ASTM D1210-05

(Test Method)Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage

Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage

SIGNIFICANCE AND USE

In making pigmented products, the pigment is usually dispersed in a portion of the vehicle in some sort of mill. At this stage, it is necessary to be able to judge if the pigment agglomerates have been sufficiently broken up so as not to interfere with the smoothness of the finished coating film. This test method describes a way of making this judgment.

SCOPE

1.1 This test method covers measurement of the degree of dispersion (commonly referred to as "fineness of grind") of the pigment in a pigment-vehicle system such as liquid coatings and their intermediates. It may also be used to assess the inclusion of particulates by a cleanliness (or texture) rating.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D1210–05

Standard Test Method for

Fineness of Dispersion of Pigment-Vehicle Systems by

1

Hegman-Type Gage

This standard is issued under the fixed designation D1210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope where the particles form a definite pattern. When the single

path gage is used it is also possible to rate “cleanliness” (see

1.1 This test method covers measurement of the degree of

6.2).

dispersion (commonly referred to as “fineness of grind”) of the

3.2 Stepped Gage—The product is spread by means of a

pigment in a pigment-vehicle system such as liquid coatings

scraper on a stepped gage. There are 2 delimited sections on

and their intermediates. It may also be used to assess the

2 2

this gage, each of 6.5 cm (1 in. ) area, and of two different

inclusion of particulates by a cleanliness (or texture) rating.

depths. A count is made of the particles deposited in the two

1.2 The values stated in SI units are to be regarded as the

delimited areas, and cleanliness (texture) reading is deter-

standard. The values given in parentheses are for information

mined.

only.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 In making pigmented products, the pigment is usually

responsibility of the user of this standard to establish appro-

dispersedinaportionofthevehicleinsomesortofmill.Atthis

priate safety and health practices and determine the applica-

stage, it is necessary to be able to judge if the pigment

bility of regulatory limitations prior to use.

agglomerates have been sufficiently broken up so as not to

2. Referenced Documents interfere with the smoothness of the finished coating film. This

2

test method describes a way of making this judgment.

2.1 ASTM Standards:

D1316 Test Method for Fineness of Grind of Printing Inks

5. Apparatus

By the NPIRI Grindometer

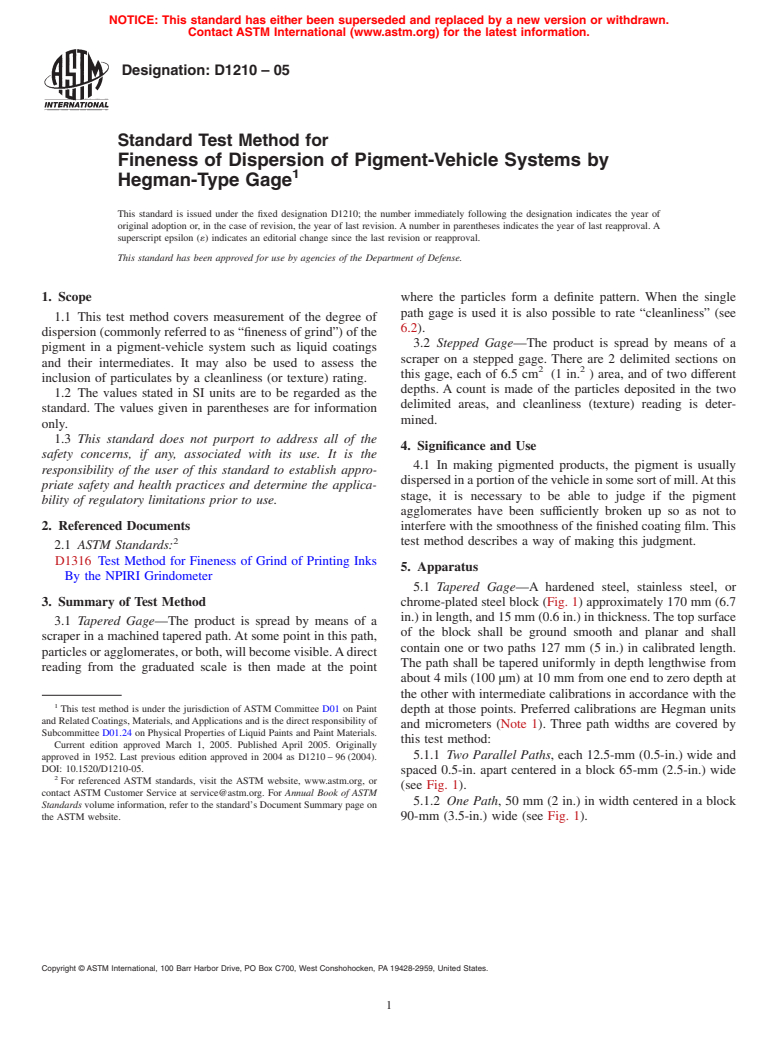

5.1 Tapered Gage—A hardened steel, stainless steel, or

3. Summary of Test Method chrome-plated steel block (Fig. 1) approximately 170 mm (6.7

in.) in length, and 15 mm (0.6 in.) in thickness.The top surface

3.1 Tapered Gage—The product is spread by means of a

of the block shall be ground smooth and planar and shall

scraper in a machined tapered path.At some point in this path,

contain one or two paths 127 mm (5 in.) in calibrated length.

