ISO/DIS 4484-3

(Main)Textiles and textile products — Microplastics from textile sources — Part 3: Measurement of collected material mass released from textile end products by domestic washing method

Textiles and textile products — Microplastics from textile sources — Part 3: Measurement of collected material mass released from textile end products by domestic washing method

Textiles et produits textiles — Microplastiques d'origines textiles — Partie 3: Mesurage de la masse de matériaux collectés libérés par les produits finis textiles par la méthode de lavage domestique

General Information

Buy Standard

Standards Content (Sample)

ISO/TC 38/SC N

Date: 2021-03

ISO DIS FDIS 4484-3:20212023(E)

ISO/TC 38/SC /WG 34

2023-01-13

Secretariat: SAC

Textiles and textile products — Microplastics from textile sources — Part 3:

Measurement of collected material mass released from textile end products by

domestic washing method

Textiles et produits textiles — Microplastiques d'origines textiles — Partie 3: Mesurage de

la masse de matériaux collectés libérés par les produits finis textiles par la méthode de

lavage domestique---------------------- Page: 1 ----------------------

ISO/FDIS 4484-3:2023(E)

© ISO 20222023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no

part of this publication may be reproduced or utilized otherwise in any form or by any means,

electronic or mechanical, including photocopying, or posting on the internet or an intranet, without

prior written permission. Permission can be requested from either ISO at the address below or

ISO's member body in the country of the requester.ISO Copyright Office

CP 401 • CH-1214 Vernier, Geneva

Phone: + 41 22 749 01 11

Email: copyright@iso.org

Email: copyright@iso.org

Website: www.iso.orgwww.iso.org

Published in Switzerland.

ii © ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 4484-3:2023(E)

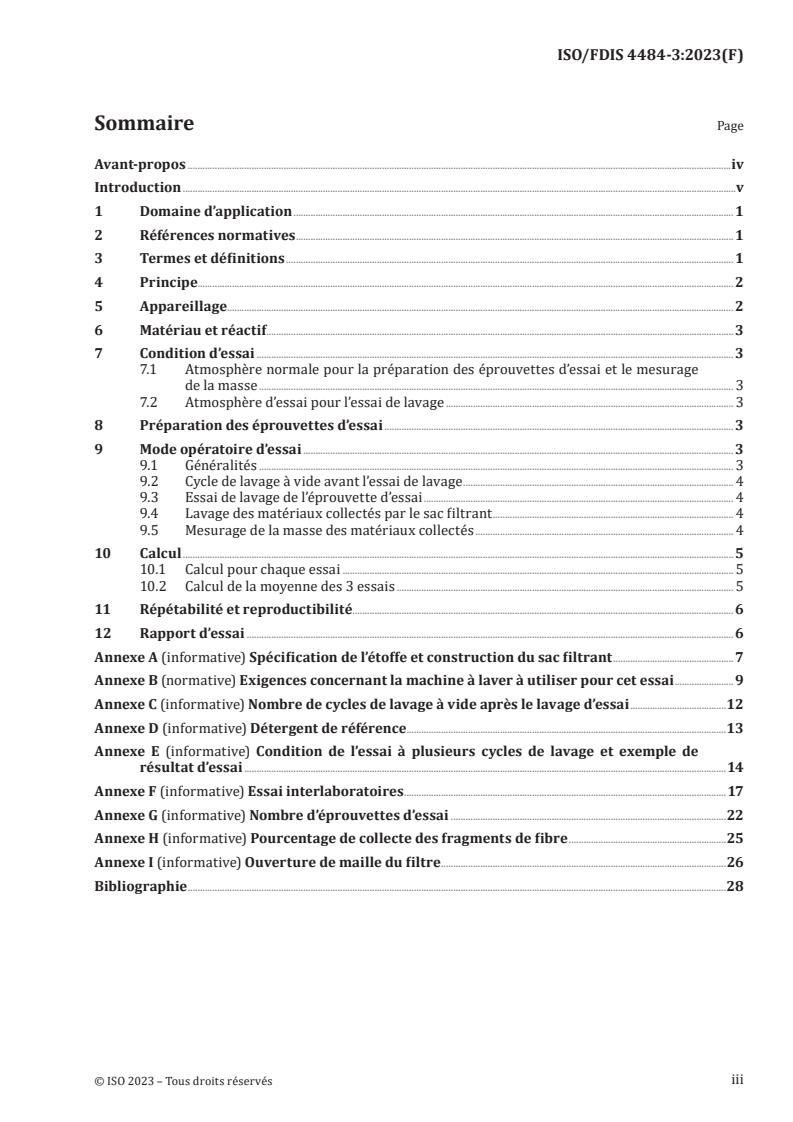

Contents Page

Foreword ......................................................................................................................................................................... iv

Introduction ..................................................................................................................................................................... v

1 Scope .................................................................................................................................................................... 1

2 Normative references .................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................... 1

4 Principle .............................................................................................................................................................. 2

5 Apparatus .......................................................................................................................................................... 2

6 Material and reagent ...................................................................................................................................... 2

7 Test condition ................................................................................................................................................... 3

8 Test specimen preparation .......................................................................................................................... 3

9 Test procedure ................................................................................................................................................. 3

10 Calculation.......................................................................................................................................................... 5

11 Repeatability and producibility ................................................................................................................. 5

12 Test report ......................................................................................................................................................... 5

Annex A (informative) Filter fabric specification and filter bag construction .......................................... 7

Annex B (normative) Requirements of the washing machine to be used in this test ............................. 9

Annex C (informative) Number of empty washing cycles after test washing .......................................... 12

Annex D (informative) Reference detergent ....................................................................................................... 13

Annex E (informative) The condition of the multiple washing cycle test and an example of

the test result ................................................................................................................................................. 14

Annex F (informative) Interlaboratory trial ...................................................................................................... 17

Annex G (informative) Number of test specimens ............................................................................................ 23

Annex H (informative) Collection percentage of the fibre fragments ....................................................... 26

Annex I (informative) Filter aperture size .......................................................................................................... 27

Bibliography ................................................................................................................................................................. 29

© ISO 2023 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 4484-3:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directiveswww.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patentswww.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the World

Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.htmlwww.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 38, Textiles, in collaboration with the

European Committee for Standardization (CEN) Technical Committee CEN/TC 248, Textiles and textile

products, in accordance with the Agreement on technical cooperation between ISO and CEN (Vienna

Agreement).A list of all parts in the ISO 4484 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found atwww.iso.org/members.htmlwww.iso.org/members.html.

iv © ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 4484-3:2023(E)

Introduction

Daily washing of textile end products generates fibre fragments which are discharged from washing

machine. The purpose of this test method is to collect materials including fibre fragments which are

discharged from the domestic washing machine through the washing process.Although there are many types of washing machines used at home, ISO 6330 has been developed for the

domestic washing test method, which specifies the domestic washing machines and test conditions. This

document utilizes one of the standard washing machines in ISO 6330.In addition, a care label is attached to textile end products in many countries of the world and this care

label specifies washing conditions to use in this document.Due to the complicated internal structure of washing machines, theits cleaning process of the washing

machines is very important to avoid the effect of contamination of washing machine. This document

proposes the checking method and the requirements of the washing machine to be used in this document.

