ISO 9001:1994

(Main)Quality systems - Model for quality assurance in design, development, production, installation and servicing

Quality systems - Model for quality assurance in design, development, production, installation and servicing

Systèmes qualité — Modèle pour l'assurance de la qualité en conception, développement, production, installation et prestations associées

La présente Norme internationale spécifie des exigences en matière de système qualité à utiliser lorsque l'aptitude d'un fournisseur à concevoir et fournir un produit conforme doit être démontrée. Les exigences spécifiées visent en premier lieu la satisfaction du client, par la prévention des non-conformités à tous les stades, depuis la conception jusqu'aux prestations associées. La présente Norme internationale est applicable lorsque a) de la conception est exigée et les exigences relatives au produit sont formulées principalement en termes de résultats ou lorsqu'il est nécessaire d'établir ces exigences, et b) la confiance dans la conformité du produit peut être obtenue par une démonstration adéquate des aptitudes d'un fournisseur en matière de conception, développement, production, installation et prestations associées. NOTE 1 Pour les références informatives, voir annexe A.

Sistemi kakovosti - Model zagotavljanja kakovosti v razvoju, proizvodnji, vgradnji in servisiranju

General Information

- Status

- Withdrawn

- Publication Date

- 29-Jun-1994

- Withdrawal Date

- 29-Jun-1994

- Technical Committee

- ISO/TC 176/SC 2 - Quality systems

- Drafting Committee

- ISO/TC 176/SC 2 - Quality systems

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 05-Jan-2004

- Completion Date

- 13-Dec-2025

Relations

- Effective Date

- 06-Jun-2022

- Effective Date

- 06-Jun-2022

- Effective Date

- 12-May-2008

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

ISO 9001:1994 - Quality systems -- Model for quality assurance in design, development, production, installation and servicing

ISO 9001:1994 - Systemes qualité -- Modele pour l'assurance de la qualité en conception, développement, production, installation et prestations associées

Frequently Asked Questions

ISO 9001:1994 is a standard published by the International Organization for Standardization (ISO). Its full title is "Quality systems - Model for quality assurance in design, development, production, installation and servicing". This standard covers: La présente Norme internationale spécifie des exigences en matière de système qualité à utiliser lorsque l'aptitude d'un fournisseur à concevoir et fournir un produit conforme doit être démontrée. Les exigences spécifiées visent en premier lieu la satisfaction du client, par la prévention des non-conformités à tous les stades, depuis la conception jusqu'aux prestations associées. La présente Norme internationale est applicable lorsque a) de la conception est exigée et les exigences relatives au produit sont formulées principalement en termes de résultats ou lorsqu'il est nécessaire d'établir ces exigences, et b) la confiance dans la conformité du produit peut être obtenue par une démonstration adéquate des aptitudes d'un fournisseur en matière de conception, développement, production, installation et prestations associées. NOTE 1 Pour les références informatives, voir annexe A.

La présente Norme internationale spécifie des exigences en matière de système qualité à utiliser lorsque l'aptitude d'un fournisseur à concevoir et fournir un produit conforme doit être démontrée. Les exigences spécifiées visent en premier lieu la satisfaction du client, par la prévention des non-conformités à tous les stades, depuis la conception jusqu'aux prestations associées. La présente Norme internationale est applicable lorsque a) de la conception est exigée et les exigences relatives au produit sont formulées principalement en termes de résultats ou lorsqu'il est nécessaire d'établir ces exigences, et b) la confiance dans la conformité du produit peut être obtenue par une démonstration adéquate des aptitudes d'un fournisseur en matière de conception, développement, production, installation et prestations associées. NOTE 1 Pour les références informatives, voir annexe A.

ISO 9001:1994 is classified under the following ICS (International Classification for Standards) categories: 03.100.70 - Management systems; 03.120.10 - Quality management and quality assurance. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 9001:1994 has the following relationships with other standards: It is inter standard links to ISO 10332:1994, ISO 9001:1994/Cor 1:1995, SIST ISO 9001:2000, ISO 9001:2000, ISO 9001:1987; is excused to ISO 9001:1994/Cor 1:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 9001:1994 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL

IS0

STANDARD

Second edition

1994-07-01

Quality systems - Model for quality

assurance in design, development,

production, installation and servicing

Sys tkmes qualit L Mod&/e pour /‘assurance de la qualit6 en conception,

dheloppement, production, installation et prestations associ6es

Reference number

IS0 9001 :1994(E)

IS0 9001:1994(E)

Contents

Page

.,.,.,,.,.,.,,.,.,,,,.,.,.,,.,.,,,,,.,.

1 Scope

. . . .~.~~~.~~.~~~.~.~.~~.

2 Normative reference

3 Definitions ,.,.,,,,.,,.,.,,.,.,.,.,,.,,.,.,.,.,,.,.

,,.,.,.,.,.,,.,,.,.,,.~.,.~. 1

4 Quality system requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Management responsibility

4.2 Quality system ,.,.,.,.,.,,.,.,,,.,,.,.

. . . . . . . . . . . . . .~.~~~.~~~.~.~.

4.3 Contract review

,.,,.,.,.,.,,.,,,.,.,,.,.,.

4.4 Design control

*.*.,.,.,.

4.5 Document and data control

4.6 Purchasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

,.,. 5

4.7 Control of customer-supplied product

.,.,,,.,,.*.,.

4.8 Product identification and traceability

,,,.,.,,.,,,,.,.,,.,,,.,,.,.,,,,,.,.*.

4.9 Process control

,,.,.,.,,.,.,.,. 6

4.10 Inspection and testing

, . . . . . . . . 7

Control of inspection, measuring and test equipment

4.11

. . . .~.~.~~~.~~~~.~~~~.~.~.

4.12 Inspection and test status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.13 Control of nonconforming product

,.,.,.,.,.

4.14 Corrective and preventive action

. . . . . 9

4.15 Handling, storage, packaging, preservation and delivery

4.16 Control of quality records .,.,,.~.,.

.,.,,.,.,.

4.17 Internal quality audits

4.18 Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.20 Statistical techniques

0 IS0 1994

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

ii

Q IS0

IS0 9001:1994(E)

Annex

A Bibliography 11

*****~~~***.*=.,,.,.,.*~

43 IS0

IS0 9001:1994(E)

I Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work

of preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard IS0 9001 was prepared by Technical Committee

lSO/rC 176, Quality management and quality assurance, Subcommittee

SC 2, Quality systems.

This second edition cancels and replaces the first edition

(IS0 9001:1987), which has been technically revised.

Annex A of this International Standard is for information only.

iv

0 IS0

IS0 9001:1994(E)

Introduction

This International Standard is one of three International Standards dealing

with quality system requirements that can be used for external quality

assurance purposes. The quality assurance models, set out in the three

International Standards listed below, represent three distinct forms of

quality system requirements suitable for the purpose of a supplier dem-

onstrating its capability, and for the assessment of the capability of a

supplier by external parties.

a) IS0 9001, Quality systems - Model for quality assurance in design,

development, production, ins talla tion and servicing

- for use when conformance to specified requirements is to be as-

sured by the supplier during design, development, production, in-

stallation and servicing.

b) IS0 9002, Quality systems - Model for quality assurance in pro-

due tion, ins talla tion and servicing

- for use when conformance to specified requirements is to be as-

sured by the supplier during production, installation and servicing.

.

1. r* I l

c) IS0 9003, Quality systems - Model for quallry assurance In TInal rn-

spection and test

- for use when conformance to specified requirements is to be as-

sured by the supplier solely at final inspection and test.

It is emphasized that the quality system requirements specified in this

International Standard, IS0 9002 and IS0 9003 are complementary (not

alternative) to the technical (product) specified requirements. They specify

requirements which determine what elements quality systems have to

encompass, but it is not the purpose of these International Standards to

enforce uniformity of quality systems. They are generic and independent

of any specific industry or economic sector. The design and implemen-

tation of a quality system will be influenced by the varying needs of an

organization, its particular objectives, the products and services supplied,

and the processes and specific practices employed.

It is intended that these International Standards will be adopted in their

present form, but on occasions they may need to be tailored by adding

or deleting certain quality system requirements for specific contractual

situations. IS0 9000-l provides guidance on such tailoring as well as on

selection of the appropriate quality assurance model, viz. IS0 9001,

IS0 9002 or IS0 9003.

This page intentionally left blank

INTERNATIONAL STANDARD 0 IS0 IS0 9001:1994(E)

- Model for quality assurance in

Quality systems

design, development, production, installation and

servicing

IS0 8402:1994, Quality management and quality as-

1 Scope

surance - Vocabulary.

