ISO 7382:2023

(Main)Ethylene for industrial use — Sampling in the liquid and the gaseous phase

Ethylene for industrial use — Sampling in the liquid and the gaseous phase

This document describes the procedures and the precautions to be taken in drawing representative samples of ethylene in the liquid phase stored at -100 °C and in the gaseous phase, for the purpose of their analysis. Annex A sets out a diagrammatic representation of a system for the disposal of the portion of the sample which is not used in the analysis.

Éthylène à usage industriel — Échantillonnage en phase liquide et en phase gazeuse

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7382

Second edition

2023-07

Ethylene for industrial use —

Sampling in the liquid and the gaseous

phase

Éthylène à usage industriel — Échantillonnage en phase liquide et en

phase gazeuse

Reference number

ISO 7382:2023(E)

© ISO 2023

---------------------- Page: 1 ----------------------

ISO 7382:2023(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 7382:2023(E)

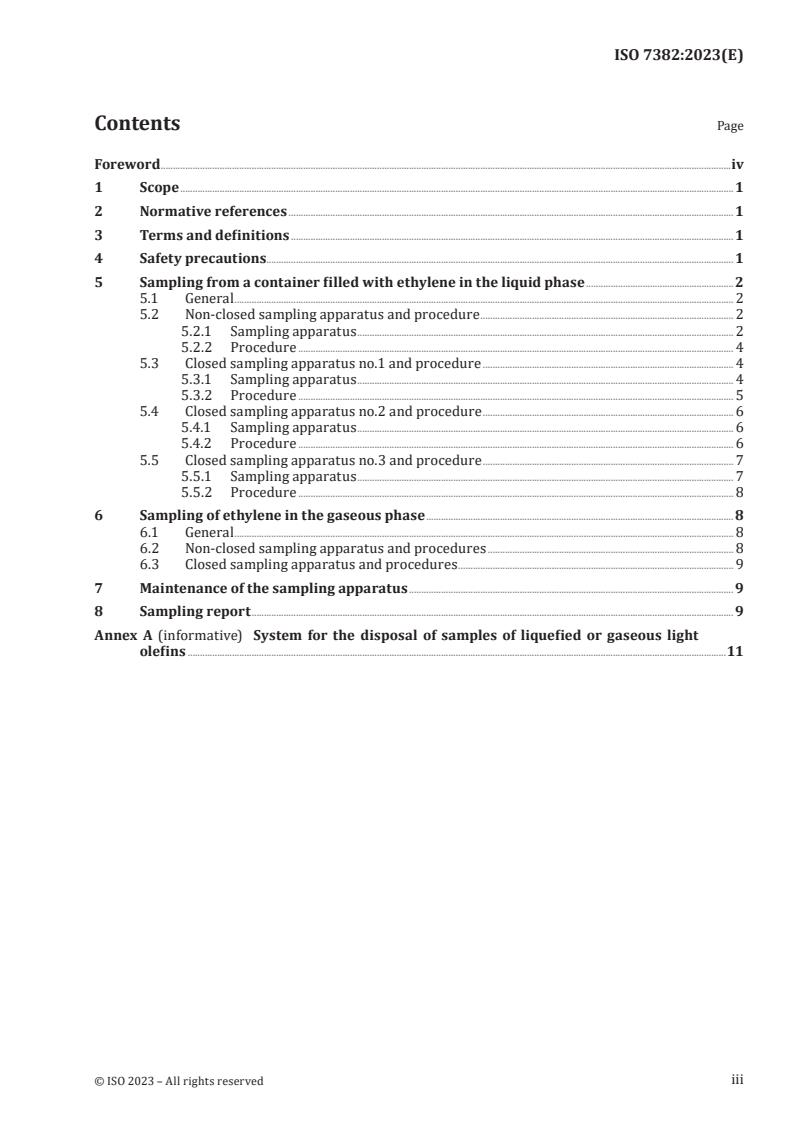

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Safety precautions. 1

5 Sampling from a container filled with ethylene in the liquid phase .2

5.1 General . 2

5.2 Non-closed sampling apparatus and procedure . 2

5.2.1 Sampling apparatus . 2

5.2.2 Procedure . 4

5.3 Closed sampling apparatus no.1 and procedure . 4

5.3.1 Sampling apparatus . 4

5.3.2 Procedure . 5

5.4 Closed sampling apparatus no.2 and procedure . 6

5.4.1 Sampling apparatus . 6

5.4.2 Procedure . 6

5.5 Closed sampling apparatus no.3 and procedure . 7

5.5.1 Sampling apparatus . 7

5.5.2 Procedure . 8

6 Sampling of ethylene in the gaseous phase . 8

6.1 General . 8

6.2 Non-closed sampling apparatus and procedures . 8

6.3 Closed sampling apparatus and procedures . 9

7 Maintenance of the sampling apparatus . 9

8 Sampling report . 9

Annex A (informative) System for the disposal of samples of liquefied or gaseous light

olefins .11

iii

© ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO 7382:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 47, Chemistry.

