ASTM E2736-10

(Guide)Standard Guide for Digital Detector Array Radiology

Standard Guide for Digital Detector Array Radiology

SIGNIFICANCE AND USE

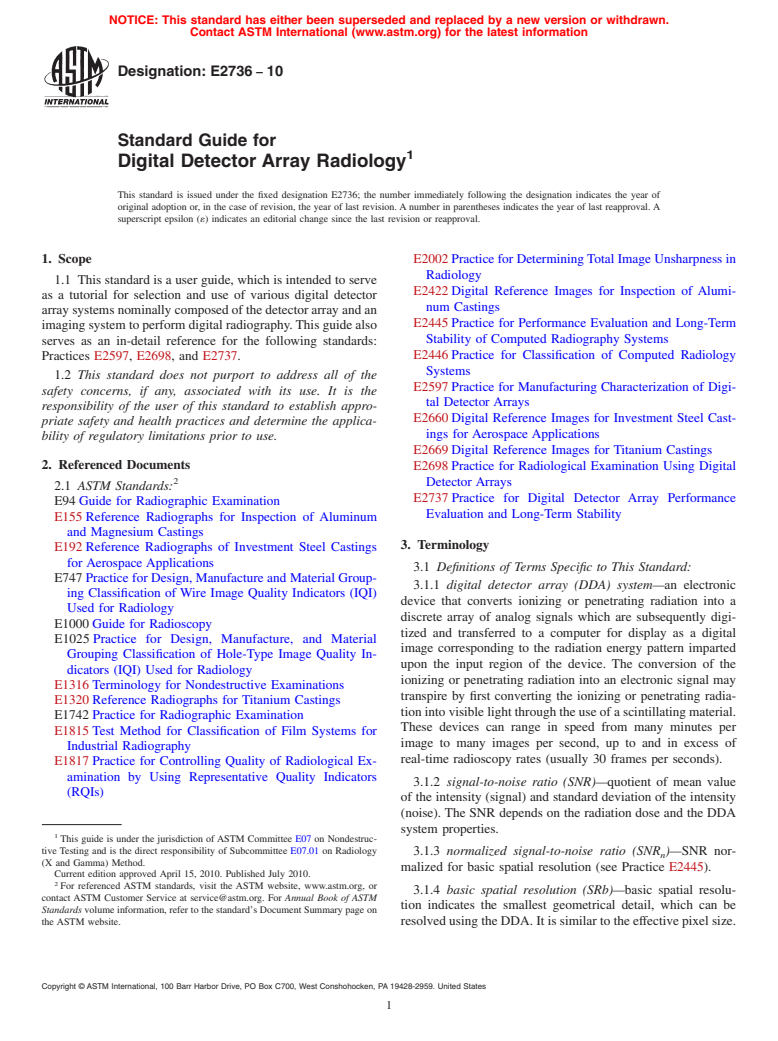

This standard provides a guide for the other DDA standards (see Practices E2597, , and E2737). It is not intended for use with computed radiography apparatus. Figure 1 describes how this standard is interrelated with the aforementioned standards.

This guide is intended to assist the user to understand the definitions and corresponding performance parameters used in related standards as stated in 4.1 in order to make an informed decision on how a given DDA can be used in the target application.

This guide is also intended to assist cognizant engineering officers, prime manufacturers, and the general service and manufacturing customer base that may rely on DDAs to provide advanced radiological results so that these parties may set their own acceptance criteria for use of these DDAs by suppliers and shops to verify that their parts and structures are of sound integrity to enter into service.

The manufacturer characterization standard for DDA (see Practice E2597) serves as a starting point for the end user to select a DDA for the specific application at hand. DDA manufacturers and system integrators will provide DDA performance data using standardized geometry, X-ray beam spectra, and phantoms as prescribed in Practice E2597. The end user will look at these performance results and compare DDA metrics from various manufacturers and will decide on a DDA that can meet the specification required for inspection by the end user. See Sections 5 and 8 for a discussion on the characterization tests and guidelines for selection of DDAs for specific applications.