This International Standard specifies quality system

requirements for use where a supplier’s capability to

3 Definitions

design and supply conforming product needs to be

demonstrated.

For the purposes of this International Standard, the

definitions given in IS0 8402 and the following defi-

The requirements specified are aimed primarily at

nitions apply.

achieving customer satisfaction by preventing non-

conformity at all stages from design through to ser-

3.1 product: Result of activities or processes.

vicing.

NOTES

This International Standard is applicable in situations

when

2 A product may include service, hardware, processed

materials, software or a combination thereof.

a) design is required and the product requirements

3 A product can be tangible (e.g. assemblies or processed

are stated principally in performance terms, or

materials) or intangible (e.g. knowledge or concepts), or a

they need to be established, and

combination thereof.

b) confidence in product conformance can be at-

4 For the purposes of this International Standard, the term

tained by adequate demonstration of a supplier’s

“product” applies to the intended product offering only and

capabilities in design, development, production,

not to unintended “by-products” affecting the environment.

installation and servicing.

This differs from the definition given in IS0 8402.

NOTE 1 For informative references, see annex A.

3.2 tender: Offer made by a supplier in response to

an invitation to satisfy a contract award to provide

product.

3.3 contract: Agreed requirements between a sup-

2 Normative reference

plier and customer transmitted by any means.

The following standard contains provisions which,

through reference in this text, constitute provisions

4 Quality system requirements

of this International Standard. At the time of publi-

cation, the edition indicated was valid. All standards

4.1 Management responsibility

are subject to revision, and parties to agreements

based on this International Standard are encouraged

to investigate the possibility of applying the most re- Quality policy

4.1 .l

cent edition of t le standard indicated below. Mem-

bers of IEC and IS0 maintain registers of currently The supplier’s management with executive responsi-

valid lnternationa bility shall define and document its policy for quality,

Standards.

Q IS0

IS0 9001:1994(E)

NOTE 5 The responsibility of a management represen-

including objectives for quality and its commitment to

tative may also include liaison with external parties on mat-

quality. The quality policy shall be relevant to the

ters relating to the supplier’s quality system.

supplier’s organizational goals and the expectations

and needs of its customers. The supplier shall ensure

4.1.3 Management review

that this policy is understood, implemented and

maintained at all levels of the organization.

The supplier’s management with executive responsi-

bility shall review the quality system at defined inter-

vals sufficient to ensure its continuing suitability and

4.1.2 Organization

effectiveness in satisfying the requirements of this

International Standard and the supplier’s stated quality

4.1.2.1 Responsibility and authority

policy and objectives (see 4.1 .l). Records of such re-

views shall be maintained (see 4.16).

The responsibility, authority and the interrelation of

personnel who manage, perform and verify work af-

4.2 Quality system

fecting quality shall be defined and documented, par-

ticularly for personnel who need the organizational

4.2.1 General

freedom and authority to:

The supplier shall establish, document and maintain

initiate action to prevent the occurrence of any

a)

a quality system as a means of ensuring that product

nonconformities relating to the product, process

conforms to specified requirements. The supplier

and quality system;

shall prepare a quality manual covering the require-

ments of this International Standard. The quality

b) identify and record any problems relating to the

manual shall include or make reference to the quality

product, process and quality system;

system procedures and outline the structure of the

documentation used in the quality system.

initiate, recommend or provide solutions through

d

designated channels;

NOTE 6 Guidance on quality manuals is given in

IS0 10013.

verify the implementation of solutions;

4.2.2 Quality system procedures

control further processing, delivery or installation

e)

of nonconforming product until the deficiency or

The supplier shall

unsatisfactory condition has been corrected.

a) prepare documented procedures consistent with

4.1.2.2 Resources the requirements of this International Standard

and the supplier’s stated quality policy, and

The supplier shall identify resource requirements and

b) effectively implement the quality system and its

provide adequate resources, including the assignment

documented procedures.

of trained personnel (see 4.18), for management,

performance of work and verification activities includ-

For the purposes of this International Standard, the

ing internal quality audits.

range and detail of the procedures that form part of

the quality system shall be dependent upon the com-

4.1.2.3 Management representative

plexity of the work, the methods used, and the skills

and training needed by personnel involved in carrying

The supplier’s management with executive responsi-

out the activity.

bility shall appoint a member of the supplier’s own

management who, irrespective of other responsi- NOTE 7 Documented procedures may make reference to

work instructions that define how an activity is performed.

bilities, shall have defined authority for

a) ensuring that a quality system is established, im-

4.2.3 Quality planning

plemented and maintained in accordance with this

International Standard, and The supplier shall define and document how the re-

quirements for quality will be met. Quality planning

b) reporting on the performance of the quality sys-

shall be consistent with all other requirements of a

tem to the supplier’s management for review and

supplier’s quality system and shall be documented in

as a basis for improvement of the quality system.

a format to suit the supplier’s method of operation.

0 IS0

IS0 9oot1994(E)

The supplier shall give consideration to the following verbal means, the supplier shall ensure that the

order requirements are agreed before their ac-

activities, as appropriate, in meeting the specified re-

quirements for products, projects or contracts: ceptance;

the preparation of quality plans; b) any differences between the contract or order re-

a)

quirements and those in the tender are resolved;

the identification and acquisition of any controls,

b)

c) the supplier has the capability to meet the con-

processes, equipment (including inspection and

test equipment), fixtures, resources and skills that tract or order requirements.

may be needed to achieve the required quality;

4.3.3 Amendment to a contract

ensuring the compatibility of the design, the pro-

d

duction process, installation, servicing, inspection The supplier shall identify how an amendment to a

contract is made and correctly transferred to the

and test procedures and the applicable documen-

functions concerned within the supplier’s organiz-

tation;

ation.

the updating, as necessary, of quality control, in-

d)

spection and testing techniques, including the

4.3.4 Records

development of new instrumentation;

Records of contract reviews shall be maintained (see

the identification of any measurement require-

e) 4.16).

ment involving capability that exceeds the known

NOTE 9 Channels for communication and interfaces with

state of the art, in sufficient time for the needed

the customer’s organization in these contract matters

capability to be developed;

should be established.

the identification of suitable verification at appro-

f 1

priate stages in the realization of product; 4.4 Design control

the clarification of standards of acceptability for

4.4.1 General

9)

all features and requirements, including those

which contain a subjective element; The supplier shall establish and maintain documented

procedures to control and verify the design of the

the identification and preparation of quality rec-

h)

product in order to ensure that the specified require-

ords (see 4.16).

ments are met.

NOTE 8 The quality plans referred to [see 4.2.3a)] may

4.4.2 Design and development planning

be in the form of a reference to the appropriate documented

procedures that form an integral part of the supplier’s qual-

The supplier shall prepare plans for each design and

ity system.

development activity. The plans shall describe or ref-

erence these activities, and define responsibility for

4.3 Contract review

their implementation. The design and development

activities shall be assigned to qualified personnel

4.3.1 General equipped with adequate resources. The plans shall be

updated as the design evolves.

The supplier shall establish and maintain documented

procedures for contract review and for the coordi-

4.4.3 Organizational and technical interfaces

nation of these activities.

Organizational and technical interfaces between dif-

ferent groups which input into the design process

4.3.2 Review

shall be defined and the necessary information docu-

mented, transmitted and regularly reviewed.

Before submission of a tender, or the acceptance of

a contract or order (statement of requirement), the

4.4.4 Design input

tender, contract or order shall be reviewed by the

supplier to ensure that:

Design input requirements relating to the product, in-

cluding applicable statutory and regulatory require-

a) the requirements are adequately defined and

ments, shall be identified, documented and their

documented; where no written statement of re-

selection reviewed by the supplier for adequacy. In-

quirement is available for an order received by

0 IS0

IS0 9001:1994(E)

4.4.8 Design validation

complete, ambiguous or conflicting requirements shall

be resolved with those responsible for imposing

Design validation shall be performed to ensure that

these requirements.

product conforms to defined user needs and/or re-

Design input shall take into consideration the results

quirements.

of any contract review activities.

NOTES

Design validation follows successful design verification

4.4.5 Design output

(see 4.4.7).

Design output shall be documented and expressed in 12 Validation is normally performed under defined operat-

ing conditions.

terms that can be verified and validated against design

input requirements.

