ISO/DIS 11135

(Main)Sterilization of health care products -- Ethylene oxide -- Requirements for development, validation and routine control of a sterilization process for medical devices

Sterilization of health care products -- Ethylene oxide -- Requirements for development, validation and routine control of a sterilization process for medical devices

Stérilisation des produits de santé -- Oxyde d'éthylène -- Exigences de développement, validation et contrôle de routine d'un processus de stérilisation pour des dispositifs médicaux

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 11135

ISO/TC 198 Secretariat: ANSI

Voting begins on: Voting terminates on:

2004-05-20 2004-10-20

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Sterilization of health care products — Ethylene oxide —Requirements for development, validation and routine control of

a sterilization process for medical devices

Stérilisation des produits de santé — Oxyde d'éthylène — Exigences de développement, validation et contrôle

de routine d'un processus de stérilisation pour des dispositifs médicaux[Revision of first edition (ISO 11135:1994)]

ICS 11.080.01

ISO/CEN PARALLEL ENQUIRY

The CEN Secretary-General has advised the ISO Secretary-General that this ISO/DIS covers a subject

of interest to European standardization. In accordance with the ISO-lead mode of collaboration as

defined in the Vienna Agreement, consultation on this ISO/DIS has the same effect for CEN

members as would a CEN enquiry on a draft European Standard. Should this draft be accepted, a

final draft, established on the basis of comments received, will be submitted to a parallel two-month FDIS

vote in ISO and formal vote in CEN.In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2004

---------------------- Page: 1 ----------------------

ISO/DIS 11135

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2004 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 11135

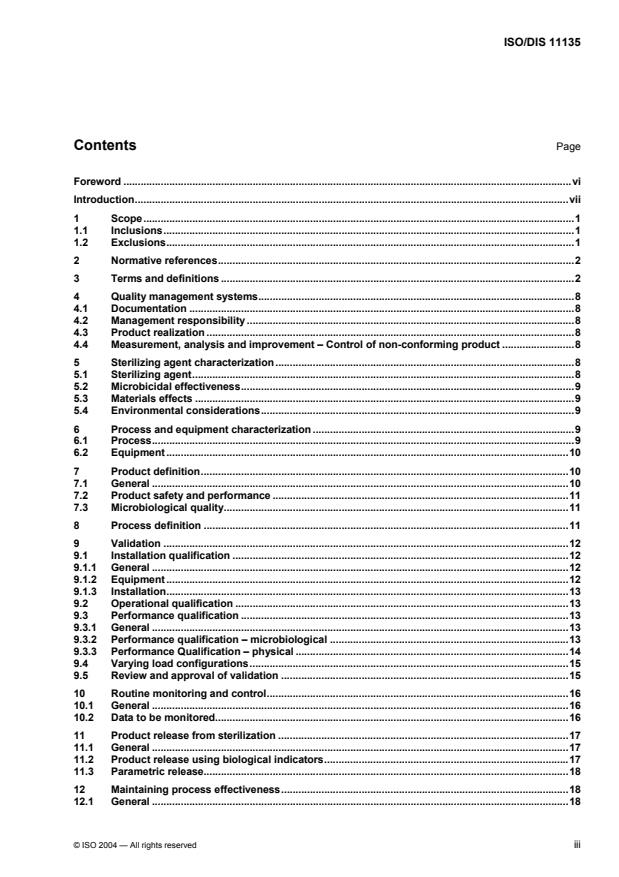

Contents Page

Foreword ............................................................................................................................................................vi

Introduction.......................................................................................................................................................vii

1 Scope......................................................................................................................................................1

1.1 Inclusions...............................................................................................................................................1

1.2 Exclusions..............................................................................................................................................1

2 Normative references............................................................................................................................2

3 Terms and definitions ...........................................................................................................................2

4 Quality management systems..............................................................................................................8

4.1 Documentation ......................................................................................................................................8

4.2 Management responsibility ..................................................................................................................8

4.3 Product realization ................................................................................................................................8

4.4 Measurement, analysis and improvement – Control of non-conforming product .........................8

5 Sterilizing agent characterization........................................................................................................8

5.1 Sterilizing agent.....................................................................................................................................8

5.2 Microbicidal effectiveness....................................................................................................................9

5.3 Materials effects ....................................................................................................................................9

5.4 Environmental considerations.............................................................................................................9

6 Process and equipment characterization ...........................................................................................9

6.1 Process...................................................................................................................................................9

6.2 Equipment ............................................................................................................................................10

7 Product definition................................................................................................................................10

7.1 General .................................................................................................................................................10

7.2 Product safety and performance .......................................................................................................11

7.3 Microbiological quality........................................................................................................................11

8 Process definition ...............................................................................................................................11

9 Validation .............................................................................................................................................12

9.1 Installation qualification .....................................................................................................................12

9.1.1 General .................................................................................................................................................12

9.1.2 Equipment ............................................................................................................................................12

9.1.3 Installation............................................................................................................................................13

9.2 Operational qualification ....................................................................................................................13

9.3 Performance qualification ..................................................................................................................13

9.3.1 General .................................................................................................................................................13