particlesoragglomerates,orboth,willbecomevisible.Adirect

The path shall be tapered uniformly in depth lengthwise from

reading from the graduated scale is then made at the point

about 4 mils (100 µm) at 10 mm from one end to zero depth at

the other with intermediate calibrations in accordance with the

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

depth at those points. Preferred calibrations are Hegman units

and Related Coatings, Materials, andApplications and is the direct responsibility of

and micrometers (Note 1). Three path widths are covered by

Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint Materials.

this test method:

Current edition approved March 1, 2005. Published April 2005. Originally

5.1.1 Two Parallel Paths, each 12.5-mm (0.5-in.) wide and

approved in 1952. Last previous edition approved in 2004 as D1210 – 96 (2004).

DOI: 10.1520/D1210-05.

spaced 0.5-in. apart centered in a block 65-mm (2.5-in.) wide

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(see Fig. 1).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.2 One Path, 50 mm (2 in.) in width centered in a block

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 90-mm (3.5-in.) wide (see Fig. 1).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1210–05

FIG. 1 Fineness Gages

5.1.3 One Path, 25 mm (1 in.) in width centered in a block 25-mm (1-in.) wide shall be cut the length of, and centered in

65-mm (2.5-in.) wide (see Fig. 1a). a block 65-mm (2.5-in.) wide. The path will be cut to two

different depths, each for half of its length.The two depths will

NOTE 1—Several arbitrary scales and modifications of the gage are

be 3 mils, and 1 mil, or as agreed upon between the buyer and

usedbyindustry.Inorderthatreadingsobtainedwiththesearbitraryscales

the seller. There shall be two tick marks, above and below the

and modifications can be reported in the preferred units, the approximate

...

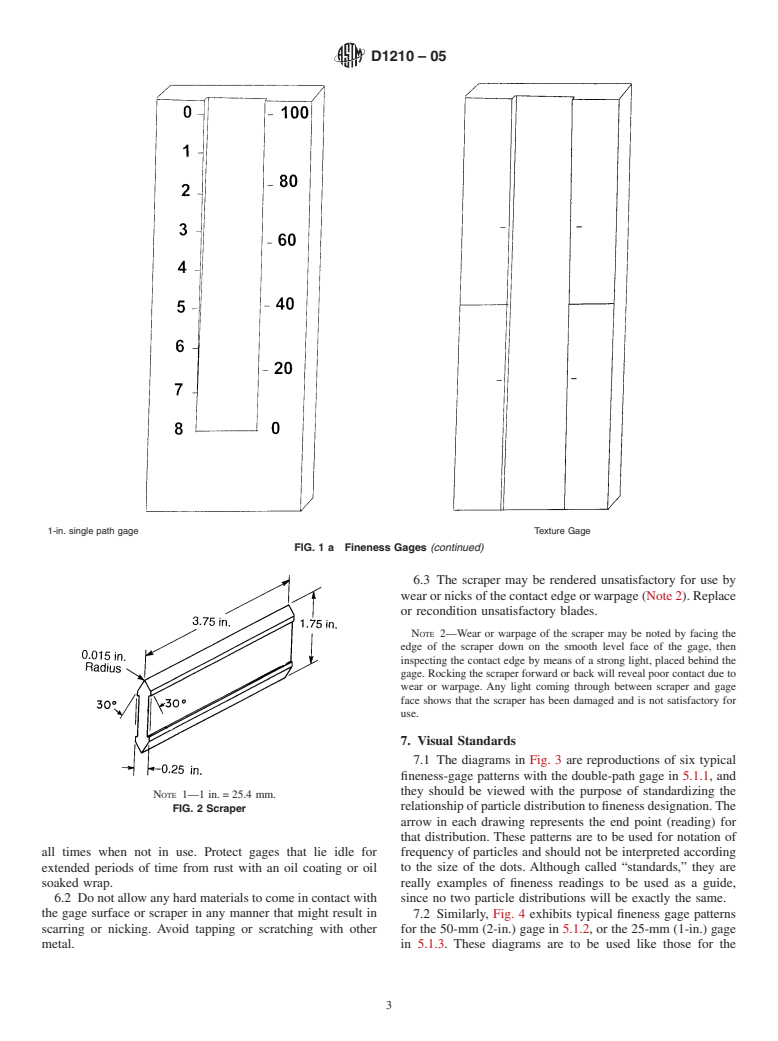

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.