13 Validation is normally performed on the final product,

but may be necessary in earlier stages prior to product

Design output shall:

completion.

a) meet the design input requirements;

14 Multiple validations may be performed if there are dif-

ferent intended uses.

b) contain or make reference to acceptance criteria;

c) identify those characteristics of the design that

4.4.9 Design changes

are crucial to the safe and proper functioning of

the product (e.g. operating, storage, handling,

All design changes and modifications shall be identi-

maintenance and disposal requirements).

fied, documented, reviewed and approved by author-

ized personnel before their implementation.

Design output documents shall be reviewed before

release.

4.5 Document and data control

4.4.6 Design review

4.5.1 General

At appropriate stages of design, formal documented

The supplier shall establish and maintain documented

reviews of the design results shall be planned and

procedures to control all documents and data that re-

conducted. Participants at each design review shall

late to the requirements of this International Standard

include representatives of all functions concerned

including, to the extent applicable, documents of ex-

with the design stage being reviewed, as well as

ternal origin such as standards and customer

other specialist personnel, as required. Records of

drawings.

such reviews shall be maintained (see 4.16).

NOTE 15 Documents and data can be in the form of any

type of media, such as hard copy or electronic media.

4.4.7 Design verification

At appropriate stages of design, design verification

4.5.2 Document and data approval and issue

shall be performed to ensure that the design stage

output meets the design stage input requirements.

The documents and data shall be reviewed and ap-

The design verification measures shall be recorded

proved for adequacy by authorized personnel prior to

(see 4.16) .

issue. A master list or equivalent document control

procedure identifying the current revision status of

NOTE 10 In addition to con ducting design reviews (see

documents shall be established and be readily avail-

4.4.61, design verification may activities such as

include

the use of invalid and/or obsolete

able to preclude

documents.

- performing alternative calculations,

This control shall ensure that:

- comparing the new design with a similar proven design,

if available,

a) the pertinent issues of appropriate documents are

available at all locations where operations essen-

- undertaking tests and demonstrations, and

tial to the effective functioning of the quality sys-

- reviewing the design stage documents before release. tem are performed;

0 IS0

IS0 9001:1994(E)

b) invalid and/or obsolete documents are promptly a) the type, class, grade or other precise identifi-

removed from all points of issue or use, or other- cation;

wise assured against unintended use;

b) the title or other positive identification, and appli-

c) any obsolete documents retained for legal and/or cable issues of specifications, drawings, process

knowledge-preservation purposes are suitably requirements, inspection instructions and other

relevant technical data, including requirements for

identified.

approval or qualification of product, procedures,

process equipment and personnel;

4.5.3 Document and data changes

c) the title, number and issue of the quality system

Changes to documents and data shall be reviewed

standard to be applied.

and approved by the same functions/organizations

that performed

...

NORME

IS0

INTERNATIONALE

Deuxi&me bdition

1994-07-01

Systhmes qualit - Modhle pour

I’assurance de la qualit en conception,

dbveloppement, production, installation et

prestations associbes

Quality systems

- Model for quality assurance in design, development,

production, installation and servicing *

Numbro de rhfhrence

IS0 3001 :I 994(F)

IS0 9001:1994(F)

Sommaire

Page

1 Domaine d’application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Reference normative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Definitions . . . . . . .*.

4 Exigences en matiere de systeme qualite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Responsabilite de la direction . 2

41 .

42 . Systeme qualite .

43 . Revue de contrat . 3

44 . MaRrise de la conception .

45 . Mai’trise des documents et des donnees . 5

Achats . 5

46 .

................................... 6

47 . Maitrise du produit fourni par le client

48 . Identification et tracabilite du produit . 6

.......................................................... 6

49 . Maltrise des processus

4.10 Controles et essais . 7

4.11 Maitrise des equipements de controle, de mesure et d’essai

4.12 ttat des controles et des essais . 8

....................................... 8

4.13 Maitrise du produit non conforme

4.14 Actions correctives et preventives . 9

4.15 Manutention, stockage, conditionnement, preservation et

livraison .

4.16 Maitrise des enregistrements relatifs a la qualite .

4.17 Audits qualite internes . 10

4.18 Formation .

Prestations associees . 10

4.19

4.20 Techniques statistiques . 11

0 IS0 1994

Droits de reproduction reserves. Sauf prescription differente, aucune partie de cette publi-

cation ne peut etre reproduite ni utilisee sous quelque forme que ce soit et par aucun pro-

cede, electronique ou mecanique, y compris la photocopie et les microfilms, sans I’accord

ecrit de I’editeur.

Organisation internationale de normalisation

Case Postale 56 l CH-1211 Geneve 20 l Suisse

Imprime en Suisse

ii

0 IS0 IS0 9001:1994(F)

Annexe

A Bibliographie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0 IS0

IS0 9001:1994(F)

Avant-propos

L’ISO (Organisation internationale de normalisation) est une federation

mondiale d’organismes nationaux de normalisation (comites membres de

I’ISO). L’elaboration des Normes internationales est en general confiee aux

comites techniques de I’ISO. Chaque comite membre interesse par une

etude a le droit de faire partie du comite technique tree 8 cet effet. Les

organisations internationales, gouvernementales et non gouvernemen-

tales, en liaison avec I’ISO participent egalement aux travaux. L’ISO colla-

bore etroitement avec la Commission electrotechnique internationale (CEI)

en ce qui concerne la normalisation electrotechnique.

Les projets de Normes internationales adopt& par les comites techniques

sont soumis aux comites membres pour vote. Leur publication comme

Normes internationales requiert I’approbation de 75 % au moins des co-

mites membres votants.

La Norme internationale IS0 9001 a ete elaboree par le comite technique

lSO/TC 176, Management et assurance de la qua/it& sous-comite SC 2,

SystGmes qua/it&

Cette deuxieme edition annule et remplace la premiere edition

(IS0 9001:1987), dont elle constitue une revision technique.

L’annexe A de la presente Norme internationale est donnee uniquement

a titre d’information.

IV

43 IS0

IS0 9001:1994(F)

Introduction

La presente Norme internationale fait par-tie d’une serie de trois Normes

internationales sur les exigences en mat&e de systeme qualite qui peu-

vent etre utilisees dans le cadre de I’assurance externe de la qualite. Les

modeles pour /‘assurance de la qualite, definis dans les trois Normes

internationales mentionnees ci-dessous, decrivent trois formes distinctes

d’exigences en mat&e de systeme qualite qui conviennent pour la de-

monstration des aptitudes d’un fournisseur et leur evaluation par des par-

ties externes.

a) IS0 9001, Systdmes qua/it6 - Modhle pour I’assurance de la qualit

en conception, dheloppemen t, production, ins talla tion et pres ta tions

associ6es

- a utiliser lorsque la conformite a des exigences specifiees est 8

assurer par le fournisseur pendant la conception, le develop-

pement, la production, I’installation et les prestations associees.

b) IS0 9002, Systhmes qua/it& - Mod&le pour I’assurance de la qualit

en production, ins talla tion et pres ta tions associ6es

- a utiliser lorsque la conformite a des exigences specifiees est a

assurer par le fournisseur pendant la production, I’installation et les

prestations associees.

c) IS0 9003, Systbmes qua/it6 - ModdIe pour I’assurance de la qualitb

en contrdle et essais finals

- 8 utiliser lorsque la conformite a des exigences specifiees est 8

assurer par le fournisseur uniquement lors des controles et essais

finals.

II faut souligner que les exigences en mat&e de systeme qualite, speci-

frees dans la presente Norme internationale, dans I’ISO 9002 et

I’ISO 9003, sont complementaires (et ne se substituent pas) aux exi-

gences techniques specifiees (pour le produit). Elles specifient des exi-

gences qui determinent les elements que doivent comprendre les

systemes qualite, mais leur but n’est pas d’imposer I’uniformite des sys-

temes qualite. Ces Normes internationales sont generiques, indepen-

dantes de tout secteur industriel ou economique particulier. La conception

et la mise en cauvre d’un systeme qualite tiendront compte des differents

besoins d’un organisme, de ses objectifs particuliers, des produits et ser-

vices fournis et des processus et pratiques specifiques en usage.

II est prevu que ces Normes internationales soient utilisees telles quelles,

mais, dans certains cas, il peut etre necessaire de les ajuster en ajoutant

ou en supprimant certaines exigences de system0 qualite en fonction de

situations contractuelles particulieres. L’ISO 9000-l fournit des indications

sur cet ajustement et sur le choix du modele approprie pour l’assurance

de la qualite, a savoir IS0 9001, IS0 9002 ou IS0 9003.