Practice is designed to assist the end user to set up the DDA with minimum requirements for radiological examinations. This standard will also help the user to get the required SNR, to set up the required magnification, and provides guidance for viewing and storage of radiographs. Discussion is also added to help the user with marking and identification of parts during radiological examinations.

Practice E2737 ...

SCOPE

1.1 This standard is a user guide, which is intended to serve as a tutorial for selection and use of various digital detector array systems nominally composed of the detector array and an imaging system to perform digital radiography. This guide also serves as an in-detail reference for the following standards: Practices E2597, , and E2737.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2736 − 10

Standard Guide for

Digital Detector Array Radiology

This standard is issued under the fixed designation E2736; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2002PracticeforDeterminingTotalImageUnsharpnessin

Radiology

1.1 This standard is a user guide, which is intended to serve

E2422Digital Reference Images for Inspection of Alumi-

as a tutorial for selection and use of various digital detector

num Castings

arraysystemsnominallycomposedofthedetectorarrayandan

E2445Practice for Performance Evaluation and Long-Term

imagingsystemtoperformdigitalradiography.Thisguidealso

Stability of Computed Radiography Systems

serves as an in-detail reference for the following standards:

E2446Practice for Classification of Computed Radiology

Practices E2597, E2698, and E2737.

Systems

1.2 This standard does not purport to address all of the

E2597Practice for Manufacturing Characterization of Digi-

safety concerns, if any, associated with its use. It is the

tal Detector Arrays

responsibility of the user of this standard to establish appro-

E2660Digital Reference Images for Investment Steel Cast-

priate safety and health practices and determine the applica-

ings for Aerospace Applications

bility of regulatory limitations prior to use.

E2669Digital Reference Images for Titanium Castings

2. Referenced Documents

E2698Practice for Radiological Examination Using Digital

Detector Arrays

2.1 ASTM Standards:

E2737Practice for Digital Detector Array Performance

E94Guide for Radiographic Examination

Evaluation and Long-Term Stability

E155Reference Radiographs for Inspection of Aluminum

and Magnesium Castings

3. Terminology

E192Reference Radiographs of Investment Steel Castings

for Aerospace Applications

3.1 Definitions of Terms Specific to This Standard:

E747Practice for Design, Manufacture and Material Group-

3.1.1 digital detector array (DDA) system—an electronic

ing Classification of Wire Image Quality Indicators (IQI)

device that converts ionizing or penetrating radiation into a

Used for Radiology

discrete array of analog signals which are subsequently digi-

E1000Guide for Radioscopy

tized and transferred to a computer for display as a digital

E1025 Practice for Design, Manufacture, and Material

image corresponding to the radiation energy pattern imparted

Grouping Classification of Hole-Type Image Quality In-

upon the input region of the device. The conversion of the

dicators (IQI) Used for Radiology

ionizing or penetrating radiation into an electronic signal may

E1316Terminology for Nondestructive Examinations

transpire by first converting the ionizing or penetrating radia-

E1320Reference Radiographs for Titanium Castings

tionintovisiblelightthroughtheuseofascintillatingmaterial.

E1742Practice for Radiographic Examination

These devices can range in speed from many minutes per

E1815Test Method for Classification of Film Systems for

image to many images per second, up to and in excess of

Industrial Radiography

real-time radioscopy rates (usually 30 frames per seconds).

E1817Practice for Controlling Quality of Radiological Ex-

amination by Using Representative Quality Indicators

3.1.2 signal-to-noise ratio (SNR)—quotient of mean value

(RQIs)

of the intensity (signal) and standard deviation of the intensity

(noise). The SNR depends on the radiation dose and the DDA

system properties.

This guide is under the jurisdiction ofASTM Committee E07 on Nondestruc-

tive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

3.1.3 normalized signal-to-noise ratio (SNR )—SNR nor-

n

(X and Gamma) Method.

malized for basic spatial resolution (see Practice E2445).

