ISO 29461-2:2022

(Main)Air intake filter systems for rotary machinery — Test methods — Part 2: Filter element endurance test in fog and mist environments

Air intake filter systems for rotary machinery — Test methods — Part 2: Filter element endurance test in fog and mist environments

This document specifies general test requirements, the test rig and equipment, the test materials and the test procedure and report for determining water endurance performance of air filter elements used in air intake filter systems for rotary machinery such as stationary gas turbines, compressors and other stationary internal combustion engines. The test evaluates water endurance performance of air filter elements under laboratory conditions. The performance results obtained in accordance with this document cannot be quantitatively applied (by themselves) to predict performance in service with regard to water endurance and lifetime.

Systèmes de filtration d'air d'admission pour machines tournantes — Méthodes d'essai — Partie 2: Essai d'endurance d'élément filtrant en brouillard et environnement brumeux

Le présent document spécifie les exigences générales d'essai, le banc et les équipements d'essai, les produits pour l'essai, le mode opératoire d'essai et le rapport pour la détermination des performances de résistance à l'eau des éléments filtrants utilisés dans les systèmes de filtration d'air d'admission des machines tournantes comme les turbines à gaz stationnaires, les compresseurs et autres moteurs stationnaires à combustion interne. L'essai évalue la performance de résistance à l'eau des éléments filtrants dans des conditions de laboratoire. Les données de performances obtenues conformément au présent document ne peuvent pas être utilisées quantitativement (par elles-mêmes) pour prédire les performances en service en termes de résistance à l'eau et de durée de vie.

General Information

Relations

Buy Standard

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 29461-2

First edition

2022-08

Air intake filter systems for rotary

machinery — Test methods —

Part 2:

Filter element endurance test in fog

and mist environments

Systèmes de filtration d'air d'admission pour machines tournantes —

Méthodes d'essai —

Partie 2: Essai d'endurance d'élément filtrant en brouillard et

environnement brumeux

Reference number

ISO 29461-2:2022(E)

© ISO 2022

---------------------- Page: 1 ----------------------

ISO 29461-2:2022(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO 2022 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 29461-2:2022(E)