V

This page intentionally left blank

NORME INTERNATIONALE 0 IS0

IS0 9001:1994(F)

SystGmes qualit - Modde pour I’assurance de la

qualit en conception, dbveloppement, production,

installation et prestations associbes

rechercher la possibilite d’appliquer l’edition la plus

1 Domaine d’application

recente de la norme indiquee ci-apres. Les membres

de la CEI et de I’ISO possedent le registre des Nor-

La presente Norme internationale specific des exi-

mes internationales en vigueur a un moment don&.

gences en matiere de systeme qualite a utiliser lors-

que I’aptitude d’un fournisseur a concevoir et fournir

IS0 8402:1994, Management de la qua/it& et assu-

un produit conforme doit etre demontree.

rance de la qua/it6 - Vocabulaire.

Les exigences specifiees visent en premier lieu la sa-

tisfaction du client, par la prevention des non-

conformites a tous les stades, depuis la conception

3 Dbfinitions

jusqu’aux prestations associees.

Pour les besoins de la presente Norme internationale,

La presente Norme internationale est applicable lors-

les definitions donnees dans I’ISO 8402 et les defini-

we

tions suivantes s’appliquent.

a) de la conception est exigee et les exigences rela-

3.1 produit: Resultat d’activites ou de processus.

tives au produit sont formulees principalement en

termes de resultats ou lorsqu’il est necessaire

NOTES

d’etablir ces exigences, et

2 Le terme produit peut inclure les services, les matkriels,

b) la confiance dans la conformite du produit peut

les produits issus de processus 2 caract&e continu, les lo-

etre obtenue par une demonstration adequate des

giciels, ou une combinaison des deux.

aptitudes d’un fournisseur en mat&e de concep-

3 Un produit peut &re materiel (par exemple, assem-

tion, developpement, production, installation et

blages ou produits issus de processus B caracthe continu)

prestations associees.

ou immatkiel (par exemple, connaissances ou concepts),

ou une combinaison des deux.

NOPE1 Pour les Gfkrences informatives, voir

annexe A.

4 Dans le cadre de la prhente Norme internationale, le

terme ((produit)) s’applique au produit intentionnel et ne

s’applique pas aux sous-produits non-intentionnels affectant

I’environnement. Ceci diff&e de la definition donnee dans

I’ISO 8402.

2 R6fkrence normative

3.2 offre: Une offre est faite par un fournisseur en

La norme suivante contient des dispositions qui, par

suite de la reference qui en est faite, constituent des reponse a un appel d’offre en vue de I’attribution d’un

contrat de fourniture d’un produit.

dispositions valables pour la presente Norme interna-

tionale. Au moment de la publication, l’edition indi-

quee etait en vigueur. Toute norme est sujette 8 3.3 contrat: Exigences ayant fait I’objet d’un accord

revision et les parties prenantes des accords fond& entre un fournisseur et un client et transmises par un

sur la presente Norme internationale sont invitees a moyen quelconque.

IS0 9001:1994(F)

0 IS0

d’autres res ponsabi lit&, doit avoir une autorite definie

4 Exigences en matike de systhme

pour

qualit

a) assurer qu’un systeme qualite est defini, mis en

4.1 Responsabilit6 de la direction

ceuvre et entretenu conformement a la presente

Norme internationale, et

4.1 .l Politique qualit

b) rendre compte du fonctionnement du systeme

La direction du fournisseur, qui a pouvoir de decision

qualite a la direction du fournisseur pour en faire

doit definir et consigner par ecrit sa politique en ma-

la revue et servir de base 8 l’amelioration du sys-

tiere de qualite, y compris ses objectifs et son enga-

teme qualite.

gement en la mat&e. La politique qualite doit etre

NOTE 5

pertinente par rapport aux objectifs generaux du four- La responsabilith du representant de la direction

peut bgalement comprendre les relations avec des parties

nisseur et aux attentes et besoins de ses clients. Le

exthieures en ce qui concerne les sujets relatifs au sys-

fournisseur doit assurer que cette politique est com-

t&me qualit& du fournisseur.

prise, mise en ceuvre et entrenue a tous les niveaux

de I’organisme.

4.1.3 Revue de direction

4.1.2 Organisation

La direction du fournisseur, qui a pouvoir de decision,

4.1.2.1 Responsabilit6 et autorite doit faire une revue du systeme qualite a une fre-

quence definie et suffisante pour assurer qu’il de-

La responsabilite, I’autorite et les relations entre les

meure constamment approprie et efficace afin de

personnes qui dirigent, executent et verifient des ta-

satisfaire aux exigences de la presente Norme inter-

ches qui ont une incidence sur la qualite doivent etre

nationale ainsi qu’a la politique et aux objectifs qualite

definies par ecrit; cela concerne, en particulier les

fixes par le fournisseur (voir 4.1 .l). Des enregis-

personnes qui ont besoin de la liberte et de I’autorite

trements de ces revues doivent etre conserves (voir

sur le plan de I’organisation pour

4.16).

a) declencher des actions permettant de prevenir

I’apparition de toute non-conformite relative au

4.2 Systhme qualit

produit, au processus et au systeme qualite;

4.2.1 GhSralit6s

b) identifier et enregistrer tout probleme relatif au

produit, au processus et au systeme qualite;

Le fournisseur doit etablir, consigner par ecrit et

entretenir un systeme qualite en tant que moyen pour

c) declencher, recommander ou fournir des solutions

assurer que le produit est conforme aux exigences

en suivant des circuits definis;

specifiees. Le fournisseur doit etablir un manuel qua-

lite couvrant les exigences de la presente Norme

d ) verifier la mise en oeuvre des solutions;

internationale. Le manuel qualite doit comprendre les

e ) maltriser la poursuite des operations relatives au procedures du systeme qualite ou y faire reference,

produit non conforme, sa livraison ou son instal- et exposer la structure de la documentation utilisee

dans le cadre du systeme qualite.

lation jusqu’a ce que la deficience ou la situation

non satisfaisante ait ete corrigee.

NOTE 6 L’ISO 10013 fournit des conseils relatifs 3 Ma-

boration des manuels qualitk

4.1.2.2 Moyens

Le fournisseur doit identifier les exigences relatives

4.2.2 Proc6dures du systhme qualit

aux moyens et fournir les moyens adequats, y com-

pris la designation de personnes formees (voir 4.18),

Le fournisseur doit

pour le management, I’execution et la verification des

taches, ainsi que les audits qualite internes.

a) etablir des procedures &rites coherentes avec les

exigences de la presente Norme internationale et

4.1.2.3 Representant de la direction avec la politique qualite qu’il a formulee, et

La direction du fournisseur, qui a pouvoir de decision, b) mettre reellement en oeuvre le systeme qualite

doit nommer un de ses membres qui, nonobstant et ses procedures &rites.

0 IS0

IS0 9001:1994(F)

NOTE 8 Les plans qualite mentionnes [voir 4.2.3a)]

Dans le cadre de la presente Norme internationale,

peuvent faire reference aux procedures &rites appropribes

l’etendue et le niveau de detail des procedures qui

qui font partie integrante du systeme qualite du fournisseur.

font partie du systeme qualite doivent dependre de la

complexite des taches, des methodes utilisees, des

competences et de la formation necessaires au per-

4.3 Revue de contrat

sonnel implique dans I’execution de ces taches.

4.3.1 Gtin6ralit6s

NOTE 7 Les procedures &rites peuvent faire reference

a des instructions de travail qui definissent comment une

Le fournisseur doit etablir et tenir a jour des procedu-

t&he est realisee.

res &rites de revue de contrat et de coordination de

ces activites.

4.2.3 Planification de la qualit

4.3.2 Revue

Le fournisseur doit definir et consigner par ecrit com-

ment satisfaire les exigences pour la qualite. La pla-

Avant soumission d’une offre ou acceptation d’un

nification de la qualite doit etre coherente avec

contrat ou d’une commande (formulation des exi-

I’ensemble des exigences du systeme qualite du

gence& l’offre, le contrat ou la commande doit Qtre

fournisseur et doit etre consignee sous une forme

revu(e) par le fournisseur afin d’assurer que

adaptee aux methodes de travail du fournisseur. Ce

dernier doit porter toute son attention sur les activites

a) les exigences sont definies et documentees de

suivantes, s’il y a lieu, pour satisfaire aux exigences

facon adequate; lorsqu’il n’existe pas d’exigences

specifiees pour les produits, les projets ou les con-

&rites pour une commande verbale, le fournis-

trats:

seur doit assurer que les exigences de cette

commande ont bien fait I’objet d’un accord avant

l’etablissement de plans qualite;

a)

d’etre acceptees;

I’identification et I’acquisition de tous moyens de

b)

b) toute difference entre les exigences d’un contrat

maTtrise des activites, processus, equipements (y

ou d’une commande et celles de l’offre a fait

compris les equipements de contrdle et d’essai),

I’objet d’une solution;

dispositifs, ensemble des moyens et compe-

tences qui peuvent etre necessaires pour obtenir

c) le fournisseur presente I’aptitude 8 satisfaire aux

la qualite requise;

exigences du contrat ou de la commande.