Current edition approved April 15, 2010. Published July 2010.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.4 basic spatial resolution (SRb)—basic spatial resolu-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion indicates the smallest geometrical detail, which can be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. resolvedusingtheDDA.Itissimilartotheeffectivepixelsize.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2736 − 10

3.1.5 effıciency—dSNR (see 3.1.6 of Practice E2597) di- end user will look at these performance results and compare

n

vided by the square root of the dose (in mGy) and is used to DDAmetrics from various manufacturers and will decide on a

measuretheresponseofthedetectoratdifferentbeamenergies DDAthat can meet the specification required for inspection by

and qualities. the end user. See Sections 5 and 8 for a discussion on the

characterization tests and guidelines for selection of DDAs for

3.1.6 achievable contrast sensitivity (CSa)—optimum con-

specific applications.

trast sensitivity (see Terminology E1316 for a definition of

contrast sensitivity) obtainable using a standard phantom with

4.5 Practice E2698 is designed to assist the end user to set

an X-ray technique that has little contribution from scatter.

up the DDA with minimum requirements for radiological

examinations. This standard will also help the user to get the

3.1.7 specific material thickness range (SMTR)—material

required SNR, to set up the required magnification, and

thickness range within which a given image quality is

provides guidance for viewing and storage of radiographs.

achieved.

Discussion is also added to help the user with marking and

3.1.8 contrast-to-noise ratio (CNR)—quotient of the differ-

identification of parts during radiological examinations.

enceofthemeansignallevelsbetweentwoimageareasandthe

4.6 Practice E2737 is designed to help the end user with a

standard deviation of the signal levels. The CNR depends on

set of tests so that the stability of the performance of the DDA

the radiation dose and the DDA system properties.

can be confirmed. Additional guidance is provided in this

3.1.9 lag—residual signal in the DDA that occurs shortly

document to support this standard.

after the exposure is completed.

4.7 Figure 1 provides a summary of the interconnectivity of

3.1.10 burn-in—change in gain of the scintillator or photo-

these four DDA standards.

conductor that persists well beyond the exposure.

3.1.11 internal scatter radiation (ISR)—scattered radiation

5. DDA Technology Description

within the detector (from scintillator, photodiodes, electronics,

5.1 General Discussion:

shielding, or other detector hardware).

5.1.1 DDAs are seeing increased use in industries to en-

3.1.12 bad pixel—a bad pixel is a pixel identified with a

hanceproductivityandqualityofnondestructivetesting.DDAs

performance outside of the specification for a pixel of a DDA

are being used for in-service nondestructive testing, as a

as defined in Practice E2597.

diagnostic tool in the manufacturing process, and for inline

3.1.13 grooved wedge—a wedge with one groove, that is

testing on production lines. DDAs are also being used as hand

5% of the base material thickness and that is used for

held, or scanned devices for pipeline inspections, in industrial

achievablecontrastsensitivitymeasurementinPracticeE2597.

computed tomography systems, and as part of large robotic

3.1.14 phantom—apartoritembeingusedtoquantifyDDA

scanning systems for imaging of large or complex structures.

characterization metrics.

Because of the digital nature of the data, a variety of new

applications and techniques have emerged recently, enabling

4. Significance and Use quantitative inspection and automatic defect recognition.

5.1.2 DDAs can be used to detect various forms of electro-

4.1 This standard provides a guide for the other DDA

magneticradiation,orparticles,includinggammarays,X-rays,

standards (see Practices E2597, E2698, and E2737). It is not

neutrons,orotherformsofpenetratingradiation.Thisstandard

intended for use with computed radiography apparatus. Figure

focuses on X-rays and gamma rays.

1 describes how this standard is interrelated with the afore-

mentioned standards.

