesh (see Figure 5) shall be used.4.16 Polytetrafluoroethylene (PTFE) split mould, with a through-hole of 6 mm and a thickness of

12 mm for the manufacture of compression specimens, constructed as a two-part split mould, such as

shown in Figure 6, with the two halves being secured by a clamp (see Clause 9).4.17 Micrometre or calliper, to measure specimen diameter, used for compression test (see Clause 9).

4.18 Glass sheet, to scrape off the bone paste protruding from the through-hole of the

Polytetrafluoroethylene (PTFE) split mould (4.16),...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.