ASTM E883-99

(Guide)Standard Guide for Reflected-Light Photomicrography

Standard Guide for Reflected-Light Photomicrography

SCOPE

1.1 This guide outlines various suggested methods which may be followed in the photography of metals and materials with the reflected-light microscope. Methods are included for preparation of prints and transparencies in black-and-white and in color, using both direct rapid and wet processes.

1.2 Descriptive material is provided where necessary to clarify procedures. References are cited where detailed descriptions may be helpful. Guidelines are suggested to yield photomicrographs of typical subjects and, to the extent possible, of atypical subjects as well. Information is included concerning techniques for the enhanced display of specific material features.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Appendix X1.7.

1.4 The sections appear in the following order: Contents Section Magnification 4 Reproduction of photomicrographs 5 Optical systems 6 Illumination sources 7 Illumination of specimens 8 Focusing 9 Filters for photomicrography 10 Illumination techniques 11 Photographic materials 12 Photographic exposure 13 Photographic processing 14 Suggestions for visual use of metallographic microscopes X1 Guide for metallographic photomacrography X2 Video image printing X3

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 883 – 99

Standard Guide for

Reflected–Light Photomicrography

This standard is issued under the fixed designation E 883; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 175 Terminology of Microscopy

E 768 Practice for Preparing and Evaluating Specimens for

1.1 This guide outlines various suggested methods which

Automatic Inclusion Assessment of Steel

may be followed in the photography of metals and materials

with the reflected-light microscope. Methods are included for

3. Significance and Use

preparation of prints and transparencies in black-and-white and

3.1 This guide is useful for determining appropriate condi-

in color, using both direct rapid and wet processes.

tions for photomicrography of metals (see Methods E 3) and

1.2 Descriptive material is provided where necessary to

materials with the reflected-light microscope and the subse-

clarify procedures. References are cited where detailed de-

quent processing of the photographic materials. It is limited to

scriptions may be helpful. Guidelines are suggested to yield

these applications.

photomicrographs of typical subjects and, to the extent pos-

sible, of atypical subjects as well. Information is included

4. Magnification

concerning techniques for the enhanced display of specific

4.1 Photomicrographs shall be made at preferred magnifi-

material features.

cations, except in those special cases where details of the

1.3 This standard does not purport to address all of the

microstructure are best revealed by unique magnifications.

safety problems, if any, associated with its use. It is the

4.2 The preferred magnifications for general use in making

responsibility of the user of this standard to establish appro-

photomicrographs, expressed in linear units, are: 253,503,

priate safety and health practices and determine the applica-

753, 1003, 2003, 2503, 4003, 5003, 7503, 8003, and

bility of regulatory limitations prior to use. Specific precau-

10003.

tionary statements are given in X1.7.

4.3 Magnifications are normally calibrated using a stage

1.4 The sections appear in the following order:

micrometer. When precision calibration is required, a certified

Contents Section

stage micrometer shall be used.

Magnification 4

Reproduction of photomicrographs 5

5. Reproduction of Photomicrographs

Optical systems 6

Illumination sources 7

5.1 Photomicrographs submitted for publication shall be

Illumination of specimens 8

enlarged or reduced to the nearest standard magnification, if

Focusing 9

Filters for photomicrography 10

necessary. A milli- or micrometre marker shall be superim-

Illumination techniques 11

posed on the photomicrograph to indicate magnification, in a

Photographic materials 12

contrasting tone. The actual linear magnification of the print

Photographic exposure 13

Photographic processing 14

shall be stated in the caption.

Suggestions for visual use of metallographic microscopes X1

5.2 Photomicrograph captions should include basic back-

Guide for metallographic photomacrography X2

ground information (for example, material identification,

Video image printing X3

etchant, mechanical or thermal treatment details) and should

2. Referenced Documents

briefly describe what is illustrated so that the photomicrograph

2.1 ASTM Standards:

can stand independent of the text.