The identification and quantification of components contained in the collected materials through the

washing process will beis determined by applying ISO 4484-2.ThisThe information gathered from this document can be utilized by the textile industry for the

development of textile end products to reduce or minimize shedding materials from textile end products

through the washing process.The International Organization for Standardization (ISO) draws attention to the fact that it is claimed that

compliance with this document may involve the use of a patent.ISO takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured ISO that he/she is willing to negotiate licences under

reasonable and non-discriminatory terms and conditions with applicants throughout the world. In this

respect, the statement of the holder of this patent right is registered with ISO. Information may be

obtained from the patent database available at www.iso.org/patents.Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights other than those in the patent database. ISO shall not be held responsible for identifying any

or all such patent rights.© ISO 2023 – All rights reserved v

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 4484-3:2023(E)

Textiles and textile products — Microplastics from textile

sources — Part 3: Measurement of collected material mass

released from textile end products by the domestic washing

method

1 Scope

This document specifies a method for measurement ofmeasuring the collected material mass released

from the outlet hose of a standard washing machine, described in ISO 6330, through the washing process.

NOTE The washing condition of textile end products is indicated by the care labelling according to ISO 3758.

This document is applicable to textile end products which is(including consumer textile products, such

as clothing, such as made of fleece, shirts, trousers, blouse, etc.,.) and home textile end products, (such

as, blankets, rugs, curtains, etc.,.) which are composed of all fibres such as natural fibres, and man-made

fibres, including mixture of the fibres that can be washed in a domestic washing machine.

This document is not applicable to fabrics and cut textile products, and. It does not cover the test for

washing machines and detergents as well.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 139, Textiles — Standard atmospheres for conditioning and testingISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 3758, Textiles — Care labelling code using symbols

ISO 6330:2021, Textiles — Domestic washing and drying procedures for textile testing

3 Terms and definitionsFor the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obphttps://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/https://www.electropedia.org/

3.1collected material

material collected by the filter attached at the outlet hose of a washing machine through the washing

process, which include fibre fragments and not non-water-soluble materials3.2

empty washing cycle

© ISO 2023 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/FDIS 4484-3:2023(E)

washing cycle without test specimens by using the test washing program

4 Principle

A given mass of textile end products is washed in a domestic washing machine under certain conditions

of temperature and mechanical conditions for a given number of washing cycles. The material shed

through the washing cycles is collected by usingin a filter bag which is attached at the outlet hose of the

washing machine. The collected materials by thein filter bag are transferred to the membrane filter and

the membrane filter with the collected materials are weighed in the weighing bottle. The membrane filter

and weighing bottle are prepared in combination. The mass of the collected materials is calculated by the

subtraction ofsubtracting the original mass of the membrane filter and weighing bottle from the mass

with the collected materials. The mass of collected materials, the ratio of the mass of the collected

materials and the test specimen mass and the ratio of the mass of the collected material and the number

of the test specimen are reported.5 Apparatus

5.1 Domestic washing machine, specified in ISO 6330, with built-in filters removed. The domestic

washing machine used to thisin document shall be metmeet the requirementrequirements in Annex B.

5.2 Filter bag, woven mesh, with aperture size of (10 ± 4) μm and; the specification for the materials and

the construction is described in Annex A. The aperture size of the filter is determined according to Annex

I.5.3 Analytical balance, with a resolution of 0,1 mg or better.

5.4 Balance, with a resolution of 1 g or better.

5.5 Oven, capable of maintaining a temperature of (105 ± 3) °C, without fan.

5.6 Cable ties, made of polyamide.

5.7 Polycarbonate membrane filter, approximately 47 mm in diameter with 10 µm aperture size.

Stainless steel filter is also applicable.5.8 Weighing bottle or dish, made of metal or glass, with a minimum diameter, approximately 47 mm,

with a lid.5.9 Vacuum filtration device, consisting of sintered filter platform and funnel, with vacuum pump.

5.10 Wash bottle, made of polyethylene or silicon resin, etc., squeezable and with nozzle.

5.11 Tweezers, made of stainless steel or plastics.5.12 Glass beaker, with a minimum capacity of 1 000 ml.

5.13 Desiccator, with drying agent.

6 Material and reagent

6.1 Water, distilled or grade 3 water according to ISO 3696.

2 © ISO 2023 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 4484-3:2023(E)

7 Test condition

7.1 Standard atmosphere for preparation of test specimens and mass measurement

The standard atmosphere for test specimen preparation and mass measurement are at the temperature

of (20 ± 2) °C and the relative humidity of (65 ± 4) % according toin accordance with ISO 139.

7.2 Test atmosphere for washing testThe condition for the washing test is ambient condition.

8 Test specimen preparation

Only one kind of textile end products is applied in this washing test. Different kinds of textile end products

shall not be mixed in the washing test. The number of the test specimens per washing test (S ) is at least

two textile end products. The maximum dry volume of all test specimens per washing test shall be not

more than half of the volume of the washing tub.The washing test is repeated for three (3) sets.

The number of the test specimens can affect to the test result, which is shown in Annex G as an example.

The test specimens are conditioned according toin accordance with ISO 139. The total mass of the

conditioned test specimens (M )), which is measured by theusing a balance (5.4)), shall be up to 1 g and

reported in the test report.109 Test procedure

10.19.1 General

The washing machine used in this test shall meet the requirement described in Annex B. Once met the

requirement, the washing machine can be used continuously for the washing test.For the consecutive washing test, take a procedure from Clause 9.2.