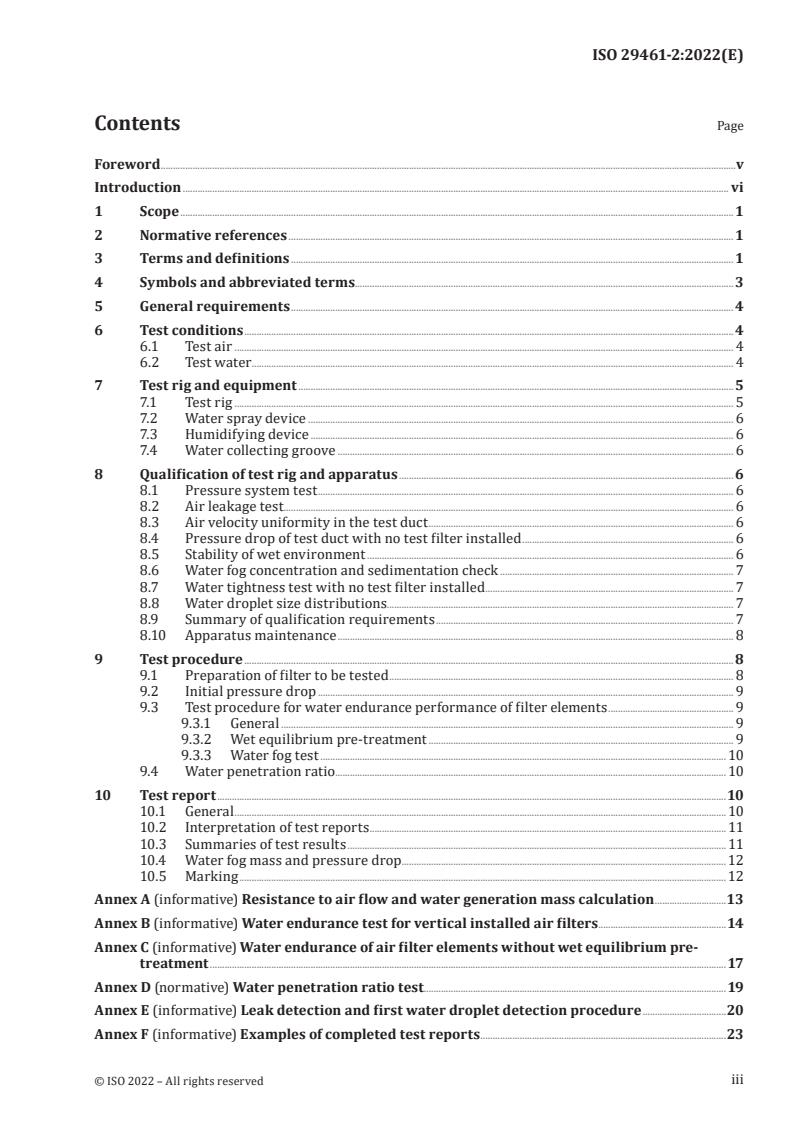

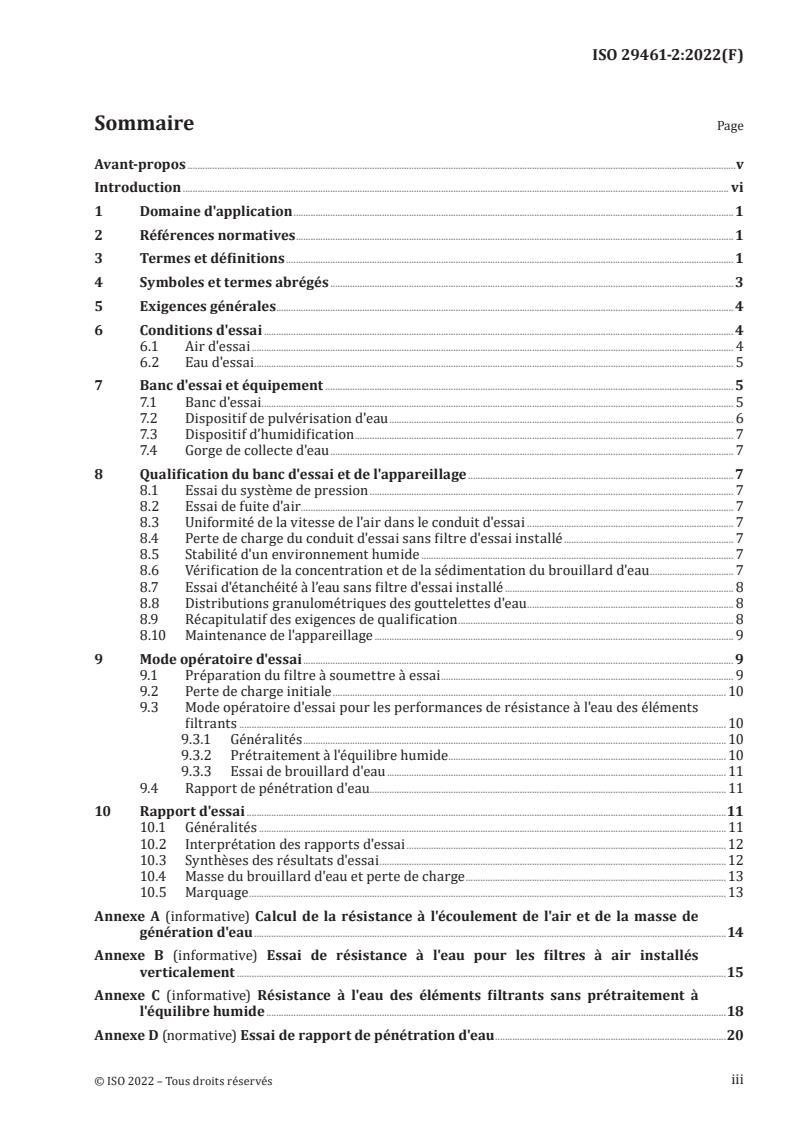

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms.3

5 General requirements . 4

6 Test conditions .4

6.1 Test air . 4

6.2 Test water . 4

7 Test rig and equipment .5

7.1 Test rig . 5

7.2 Water spray device . 6

7.3 Humidifying device . 6

7.4 Water collecting groove . 6

8 Qualification of test rig and apparatus . 6

8.1 Pressure system test . 6

8.2 Air leakage test. 6

8.3 Air velocity uniformity in the test duct . 6

8.4 Pressure drop of test duct with no test filter installed . 6

8.5 Stability of wet environment . 6

8.6 Water fog concentration and sedimentation check . 7

8.7 Water tightness test with no test filter installed . 7

8.8 Water droplet size distributions. 7

8.9 Summary of qualification requirements . 7

8.10 Apparatus maintenance . 8

9 Test procedure .8

9.1 Preparation of filter to be tested . 8

9.2 Initial pressure drop . 9

9.3 Test procedure for water endurance performance of filter elements . 9

9.3.1 General . 9

9.3.2 Wet equilibrium pre-treatment . 9

9.3.3 Water fog test . 10

9.4 Water penetration ratio . 10

10 Test report .10

10.1 General . 10

10.2 Interpretation of test reports . 11

10.3 Summaries of test results . 11

10.4 Water fog mass and pressure drop.12

10.5 Marking .12

Annex A (informative) Resistance to air flow and water generation mass calculation .13

Annex B (informative) Water endurance test for vertical installed air filters .14

Annex C (informative) Water endurance of air filter elements without wet equilibrium pre-

treatment .17

Annex D (normative) Water penetration ratio test .19

Annex E (informative) Leak detection and first water droplet detection procedure .20

Annex F (informative) Examples of completed test reports .23

iii

© ISO 2022 – All rights reserved

---------------------- Page: 3 ----------------------

ISO 29461-2:2022(E)

Bibliography .31

iv

© ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 29461-2:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 142, Cleaning equipment for air and other

gases, in collaboration with the European Committee for Standardization (CEN) Technical Committee

CEN/TC 195, Cleaning equipment for air and other gases, in accordance with the Agreement on technical

cooperation between ISO and CEN (Vienna Agreement).

A list of all parts in the ISO 29461 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