I’assurance de la compatibilite de la conception,

d

du processus de production, de I’installation, des 4.3.3 Avenant au contrat

prestations associees, des procedures de contrble

Le fournisseur doit definir comment un avenant a un

et d’essai et de la documentation applicable;

contrat est trait6 et comment il le transmet correc-

la mise a jour, autant que necessaire, des techni-

d) tement aux fonctions concernees de son organisation.

ques de maltrise de la qualite, de controle et

d’essai, y compris le developpement d’une nou-

4.3.4 Enregistrements

velle instrumentation;

Des enregistrements de ces revues de contrat doi-

I’identification, en temps voulu, de toute exigence

e)

vent etre consewes (voir 4.16).

en mat&e de mesurage mettant en jeu une apti-

tude qui depasse les possibilites actuelles de

II convient de constituer des circuits de com-

NOTE 9

l’etat de I’art, afin de developper I’aptitude neces-

munication et des interfaces avec le client en matiere de

contrat.

saire;

I’identification des verifications adequates aux

4.4 Maitrise de la conception

phases appropriees de la realisation du produit;

la clarification des normes d’acceptation pour 4.4.1 G6n6ralitbs

toutes les caracteristiques et exigences, y com-

pris celles qui contiennent un element subjectif; Le fournisseur doit etablir et tenir a jour des procedu-

res &rites pour mai’triser et verifier la conception du

I’identification et la preparation d’enregistrements produit afin d’assurer que les exigences specifiees

h)

relatifs a la qualite (voir 4.16). sont satisfaites.

IS0 9001:1994(F) 0 IS0

4.4.2 Planification de la conception et du Les documents relatifs aux donnees de sortie de la

dkveloppement conception doivent etre revus avant leur mise en cir-

culation.

Le fournisseur doit elaborer des plans pour chaque

activite de conception et de developpement. Ces

4.4.6 Revue de conception

plans decrivent ces activites ou y font reference, et

definissent les responsabilites pour leur mise en

Des revues formelles et consignees par ecrit des re-

oeuvre. Les activites de conception et de develop-

su!tats de la conception doivent etre planifiees et

pement doivent etre affectees 8 du personnel qualifie

conduites a des phases appropriees de la conception.

dote de moyens adequats. Les plans doivent etre mis

Les participants a chacune de ces revues doivent

a jour au fur et 8 mesure de l’evolution de la concep-

comprendre des representants de toutes les fonc-

tion.

tions concernees par la phase de conception, objet

de la revue, ainsi que tout autre expert, comme re-

quis. Des enregistrements de ces revues doivent etre

Interfaces organisationnelles et techniques

4.4.3

conserves (voir 4.16).

Les interfaces organisationnelles et techniques entre

4.4.7 Wrification de la conception

les differents groupes, qui contribuent au processus

de conception, doivent etre definies et les infor-

La verification de la conception doit etre effect&e a

mations necessaires doivent etre consignees par

des phases appropriees de la conception afin d’assu-

ecrit, transmises et revues regulierement.

rer que les donnees de sortie de chacune de ces

phases satisfont aux exigences des donnees d’entree

Donnbes d’entree de la conception

4.4.4

de cette meme phase. Les actions de verification de

la conception doivent etre enregistrees (voir 4.16).

Les exigences concernant le produit relatives aux

NOTE 10 En plus des revues de conception (voir 4.4.6),

donnees d’entree de la conception et comprenant les

la verification de la conception peut comprendre des taches

exigences legales et reglementaires applicables doi-

telles que

vent etre identifiees et consignees par ecrit, et leur

selection doit etre revue par le fournisseur quant 8

- I’execution de calculs par d’autres methodes,

leur adequation. II faut apporter une solution aux exi-

gences incompletes, ambigijes ou incompatibles avec

- la comparaison de la nouvelle conception avec une

ceux qui les ont imposees.

conception similaire elle existe,

eprouvee si

Les donnees d’entree de la conception doivent pren-

- la realisation d’essais et de modeles de demonstration,

dre en compte les resultats de toutes les activites de

et

revue de contrat.

- la revue des documents relatifs aux differentes phases

de la conception avant leur mise en circulation.

Donnbes de sortie de la conception

4.4.5

4.4.8 Validation de la conception

Les donnees de sortie de la conception doivent etre

consignees par ecrit et exprimees de facon 8 pouvoir

La validation de la conception doit etre effect&e pour

etre verifiees et validees par rapport aux donnees

assurer que le produit est conforme aux besoins

d’entree de la conception.

et/au aux exigences definis de I’utilisateur.

Les donnees de sortie de la conception doivent

NOTES

a) satisfaire aux exigences des donnees d’entree de

11 Cette validation fait suite a une verification satisfaisante

la conception; de la conception (voir 4.4.7).

12 La validation est effect&e normalement dans des

b) contenir ou faire reference a des criteres d’ac-

conditions de fonctionnement definies.

ceptation;

13 La validation est effectuee normalement sur le produit

c) identifier les caracteristiques de conception criti-

final, mais peut etre necessaire a des phases anterieures a

ques pour le fonctionnement correct et en toute

l’achevement du produit.

securite du produit (par exemple, les exigences

en mat&e d’exploitation, de stockage, de manu-

14 Des validations multiples peuvent etre executees si

differentes utilisations sont prevues.

tention, de maintenance et de mise hors service).

Q IS0

IS0 9001:1994(F)

4.4.9 Modifications de la conception Les fonctions/organismes design& doivent avoir ac-

ces 8 toutes informations appropriees sur lesquelles

Tous les changements et toutes les modifications de

ils peuvent fonder leur revue et leur approbation.

la conception doivent etre identifies, consign& par

Lorsque cela est realisable, la nature de la modifica-

ecrit, revus et approuves par des personnes habilitees

tion doit etre identifiee dans le document ou dans les

avant d’etre mis en ceuvre.

annexes appropriees.

4.5 Maltrise des documents et des donnkes

4.6 Achats

4.5.1 Gknkralit&

4.6.1 Ghn&alit&

Le fournisseur doit etablir et tenir a jour des procedu-

Le fournisseur doit etablir et tenir a jour des procedu-

res &rites pour maitriser tous les documents et don-

res &rites pour assurer que le produit achete (voir

nees relatifs aux exigences de la presente Norme

3.1) est conforme aux exigences specifiees.

internationale, y compris, dans les limites de ce qui

est applicable, des documents d’origine exterieure

4.6.2 Evaluation des sous-contractants

tels que les normes et les plans du client.

NOTE 15 Les documents et les donnbes peuvent se Le fournisseur doit

presenter sur tout support, tel que support papier ou sup-

port informatique.

a) evaluer et selectionner les sous-contractants sur

la base de leur aptitude a satisfaire aux exigences

de la sous-commande, y compris les exigences

4.52 Approba tion et d iff usio n des docu ments et

de systeme qualite et toutes exigences specifi-

des donnbes

ques d’assurance de la qualite;

Avant leur diffusion, les documents et les donnees

b) definir le type et l’etendue de la maltrise exercee

doivent etre revus et approuves en ce qui concerne

par le fournisseur sur ses sous-contractants.

leur adequation, par des personnes habilitees. Une

Celle-ci doit dependre du type de produit com-

liste de reference ou toute procedure de ma7trise de

mande au sous-contractant, de I’incidence de ce

documents equivalente indiquant la revision en vi-

produit sur la qualite du produit final et, lorsque

gueur des documents doit etre etablie et etre faci-

cela est applicable, des rapports d’audits qualite

lement accessible pour empecher I’utilisation de

et/au des enregistrements relatifs aux aptitudes

documents non valables et/au perimes.

et performances dont le sous-contractant a fait la

Cette mai;trise doit assurer que

demonstration precedemment;

a) les editions pertinentes des documents appro- c) etablir, tenir a jour et conserver des enregis-

pries sont disponibles 8 tous les en

...