The washing conditions of this test procedure is indicated by the care label attached to the textile end

products according toin accordance with ISO 3758. The details of the washing condition are referred to

ISO 6330.If the countries use their own care label system or care instruction system, set the washing condition

indicated by their system or if there is no label, run the washing program agreed among the interested

parties.10.29.2 Empty washing cycle before the washing test

Mount the filter bag (5.2) to the outlet hose of the domestic washing machine (5.1) and tie up by cable tie

(5.6). Run one washing cycle of the washing program without test specimens. The washing program is

the same as the washing test as Clause 9.3. After completion of the washing cycle, remove the filter bag

from outlet hose. Measure the mass of the collected materials by following the steps from Clause 9.4 to

9.5 and Clause 10 and report the mass of the collected materials from the empty washing cycle in the test

report. This is an information of the test washing machine condition.10.39.3 Washing test of the test specimen

Mount the filter bag (5.2) to the outlet hose of the domestic washing machine (5.1) and tie up by cable tie

(5.6). Put the test specimens into the washing tub and run one test washing cycle of the washing program.

The detergent may be used for washing test and the preferable detergent is introduced in Annex D.

© ISO 2023 – All rights reserved 3---------------------- Page: 8 ----------------------

ISO/FDIS 4484-3:2023(E)

When the multiple numbers of the test washing cycle are required, run the number of the washing cycles

as determined by the interested parties according to Annex E. An example of the results of the multiple

numbers of test washing cycles are shown in Annex E.After completion of the washing cycle, remove the test specimens from the washing tub.

Then, run 2 empty washing cycles by the same washing program.The number of empty washing cycles (2 empty washing cycles) after test washing was determined by the

results as shown in Annex C.After completion of the empty washing cycle, remove the filter bag from outlet hose.

nd rdFor the 2 and 3 sets of the test specimens, run the washing test in Clause 9.3.

10.49.4 Washing of the collected material from the filter bag

Prepare four (4) glass beakers (5.12) containing 1 l of water (6.1) separately. Wash the filter bags of

Clause 9.2 and 9.3 in the glass beakers by turning inside out the filter bags. The solution in the beaker is

the suspension solution of the collected materials.10.59.5 Measurement of the mass of the collected materials

Prepare four (4) polycarbonate membrane filters (5.7) and four (4) weighing bottles (5.8) in combination

and separately, it is essential to keep each membrane filter/weighing bottle combination consistent

throughout the duration of the test. Measure the mass of the original membrane filter (5.7) and a

weighing bottle (5.8)), respectively, and record them up to 0,1 mg and denoted as (M ).

Membrane filters (5.7) are handled by tweezers (5.11). The membrane filter (5.7) shall be kept in the

weighing bottle (5.8) to prevent contamination from the environment.Set the membrane filter (5.7) on a vacuum filtration device (5.9).

Filter the suspension solution of Clause 9.4 by the membrane filters on a vacuum filtration device (5.9).

Add 1 l of water (6.1) to the beaker and wash the filter bag again and filter the suspension solution by

the same membrane filter. Repeat this procedure at least twice. Finally, wash the surface of the filter bag

and the inside of the beaker by water (6.1) using a wash bottle (5.10), and this suspension solution is also

filtered by the same membrane filter.Place the membrane filter with collected materials into the original weighing bottle of Clause 9.5 in

combination and dry for 2 h at (105 ± 3) °C in the oven (5.5). Then place the weighing bottle with the

membrane filter and collected materials in desiccator (5.13) to cool down to the room temperature.

Condition the membrane filter with the collected materials and the weighing bottle under standard

atmospheres in Clause 7.1.Measure the mass of the conditioned membrane filter with the collected material and the weighing bottle

up to 0,1 mg by the analytical balance (5.3) and record the result as (M ).At this time, measure of the mass several times at intervals of 1 h or more. The mass is determined as the

weighed value that shows a difference compared to the former and subsequent measurements within

0,1 % of the subsequent value.1110 Calculation

11.110.1 Calculation for each test run

The mass of the collected materials, C in mg is calculated by the Formula (1).

C = = M – – M (1)

m f2 f1

where

4 © ISO 2023 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/FDIS 4484-3:2023(E)

C is the mass of the collected materials through the test washing process in mg;

M is the mass of the original membrane filter and weighing bottle in mg;M is the mass of the membrane filter with the collected materials and weighing bottle in mg;.

The mass of the collected material per textile end product (C ) in mg per product is calculated by

Formula (2).C = = C / / S (2)

mp m n

where

C is the mass of the collected materials in mg/product;

C is the mass of the collected materials through the test washing process in mg;

S is the number of test specimens for one washing test;.The mass of the collected materials per the mass of the textile end products, C in mg/kg is calculated

by Formula (3).C = = (C × × 1 000) / / M (3)

mw m p

where

C is the mass of the collected materials per mass of textile end products in mg/kg;

C is the mass of the collected materials through the test washing process in mg;

M is the mass of test specimens in g;.11.210.2 Calculation of average for 3 test runs

Take averages of 3 test runs for C , C and C as the test results.

m mp mw

1211 Repeatability and reproducibility

The interlaboratory test according to this document is showngiven in Annex F.

1312 Test report

The test report shall include the following information:

a) a reference to this document, i.e. ISO 4484-3: 2023;

b) date of the test;

c) type of a washing machine and test conditions;

d) test method (number of washing cycles, etc.);

e) test environment conditions;

f) number of test specimen put into the washing tub;

g) total mass of the test specimens put into the washing tub;

h) the collected mass in the empty washing cycle before test washing;

i) the average mass of the collected materials through the test washing process;

j) the average mass of the collected materials per a textile end product;

k) the average mass of the collected materials per the mass of textile end products;

l) material, fibre, product construction, etc. of specimen tested;© ISO 2023 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/FDIS 4484-3:2023(E)

m) any deviation from the procedure;

n) any unusual features observed;

o) if detergent is used, report the kind and amount of detergent.

6 © ISO 2023 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/FDIS 4484-3:2023(E)

Annex A

(informative)

Filter fabric specification and filter bag construction

A.1 Fabric structure for filter bag

The image of the mesh fabric is shown in the Figure A.1 as an example and the product specification by

manufacturer is as follows:a) fibre material: 100 % polyamide monofilament yarn;

b) weave structure: 2/2 twill weave;

c) linear density (dtex): warp, 9, weft, 9;

d) number of threads per centimetre (T/cm): warp, 198, weft, 184;

e) mass per unit area (g/m ): 35.

Figure A.1 — Photo of a polyamide monofilament mesh filter as an example

A.2 Filter bag construction

This is an example of the filter bag construction. The other construction of the filter bag can be applied

for the purpose of the collecting the materials from the outlet hose of the washing machine.

a) Shape: Rectangular form.© ISO 2023 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/FDIS 4484-3:2023(E)

b) Bag dimension in mm: The longer side is approximately 600 mm and the shorter side is

approximately 90 mm which includes bonding allowance approximately 15 mm as shown in

Figure A.2 by dark thicker line.c) Bonding: The step for the formation of filter bag is shown in Figure A.2. The filter fabric is heat-cut in

rectangular fabric (key 1). The iron-on fusing tape with about 1 cm width is attached in two sides

(key 2). The fabric is folded in two (key 3) and adhered together by iron-on fusing tape (key 4) with

no gaps.How to use the iron-on fusing tape is given by the manufacturer’s instruction.