© ISO 2022 – All rights reserved

---------------------- Page: 5 ----------------------

ISO 29461-2:2022(E)

Introduction

The ISO 29461 series provides a way to compare these products in a similar method and define what

criteria are important for air intake filter systems for rotary machinery performance protection. The

aim is to compare the performance of different filters and filter types with respect to the operating

conditions in which they will be finally used.

Air intake filter system of rotary machinery is an important part of the whole gas turbine and air

compressor systems. It usually consists of filter elements with a suitable way to be installed. The

operating environment of rotary machinery including gas turbine and compressor and their air intake

filtration units are complicated and challenging. Air filters intercept water mist and droplets when air

passes through the air filter unit in case the equipment is working in rainy, foggy, hazy or other high-

humidity environments or a local production environment which contains a large amount of water

vapour, e.g. the cooling tower. If excessive water holds up, the performance of filters can be affected;

pressure drop rises rapidly, causing a shut down in severe cases.

Reliability and non-break down operation of rotary machinery are regarded as a top priority for the

end users, with the rapidly rising pressure drop under high-humidity conditions usually being their

main concern. There are rotary machinery operating accidents caused by high-humidity conditions all

over the world, whether it be inland or along the river or coastal.

To meet the requirements of production and operation, the water endurance performance of air filter

elements needs to be considered besides assessing the performance of initial pressure drop, filtration

efficiency and dust-holding capacity, especially when the air filter elements are used in high-humidity

environments or intake air contains a large quantity of liquid droplets.

This document provides a water endurance test method for filter elements and can be used for

evaluating performance variation trends of filter elements when encountering water and fog. This

document can be used for:

— product development for filter manufacturers;

— supplier selection for end users;

— development of water endurance media by media manufacturers.

