ASTM D2919-01e1

(Test Method)Standard Test Method for Determining Durability of Adhesive Joints Stressed in Shear by Tension Loading

Standard Test Method for Determining Durability of Adhesive Joints Stressed in Shear by Tension Loading

SCOPE

1.1 This test method provides data for assessing the durability of adhesive lap-shear joints while stressed in contact with air, air in equilibrium with certain solutions, water, aqueous solutions, or other environments at various temperatures.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.4. 1.3 The values stated in SI units are considered to be the standard. The values in parentheses ar for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D2919–01

Standard Test Method for

Determining Durability of Adhesive Joints Stressed in Shear

1

by Tension Loading

This standard is issued under the fixed designation D 2919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Adjunct references were corrected editorially in April 2006.

1. Scope 2.2 ASTM Adjuncts:

3

Durability Test Apparatus Drawings

1.1 This test method provides data for assessing the dura-

bilityofadhesivelap-shearjointswhilestressedincontactwith

3. Terminology

air, air in equilibrium with certain solutions, water, aqueous

3.1 Definitions—Definitions of terms in this test method

solutions, or other environments at various temperatures.

may be found in Terminology D 907.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 The combination of stress and moisture decreases the

priate safety and health practices and determine the applica-

durability of most adhesive joints. Stresses in the presence of

bility of regulatory limitations prior to use. Specific precau-

water or water vapor may cause some adhesive joints to fail at

tionary statements are given in 7.4.

some small fraction of the stress required to break the dry joint.

1.3 The values stated in SI units are considered to be the

The time to failure for a given adhesive joint generally

standard. The values in parentheses are for information only.

decreases with increasing stress, temperature, and relative

2. Referenced Documents humidity.

2 4.2 This test method may be used as an accelerated screen-

2.1 ASTM Standards:

ingtestforassessingthedurabilityofadhesivejoints.Itmaybe

D 907 Terminology of Adhesives

used to measure durability of adhesive joints exposed outdoors

D 1002 Test Method forApparent Shear Strength of Single-

or to environmental conditions experienced by adhesive joints

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

in service. The tests may also be used to determine the effects

sion Loading (Metal-to-Metal)

of various surface preparations or substrates on durabilities of

D 1828 Practice for Atmospheric Exposure of Adhesive-

adhesive joints.

Bonded Joints and Structures

4.3 The durability performance of various adhesives may be

D 2294 Test Method for Creep Properties of Adhesives in

compared by using this test method under uniform sets of

Shear by Tension Loading (Metal-to-Metal)

conditions.To assess the overall durability of a given adhesive,

D 3165 Test Method for Strength Properties ofAdhesives in

lap-shear joints should be tested under a range of stress,

Shear by Tension Loading of Single-Lap-Joint Laminated

relative humidity, and temperature. For a specific end use it

Assemblies

may be possible to obtain the needed durability data using only

E4 Practices for Force Verification of Testing Machines

one set of test conditions.