5.2 DDA architecture:

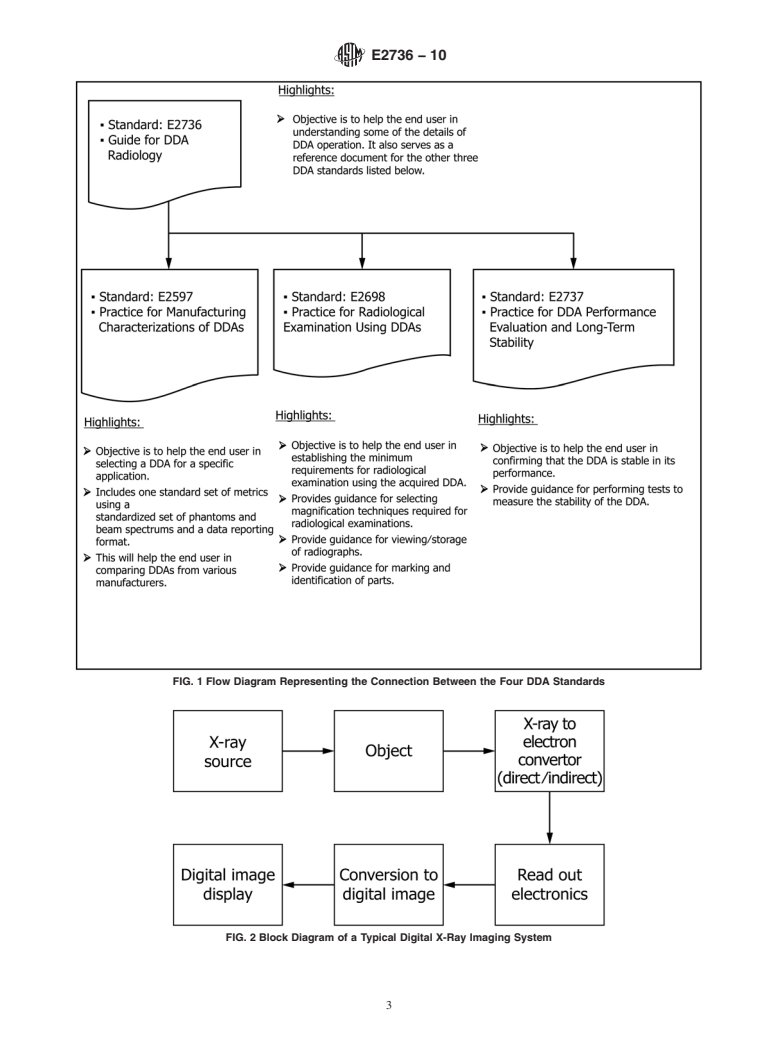

5.2.1 A common aspect of the different forms of this

4.2 This guide is intended to assist the user to understand

technology is the use of discrete sensors (position-sensitive)

thedefinitionsandcorrespondingperformanceparametersused

where, the data from each discrete location is read out into a

in related standards as stated in 4.1 in order to make an

file structure to form pixels of a digital image file. In all its

informed decision on how a given DDA can be used in the

simplicity, the device has an X-ray capture material as its

target application.

primary means for detecting X-rays, which is then coupled to

4.3 This guide is also intended to assist cognizant engineer-

a solid-state pixelized structure, where such a structure is

ing officers, prime manufacturers, and the general service and

similar to the imaging chips used in visible-wavelength digital

manufacturing customer base that may rely on DDAs to

photography and videography devices. Figure 2 shows a block

provide advanced radiological results so that these parties may

diagram of a typical digital X-ray imaging system.

set their own acceptance criteria for use of these DDAs by

5.2.2 An important difference between X-ray imaging and

suppliers and shops to verify that their parts and structures are

visible-light imaging is the size of the read-out device. The

of sound integrity to enter into service.

imagers found in cameras and for visible-light are typically on

4.4 The manufacturer characterization standard for DDA the order of 1 to 2 cm in area. Since X-rays are not easily

(see Practice E2597) serves as a starting point for the end user focused, as is the case for visible light, the imaging medium

to select a DDA for the specific application at hand. DDA must be the size of the object. Hence, the challenge lies in

manufacturers and system integrators will provide DDA per- meeting the requirement of a large uniform imaging area

formance data using standardized geometry, X-ray beam without loss of spatial information. This in turn requires high

spectra, and phantoms as prescribed in Practice E2597. The pixel densities of the read-out device over the object under

E2736 − 10

FIG. 1 Flow Diagram Representing the Connection Between the Four DDA Standards

FIG. 2 Block Diagram of a Typical Digital X-Ray Imaging System

E2736 − 10

examination, as well a primary sensing medium that also canbeextractedfromthedata.Thisissometimesreferredtoas

retains the radiologic pattern in its structure. Therefore, each the detector dynamic range.

