SIST EN 13310:2015+A1:2018

(Main)Kitchen sinks - Functional requirements and test methods

Kitchen sinks - Functional requirements and test methods

This European Standard specifies the functional requirements of and test methods for kitchen sinks for domestic purposes, which ensure that the product, when installed in accordance with the manufacturers’ instructions, gives satisfactory performance.

NOTE 1 For the purposes of this standard, the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings.

This document does not specify aesthetic requirements and the overall dimensions of kitchen sinks.

It does not apply to industrial kitchen sinks.

NOTE 2 All drawings are examples only; other forms are permissible.

Küchenspülen - Funktionsanforderungen und Prüfverfahren

Diese Europäische Norm legt Funktions!eigenschaften" und Prüfverfahren für Haushaltsküchenspülen fest, die sicherstellen, dass bei Einbau nach den Herstelleranweisungen das Produkt eine zufriedenstellende Gebrauchstauglichkeit aufweist.

ANMERKUNG 1 Im Sinne dieser Norm schließt der Begriff „für den Hausgebrauch“ den Einsatz in Hotels, Studentenwohnheimen, Krankenhäusern und ähnlichen Einrichtungen ein.

Diese Norm legt keine ästhetischen !Eigenschaften" und Gesamtabmessungen von Küchenspülen fest.

Sie gilt nicht für Küchenspülen für den gewerblichen Bereich.

ANMERKUNG 2 Bei allen Zeichnungen handelt es sich lediglich um Beispiele; andere Formen sind zulässig.

Éviers de cuisine - Prescriptions fonctionnelles et méthodes d'essai

Ce document détermine les exigences fonctionnelles et les méthodes d'essai relatives aux éviers de cuisine à usage domestique qui garantissent que le produit, installé selon les instructions du fabricant, donne une performance satisfaisante.

NOTE 1 Pour les besoins de la présente norme, le terme « usages domestiques » s’applique à l’utilisation dans les hôtels, logements pour étudiants, hôpitaux et bâtiments similaires.

Ce document ne détermine pas d'exigences en termes d'esthétique et de dimensions hors tout.

Elle ne s'applique pas aux éviers de cuisine à usage industriel.

NOTE 2 Tous les dessins ne sont donnés qu'à titre d'exemples ; d'autres formes sont admissibles.

Kuhinjska korita - Funkcionalne zahteve in preskusne metode

Ta evropski standard določa funkcionalne zahteve in preskusne metode za kuhinjska korita za domačo uporabo, ki zagotavljajo, da izdelek, ki je vgrajen v skladu z navodili proizvajalca, deluje zadovoljivo.

OPOMBA 1: Za namene tega standarda izraz »domača uporaba« vključuje uporabo v hotelih, namestitvah za študente, bolnišnicah in podobnih stavbah.

Ta dokument ne določa estetskih zahtev in skupnih mer kuhinjskih korit.

Ne zajema industrijskih kuhinjskih korit.

OPOMBA 2: Vse risbe so samo primeri; dopustne so druge oblike.

General Information

- Status

- Published

- Publication Date

- 07-Nov-2018

- Technical Committee

- IOVO - Water supply and waste water engineering

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Nov-2018

- Due Date

- 10-Jan-2019

- Completion Date

- 08-Nov-2018

Relations

- Effective Date

- 01-Dec-2018

- Consolidates

SIST EN 13310:2015/oprA1:2017 - Kitchen sinks - Functional requirements and test methods - Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

Overview

EN 13310:2015+A1:2018 - published by CEN - defines the functional requirements and test methods for kitchen sinks for domestic purposes. It ensures that, when installed according to the manufacturer’s instructions, a kitchen sink gives satisfactory performance in everyday use (including use in hotels, student accommodation, hospitals and similar buildings). The standard does not cover aesthetic requirements, overall dimensions or industrial kitchen sinks.

Key topics and technical requirements

- Scope & applicability

- Domestic kitchen sinks (including hotel and healthcare settings); excludes industrial sinks.

- Drawings are illustrative; other designs are permissible.

- Essential functional characteristics

- Draining of water: surfaces must be inclined toward bowls/outlets so water drains to the waste (test uses colored tap water; minimum test volume specified).

- Resistance to dry heat: surfaces must resist contact with hot cookware (test uses glycerol tristearate heated to ~180 °C).

- Resistance to temperature changes: no cracking or delamination after thermal cycling.

- Resistance to chemicals and staining agents: no permanent deterioration from household chemicals, foodstuffs, or cleaning agents.

- Surface stability (multi-layer sinks only):

- Resistance to scratching: any scratch ≤ 0.10 mm or not deeper than the top layer.

- Resistance to abrasion: top layer must not be abraded through.

- Load stability: wall-hung sinks must not crack, fall or show permanent distortion under load.

- Overflow performance: overflow flow rate ≥ 0.20 l/s.

- Test sequencing and conditions

- Tests are specified in clauses 5.2–5.9; typical test order and ambient conditions (23 ± 5 °C) are given.

- Marking, instructions and durability

- Instructions for installation, use and care are required (Annex A gives care guidance).