This document provides a repeatable, easy-to-conduct and economical test method, which is applicable

to pulse-jet cleaning filter elements and filter elements for general ventilation.

vi

© ISO 2022 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 29461-2:2022(E)

Air intake filter systems for rotary machinery — Test

methods —

Part 2:

Filter element endurance test in fog and mist

environments

1 Scope

This document specifies general test requirements, the test rig and equipment, the test materials and

the test procedure and report for determining water endurance performance of air filter elements used

in air intake filter systems for rotary machinery such as stationary gas turbines, compressors and other

stationary internal combustion engines.

The test evaluates water endurance performance of air filter elements under laboratory conditions. The

performance results obtained in accordance with this document cannot be quantitatively applied (by

themselves) to predict performance in service with regard to water endurance and lifetime.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 16890-2:2022, Air filters for general ventilation — Part 2: Measurement of fractional efficiency and air

flow resistance

3 Terms and definitions

For the purposes of this document the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Air flow and pressure drop

3.1.1

air flow rate

volume of air flowing through the filter per unit time

[SOURCE: ISO 29464:2017, 3.1.24]

3.1.2

test air flow rate

volumetric airflow rate used for testing

[SOURCE: ISO 29464:2017, 3.3.2]

1

© ISO 2022 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 29461-2:2022(E)

3.1.3

pressure drop

difference in absolute (static) pressure between two points in a system

Note 1 to entry: Resistance to air flow is measured in Pa.

[SOURCE: ISO 29464:2017, 3.1.36]

3.1.4

initial pressure drop

pressure drop (3.1.3) of the clean filter operating at the test airflow rate

[SOURCE: ISO 29464:2017, 3.3.17]

3.1.5

final test pressure drop

maximum pressure drop (3.1.3) of the filter up to which the filtration performance is measured

[SOURCE: ISO 29464:2017, 3.3.15]

3.2 Filters

3.2.1

test device

filter element (3.2.2) being subjected to performance testing

[SOURCE: ISO 29464:2017, 3.1.38]

3.2.2

filter element

structure made of the filtering material, its supports and its interfaces with the filter housing

[SOURCE: ISO 29464:2017, 3.2.77]

3.2.3

upstream

area or region from which fluid flows as it enters the test device (3.2.1)

[SOURCE: ISO 29464:2017, 3.1.39]

3.2.4

downstream

area or region into which fluid flows on leaving the test device (3.2.1)

[SOURCE: ISO 29464:2017, 3.1.11]

3.2.5

static filter

air filter that will be removed (exchanged) after it has reached its final test pressure drop (3.1.5) and

that is not cleaned with jet pulses or other means in order to fully, or partially, retrieve its initial

performance (pressure drop and efficiency)

[SOURCE: ISO 29464:2017, 3.3.12]

3.2.6

pulse jet filter

cleanable air filter, that typically is cleaned with air jet pulses to provide a longer service life

[SOURCE: ISO 29464:2017, 3.3.11]

2

© ISO 2022 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 29461-2:2022(E)

3.3

test duration

period of reaching a certain pressure drop (3.1.3) or other termination conditions to end the test

3.4 Test materials

3.4.1

water fog

water droplets and mist generated by water spray device

3.4.2

saturated air

air that contains the maximum amount of water vapour it can hold at its temperature and pressure

3.4.3

water fog mass concentration

mass of liquid water droplets per unit volume of air

3.5

two-fluid nozzle

nozzles capable of spraying fine mists by mixing fluid and air at the same time

3.6

coefficient of variation

CV

standard deviation of a group of measurements divided by the mean

[SOURCE: ISO 29464:2017, 3.2.31]