SLOVENSKI SIST ISO 9001

druga izdaja

STANDARD

junij 1995

Sistemi kakovosti - Model zagotavljanja kakovosti v razvoju,

proizvodnji, vgradnji in servisiranju (identi~en z ISO 9001:1994)

Quality sistems - Model for quality assurance in design, development,

production, installation and servicing

Systèmes qualité - Modèle pour l’assurance de la qualité en conception,

devéloppement, production, installation et prestations associées

Qualitaetssicherungssysteme - Modell zur Darlegung des

Qualitaetsmanagementsystems in Design/Entwicklung, Produktion, Montage

und Wartung

Deskriptorji: zagotavljanje kakovosti, program zagotavljanja kakovosti, sistemi

zagotavljanja kakovosti, razvoj, (delo), proizvodnja, vgradnja, poprodajne

storitve, referen~ni modeli

Referen~na {tevilka

ICS 03.120.10 SIST ISO 9001:1995 (sl, en)

Nadaljevanje na straneh od 2 do 32

© Standard je zalo`il in izdal Urad Republike Slovenije za standardizacijo in meroslovje pri Ministrstvu za znanost in tehnologijo.

Razmno`evanje ali kopiranje celote ali delov tega standarda ni dovoljeno.

SIST ISO 9001 : 1995

UVOD

Standard SIST ISO 9001, Sistemi kakovosti - Model zagotavljanja kakovosti v razvoju,

proizvodnji, vgradnji in servisiranju, druga izdaja, 1995, ima status slovenskega standarda in

je identi~en mednarodnemu standardu ISO 9001, Quality sistems - Model for quality

assurance in design, development, production, installation and servicing, second edition, 1994-

07-01.

NACIONALNI PREDGOVOR

Mednarodni standard ISO 9001:1994 je pripravil tehni~ni odbor Mednarodne organizacije za

standardizacijo ISO/TC 176 Vodenje kakovosti in zagotavljanje kakovosti. Slovenski standard

V primeru spora glede besedila slovenskega prevoda v tem standardu je odlo~ilen izvirni

mednarodni standard v angle{kem jeziku. Slovensko-angle{ko izdajo standarda je pripravil

tehni~ni odbor USM/TC QAS Zagotavljanje kakovosti.

Ta slovenski standard je dne 1995-06-23 odobril direktor USM.

ZVEZE S STANDARDI

S prevzemom tega mednarodnega standarda veljajo naslednje zveze:

SIST ISO 8402:-* idt ISO 8402:1994

*

SIST ISO 9000-1:- idt ISO 9000-1:1994

SIST ISO 9002:1995 idt ISO 9002:1994

SIST ISO 9003:1995 idt ISO 9003:1994

SIST ISO 9004-1:-* idt ISO 9004-1:1994

Oznake in naslovi navedenih slovenskih standardov so:

SIST ISO 8402:-* Vodenje kakovosti in zagotavljanje kakovosti - Slovar (identi~en z

ISO 8402:1994)

SIST ISO 9000-1:-* Standardi za vodenje in zagotavljanje kakovosti - 1. del: Smernice

za izbiro in uporabo (identi~en z ISO 9000-1:1994)

SIST ISO 9002:1995 Sistemi kakovosti - Model zagotavljanja kakovosti v proizvodnji,

vgradnji in servisiranju (identi~en z ISO 9002:1994)

SIST ISO 9003:1995 Sistemi kakovosti - Model zagotavljanja kakovosti v kon~ni kontroli in

presku{anju (identi~en z ISO 9003:1994)

SIST ISO 9004-1:-* Vodenje kakovosti in elementi sistema kakovosti - Smernice

(identi~en z ISO 9004-1:1994)

*

V pripravi

SIST ISO 9001 : 1995

PREDHODNE IZDAJE

- SLS ISO 9001:1992

OSNOVA ZA IZDAJO STANDARDA

- Prevzem standarda ISO 9001:1994, druga izdaja

OPOMBE:

- Povsod, kjer se v besedilu standarda uporablja izraz “mednarodni standard”, pomeni to

v SIST ISO 9001:1995 “slovenski standard”.

- Uvod in nacionalni predgovor nista sestavni del standarda.

- Povsod, kjer se v angle{kem besedilu uporabljata besedi “design” in “development”, je

to v slovenskem besedilu standarda prevedeno kot “razvoj”.

- Slovenski standard SIST ISO 9001:1995 je identi~en tudi standardu EN ISO 9001:1994.

SIST ISO 9001 : 1995

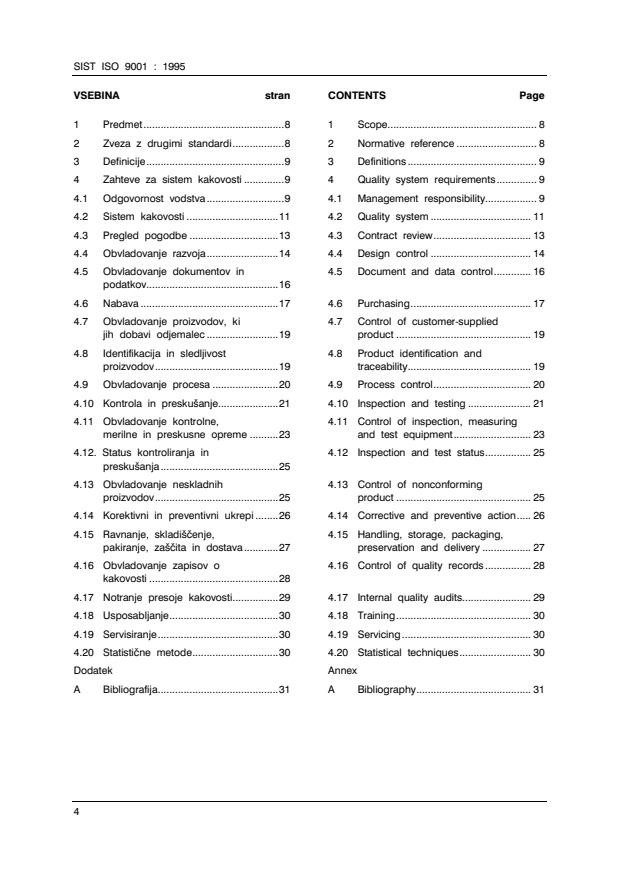

VSEBINA stran CONTENTS Page

1 Predmet.8 1 Scope.8

2 Zveza z drugimi standardi.8 2 Normative reference.8

3 Definicije.9 3 Definitions.9

4 Zahteve za sistem kakovosti.9 4 Quality system requirements.9

4.1 Odgovornost vodstva.9 4.1 Management responsibility.9

4.2 Sistem kakovosti.11 4.2 Quality system.11

4.3 Pregled pogodbe.13 4.3 Contract review.13

4.4 Obvladovanje razvoja.14 4.4 Design control.14

4.5 Obvladovanje dokumentov in 4.5 Document and data control.16

podatkov.16

4.6 Nabava.17 4.6 Purchasing.17

4.7 Obvladovanje proizvodov, ki 4.7 Control of customer-supplied

jih dobavi odjemalec.19 product.19

4.8 Identifikacija in sledljivost 4.8 Product identification and

proizvodov.19 traceability.19

4.9 Obvladovanje procesa.20 4.9 Process control.20

4.10 Kontrola in presku{anje.21 4.10 Inspection and testing.21

4.11 Obvladovanje kontrolne, 4.11 Control of inspection, measuring

merilne in preskusne opreme.23 and test equipment.23

4.12. Status kontroliranja in 4.12 Inspection and test status.25

presku{anja.25

4.13 Obvladovanje neskladnih 4.13 Control of nonconforming

proizvodov.25 product.25

4.14 Korektivni in preventivni ukrepi.26 4.14 Corrective and preventive action.26

4.15 Ravnanje, skladi{~enje, 4.15 Handling, storage, packaging,

pakiranje, za{~ita in dostava.27 preservation and delivery.27

4.16 Obvladovanje zapisov o 4.16 Control of quality records.28

kakovosti.28

4.17 Notranje presoje kakovosti.29 4.17 Internal quality audits.29

4.18 Usposabljanje.30 4.18 Training.30

4.19 Servisiranje.30 4.19 Servicing.30

4.20 Statisti~ne metode.30 4.20 Statistical techniques.30

Dodatek Annex

A Bibliografija.31 A Bibliography.31

SIST ISO 9001 : 1995

PREDGOVOR FOREWORD

ISO (Mednarodna organizacija za ISO (the International Organization for

standardizacijo) je svetovna zveza Standardization) is a worldwide federation of

nacionalnih organov za standarde (~lanov national standards bodies (ISO member

ISO). Mednarodne standarde obi~ajno bodies). The work of preparing International

pripravljajo tehni~ni odbori ISO. Vsak ~lan, Standards is normally carried out through

ki `eli delovati na dolo~enem podro~ju, za ISO technical committees. Each member

katero je ustanovljen tehni~ni odbor, ima body interested in a subject for which a

pravico biti zastopan v tem odboru. Pri delu technical committee has been established

has the right to be represented on that

sodelujejo tudi vladne in nevladne

mednarodne organizacije, povezane z ISO. committee. International organizations,

V vseh zadevah, ki so povezane s governmental and non-governmental, in

standardizacijo na podro~ju elektrotehnike, liasion with ISO, also take part in the work.