E 3 Methods of Preparation of Metallographic Specimens

5.3 Arrows or other markings, in a contrasting tone, shall be

E 7 Terminology Relating to Metallography

used to designate specific features in a photomicrograph. Any

marking used shall be referenced in the caption.

6. Optical Systems

This guide is under the jurisdiction of ASTM Committee E-4 on Metalogra-

6.1 The microscope objective forms an image of the speci-

phyand is the direct responsibility of Subcommittee E04.01on Sampling, Specimen

mens in a specific plane within the microscope called the

Preparation, and Photography.

Current edition approved April 10, 1999. Published July 1999. Originally

published as E 883 – 82. Last previous edition E 883 – 94.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 883

intermediary plane. Objectives are available in increasing order with their strong UV and near-UV output, are particularly

of correction as achromats, semiapochromats (fluorite), and useful to obtain maximum resolution. Their color quality is

apochromats (see Terminology E 7 and E 175). Plan objectives deficient in red and cannot be balanced for color photomicro-

are recommended for photographic purposes due to their graphy. Zirconium arcs have strong spectral output lines in the

correction to provide flatness of field. near infrared, requiring filtation. Within the visible region, they

6.2 The eyepiece magnifies the intermediary image for are rated at a 3200 K color temperature.

observation or photomicrography. Eyepieces are sometimes 7.4 Arc lamps require heat protection for filters and other

also used to accomplish the full correction of the objective’s optical components, and certainly for eye safety. Infrared

spherical aberration and to improve the flatness of field. The removal may be obtained by: “hot” mirrors in the illumination

pupil of the observer’s eye must be brought to coincidence with beam to reflect IR while transmitting visible light; heat-

the eyepoint of the eyepiece while viewing the microscopical absorbing filters to transmit visible light while absorbing IR,

image. for example, solid glass filters or liquid-filled cells. Xenon arc

6.3 Intermediate lenses (relay or tube lenses) are often lamps that do not produce ozone should be used.

required to transfer the specimen image from the intermediary 7.5 A detailed discussion of illumination sources and the

plane of the objective to that of the eyepiece. They may also quality of illuminants is given by Loveland (2).

add their own magnification factor, as in the case of zoom 7.6 Some advice on using metallographic microscopes for

systems. visual observation has been compiled in Appendix X1.

6.4 The objective, the eyepiece, and the compound micro-

8. Illumination of Specimens

scope (including any intermediate lenses) are designed as a

8.1 The goal of an illumination system is to establish an

single optical unit. It is recommended to use only objectives

and eyepieces which are intended for the microscope in use. optical train from light source to specimen plane which

illuminates the field of view evenly and completely fills the

6.5 The resolution of the microscope depends primarily on

the numerical aperture of the objective in use (1) . High aperture of the objective.

8.2 Photomicrographs are made with a compound micro-

degrees of print or visual magnification (above approximately

1100 times the numerical aperture) do not add information scope comprising at least an objective and an eyepiece with a

vertical illuminator between them. Field and aperture dia-

content to the image and are called empty magnification.

Magnification above this limit may be useful in certain cases, phragms, with associated lamp condensing optics, are integral

with the system.

for example, as in measuring the distance between two points.

8.2.1 The vertical illuminator is a thin-film-coated plane

7. Illumination Sources

glass reflector set at 45° to the optical axis behind the objective.

It reflects the illumination beam into the objective and trans-

7.1 Metallographic photomicrography typically uses Köhler

mits the image beam from the objective to the eyepiece. In

illumination. To obtain Köhler illumination, an image of the

some microscopes a prism is used to perform this function.

field diaphragm is focused in the specimen plane, and an image

8.2.2 The field diaphragm is an adjustable aperture which

of the lamp filament or arc is focused in the plane of the

restricts the illuminated area of the specimen to that which is to

aperture diaphragm. Specific steps to obtain Köhler illumina-

be photographed. It eliminates contrast-reducing stray light.

tion vary with the microscope used. The manufacturer’s

The field diaphragm is also a useful target when focusing a

instructions should be followed closely.

low-contrast specimen.