Dimensions in millimetres

8 © ISO 2023 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/FDIS 4484-3:2023(E)

Key

1 fabric cut by heat-cutting

2 position for iron-on fusing tape with about 1 cm in width

3 centre line to be folded

4 finished filter bag shape

Figure A.2 — Example of filter bag construction

A.3 Filter checking

As for reuse ofreusing the filter bag, the filter surface condition should be checked by light microscope

whether there is no damage and no foreign materials. The example of inspection condition is as follows:

1) the magnification: x 40;2) the number of inspection points: 100;

3) the criteria for reusable: no damage and no foreign materials comparing with new filter bag.

© ISO 2023 – All rights reserved 9---------------------- Page: 14 ----------------------

ISO/FDIS 4484-3:2023(E)

Annex B

(normative)

Requirements of the washing machine to be used in this test

B.1 General

The domestic washing machines used for this test shall meet the requirement described in this Annex

Bannex.B.2 Empty washing test procedure

B.2.1 Mount the filter bag (5.2) to the outlet hose of the washing machine (5.1) and tie up by cable tie

(5.6).B.2.2 Run one empty washing cycle of the washing program which shall be 4N according to ISO 6330:

2021 or equivalent.B.2.3 After completion of the empty washing cycle, remove the filter bag from the outlet hose.

B.2.4 Wash the collected materials from the filter bag according to Clause 9.4. Measure and calculate

the mass of collected materials (C ) from each empty washing cycle according to Clause 9.5 and Clause

10.B.2.5 Repeat to run the numbers of the empty washing cycles from Clause B.2.1 to B.2.4 by three (3)

empty washing cycle or more.B.2.6 Calculate CV (%) using the C values for the consecutive 3 cycles.

B.3 Requirements of the test washing machine to be used for this test

The coefficient of variation CV (%) of the mass of the collected materials is required to be 10 % or less

for three consecutive empty washing cycles, or the C shall be 1,0 mg or less three times in a row. The

flow of the procedure is shown in Figure B.1Repeat the empty washing cycle until the requirement is achieved. If the washing machine cannot meet

the requirements after numbers of the empty washing cycle, the washing machine is considered as

unsuitable for this washing test.If the washing machine is heavily soiled, it may be washed with a cleaning agent recommended by the

washing machine manufacturer.10 © ISO 2023 – All rights reserved

---------------------- Page: 15 ----------------------

ISO/FDIS 4484-3:2023(E)

© ISO 2023 – All rights reserved 11

---------------------- Page: 16 ----------------------

ISO/FDIS 4484-3:2023(E)

Figure B.1 — — Flowchart of checking of the washing machine to be used in this test

B.4 Example of the empty washing test resultThe example of the empty washing test result is shown in Table B.1. As shown in Table B.1, the CV (%)

becomes 10 % or less after 5 cleaning washing.Table B.1 — One example of empty washing test result

12 © ISO 2023 – All rights reserved

---------------------- Page: 17 ----------------------

ISO/FDIS 4484-3:2023(E)

Remarks

Coefficient

Standard

No. of Total collected Running

of variation

deviation (Data used

cleanings mass (mg) mean

(SD)

CV (%)

for mean and SD)

1 1,34 -— -— -— —

-— -— -— —

2 1,15

rd st nd rd

1 , 2 , 3

3 0,75 1,080 0,301 27,9

th nd rd th

4 0,84 0,913 0,210 23,0 2 , 3 , 4

rd th th

5 0,75 0,780 0,052 6,7 3 , 4 , 5

© ISO 2023 – All rights reserved 13

---------------------- Page: 18 ----------------------

ISO/FDIS 4484-3:2023(E)

Annex C

(informative)

Number of empty washing cycles after test washing

C.1 General

From this test, the number of the empty washing cycles after the test washing cycle of the specimens was

determined. Test specimens are shown in Table C.1.Table C.1 — Details of test specimens

Specimen name and Mass of

Specimen No. Composition

structure spe

...

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 4484-3

ISO/TC 38

Textiles and textile products —

Secretariat: SAC

Microplastics from textile sources —

Voting begins on:

2023-01-30

Part 3:

Voting terminates on:

Measurement of collected material

2023-03-27

mass released from textile end

products by domestic washing method

Textiles et produits textiles — Microplastiques d'origines textiles —

Partie 3: Mesurage de la masse de matériaux collectés libérés par les

produits finis textiles par la méthode de lavage domestique

ISO/CEN PARALLEL PROCESSING

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 4484-3:2023(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. © ISO 2023

---------------------- Page: 1 ----------------------

ISO/FDIS 4484-3:2023(E)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 4484-3

ISO/TC 38

Textiles and textile products —

Secretariat: SAC

Microplastics from textile sources —

Voting begins on:

Part 3:

Voting terminates on:

Measurement of collected material

mass released from textile end

products by domestic washing method

Textiles et produits textiles — Microplastiques d'origines textiles —

Partie 3: Mesurage de la masse de matériaux collectés libérés par les

produits finis textiles par la méthode de lavage domestique

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

ISO/CEN PARALLEL PROCESSING

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.RECIPIENTS OF THIS DRAFT ARE INVITED TO

ISO copyright office

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

CP 401 • Ch. de Blandonnet 8

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

CH-1214 Vernier, Geneva

DOCUMENTATION.