ISO tesno sodeluje z Mednarodno ISO collaborates closely with the

International Electrotechnical Commission

elektrotehni{ko komisijo (IEC).

(IEC) on all matters of electrotechnical

standardization.

Osnutki mednarodnih standardov, ki jih Draft International Standards adopted by the

sprejmejo tehni~ni odbori, se po{ljejo vsem technical committees are circulated to the

~lanicam v glasovanje. Za objavo member bodies for voting. Publication as an

mednarodnega standarda je treba pridobiti International Standard requires approval by

soglasje najmanj 75 odstotkov ~lanic, ki se at least 75 % of the member bodies

udele`ijo glasovanja. casting a vote.

Mednarodni standard ISO 9001 je pripravil International Standard ISO 9001 was

tehni~ni odbor ISO/TC 176 Vodenje prepared by Technical Committee

kakovosti in zagotavljanje kakovosti, ISO/TC 176, Quality management and quality

pododbor SC 2 Sistemi kakovosti. assurance, Subcommittee SC 2, Quality

systems.

Ta, druga izdaja preklicuje in zamenjuje This second edition cancels and replaces

prvo (ISO 9001:1987), ki je bila tehni~no the first edition (ISO 9001:1987), which has

predelana. been technically revised.

Dodatek A tega mednarodnega standarda je Annex A of this International Standard is for

podan samo kot informacija. information only.

SIST ISO 9001 : 1995

UVOD INTRODUCTION

Ta mednarodni standard je eden od treh This International Standard is one of three

mednarodnih standardov, ki obravnavajo International Standards dealing with quality

zahteve za sistem kakovosti in se lahko system requirements that can be used for

uporabljajo za zagotavljanje kakovosti external quality assurance purposes. The

navzven. Modeli zagotavljanja kakovosti, quality assurance models, set out in the

opisani v treh spodaj navedenih three International Standards listed below,

mednarodnih standardih, predstavljajo tri represent three distinct forms of quality

razli~ne oblike zahtev za sistem kakovosti, system requirements suitable for the

ki so primerne tako, kadar dobavitelj `eli purpose of a supplier demonstrating its

dokazati svojo sposobnost, kot tudi, kadar capability, and for the assessment of the

`eli sposobnosti dobavitelja oceniti zunanja capability of a supplier by external parties.

stranka.

a) ISO 9001, Sistemi kakovosti - Model a) ISO 9001, Quality systems - Model for

zagotavljanja kakovosti v razvoju, quality assurance in design,

proizvodnji, vgradnji in servisiranju development, production, installation

and servicing

Uporablja se, kadar mora dobavitelj

zagotoviti skladnost s specificiranimi - for use when conformance to

zahtevami v razvoju, proizvodnji, specified requirements is to be

vgradnji in servisiranju. assured by the supplier during design,

development, production, installation

and servicing.

b) ISO 9002, Sistemi kakovosti - Model b) ISO 9002, Quality systems - Model for

zagotavljanja kakovosti v proizvodnji, quality assurance in production,

vgradnji in servisiranju installation and servicing

Uporablja se, kadar mora dobavitelj - for use when conformance to

zagotoviti skladnost s specificiranimi specified requirements is to be

zahtevami v proizvodnji, vgradnji in assured by the supplier during

servisiranju. production, installation and servicing.

c) ISO 9003, Sistemi kakovosti - Model c) ISO 9003, Quality systems - Model for

zagotavljanja kakovosti v kon~ni quality assurance in final inspection

kontroli in presku{anju and test

Uporablja se, kadar mora dobavitelj - for use when conformance to

zagotoviti skladnost s specificiranimi specified requirements is to be

zahtevami samo v kon~ni kontroli in assured by the supplier solely at final

presku{anju. inspection and test.

Poudariti je treba, da so zahteve za sistem It is emphasized that the quality system

kakovosti, specificirane v tem mednarodnem requirements specified in this International

standardu in v standardih ISO 9002 in ISO Standard, ISO 9002 and ISO 9003 are

9003, samo dopolnilo (ne zamenjava) complementary (not alternative) to the

tehni~nim zahtevam (za proizvod). Podrobno technical (product) specified requirements.

specificirajo zahteve, ki dolo~ajo, katere They specify requirements which determine

elemente morajo vsebovati sistemi kakovosti, what elements quality systems have to

pri ~emer ti mednarodni standardi nimajo encompass, but it is not the purpose of

namena vsiljevati enoli~nosti sistemov these International Standards to enforce

kakovosti. Ti standardi so splo{ni in uniformity of quality systems. They are

SIST ISO 9001 : 1995

neodvisni od katerekoli specifi~ne industrije generic and independent of any specific

ali gospodarskega sektorja. Na razvoj in industry or economic sector. The design

izvedbo sistema kakovosti bodo vplivale and implementation of a quality system will

razli~ne potrebe organizacije, njeni posebni be influenced by the varying needs of an

cilji, vrste proizvodov in storitev ter organization, its particular objectives, the

uporabljeni procesi in specifi~ni postopki products and services supplied, and the

izvajanja. processes and specific practices employed.

Namen je, da se ti mednarodni standardi It is intended that these International

uporabljajo v izvirni obliki, vendar se v Standards will be adopted in their present

posebnih primerih z dodajanjem ali form, but on occasions they may need to

odvzemanjem dolo~enih zahtev za sistem be tailored by adding or deleting certain

kakovosti lahko prilagodijo specifi~nim quality system requirements for specific

pogodbenim situacijam. Vodila za take contractual situations. ISO 9000-1 provides

prilagoditve kakor tudi navodila za izbiro guidance on such tailoring as well as on

ustreznega modela zagotavljanja kakovosti, selection of the appropriate quality

to je izbiro standarda ISO 9001, ISO 9002 assurance model, viz. ISO 9001, ISO 9002

ali ISO 9003, vsebuje standard ISO 9000-1. or ISO 9003.

SIST ISO 9001 : 1995

Sistemi kakovosti - Model Quality system - Model for

zagotavljanja kakovosti v quality assurance in design,

razvoju, proizvodnji, vgradnji development, production,

in servisiranju installation and servicing

1 Predmet 1 Scope

Ta mednarodni standard specificira zahteve This International Standard specifies quality

za sistem kakovosti. Uporablja se, kadar system requirements for use where a

mora dobavitelj dokazati, da je sposoben supplier's capability to design and supply

razviti in dobaviti skladen proizvod. conforming product needs to be

demonstrated.

Navedene zahteve so namenjene predvsem The requirements specified are aimed

doseganju zadovoljstva odjemalca tako, da primarily at achieving customer satisfaction

se neskladnosti prepre~ujejo v vseh fazah by preventing nonconformity at all stages

od razvoja do servisiranja. from design through to servicing.

Ta mednarodni standard se uporablja: This International Standard is applicable in

situations when

a) kadar je zahtevan razvoj in so zahteve a) design is required and the product

za proizvod podane predvsem z requirements are stated principally in

opisom lastnosti ali jih je treba {ele performance terms, or they need to

ugotoviti, in be established, and

b) kadar je mogo~e dose~i zaupanje v b) confidence in product conformance

skladnost proizvoda s primernim can be attained by adequate

prikazom zmo`nosti dobavitelja v demonstration of a supplier's

razvoju, proizvodnji, vgradnji in capabilities in design, development,

servisiranju. production, installation and servicing.

Opomba 1: Informativne reference glej v dodatku A NOTE 1 For informative references, see annex A.