7.2 For incandescent lamps, the applied voltage determines

8.2.3 The aperture diaphragm establishes the optimum bal-

the unit brightness and the color temperature of the source.

ance between contrast, resolution, and depth of field. It should

Evaporated tungsten blackens the envelope, resulting in dimin-

be set to illuminate about 70 % of the objective’s aperture

ished brightness and color temperature as the lamp ages.

diameter. This can be observed by removing the eyepiece and

Tungsten-halogen lamps minimize envelope blackening, main-

inspecting the back of the objective, either directly or with a

taining constant brightness and color temperature for most of

pinhole eyepiece. Some instruments have“ Bertrand” lenses for

their life. The high brightness and 3200 K color temperature of

this purpose. The aperture diaphragm should never be used as

these lamps makes them especially suitable for color photomi-

a light intensity control.

crography.

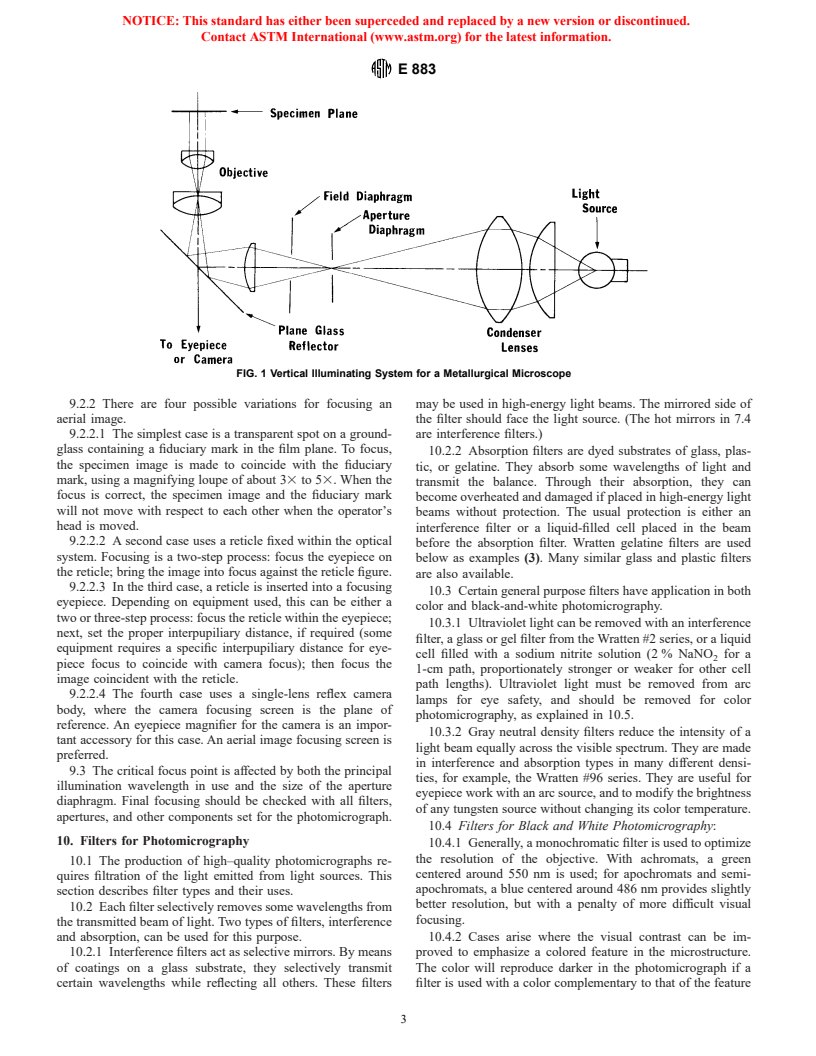

8.2.4 See Fig. 1 for an illustration of a typical vertical

7.3 With arc sources, brightness per unit area is substan-

illumination system.

tially higher than that from any incandescent source. Their

spectral output contains high energy spikes superimposed on a

9. Focusing

white-light continuum. Xenon arcs produce a spectral quality

9.1 Sharp focus is necessary to obtain good photomicro-

close to daylight (5600 K) with a strong spike at 462 nm. There

graphs.