4 Symbols and abbreviated terms

3

c

water fog mass concentration, g/m

wm

d

saturated wet air moisture content, g/kg

d

ambient air moisture content, g/kg

0

m

water mass penetrated through tested filter at the end of the test, kg

p

m

total water fog generation amount, kg

tot

m

sedimentary water mass upstream of filter, kg

u

m

total water fog generation amount per hour, kg/h

wm

m

water fog generation amount per hour at saturated humidifying air, kg/h

wm, 1

m

water fog generation amount per hour, kg/h

wm, 2

p

atmospheric pressure, Pa

absolute air pressure upstream of filter, Pa

p

a

partial vapour pressure of water in air, Pa

p

w

saturated vapour pressure of humidifying air, Pa

p

ws

3

q

volumetric flow of non-humidifying air, m /h

v

t

temperature downstream of filter, °C

d

3

© ISO 2022 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 29461-2:2022(E)

t

dry bulb temperature of ambient air, °C

0

t

temperature upstream of filter, °C

u

t

wet bulb temperature of ambient air, °C

wb

T

testing time, min

T

total testing time, min

tot

filter initial pressure drop at the test air flow rate, Pa

Δp

b

filter final test pressure drop at the test air flow rate, Pa

Δp

f

filter pressure drop at the test air flow rate at the T time after spraying, Pa

Δp

T

η

water penetration ratio

p

ρ 3

ambient air density, kg/ m

3

ρ

air density upstream of filter, kg/m

a

3

ρ

saturated wet air density, kg/m

s

ϕ

relative humidity, %

ϕ

relative humidity upstream of filter, %

u

ϕ

relative humidity downstream of filter, %

d

CV coefficient of variation

5 General requirements

Air filter systems normally use multiple stages of coarse and fine filter elements to protect the

machinery. The scope of this document includes methods for a water endurance test of individual

filter elements. It does not include methods for the direct measurement of the performance of entire

systems as installed in service except in cases where they can meet the qualification criteria for the test

assembly.

The test client can refer to the test results to rank the water endurance performance of multiple

candidate filters.

6 Test conditions

6.1 Test air

Room air or outdoor air is used as the test air source. The air temperature shall be in the range of

10 °C to 38 °C (before wet equilibrium pre-treatment). The exhaust flow shall be discharged outdoors,

indoors or re-circulated. Filtration of the exhaust flow is recommended when the test aerosol or loading

dust is present.

6.2 Test water

The test water pH value shall be in the range of 6 to 8; alkalinity shall be no more than 50 mg/l; full

hardness shall be no more than 70 mg/l. The temperature of the test water shall not be higher than the

temperature of the test air.

4

© ISO 2022 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 29461-2:2022(E)

7 Test rig and equipment

7.1 Test rig

The test rig consists of several square duct sections with typical 610 mm × 610 mm nominal inner

dimensions except for the section where the filter is installed. This section has nominal inner dimensions

between 616 mm and 622 mm. The length of this duct section shall be at least 1,1 times the length of the

filter, with a minimum length of 1,5 m. A schematic diagram of the test rig is shown in Figure 1.

The test rig can be operated either in a negative or positive pressure air flow arrangement; and negative

pressure operation is recommended. The test duct shall be sealed well to avoid water fog leakage if

operated in positive pressure. A condensed water borehole should be provided at the lowest point in

the fan housing in the event of formation of condensation.

The duct material shall be electrically conductive and electrically grounded and shall have a smooth

interior finish and be sufficiently rigid to maintain its shape at the operating pressure. Smaller parts

of the test duct can be made in glass or plastic to expose the filter and equipment to view. Provision of

windows to allow monitoring of test progress is desirable.

Dimensions in millimetres

Key

A duct section of the test rig (inlet plenum) 7 example of water droplet size instrument location

B upstream duct section of the test rig 8 upstream pressure measuring point

C duct section of filter to be tested 9 upstream water collecting groove

D diameter of recirculated duct 10 filter to be tested

E downstream duct section of the test rig 11 midstream water collecting groove

downstream measuring point of temperature and

F recirculated duct section of the test rig 12

humidity (secondary)

1 HEPA filter 13 downstream pressure measuring point

2 humidifying device 14 downstream water collecting groove

3 water mass flow metering device 15 final filter - eliminate water

4 water mass flow metering device 16 frequency converted fan

5 water spray device 17 air flow measuring point

upstream measuring point of temperature and

6

humidity (primary)

Figure 1 — Schematic diagram of the test rig

5

© ISO 2022 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 29461-2:2022(E)

7.2 Water spray device

The water spray device is used to generate uniform water fog continuously to feed the filter to be tested

during the test.