Phone: +41 22 749 01 11

IN ADDITION TO THEIR EVALUATION AS

Reference number

Email: copyright@iso.org

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 4484-3:2023(E)

Website: www.iso.org

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

Published in Switzerland

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

© ISO 2023 – All rights reserved

NATIONAL REGULATIONS. © ISO 2023

---------------------- Page: 2 ----------------------

ISO/FDIS 4484-3:2023(E)

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction .................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ..................................................................................................................................................................................... 1

3 Terms and definitions .................................................................................................................................................................................... 1

4 Principle ........................................................................................................................................................................................................................ 2

5 Apparatus .................................................................................................................................................................................................................... 2

6 Material and reagent ....................................................................................................................................................................................... 3

7 Test condition ..........................................................................................................................................................................................................3

7.1 Standard atmosphere for preparation of test specimens and mass measurement .................. 3

7.2 Test atmosphere for washing test ......................................................................................................................................... 3

8 Test specimen preparation ....................................................................................................................................................................... 3

9 Test procedure .......................................................................................................................................................................................................3

9.1 General ........................................................................................................................................................................................................... 3

9.2 Empty washing cycle before the washing test ........................................................................................................... 3

9.3 Washing test of the test specimen ......... ................................................................................................................................ 4

9.4 Washing of the collected material from the filter bag......................................................................................... 4

9.5 Measurement of the mass of the collected materials ........................................................................................... 4

10 Calculation .................................................................................................................................................................................................................. 5

10.1 Calculation for each test run ...................................................................................................................................................... 5

10.2 Calculation of average for 3 test runs ................................................................................................................................ 5

11 Repeatability and reproducibility ....................................................................................................................................................5

12 Test report .................................................................................................................................................................................................................. 5

Annex A (informative) Filter fabric specification and filter bag construction .......................................................7

Annex B (normative) Requirements of the washing machine to be used in this test ......................................9

Annex C (informative) Number of empty washing cycles after test washing ........................................................12

Annex D (informative) Reference detergent ............................................................................................................................................13

Annex E (informative) Condition of the multiple washing cycle test and example of the test

result ..............................................................................................................................................................................................................................14

Annex F (informative) Interlaboratory trial ............................................................................................................................................17

Annex G (informative) Number of test specimens .............................................................................................................................22

Annex H (informative) Collection percentage of the fibre fragments ..........................................................................25

Annex I (informative) Filter aperture size .................................................................................................................................................26

Bibliography .............................................................................................................................................................................................................................28

iii© ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/FDIS 4484-3:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.This document was prepared by Technical Committee ISO/TC 38, Textiles, in collaboration with the

European Committee for Standardization (CEN) Technical Committee CEN/TC 248, Textiles and textile

products, in accordance with the Agreement on technical cooperation between ISO and CEN (Vienna

Agreement).A list of all parts in the ISO 4484 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.© ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 4484-3:2023(E)

Introduction

Daily washing of textile end products generates fibre fragments which are discharged from washing

machine. The purpose of this test method is to collect materials including fibre fragments which are

discharged from the domestic washing machine through the washing process.Although there are many types of washing machines used at home, ISO 6330 has been developed for

the domestic washing test method, which specifies the domestic washing machines and test conditions.

This document utilizes one of the standard washing machines in ISO 6330.In addition, a care label is attached to textile end products in many countries of the world and this care

label specifies washing conditions to use in this document.Due to the complicated internal structure of washing machines, its cleaning process is very important

to avoid contamination. This document proposes the checking method and the requirements of the

washing machine to be used in this document.The identification and quantification of components contained in the collected materials through the

washing process is determined by applying ISO 4484-2.The information gathered from this document can be utilized by the textile industry for the development

of textile end products to reduce or minimize shedding materials from textile end products through the

washing process.The International Organization for Standardization (ISO) draws attention to the fact that it is claimed

that compliance with this document may involve the use of a patent.ISO takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured ISO that he/she is willing to negotiate licences under

reasonable and non-discriminatory terms and conditions with applicants throughout the world. In

this respect, the statement of the holder of this patent right is registered with ISO. Information may be

obtained from the patent database available at www.iso.org/patents.Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights other than those in the patent database. ISO shall not be held responsible for identifying

any or all such patent rights.© ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 4484-3:2023(E)

Textiles and textile products — Microplastics from textile

sources —

Part 3:

Measurement of collected material mass released from

textile end products by domestic washing method

1 Scope

This document specifies a method for measuring the collected material mass released from the outlet

hose of a standard washing machine, described in ISO 6330, through the washing process.

NOTE The washing condition of textile end products is indicated by the care labelling according to ISO 3758.

This document is applicable to textile end products (including consumer textile products, such as

clothing made of fleece, shirts, trousers, blouse, etc.) and home textile end products (such as, blankets,

rugs, curtains, etc.) which are composed of all fibres such as natural fibres, and man-made fibres,

including mixture of the fibres that can be washed in a domestic washing machine.

This document is not applicable to fabrics and cut textile products. It does not cover the test for washing

machines and detergents as well.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 139, Textiles — Standard atmospheres for conditioning and testingISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 3758, Textiles — Care labelling code using symbols

ISO 6330:2021, Textiles — Domestic washing and drying procedures for textile testing

3 Terms and definitionsFor the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1

collected material

material collected by the filter attached at the outlet hose of a washing machine through the washing

process, which include fibre fragments and non-water-soluble materials© ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/FDIS 4484-3:2023(E)

3.2

empty washing cycle

washing cycle without test specimens by using the test washing program

4 Principle

A given mass of textile end products is washed in a domestic washing machine under certain

temperature and mechanical conditions for a given number of washing cycles. The material shed

through the washing cycles is collected in a filter bag which is attached at the outlet hose of the

washing machine. The collected materials in filter bag are transferred to the membrane filter and the

membrane filter with the collected materials are weighed in the weighing bottle. The membrane filter

and weighing bottle are prepared in combination. The mass of the collected materials is calculated by

the subtracting the original mass of the membrane filter and weighing bottle from the mass with the

collected materials. The mass of collected materials, the ratio of the mass of the collected materials and

the test specimen mass and the ratio of the mass of the collected material and the number of the test

specimen are reported.5 Apparatus

5.1 Domestic washing machine, specified in ISO 6330, with built-in filters removed. The domestic

washing machine used in document shall meet the requirements in Annex B.5.2 Filter bag, woven mesh, with aperture size of (10 ± 4) μm; the specification for the materials

and the construction is described in Annex A. The aperture size of the filter is determined according to

Annex I.5.3 Analytical balance, with a resolution of 0,1 mg or better.

5.4 Balance, with a resolution of 1 g or better.

5.5 Oven, capable of maintaining a temperature of (105 ± 3) °C, without fan.

5.6 Cable ties, made of polyamide.

5.7 Polycarbonate membrane filter, approximately 47 mm in diameter with 10 µm aperture size.

Stainless steel filter is also applicable.5.8 Weighing bottle or dish, made of metal or glass, with a minimum diameter, approximately

47 mm, with a lid.5.9 Vacuum filtration device, consisting of sintered filter platform and funnel, with vacuum pump.