DDA consists of a primary X-ray or gamma ray capture

5.3.5 The dynamic range is different from the specific

medium followed by a pixelized read structure, with various

material thickness range (SMTR) as defined in this standard

meansoftransferringtheabovesaidcapturedpattern.Foreach

and Practice E2597. That range is a true practical range of the

of these elements, there are numerous options that can be

DDA at hand, a range significantly tighter than the DDA

selected in the creation of DDAs. For the primary X-ray

dynamic range.

conversion material, there are either luminescent materials

5.3.6 TheSMTRisoneofthepropertiestoconsiderinDDA

such as scintillators or phosphors, and photoconductive mate-

selection, as it impacts the thickness range that can be

rials also known as direct converter semiconductors.

interpreted in a single view. This is dependent on the charac-

5.2.3 For read-out structures, the technology consists of

teristics of the read device and the digitization level. This test

charge coupled detectors (CCDs), complementary metal oxide

provides a means of determining an effective range without

silicon (CMOS) based detectors, amorphous silicon thin film

understanding the subtle nuances of the detector readout, and

transistor diode read-out structures, and linear or area crystal-

avoids erroneous parallels between bit depth and its relation to

line silicon pixel diode structures. Other materials and struc-

thickness range, and maximum possible signal from a device.

tures are also possible, but in the end, a pixelized pattern is

5.4 Specific DDA components—Therearenumerousoptions

captured and transferred to a computer for review.

ineachcomponentoftheimagingchaintoproduceaDDA.To

5.2.4 Eachprimaryconversionmaterialcanbecoupledwith

understand the options and limitations of each category, and to

the various read structures mentioned through a wide range of

bestassesswhichtechnologytopursueforagivenapplication,

couplingmedia,devices,orcircuitry.Withallofthesepossible

theunderlyingtechnologywillbediscussedbeginningwiththe

combinations, there are many different types of DDAs that

image capture medium. This is followed by the image read

have been produced. But all result in a digital X-ray or gamma

structureandthentheimagetransferdeviceisdiscussedforthe

ray image that can be used for different NDT applications.

various configurations of the read-out devices. For a more

5.2.5 Following the capture of the X-rays and conversion

detailed description of the architectures of these devices, the

into an analog signal on the read-out device, this signal is

reader is referred to Ref. (2).

typically amplified and digitized.There are numerous schemes

3 5.4.1 X-ray Capture—Scintillators (phosphors)—

for each of these steps, and the reader is referred to (1, 2, 3)

Scintillators are materials that convert X-ray or gamma ray

for further discussion on this topic.

photons into visible-light photons, which are then converted to

5.3 Digitization Methods:

a digital signal using technologies such as amorphous silicon

5.3.1 Digitization techniques typically convert the analog

(a-Si) arrays, CCDs or CMOS devices together with an

signal to discrete pixel values. For DDAs the digitization is

analog-to-digital converter. This will facilitate real time acqui-

typically, 8-bit (256 gray values), 12-bits (4096 gray values),

sition of images without the need for offline processing. Since

14-bits (16,384 gray levels) or 16-bits (65,536 values). The

therearevariousstagesofconversioninvolvedinrecordingthe

higher the bit depth, the more finely the signal is sampled.

digital image, it is very important to ensure that minimum

5.3.2 The digitization does not necessarily define the gray

information is lost during conversion in the scintillator. The

level range of the DDA. The useful range of performance is

propertiesdesirableofid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.