ASTM D5646-13(2018)

(Terminology)Standard Terminology Relating to Seams and Stitches Used in Home Sewing

Standard Terminology Relating to Seams and Stitches Used in Home Sewing

SCOPE

1.1 This terminology covers basic stitches made by sewing machines designed for home use and provides a uniform, easily understood language for the definitions and descriptions of seams and seam finishes used in home sewing.

1.1.1 These terms and definitions are not necessarily consistent with those used in the apparel or home furnishings manufacturing industries.

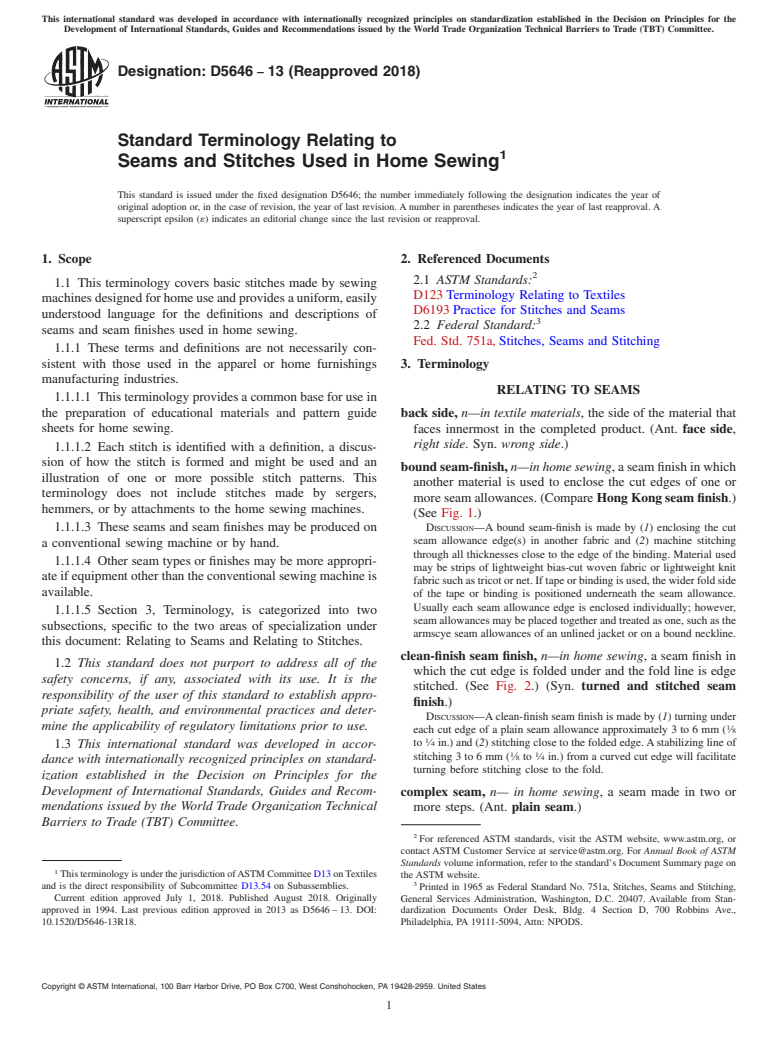

1.1.1.1 This terminology provides a common base for use in the preparation of educational materials and pattern guide sheets for home sewing.

1.1.1.2 Each stitch is identified with a definition, a discussion of how the stitch is formed and might be used and an illustration of one or more possible stitch patterns. This terminology does not include stitches made by sergers, hemmers, or by attachments to the home sewing machines.