5.10 Wash bottle, made of polyethylene or silicon resin, etc., squeezable and with nozzle.

5.11 Tweezers, made of stainless steel or plastics.5.12 Glass beaker, with a minimum capacity of 1 000 ml.

5.13 Desiccator, with drying agent.

© ISO 2023 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 4484-3:2023(E)

6 Material and reagent

6.1 Water, distilled or grade 3 water according to ISO 3696.

7 Test condition

7.1 Standard atmosphere for preparation of test specimens and mass measurement

The standard atmosphere for test specimen preparation and mass measurement are at the temperature

of (20 ± 2) °C and the relative humidity of (65 ± 4) % in accordance with ISO 139.

7.2 Test atmosphere for washing testThe condition for the washing test is ambient condition.

8 Test specimen preparation

Only one kind of textile end products is applied in this washing test. Different kinds of textile end

products shall not be mixed in the washing test. The number of the test specimens per washing test (S )

is at least two textile end products. The maximum dry volume of all test specimens per washing test

shall be not more than half of the volume of the washing tub.The washing test is repeated for three (3) sets.

The number of the test specimens can affect the test result, which is shown in Annex G as an example.

The test specimens are conditioned in accordance with ISO 139. The total mass of the conditioned test

specimens (M ), which is measured using a balance (5.4), shall be up to 1 g and reported in the test

report.9 Test procedure

9.1 General

The washing machine used in this test shall meet the requirement described in Annex B. Once met the

requirement, the washing machine can be used continuously for the washing test.For the consecutive washing test, take a procedure from 9.2.

The washing conditions of this test procedure is indicated by the care label attached to the textile end

products in accordance with ISO 3758. The details of the washing condition are referred to ISO 6330.

If the countries use their own care label system or care instruction system, set the washing condition

indicated by their system or if there is no label, run the washing program agreed among the interested

parties.9.2 Empty washing cycle before the washing test

Mount the filter bag (5.2) to the outlet hose of the domestic washing machine (5.1) and tie up by cable

tie (5.6). Run one washing cycle of the washing program without test specimens. The washing program

is the same as the washing test as 9.3. After completion of the washing cycle, remove the filter bag

from outlet hose. Measure the mass of the collected materials by following the steps from 9.4 to 9.5

and Clause 10 and report the mass of the collected materials from the empty washing cycle in the test

report. This is an information of the test washing machine condition.© ISO 2023 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/FDIS 4484-3:2023(E)

9.3 Washing test of the test specimen

Mount the filter bag (5.2) to the outlet hose of the domestic washing machine (5.1) and tie up by cable

tie (5.6). Put the test specimens into the washing tub and run one test washing cycle of the washing

program.The detergent may be used for washing test and the preferable detergent is introduced in Annex D.

When the multiple numbers of the test washing cycle are required, run the number of the washing

cycles as determined by the interested parties according to Annex E. An example of the results of the

multiple numbers of test washing cycles are shown in Annex E.After completion of the washing cycle, remove the test specimens from the washing tub.

Then, run 2 empty washing cycles by the same washing program.The number of empty washing cycles (2 empty washing cycles) after test washing was determined by

the results as shown in Annex C.After completion of the empty washing cycle, remove the filter bag from outlet hose.

nd rdFor the 2 and 3 sets of the test specimens, run the washing test in 9.3.

9.4 Washing of the collected material from the filter bag

Prepare four (4) glass beakers (5.12) containing 1 l of water (6.1) separately. Wash the filter bags of

9.2 and 9.3 in the glass beakers by turning inside out the filter bags. The solution in the beaker is the

suspension solution of the collected materials.9.5 Measurement of the mass of the collected materials

Prepare four (4) polycarbonate membrane filters (5.7) and four (4) weighing bottles (5.8) in

combination and separately, it is essential to keep each membrane filter/weighing bottle combination

consistent throughout the duration of the test. Measure the mass of the original membrane filter (5.7)

and a weighing bottle (5.8), respectively, and record them up to 0,1 mg and denoted as (M ).

Membrane filters (5.7) are handled by tweezers (5.11). The membrane filter (5.7) shall be kept in the

weighing bottle (5.8) to prevent contamination from the environment.Set the membrane filter (5.7) on a vacuum filtration device (5.9).

Filter the suspension solution of 9.4 by the membrane filters on a vacuum filtration device (5.9). Add 1 l

of water (6.1) to the beaker and wash the filter bag again and filter the suspension solution by the same

membrane filter. Repeat this procedure at least twice. Finally, wash the surface of the filter bag and

the inside of the beaker by water (6.1) using a wash bottle (5.10), and this suspension solution is also

filtered by the same membrane filter.Place the membrane filter with collected materials into the original weighing bottle of 9.5 in combination

and dry for 2 h at (105 ± 3) °C in the oven (5.5). Then place the weighing bottle with the membrane filter

and collected materials in desiccator (5.13) to cool down to the room temperature.

Condition the membrane filter with the collected materials and the weighing bottle under standard

atmospheres in 7.1.Measure the mass of the conditioned membrane filter with the collected material and the weighing

bottle up to 0,1 mg by the analytical balance (5.3) and record the result as (M ).

At this time, measure of the mass several times at intervals of 1 h or more. The mass is determined

as the weighed value that shows a difference compared to the former and subsequent measurements

within 0,1 % of the subsequent value.© ISO 2023 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/FDIS 4484-3:2023(E)

10 Calculation

10.1 Calculation for each test run

The mass of the collected materials, C in mg is calculated by the Formula (1).

C = M – M (1)

m f2 f1

where

C is the mass of the collected materials through the test washing process in mg;

M is the mass of the original membrane filter and weighing bottle in mg;M is the mass of the membrane filter with the collected materials and weighing bottle in mg.

The mass of the collected material per textile end product (C ) in mg per product is calculated by

Formula (2).C = C / S (2)

mp m n

where

C is the mass of the collected materials in mg/product;

C is the mass of the collected materials through the test washing process in mg;

S is the number of test specimens for one washing test.The mass of the collected materials per the mass of the textile end products, C in mg/kg is calculated

by Formula (3).C = (C × 1 000) / M (3)

mw m p

where

C is the mass of the collected materials per mass of textile end products in mg/kg;

C is the mass of the collected materials through the test washing process in mg;

M is the mass of test specimens in g.10.2 Calculation of average for 3 test runs

Take averages of 3 test runs for C , C and C as the test results.

m mp mw

11 Repeatability and reproducibility

The interlaboratory test according to this document is given in Annex F.