A two-fluid nozzle is recommended; and the spraying direction with respect to the inlet air flow shall

be the same. The distance between the nozzle orifices and the duct section of filter to be tested shall be

no less than 1 m.

The water fog particle can be adjusted by compressed air, or other means as called out by the nozzle

manufacturer. The cumulative volume of water fog particles in the size range of 5 μm to 30 μm shall be

more than 90 % of the total water fog volume.

Other types of water spray devices, such as ultrasonic humidifier and nozzle humidifier, can be used if

these devices can achieve the same performance.

7.3 Humidifying device

The humidifying device shall maintain the required humidity in the test duct, which can be used for

wet equilibrium pre-treatment. The optional humidifying devices, such as ultrasonic humidifier and

atomizer, shall meet the requirements of 8.5.

7.4 Water collecting groove

The water collecting grooves shall be installed at the bottom of upstream and downstream of tested

filter to collect water during the test.

8 Qualification of test rig and apparatus

8.1 Pressure system test

Carry out the pressure system test in accordance with ISO 16890-2:2022, 8.2.1.

8.2 Air leakage test

Carry out the air leakage test in accordance with ISO 16890-2:2022, 8.2.8.

8.3 Air velocity uniformity in the test duct

Carry out the air velocity uniformity test in the test duct in accordance with ISO 16890-2:2022, 8.2.9.

8.4 Pressure drop of test duct with no test filter installed

Carry out the test of pressure drop of test duct with no test filter installed in accordance with

ISO 16890-2:2022, 8.2.12.

8.5 Stability of wet environment

The temperature measuring instrument used shall be capable of measuring temperature with an

accuracy of ±1 °C. The relative humidity measuring instrument used shall be capable of measuring the

relative humidity with an accuracy of ±2 %. The equipment shall be calibrated at regular intervals to

ensure the required accuracy.

Turn on the humidifying device until the measured relative humidity of the upstream and downstream

3

test duct exceeds 95 % at the qualification air flow rate of 3 400 m /h. Start to record the temperature

and relative humidity of the upstream and downstream test duct every 2 min. The total test time is

30 min.

6

© ISO 2022 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 29461-2:2022(E)

The relative humidity of upstream and downstream shall always exceed 95 % during the test.

To ensure the stability of the wet environment, it is important to limit the condensation and sediment

water mass to a low level and thus minimize the effect on the water fog concentration and results of

the test, therefore the total mass of water collected in the whole test duct section shall be less than 50 g

after the test.

8.6 Water fog concentration and sedimentation check

This test is used to ensure that the water fog concentration, in the section where the filter is installed,

can meet the requirements of this document.

3

Weigh and then install the final filter. Start to generate humidity at an air flow rate of 3 400 m /h. The

relative humidity in the upstream duct shall not be less than 95 %.

3

Turn on the water spray device and adjust the water fog concentration to 6,0 g/m . The duration time is

30 min and the relative humidity in the upstream test duct shall not be less than 95 % during the test.

Turn off the water spray device after 30 min. Weigh the final filter.

Collect the water in the upstream test duct to the upstream groove. The collected water mass shall be

less than 5 % of the total water mass.

8.7 Water tightness test with no test filter installed

This test is used to ensure the water tightness of the duct and that no leakage is found during the whole

water endurance test.

This test is carried out along with the instructions in 8.5 and 8.6.

No droplets leakage shall be found from the test duct during the test.

Collect the water in the upstream and downstream test duct of the filter to be tested and final filter. The

collected water mass shall not be less than 90 % of the total water mass.

8.8 Water droplet size distributions

This test is used to ensure that the water droplet size distribution, in the section where the filter is

installed, can meet the requirements of this document.

A laser diffraction particle size analyser is recommended, which uses the technique of laser diffraction

for measurement of the size of spray droplets and the accuracy shall be better than 3 %. The measuring

point shall be located in the lateral centre of the upstream duct section, and as close as possible to the

duct section of the filter to be tested.

3 3

Turn on the water spray device and adjust the water fog concentration to 6,0 g/m at 3 400 m /h. The

relative humidity in t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.