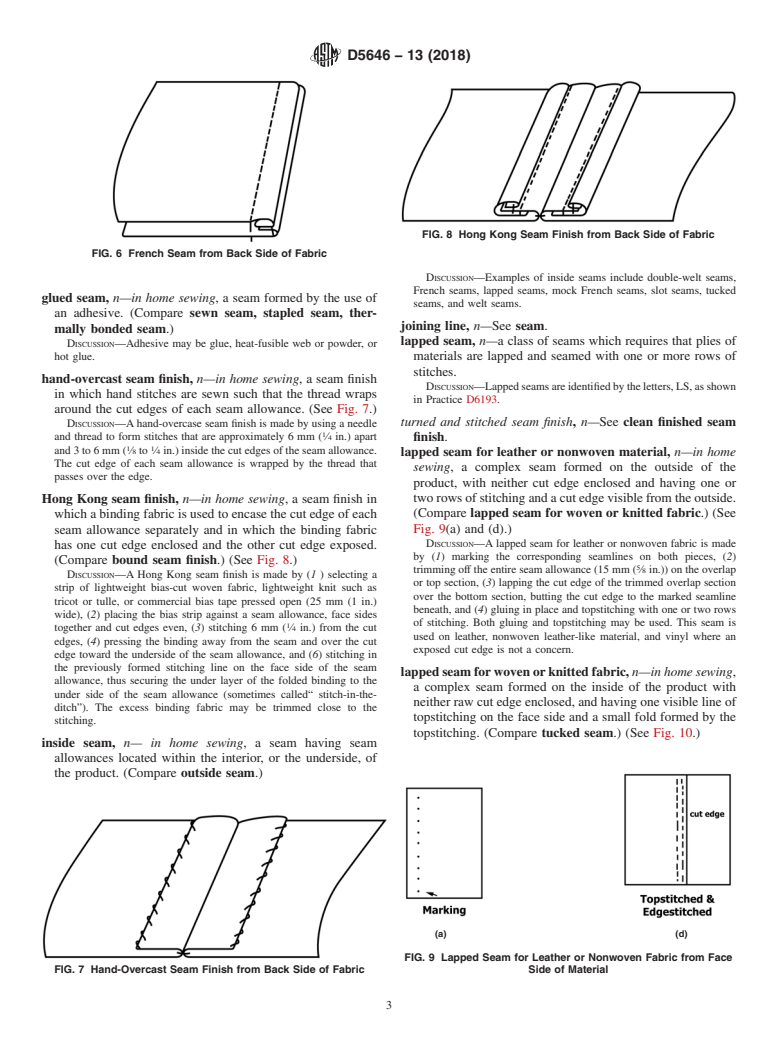

1.1.1.3 These seams and seam finishes may be produced on a conventional sewing machine or by hand.

1.1.1.4 Other seam types or finishes may be more appropriate if equipment other than the conventional sewing machine is available.

1.1.1.5 Section 3, Terminology, is categorized into two subsections, specific to the two areas of specialization under this document: Relating to Seams and Relating to Stitches.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5646 − 13 (Reapproved 2018)

Standard Terminology Relating to

1

Seams and Stitches Used in Home Sewing

This standard is issued under the fixed designation D5646; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This terminology covers basic stitches made by sewing

D123 Terminology Relating to Textiles

machinesdesignedforhomeuseandprovidesauniform,easily

D6193 Practice for Stitches and Seams

understood language for the definitions and descriptions of

3

2.2 Federal Standard:

seams and seam finishes used in home sewing.

Fed. Std. 751a, Stitches, Seams and Stitching

1.1.1 These terms and definitions are not necessarily con-

sistent with those used in the apparel or home furnishings 3. Terminology

manufacturing industries.

RELATING TO SEAMS

1.1.1.1 This terminology provides a common base for use in

the preparation of educational materials and pattern guide back side, n—in textile materials, the side of the material that

sheets for home sewing. faces innermost in the completed product. (Ant. face side,

right side. Syn. wrong side.)

1.1.1.2 Each stitch is identified with a definition, a discus-

sion of how the stitch is formed and might be used and an

bound seam-finish, n—in home sewing,aseamfinishinwhich

illustration of one or more possible stitch patterns. This

another material is used to enclose the cut edges of one or

terminology does not include stitches made by sergers,

more seam allowances. (Compare Hong Kong seam finish.)

hemmers, or by attachments to the home sewing machines.

(See Fig. 1.)

1.1.1.3 These seams and seam finishes may be produced on DISCUSSION—A bound seam-finish is made by (1) enclosing the cut

seam allowance edge(s) in another fabric and (2) machine stitching

a conventional sewing machine or by hand.

through all thicknesses close to the edge of the binding. Material used

1.1.1.4 Other seam types or finishes may be more appropri-

may be strips of lightweight bias-cut woven fabric or lightweight knit

ate if equipment other than the conventional sewing machine is

fabricsuchastricotornet.Iftapeorbindingisused,thewiderfoldside

available.

of the tape or binding is positioned underneath the seam allowance.

Usually each seam allowance edge is enclosed individually; however,

1.1.1.5 Section 3, Terminology, is categorized into two

seam allowances may be placed together and treated as one, such as the

subsections, specific to the two areas of specialization under

armscye seam allowances of an unlined jacket or on a bound neckline.

this document: Relating to Seams and Relating to Stitches.

clean-finish seam finish, n—in home sewing, a seam finish in

1.2 This standard does not purport to address all of the

which the cut edge is folded under and the fold line is edge

safety concerns, if any, associated with its use. It is the

stitched. (See Fig. 2.) (Syn. turned and stitched seam

responsibility of the user of this standard to establish appro-

finish.)

priate safety, health, and environmental practices and deter-

DISCUSSION—Aclean-finish seam finish is made by (1) turning under

mine the applicability of regulatory limitations prior to use.

1

each cut edge of a plain seam allowance approximately 3 to 6 mm ( ⁄8

1

to ⁄4 in.) and (2) stitching close to the folded edge.Astabilizing line of

1.3 This international standard was developed in accor-

1 1

stitching 3 to 6 mm ( ⁄8 to ⁄4 in.) from a curved cut edge will facilitate

dance with internationally recognized principles on standard-

turning before stitching close to the fold.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

complex seam, n— in home sewing, a seam made in two or

mendations issued by the World Trade Organization Technical more steps. (Ant. plain seam.)

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles the ASTM website.

3

and is the direct responsibility of Subcommittee D13.54 on Subassemblies. Printed in 1965 as Federal Standard No. 751a, Stitches, Seams and Stitching,

Current edition approved July 1, 2018. Published August 2018. Originally General Services Administration, Washington, D.C.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.