12 Test report

The test report shall include the following information:

a) a reference to this document, i.e. ISO 4484-3:2023;

b) date of the test;

© ISO 2023 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/FDIS 4484-3:2023(E)

c) type of a washing machine and test conditions;

d) test method (number of washing cycles, etc.);

e) test environment conditions;

f) number of test specimen put into the washing tub;

g) total mass of the test specimens put into the washing tub;

h) the collected mass in the empty washing cycle before test washing;

i) the average mass of the collected materials through the test washing process;

j) the average mass of the collected materials per a textile end product;

k) the average mass of the collected materials per the mass of textile end products;

l) material, fibre, product construction, etc. of specimen tested;m) any deviation from the procedure;

n) any unusual features observed;

o) if detergent is used, report the kind and amount of detergent.

© ISO 2023 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/FDIS 4484-3:2023(E)

Annex A

(informative)

Filter fabric specification and filter bag construction

A.1 Fabric structure for filter bag

The image of the mesh fabric is shown in the Figure A.1 as an example and the product specification by

manufacturer is as follows:a) fibre material: 100 % polyamide monofilament yarn;

b) weave structure: 2/2 twill weave;

c) linear density (dtex): warp, 9, weft, 9;

d) number of threads per centimetre (T/cm): warp, 198, weft, 184;

e) mass per unit area (g/m ): 35.

Figure A.1 — Photo of a polyamide monofilament mesh filter as an example

A.2 Filter bag construction

This is an example of the filter bag construction. The other construction of the filter bag can be applied

for the purpose of the collecting the materials from the outlet hose of the washing machine.

a) Shape: Rectangular form.b) Bag dimension in mm: The longer side is approximately 600 mm and the shorter side is

approximately 90 mm which includes bonding allowance approximately 15 mm as shown in

Figure A.2 by dark thicker line.c) Bonding: The step for the formation of filter bag is shown in Figure A.2. The filter fabric is heat-

cut in rectangular fabric (key 1). The iron-on fusing tape with about 1 cm width is attached in

two sides (key 2). The fabric is folded in two (key 3) and adhered together by iron-on fusing tape

(key 4) with no gaps.How to use the iron-on fusing tape is given by the manufacturer’s instruction.

© ISO 2023 – All rights reserved

---------------------- Page: 12 ----------------------

ISO/FDIS 4484-3:2023(E)

Dimensions in millimetres

Key

1 fabric cut by heat-cutting

2 position for iron-on fusing tape with about 1 cm in width

3 centre line to be folded

4 finished filter bag shape

Figure A.2 — Example of filter bag construction

A.3 Filter checking

As for reusing the filter bag, the filter surface condition should be checked by light microscope whether

there is no damage and no foreign materials. The example of inspection condition is as follows:

1) the magnification: x 40;2) the number of inspection points: 100;

3) the criteria for reusable: no damage and no foreign materials comparing with new filter bag.

© ISO 2023 – All rights reserved...

PROJET

NORME ISO/FDIS

FINAL

INTERNATIONALE 4484-3

ISO/TC 38

Textiles et produits textiles —

Secrétariat: SAC

Microplastiques d'origines textiles —

Début de vote:

2023-01-30

Partie 3:

Vote clos le:

Mesurage de la masse de matériaux

2023-03-27

collectés libérés par les produits finis

textiles par la méthode de lavage

domestique

Textiles and textile products — Microplastics from textile sources —

Part 3: Measurement of collected material mass released from textile

end products by domestic washing method

TRAITEMENT PARALLÈLE ISO/CEN

LES DESTINATAIRES DU PRÉSENT PROJET SONT

INVITÉS À PRÉSENTER, AVEC LEURS OBSER-

VATIONS, NOTIFICATION DES DROITS DE PRO-

PRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENT

CONNAISSANCE ET À FOURNIR UNE DOCUMEN-

TATION EXPLICATIVE.

OUTRE LE FAIT D’ÊTRE EXAMINÉS POUR

ÉTABLIR S’ILS SONT ACCEPTABLES À DES FINS

INDUSTRIELLES, TECHNOLOGIQUES ET COM-

Numéro de référence

MERCIALES, AINSI QUE DU POINT DE VUE

ISO/FDIS 4484-3:2023(F)

DES UTILISATEURS, LES PROJETS DE NORMES

INTERNATIONALES DOIVENT PARFOIS ÊTRE

CONSIDÉRÉS DU POINT DE VUE DE LEUR POSSI-

BILITÉ DE DEVENIR DES NORMES POUVANT

SERVIR DE RÉFÉRENCE DANS LA RÉGLEMENTA-

TION NATIONALE. © ISO 2023

---------------------- Page: 1 ----------------------

ISO/FDIS 4484-3:2023(F)

PROJET

NORME ISO/FDIS

FINAL

INTERNATIONALE 4484-3

ISO/TC 38

Textiles et produits textiles —

Secrétariat: SAC

Microplastiques d'origines textiles —

Début de vote:

2023-01-30

Partie 3:

Vote clos le:

Mesurage de la masse de matériaux

2023-03-27

collectés libérés par les produits finis

textiles par la méthode de lavage

domestique

Textiles and textile products — Microplastics from textile sources —

Part 3: Measurement of collected material mass released from textile

end products by domestic washing method

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2023

TRAITEMENT PARALLÈLE ISO/CEN

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

LES DESTINATAIRES DU PRÉSENT PROJET SONTy compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

INVITÉS À PRÉSENTER, AVEC LEURS OBSER-VATIONS, NOTIFICATION DES DROITS DE PRO-

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

PRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENTISO copyright office

CONNAISSANCE ET À FOURNIR UNE DOCUMEN-

TATION EXPLICATIVE.

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève OUTRE LE FAIT D’ÊTRE EXAMINÉS POUR

ÉTABLIR S’ILS SONT ACCEPTABLES À DES FINS

Tél.: +41 22 749 01 11

INDUSTRIELLES, TECHNOLOGIQUES ET COM-

Numéro de référence

E-mail: copyright@iso.org

MERCIALES, AINSI QUE DU POINT DE VUE

ISO/FDIS 4484-3:2023(F)

Web: www.iso.org

DES UTILISATEURS, LES PROJETS DE NORMES

INTERNATIONALES DOIVENT PARFOIS ÊTRE

Publié en Suisse

CONSIDÉRÉS DU POINT DE VUE DE LEUR POSSI-

BILITÉ DE DEVENIR DES NORMES POUVANT

SERVIR DE RÉFÉRENCE DANS LA RÉGLEMENTA-

© ISO 2023 – Tous droits réservés

TION NATIONALE. © ISO 2023

---------------------- Page: 2 ----------------------

ISO/FDIS 4484-3:2023(F)

Sommaire Page

Avant-propos .............................................................................................................................................................................................................................iv

Introduction .................................................................................................................................................................................................................................v