5. Apparatus

3

1

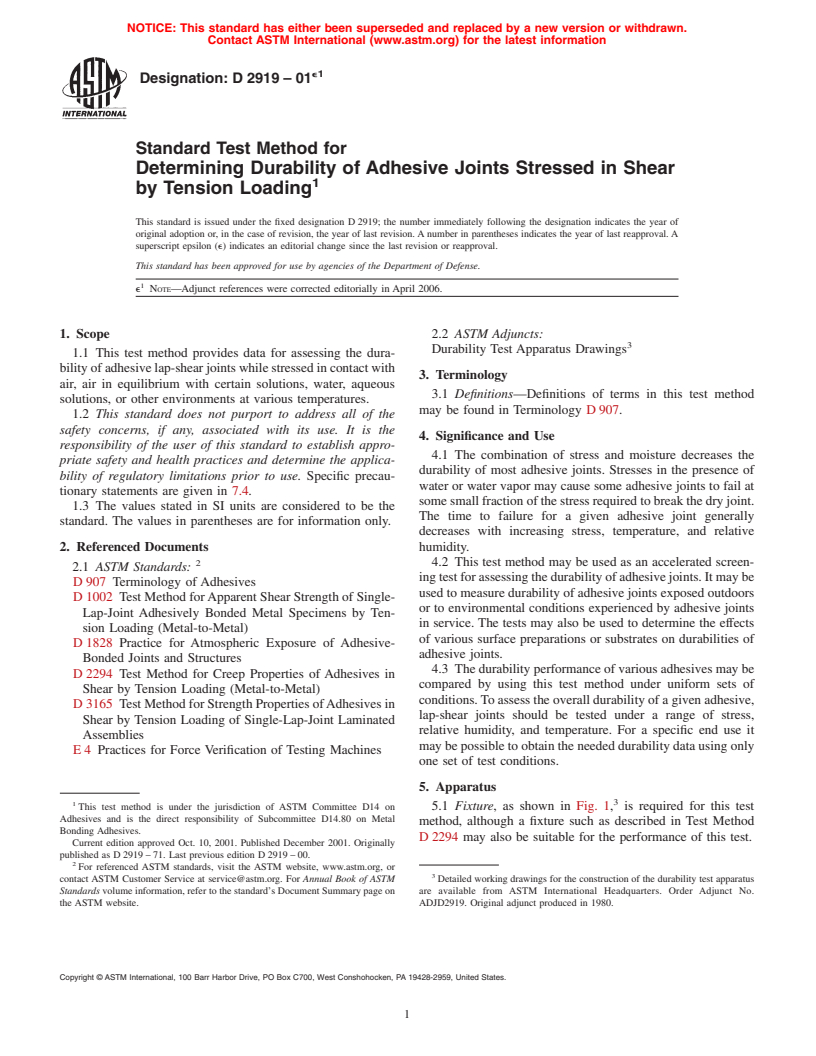

This test method is under the jurisdiction of ASTM Committee D14 on 5.1 Fixture, as shown in Fig. 1, is required for this test

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

method, although a fixture such as described in Test Method

Bonding Adhesives.

D 2294 may also be suitable for the performance of this test.

Current edition approved Oct. 10, 2001. Published December 2001. Originally

published as D 2919 – 71. Last previous edition D 2919 – 00.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Detailed working drawings for the construction of the durability test apparatus

Standards volume information, refer to the standard’s Document Summary page on are available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD2919. Original adjunct produced in 1980.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D2919–01

FIG. 1 Durability Test Apparatus

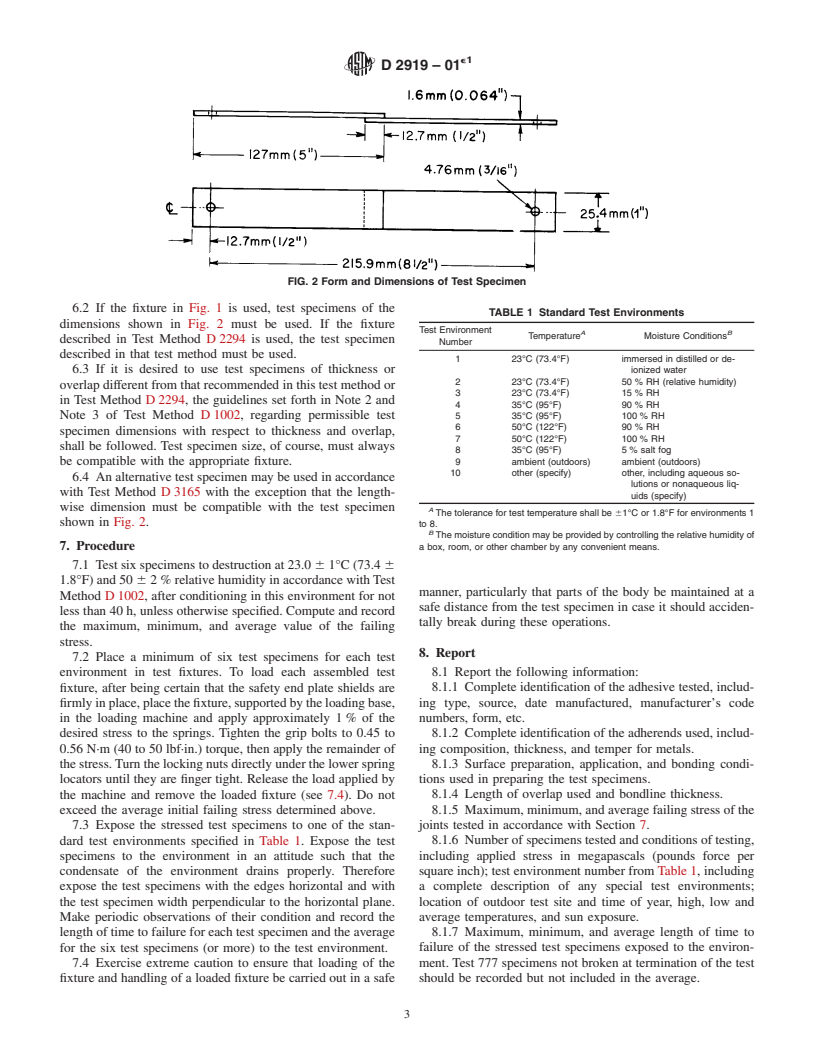

5.2 Testing Machine, or other suitable machine capable of 6. Test Specimens

applying measured compressive loads. Force measurements

6.1 The successful use of this test method depends on

have an accuracy of 61 % of any reading when calibrated in

preparing good quality lap-shear joints. The test joints must be

compliance with Practices E4 requirements. Machine that is

prepared carefully in accordance w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.