9.3.2 Performance qualification – microbiological ...................................................................................13

9.3.3 Performance Qualification – physical ...............................................................................................14

9.4 Varying load configurations...............................................................................................................15

9.5 Review and approval of validation ....................................................................................................15

10 Routine monitoring and control.........................................................................................................16

10.1 General .................................................................................................................................................16

10.2 Data to be monitored...........................................................................................................................16

11 Product release from sterilization .....................................................................................................17

11.1 General .................................................................................................................................................17

11.2 Product release using biological indicators.....................................................................................17

11.3 Parametric release...............................................................................................................................18

12 Maintaining process effectiveness....................................................................................................18

12.1 General .................................................................................................................................................18

© ISO 2004 — All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 11135

12.2 Maintenance of equipment ................................................................................................................ 18

12.3 Requalification .................................................................................................................................... 18

12.4 Assessment of change....................................................................................................................... 19

Annex A (normative) Bioburden Method ....................................................................................................... 20

A.1 General– Bioburden-Approach Method ........................................................................................... 20

A.2 Bioburden evaluations ....................................................................................................................... 20

A.3 Sampling.............................................................................................................................................. 20

A.4 Procedure ............................................................................................................................................ 21

Annex B (normative): Biological Indicator/Bioburden Method................................................................... 22

B.1 General................................................................................................................................................. 22

B.2 Procedure ............................................................................................................................................ 22

B.3 Enumeration........................................................................................................................................ 23

B.3.1 Direct enumeration ............................................................................................................................. 23

B.3.2 Fraction Negative Method using Spearman Karber........................................................................ 23

B.3.3 Fraction Negative Method using Stumbo Murphy Cochran........................................................... 23

Annex C (Normative): Overkill....................................................................................................................... 24

C.1 Conservative process definition based on the inactivation of reference microorganisms........ 24

C.2 Procedure ............................................................................................................................................ 24

Annex D (Informative) - General guidance .................................................................................................... 26

D.1 Scope ................................................................................................................................................... 26

D.1.1 Inclusions ............................................................................................................................................ 26

D.1.2 Exclusions........................................................................................................................................... 26

D.2 Normative references ......................................................................................................................... 26

D.3 Terms and definitions ........................................................................................................................ 26

D.4 Quality management systems........................................................................................................... 26

D.4.1 Documentation.................................................................................................................................... 27

D.4.2 Management responsibility ............................................................................................................... 27

D.4.3 Product realization.............................................................................................................................. 27

D.4.4 Measurement, analysis and improvement – Control of non-conforming product....................... 28

D.5 Sterilizing agent characterization ..................................................................................................... 28

D.5.1 Sterilizing agent .................................................................................................................................. 28

D.5.2 Microbicidal effectiveness ................................................................................................................. 28

D.5.3 Materials effects.................................................................................................................................. 28

D.5.4 Environmental considerations .......................................................................................................... 28

D.6 Process and equipment characterization ........................................................................................ 28

D.6.1 Process ................................................................................................................................................ 28

D.6.2 Equipment ........................................................................................................................................... 28

D.7 Product definition ............................................................................................................................... 29

D.7.1 General................................................................................................................................................. 29

D.7.2 Product safety and performance....................................................................................................... 29

D.7.3 Microbiological quality....................................................................................................................... 30

D.8 Process definition............................................................................................................................... 30

D.9 Validation............................................................................................................................................. 32

D.9.1 Installation Qualification .................................................................................................................... 32

D.9.2 Operational Qualification ................................................................................................................... 32

D.9.3 Performance Qualification................................................................................................................. 33

D.9.4 Varying load configurations .............................................................................................................. 35

D.9.5 Review and approval of validation.................................................................................................... 35

D.10 Routine monitoring and control........................................................................................................ 35

D.11 Product release from sterilization..................................................................................................... 36

D.11.1 General................................................................................................................................................. 36

D.11.2 Product release using biological indicators .................................................................................... 36

D.11.3 Parametric release.............................................................................................................................. 36

D.12 Maintaining process effectiveness ................................................................................................... 36

D.12.1 General................................................................................................................................................. 36

D.12.2 Maintenance of equipment ................................................................................................................ 36

D.12.3 Requalification .................................................................................................................................... 36

D.12.4 Assessment of change....................................................................................................................... 37

iv © ISO 2004 — All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 11135

Annex E (informative) Microbiological performance qualification — Method for calculating D

values using the BI/Biodurden approach .........................................................................................40

Bibliography........................................................................................................................................................1

Annex ZA (normative) Normative references to international publications with their relevant

European publications..........................................................................................................................2

Annex ZB (informative) Relationship between this European Standard and the Essential

Requirements of EU Directives 90/385/EEC of 20 June 1990 concerning activeimplantable medical devices, 93/42/EEC of 14 June 1993 concerning medical devices and

98/78/EC of 7 December 1988 concerning in vitro diagnostic medical devices .............................4

© ISO 2004 — All rights reserved v---------------------- Page: 5 ----------------------

ISO/DIS 11135

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 11135 was prepared by Technical Committee ISO/TC 198.This second edition cancels and replaces the first edition and has been extensively revised.