1 Domaine d’application ................................................................................................................................................................................... 1

2 Références normatives ..................................................................................................................................................................................1

3 Termes et définitions ...................................................................................................................................................................................... 1

4 Principe.......................................................................................................................................................................................................................... 2

5 Appareillage .............................................................................................................................................................................................................. 2

6 Matériau et réactif ........................................................................................................................................... ...................................................3

7 Condition d’essai .................................................................................................................................................................................................. 3

7.1 Atmosphère normale pour la préparation des éprouvettes d’essai et le mesurage

de la masse ................................................................................................................................................................................................. 3

7.2 Atmosphère d’essai pour l’essai de lavage ..................................................................................................................... 3

8 Préparation des éprouvettes d’essai .............................................................................................................................................. 3

9 Mode opératoire d’essai ............................................................................................................................................................................... 3

9.1 Généralités ................................................................................................................................................................................................. 3

9.2 Cycle de lavage à vide avant l’essai de lavage .............................................................................................................. 4

9.3 Essai de lavage de l’éprouvette d’essai .............................................................................................................................. 4

9.4 Lavage des matériaux collectés par le sac filtrant .................................................................................................. 4

9.5 Mesurage de la masse des matériaux collectés ......................................................................................................... 4

10 Calcul ................................................................................................................................................................................................................................ 5

10.1 Calcul pour chaque essai ............................................................................................................................................................... 5

10.2 Calcul de la moyenne des 3 essais ......................................................................................................................................... 5

11 Répétabilité et reproductibilité ........................................................................................................................................................... 6

12 Rapport d’essai ...................................................................................................................................................................................................... 6

Annexe A (informative) Spécification de l’étoffe et construction du sac filtrant .................................................7

Annexe B (normative) Exigences concernant la machine à laver à utiliser pour cet essai ........................9

Annexe C (informative) Nombre de cycles de lavage à vide après le lavage d’essai .......................................12

Annexe D (informative) Détergent de référence ..................................................................................................................................13

Annexe E (informative) Condition de l’essai à plusieurs cycles de lavage et exemple de

résultat d’essai ....................................................................................................................................................................................................14

Annexe F (informative) Essai interlaboratoires ...................................................................................................................................17

Annexe G (informative) Nombre d’éprouvettes d’essai ................................................................................................................22

Annexe H (informative) Pourcentage de collecte des fragments de fibre ................................................................25

Annexe I (informative) Ouverture de maille du filtre ....................................................................................................................26

Bibliographie ...........................................................................................................................................................................................................................28

iii© ISO 2023 – Tous droits réservés

---------------------- Page: 3 ----------------------

ISO/FDIS 4484-3:2023(F)

Avant-propos

L’ISO (Organisation internationale de normalisation) est une fédération mondiale d’organismes

nationaux de normalisation (comités membres de l’ISO). L’élaboration des Normes internationales est

en général confiée aux comités techniques de l’ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l’ISO participent également aux travaux.

L’ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d’approbation requis pour les différents types de documents ISO. Le présent document

a été rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2

(voir www.iso.org/directives).L’attention est attirée sur le fait que certains des éléments du présent document peuvent faire l’objet de

droits de propriété intellectuelle ou de droits analogues. L’ISO ne saurait être tenue pour responsable

de ne pas avoir identifié de tels droits de propriété et averti de leur existence. Les détails concernant

les références aux droits de propriété intellectuelle ou autres droits analogues identifiés lors de

l’élaboration du document sont indiqués dans l’Introduction et/ou dans la liste des déclarations de

brevets reçues par l’ISO (voir www.iso.org/brevets).Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l’intention des utilisateurs et ne sauraient constituer un

engagement.Pour une explication de la nature volontaire des normes, la signification des termes et expressions

spécifiques de l’ISO liés à l’évaluation de la conformité, ou pour toute information au sujet de l’adhésion

de l’ISO aux principes de l’Organisation mondiale du commerce (OMC) concernant les obstacles

techniques au commerce (OTC), voir le lien suivant: www.iso.org/iso/fr/avant-propos.

Le présent document a été élaboré par le comité technique ISO/TC 38, Textiles, en collaboration avec le

comité technique CEN/TC 248, Textiles et produits textiles, du Comité européen de normalisation (CEN),

conformément à l’Accord de coopération technique entre l’ISO et le CEN (Accord de Vienne).

Une liste de toutes les parties de la série ISO 4484 se trouve sur le site web de l’ISO.

Il convient que l’utilisateur adresse tout retour d’information ou toute question concernant le présent

document à l’organisme national de normalisation de son pays. Une liste exhaustive desdits organismes

se trouve à l’adresse www.iso.org/fr/members.html.© ISO 2023 – Tous droits réservés

---------------------- Page: 4 ----------------------

ISO/FDIS 4484-3:2023(F)

Introduction

Le lavage quotidien des produits finis textiles génère des fragments de fibre qui sont évacués du lave-

linge. La présente méthode d’essai vise à collecter les matériaux incluant des fragments de fibre qui

sont évacués du lave-linge domestique lors du processus de lavage.Même si les lave-linges utilisés à domicile sont de types très divers, l’ISO 6330 a été élaborée pour

spécifier la méthode d’essai de lavage domestique, laquelle définit les machines à laver domestiques

et les conditions d’essai. Le présent document recourt à l’une des machines à laver normalisées de

l’ISO 6330.En outre, une étiquette d’entretien est apposée sur les produits finis textiles dans bon nombre de pays

à travers le monde et cette étiquette d’entretien spécifie les conditions de lavage à utiliser dans le cadre

du présent document.En raison de la structure interne complexe des machines à laver, le processus de nettoyage de la

machine est un aspect très important pour éviter une contamination. Le présent document indique

la méthode de vérification et les exigences concernant la machine à laver à utiliser dans le cadre du

présent document.L’identification et la quantification de composés contenus dans les matériaux collectés lors du processus

de lavage sont déterminées en appliquant l’ISO 4484-2.Les informations recueillies à l’aide du présent document peuvent être utilisées par l’industrie textile

dans le cadre du développement de produits finis textiles afin de limiter ou de réduire le plus possible

les pertes de matières des produits finis textiles lors du processus de lavage.L’Organisation internationale de normalisation (ISO) attire l’attention sur le fait qu’il est déclaré que la

conformité avec les dispositions du présent document peut impliquer l’utilisation d’un brevet.

L’ISO ne prend pas position quant à la preuve, à la validité et à la portée de ces droits de propriété.

Le détenteur de ces droits de propriété a donné l’assurance à l’ISO qu’il consent à négocier des licences