- Sinks meeting the listed characteristics (draining, heat/chemical resistance, surface stability, load and overflow) are deemed durable.

- Assessment & conformity

- Includes provisions for type testing and factory production control (AVCP) and links to EU regulatory requirements (Annex ZA).

Applications - who uses this standard

- Manufacturers - product design, materials selection, type testing, production control and marking.

- Test laboratories - to perform standardized functional tests (heat, abrasion, scratching, overflow, load).

- Specifiers / Architects / Interior designers - selecting compliant domestic sinks for residential, hospitality or healthcare projects.

- Installers & facility managers - validating installation and performance expectations.

- Procurement & regulators - conformity assessment, tender specifications and compliance with EU Construction Products Regulation references.

Related standards and references

- EN 695 - Kitchen sinks - Connecting dimensions

- EN ISO 6506-1 - Brinell hardness test (relevant for metallic sink components)

- ISO 4211-3 - Tests for surface finishes - Resistance to dry heat

- ISO 9352 - Plastics - Resistance to wear by abrasive wheels

- Regulation (EU) No. 305/2011 - Construction Products Regulation (see Annex ZA in EN 13310)

EN 13310:2015+A1:2018 is essential for anyone who needs reliable, test-backed requirements for domestic kitchen sink performance, helping ensure safety, durability and user satisfaction.

Frequently Asked Questions

SIST EN 13310:2015+A1:2018 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Kitchen sinks - Functional requirements and test methods". This standard covers: This European Standard specifies the functional requirements of and test methods for kitchen sinks for domestic purposes, which ensure that the product, when installed in accordance with the manufacturers’ instructions, gives satisfactory performance. NOTE 1 For the purposes of this standard, the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings. This document does not specify aesthetic requirements and the overall dimensions of kitchen sinks. It does not apply to industrial kitchen sinks. NOTE 2 All drawings are examples only; other forms are permissible.

This European Standard specifies the functional requirements of and test methods for kitchen sinks for domestic purposes, which ensure that the product, when installed in accordance with the manufacturers’ instructions, gives satisfactory performance. NOTE 1 For the purposes of this standard, the term "domestic purposes" includes use in hotels, accommodation for students, hospitals and similar buildings. This document does not specify aesthetic requirements and the overall dimensions of kitchen sinks. It does not apply to industrial kitchen sinks. NOTE 2 All drawings are examples only; other forms are permissible.

SIST EN 13310:2015+A1:2018 is classified under the following ICS (International Classification for Standards) categories: 97.040.10 - Kitchen furniture. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13310:2015+A1:2018 has the following relationships with other standards: It is inter standard links to SIST EN 13310:2015, SIST EN 13310:2015/oprA1:2017, SIST EN 13310:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13310:2015+A1:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/110. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 13310:2015+A1:2018 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kuhinjska korita - Funkcionalne zahteve in preskusne metodeKüchenspülen - Funktionsanforderungen und PrüfverfahrenÉviers de cuisine - Prescriptions fonctionnelles et méthodes d'essaiKitchen sinks - Functional requirements and test methods97.040.10Kuhinjsko pohištvoKitchen furnitureICS:Ta slovenski standard je istoveten z:EN 13310:2015+A1:2018SIST EN 13310:2015+A1:2018en,fr,de01-december-2018SIST EN 13310:2015+A1:2018SLOVENSKI

STANDARDSIST EN 13310:20151DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13310:2015+A1

October

t r s z ICS

{ yä r v rä s r English Version

Kitchen sinks æ Functional requirements and test methodsÉviers de cuisine æ Prescriptions fonctionnelles et méthodes d 5essai

Küchenspülen æ Funktionsanforderungen und Prüfverfahren This European Standard was approved by CEN on

w June

t r s w and includes Amendment

s approved by CEN on

s v April

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u u s rã t r s w ªA sã t r s z ESIST EN 13310:2015+A1:2018