This second edition cancels and replaces the first edition (ISO 7382:1986), which has been technically

revised.

The main changes are as follows:

— the Scope has been expanded to apply to sampling for the determination of trace polar compounds

in ethylene products;

— Clauses 2 and 3 have been added;

— content from Clauses 4 and 7, including safety precaution and maintenance of sampling apparatus,

has been moved elsewhere in the document;

— in Clause 4, the critical pressure for ethylene has been corrected to 5,04 MPa;

— in Clause 5, explanations regarding apparatus have been added;

— in Clause 5, some specific parameters, including volume of sampling cylinder, size of connecting

pipe and time to purge sampling cylinder, have been deleted;

— in 5.2.1, specially passivated sampling apparatus has been recommended, especially when sampling

for the determination of trace polar compounds in ethylene products.

— Annex A, and Figures 1, 5 and A.1 have been revised.

— in 5.2.2: the procedure of purging and sampling for non-closed sampling apparatus has been revised;

iv

© ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 7382:2023(E)

— sampling apparatus -no.2 in the first edition and its procedure have been deleted and a new sampling

apparatus was introduced as closed sampling apparatus no.2;

— in 5.3, 5.4, 5.5, two closed-sampling apparatuses for liquefied ethylene and a sampling apparatus

with heated pressure regulator have been added.

— in 6.2, the connecting pipes for non-closed sampling of gaseous ethylene has been revised;

— in 6.3, the closed-sampling apparatuses for gaseous ethylene has been added.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

© ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 7382:2023(E)

Ethylene for industrial use — Sampling in the liquid and

the gaseous phase

WARNING — The use of this document can involve hazardous material, operation and equipment.

This document does not purport to address all of the safety problems associated with its use.

It is the responsibility of the users of this document to take appropriate measures to ensure

the safety, health of personnel prior to application of the document and fulfil other applicable

requirement for this purpose.

1 Scope

This document describes the procedures and the precautions to be taken in drawing representative

samples of ethylene in the liquid phase stored at -100 °C and in the gaseous phase, for the purpose of

their analysis.

Annex A sets out a diagrammatic representation of a system for the disposal of the portion of the sample

which is not used in the analysis.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3165:1976, Sampling of chemical products for industrial use — Safety in sampling

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

closed sampling apparatus

set of apparatus assembled by a sampling cylinder and connecting pipes to take samples under closed

conditions, by which the sampling process does not permit the release of any sample or vapour to the

surrounding environment

3.2

non-closed sampling apparatus

set of apparatus assembled by a sampling cylinder and connecting pipes to take samples in open air, by

which the sampling process permits the release of sample or vapour to the surrounding environment

4 Safety precautions

The safety precautions in all sampling and testing operations with liquefied and gaseous ethylene shall

be carefully followed in accordance with ISO 3165:1976. Relevant legal and statutory regulations to

ensure the safety, health and environmental protection in the procedure of the sampling methods can

apply.

1

© ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 7382:2023(E)

The ethylene shall be stored and transported in the liquid phase at a temperature below - 100 °C.

The critical temperature of ethylene is 9,5 °C and its critical pressure is 5,04 MPa. As the boiling

temperature of ethylene at atmospheric pressure is -103,9 °C, it follows that ethylene sampled in the

liquid phase cannot be kept in the state at room temperature, without taking account of the pressure.

All sampling equipment shall be capable of resisting the sample pressure after complete vaporization. It

is presupposed that the use of the vessels, the plant and the equipment conform to the legal regulations

in force. Users shall have the vessels periodically pressure tested by an approved organization.

The construction materials shall be capable of withstanding rapid changes in temperature, for example,

rising from – 100 °C to +20 °C in 1 to 2 min. Passivated stainless steel should be selected for preference.

Owing to the low temperatures of the product and its associated equipment, operators shall wear well-

insulating, non-cracking plastics or rubber-coated gloves to protect themselves from burns. They shall

also wear close-fitting protective goggles.

Ethylene is extremely flammable, and all precautions shall be taken to avoid forming an explosive

atmosphere. Suitable ventilation is essential, particularly during the purging operations.

Also, the sampling apparatus shall always be electrically grounded.

The safety precautions shall be taken when cleaning apparatus, discharging ethylene, wastes liquid

and steam. The discharging site shall be equipped with safety devices. It is expected that the sites meet

relevant safety, health and environmental protection requirements.

If the container is to be transported, it is expected to conform to specifications of applicable legislation

regarding transportation for hazardous materials.

5 Sampling from a container filled with ethylene in the liquid phase

5.1 General

Given the wide variation in the sampling apparatus for ethylene, it is difficult to specify a uniform

method for obtaining representative samples of heterogeneous mixtures. The four examples of non-

closed and closed sampling apparatus described in 5.2 and 5.3 have been found satisfactory and are

available commercially. Any other sampling apparatus may be used, however, it is presupposed that

they

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.