2 Zveza z drugimi standardi 2 Normative reference

Spodaj navedeni standard vsebuje dolo~ila, The following standard contains provisions

ki v povezavi s tem besedilom tvorijo which, through reference in this text,

dolo~ila tega mednarodnega standarda. V constitute provisions of this International

~asu objave je bila veljavna spodaj Standard. At the time of publication, the

navedena izdaja. Vsi standardi se revidirajo edition indicated was valid. All standards

in strankam, ki sklenejo pogodbo, are subject to revision, and parties to

zasnovano na tem mednarodnem standardu, agreements to investigate the possibility of

se priporo~a, naj razi{~ejo mo`nost uporabe applying the most recent edition of the

najnovej{e izdaje spodaj navedenega standard indicated below. Members of IEC

standarda. ^lani IEC in ISO vzdr`ujejo and ISO maintain registers of currently valid

register veljavnih mednarodnih standardov. International Standards.

ISO 8402:1994, Vodenje kakovosti in ISO 8402:1994, Quality management and

zagotavljanje kakovosti - Slovar quality assurance - Vocabulary

SIST ISO 9001 : 1995

3 Definicije 3 Definitions

V tem mednarodnem standardu se For the purposes of this International

uporabljajo definicije, podane v standardu Standard, the definitions given in ISO 8402

ISO 8402, in naslednje definicije: and the following definitions apply.

3.1 Proizvod: Rezultat aktivnosti ali 3.1 product: Result of activities or

procesov. processes.

Opombe: 2 Proizvod je lahko storitev, strojna NOTES 2A product may include service,

oprema, predelani materiali, programska hardware, processed materials, software

oprema ali njihova kombinacija. or a combination thereof.

3 Proizvod je lahko materialen (na primer 3 A product can be tangible (e.g.

sestavi ali predelani materiali) ali assemblies or processed materials) or

nematerialen (na primer znanje ali intangible (e.g. knowledge or concepts),

zamisli) ali kombinacija obeh. or a combination thereof.

4 V tem mednarodnem standardu se izraz 4 For the purposes of this International

“proizvod” nana{a samo na namerni Standard, the term “product” applies to

ponujeni proizvod, ki se nudi, in ne na the intended product offering only and

nenamerne "stranske" proizvode, ki not to unintended “by-products” affecting

vplivajo na okolje. V tem je razlika v the environment. This differs from the

primerjavi z definicijo proizvoda, podano definition given in ISO 8402.

v standardu ISO 8402.

3.2 Ponudba na razpis (tender): Ponudba, 3.2 tender: Offer made by a supplier in

ki jo pripravi dobavitelj kot odgovor na response to an invitation to satisfy a

povabilo za izpolnitev pogodbenih dolo~il contract award to provide product.

za dobavo proizvoda.

3.3 Pogodba: Dogovorjene zahteve med 3.3 contract: Agreed requirements between

dobaviteljem in odjemalcem, sporo~ene na a supplier and customer transmitted by any

kakr{enkoli na~in. means.

4 Zahteve za sistem kakovosti 4 Quality system requirements

4.1 Odgovornost vodstva 4.1 Management responsibility

4.1.1 Politika kakovosti 4.1.1 Quality policy

Vodstvo dobavitelja z izvr{ilno odgovornostjo The supplier's management with executive

mora dolo~iti in dokumentirati svojo politiko responsibility shall define and document its

kakovosti, vklju~no s cilji kakovosti in s policy for quality, including objectives for

svojo zavezanostjo za kakovost. Politika quality and its commitment to quality. The

kakovosti mora biti primerna dobaviteljevim quality policy shall be relevant to the

organizacijskim ciljem ter pri~akovanjem in supplier's organizational goals and the

potrebam njegovih odjemalcev. Dobavitelj expectations and needs of its customers.

mora zagotoviti, da politiko kakovosti The supplier shall ensure that this policy is

razumejo, izvajajo in vzdr`ujejo na vseh understood, implemented and maintained at

ravneh organizacije. all levels of the organization.

SIST ISO 9001 : 1995

4.1.2 Organizacija 4.1.2 Organization

4.1.2.1 Odgovornosti in pooblastila 4.1.2.1 Responsibility and authority

Odgovornosti, pooblastila in medsebojni The responsibility, authority and the

odnos osebja, ki vodi, izvaja in overja delo, interrelation of personnel who manage,

ki vpliva na kakovost, morajo biti dolo~eni perform and verify work affecting quality

in dokumentirani, {e posebej za tisto shall be defined and documented,

osebje, ki potrebuje organizacijsko svobodo particularly for personnel who need the

in pooblastila za: organizational freedom and authority to:

a) uvajanje ukrepov, s katerimi se a) initiate action to prevent the

prepre~uje pojavljanje neskladnosti pri occurrence of any nonconformities

proizvodih, v procesih in v sistemih relating to the product, process and

kakovosti; quality system;

b) identificiranje in zapisovanje vseh b) identify and record any problems

problemov, povezanih s proizvodom, relating to the product, process and

procesom in sistemom kakovosti; quality system;

c) uvajanje, priporo~anje ali omogo~anje c) initiate, recommend or provide

izvedbe re{itev po ustaljenih poteh; solutions through designated channels;

d) overjanje izvajanja re{itev; d) verify the implementation of solutions;

e) nadzor nadaljnje obdelave, dostave ali e) control further processing, delivery or

vgradnje neskladnega proizvoda, installation of nonconforming product

dokler pomanjkljivost ali nezadovoljivo until the deficiency or unsatisfactory

stanje ni odpravljeno. condition has been corrected.

4.1.2.2 Viri 4.1.2.2 Resources

Dobavitelj mora identificirati zahteve v zvezi The supplier shall identify resource

z viri in zagotoviti primerne vire vklju~no z requirements and provide adequate

imenovanjem usposobljenega osebja (glej resources, including the assignment of

4.18) za vodenje, izvajanje dela in trained personnel (see 4.18), for

overitvene aktivnosti, vklju~no z notranjimi management, performance of work and

presojami kakovosti. verification activities including internal quality

audits.

4.1.2.3 Predstavnik vodstva 4.1.2.3 Management representative

Dobaviteljevo vodstvo z izvr{ilno The supplier's management with executive

odgovornostjo mora imenovati ~lana responsibility shall appoint a member of the

dobaviteljevega lastnega vodstva, ki mora supplier's own management who,

imeti ne glede na druge odgovornosti irrespective of other responsibilities, shall

dolo~ena pooblastila za: have defined authority for

a) zagotavljanje, da je sistem kakovosti a) ensuring that a quality system is

vzpostavljen, da se izvaja in vzdr`uje established, implemented and

v skladu s tem mednarodnim maintained in accordance with this

standardom, in International Standard, and

b) poro~anje o delovanju sistema b) reporting on the performance of the

kakovosti dobaviteljevemu vodstvu za quality system to the supplier's

pregled in kot osnovo za izbolj{anje management for review and as a

sistema kakovosti. basis for improvement of the quality

system.

SIST ISO 9001 : 1995

Opomba 5: Odgovornost predstavnika vodstva lahko NOTE 5 The responsibility of a management

vklju~uje tudi sodelovanje z zunanjimi representative may also include liaison

strankami v zadevah, povezanih z with external parties on matters relating

dobaviteljevim sistemom kakovosti. to the supplier's quality system.

4.1.3 Pregled s strani vodstva 4.1.3 Management review

Dobaviteljevo vodstvo z izvr{ilno The supplier's management with executive

odgovornostjo mora pregledovati sistem responsibility shall review the quality system

kakovosti v dolo~enih ~asovnih presledkih, at defined intervals sufficient to ensure its

zadostnih, da sta zagotovljeni stalna continuing suitability and effectiveness in

ustreznost in u~inkovitost v izpolnjevanju satisfying the requirements of this

zahtev tega mednarodnega standarda ter International Standard and the supplier's

izra`eni politika in cilji kakovosti dobavitelja stated quality policy and objectives (see

(glej 4.1.1). Vzdr`evati se morajo zapisi o 4.1.1). Records of such reviews shall be

pregledih (glej 4.16). maintained (see 4.16).

4.2 Sistem kakovosti 4.2 Quality system

4.2.1 Splo{no 4.2.1 General

Dobavitelj mora vzpostaviti, dokumentirati in The supplier shall establish, document and

vzdr`evati sistem kakovosti, s katerim maintain a quality system as a means of

zagotavlja, da je proizvod skladen s ensuring that product conforms to specified

specificiranimi zahtevami. Dobavitelj mora requirements. The supplier shall prepare a

izdelati poslovnik kakovosti, ki pokriva quality manual covering the requirements of

zahteve tega mednarodnega standarda. this International Standard. The quality

Poslovnik kakovosti mora vsebovati postopke manual shall include or make reference to