are also strong emissions in the infrared, which should be

9.2 There are two systems for obtaining sharp focus:

removed (see 7.4). Carbon arcs have a continuous output in the

ground-glass focusing and aerial image focusing.

visible portion of the spectrum, with a color temperature near

9.2.1 For ground-glass focusing, relatively glare-free sur-

3800 K and a strong emission line at 400 nm. Mercury arcs,

roundings and a magnifier up to about 33 are required. To

focus, the focusing knob is oscillated between underfocus and

4 overfocus in succeedingly smaller increments until the image is

The boldface numbers in parentheses refer to the list of references appended to

this guide. sharp.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 883

FIG. 1 Vertical Illuminating System for a Metallurgical Microscope

9.2.2 There are four possible variations for focusing an may be used in high-energy light beams. The mirrored side of

aerial image. the filter should face the light source. (The hot mirrors in 7.4

9.2.2.1 The simplest case is a transparent spot on a ground- are interference filters.)

glass containing a fiduciary mark in the film plane. To focus,

10.2.2 Absorption filters are dyed substrates of glass, plas-

the specimen image is made to coincide with the fiduciary

tic, or gelatine. They absorb some wavelengths of light and

mark, using a magnifying loupe of about 33 to 53. When the

transmit the balance. Through their absorption, they can

focus is correct, the specimen image and the fiduciary mark

become overheated and damaged if placed in high-energy light

will not move with respect to each other when the operator’s

beams without protection. The usual protection is either an

head is moved.

interference filter or a liquid-filled cell placed in the beam

9.2.2.2 A second case uses a reticle fixed within the optical

before the absorption filter. Wratten gelatine filters are used

system. Focusing is a two-step process: focus the eyepiece on

below as examples (3). Many similar glass and plastic filters

the reticle; bring the image into focus against the reticle figure.

are also available.

9.2.2.3 In the third case, a reticle is inserted into a focusing

10.3 Certain general purpose filters have application in both

eyepiece. Depending on equipment used, this can be either a

color and black-and-white photomicrography.

two or three-step process: focus the reticle within the eyepiece;

10.3.1 Ultraviolet light can be removed with an interference

next, set the proper interpupiliary distance, if required (some

filter, a glass or gel filter from the Wratten #2 series, or a liquid

equipment requires a specific interpupiliary distance for eye-

cell filled with a sodium nitrite solution (2 % NaNO for a

piece focus to coincide with camera focus); then focus the

1-cm path, proportionately stronger or weaker for other cell

image coincident with the reticle.

path lengths). Ultraviolet light must be removed from arc

9.2.2.4 The fourth case uses a single-lens reflex camera

lamps for eye safety, and should be removed for color

body, where the camera focusing screen is the plane of

photomicrography, as explained in 10.5.

reference. An eyepiece magnifier for the camera is an impor-

10.3.2 Gray neutral density filters reduce the intensity of a

tant accessory for this case. An aerial image focusing screen is

light beam equally across the visible spectrum. They are made

preferred.

in interference and absorption types in many different densi-

9.3 The critical focus point is affected by both the principal

ties, for example, the Wratten #96 series. They are useful for

illumination wavelength in use and the size of the aperture

eyepiece work with an arc source, and to modify the brightness

diaphragm. Final focusing should be checked with all filters,

of any tungsten source without changing its color temperature.

apertures, and other components set for the photomicrograph.

10.4 Filters for Black and White Photomicrography:

10. Filters for Photomicrography

10.4.1 Generally, a monochromatic filter is used to optimize

the resolution of the objective. With achromats, a green

10.1 The production of high–quality photomicrographs re-

centered around 550 nm is used; for apochromats and semi-

quires filtration of the light emitted from light sources. This

apochromats, a blue centered around 486 nm provides slightly

section describes filter types and their uses.

better resolution, but with a penalty of more difficult visual

10.2 Each filter selectively removes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.