vi © ISO 2004 — All rights reserved---------------------- Page: 6 ----------------------

ISO/DIS 11135

Introduction

A sterile medical device is one which is free of viable microorganisms. International Standards, which specify

requirements for validation and routine control of sterilization processes, require, when it is necessary to

supply a sterile medical device, that adventitious microbiological contamination of a medical device prior to

sterilization be minimised. Even so, medical devices produced under standard manufacturing conditions in

accordance with the requirements for quality management systems (see, for example, ISO 13485) may, prior

to sterilization, have microorganisms on them, albeit in low numbers. Such products are non-sterile. The

purpose of sterilization is to inactivate the microbiological contaminants and thereby transform the non-sterile

products into sterile ones.The kinetics of inactivation of a pure culture of microorganisms by physical and/or chemical agents used to

sterilize medical devices can generally best be described by an exponential relationship between the numbers

of microorganisms surviving and the extent of treatment with the sterilizing agent; inevitably this means that

there is always a finite probability that a microorganism may survive regardless of the extent of treatment

applied. For a given treatment, the probability of survival is determined by the number and resistance of

microorganisms and by the environment in which the organisms exist during treatment. It follows that the

sterility of any one product in a population subjected to sterilization processing cannot be guaranteed and the

sterility of a processed population is defined in terms of the probability of there being a viable microorganism

present on a product.This International Standard describes requirements which will enable the demonstration that an ethylene

oxide sterilization process intended to sterilize medical devices has appropriate microbicidal activity. This

activity is both reliable and reproducible, such that the relationship for the inactivation of microorganisms can

be extrapolated with reasonable confidence to low levels of probability of there being a viable microorganism

present on a product after sterilization processing. This international standard does not specify the maximal

value to be taken by this probability; specification of this probability is a matter for regulatory authorities and

may vary from country to country (see, for example, EN 556-1 and ANSI/AAMI ST67).

Generic requirements of the quality management systems for design/development, production, installation and

servicing are given in ISO 9001 and particular requirements for quality management systems for medical

device production in ISO 13485. The standards for quality management systems recognise that, for certain

processes used in manufacturing or reprocessing, the effectiveness of the process cannot be fully verified by

subsequent inspection and testing of the product. Sterilization is an example of such a process. For this

reason, sterilization processes are validated for use, the performance of the sterilization process monitored

routinely and the equipment maintained.Exposure to a properly validated, accurately controlled sterilization process is not the only factor associated

with the provision of reliable assurance that the product is sterile and, in this regard, suitable for its intended

use. Attention is therefore given to a number of factors including:a) the microbiological status of incoming raw materials and/or components,

b) the validation and routine control of any cleaning and disinfection procedures used on the product,

c) the control of the environment in which the product is manufactured, assembled and packaged,

d) the control of equipment and processes,e) the control of personnel and their hygiene,

f) the manner and materials in which the product is packaged, and,

g) the conditions under which product is stored.

© ISO 2004 — All rights reserved vii

---------------------- Page: 7 ----------------------

ISO/DIS 11135

The type of contamination on a product to be sterilized varies and this impacts upon the effectiveness of a

sterilization process. Products that have been used in a health care setting and are being presented for

resterilization in accordance with the manufacturer's instructions (see ISO 17664), should be regarded as a

special case. There is the potential for such products to possess a wide range of contaminating

microorganisms and residual inorganic and/or organic contamination in spite of the application of a cleaning

process. Hence, particular attention should be given to the validation and control of the cleaning and

disinfection processes used during reprocessing.The requirements are the normative parts of this standard with which compliance is claimed. The guidance

given in the informative annexes is not normative and is not provided as a check list for auditors. The

guidance provides explanations as well as methods that are accepted as being suitable means for complying

with the requirements. Approaches other than those given in the guidance may be used, if they are effective in

achieving compliance with the requirements of this International Standard.The development, validation and routine control of a sterilization process comprise a number of discrete but

interrelated activities, for example calibration, maintenance, product definition, process definition, installation

qualification, operational qualification, and performance qualification. While the activities required by this

standard have been grouped together and are presented in a particular order; this international standard does

not require that the activities be performed in the order that they are presented. The activities required are not

necessarily sequential, as the programs of development and validation may be iterative. It is possible that

performing these different activities will involve a number of separate individuals and/or organizations, each of

whom undertake one or more of these activities. This International Standard does not specify the particular

individuals or organizations to carry out the activities.viii © ISO 2004 — All rights reserved

---------------------- Page: 8 ----------------------

Sterilization of health care products — Ethylene oxide —

Requirments for the development, validation and routine

control of a sterilization process for medical devices

1 Scope

1.1 Inclusions

This International Standard specifies requirements for the development, validation and routine control of an

ethylene oxide sterilization process for medical devices.NOTE Although the scope of this standard is limited to medical devices, it specifies requirements and provides

guidance that may be applicable to other health care products.1.2 Exclusions

1.2.1 Sterilization processes validated and controlled in accordance with the requirements of this standard

should not be assumed to be effective in inactivating the causative agents of spongiform encephalopathies

such as scrapie, bovine spongiform encephalopathy and Creutzfeld-Jacob disease...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.