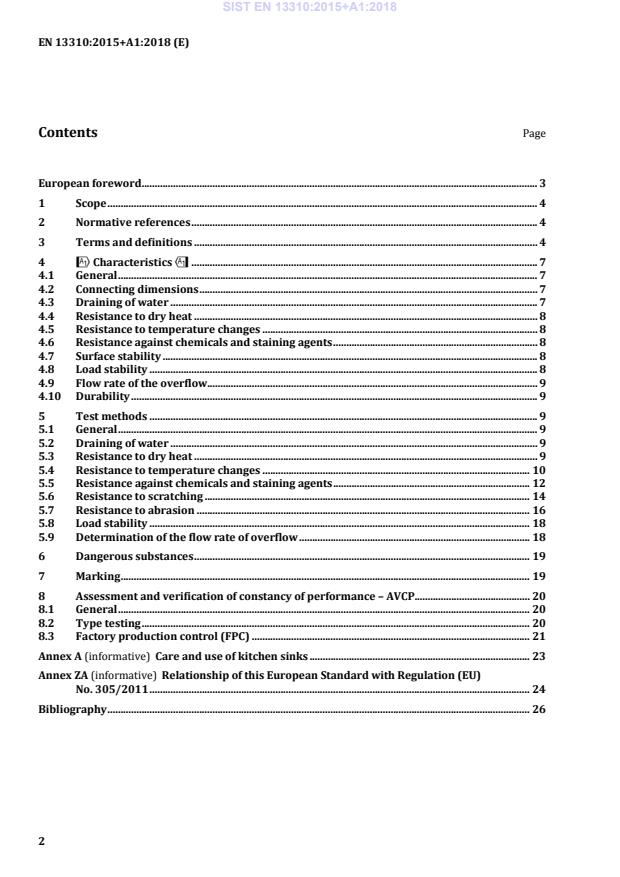

European foreword . 3 1 Scope . 4 2 Normative references . 4 3 Terms and definitions . 4 4 !Characteristics" . 7 4.1 General . 7 4.2 Connecting dimensions . 7 4.3 Draining of water . 7 4.4 Resistance to dry heat . 8 4.5 Resistance to temperature changes . 8 4.6 Resistance against chemicals and staining agents . 8 4.7 Surface stability . 8 4.8 Load stability . 8 4.9 Flow rate of the overflow. 9 4.10 Durability . 9 5 Test methods . 9 5.1 General . 9 5.2 Draining of water . 9 5.3 Resistance to dry heat . 9 5.4 Resistance to temperature changes . 10 5.5 Resistance against chemicals and staining agents . 12 5.6 Resistance to scratching . 14 5.7 Resistance to abrasion . 16 5.8 Load stability . 18 5.9 Determination of the flow rate of overflow . 18 6 Dangerous substances . 19 7 Marking . 19 8 Assessment and verification of constancy of performance – AVCP. 20 8.1 General . 20 8.2 Type testing . 20 8.3 Factory production control (FPC) . 21 Annex A (informative)

Care and use of kitchen sinks . 23 Annex ZA (informative)

Relationship of this European Standard with Regulation (EU) No. 305/2011 . 24 Bibliography . 26

This document supersedes !EN 13310:2015". The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association. For relationship with EU Construction Products Regulation, see informative Annex ZA, which is an integral part of this document. !The main changes introduced in EN 13310 were the following:

a) introduction of a new Annex ZA in accordance with the latest template (in the format of TF N 678 rev 1 of 2015-06-02); b) modification in the test procedure for resistance to scratching; c) modification of the marking of products; d) editorial modifications as agreed between representatives of EU/DG Growth, CEN/TC 163 and FECS on 2016-07-07 in Brussels for citation of standard in OJEU." According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 13310:2015+A1:2018

Note 1 to entry: See Figure 1: SIST EN 13310:2015+A1:2018

Figure 1 — Wall-hung sink 3.1.2 sit-on sink sink which is mounted on top of a suitable base unit Note 1 to entry: See Figure 2:

Figure 2 — Sit-on sink 3.1.3 inset sink sink which is set into a kitchen work top from above, with the rim resting on the work top Note 1 to entry: See Figure 3:

Figure 3 — Inset sink 3.1.4 flush-sit sink sink which is set into a kitchen work top with the rim flush with, or within the thickness of the work top Note 1 to entry: See Figure 4: SIST EN 13310:2015+A1:2018

Figure 4 — flush-sit sink 3.1.5 under-mounted sink sink which is set into a kitchen work top from below, butting up against the work top Note 1 to entry: See Figure 5:

Figure 5 — Under-mounted sink 3.2 multi-layer kitchen sink kitchen sink consisting of two or more layers 3.3 overflow device which prevents water from spilling over the external rim of the kitchen sink or work top 3.4 outside dimensions overall dimensions L, B and H of the kitchen sink Note 1 to entry: See Figure 6: SIST EN 13310:2015+A1:2018

Figure 6 — Outside dimensions 3.5 product type !set of representative performance levels or classes of a construction product, in relation to its essential characteristics, produced using a given combination of raw materials or other elements in a specific production process Note 1 to entry: The definition is taken from Regulation (EU) No. 305/2011." 4 !Characteristics" 4.1 General !Instructions for installation, use and care shall be supplied. Annex A gives advice on the care and use of kitchen sinks which can be included in the instructions for use and care. NOTE The manufacturer's declaration of conformity with applicable European Directives is made in his instructions for use and care on materials intended to come into contact with foodstuffs (see Bibliography)." 4.2 Connecting dimensions The connecting dimensions shall meet the requirements specified in EN 695. 4.3 Draining of water When tested in accordance with 5.2 all surfaces of the kitchen sink shall be inclined towards the bowl(s) and/or outlet(s) to ensure the drainage of water. The requirement shall apply only to the bowl and the draining area (if applicable). The requirement shall not apply to tap platforms. SIST EN 13310:2015+A1:2018

Key 1 cold water supply 4 discharge pipe 2 hot water supply 5 rigid framework 3 manifold

Figure 7 — Test rack 5.5 Resistance against chemicals and staining agents 5.5.1 Test apparatus and chemicals a) chemicals/reagents The list of chemicals is given in Table 1. Each solution shall be prepared immediately before use with deionized water, and applied at a temperature of (23 ± 5) °C. SIST EN 13310:2015+A1:2018

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...