ASTM E2206-11

(Test Method)Standard Test Method for Force Calibration of Thermomechanical Analyzers

Standard Test Method for Force Calibration of Thermomechanical Analyzers

SIGNIFICANCE AND USE

Most thermomechanical analysis experiments are carried out with some force applied to the test specimen. This force is often created electronically. It may be constant or changed during the experiment.

This method demonstrates conformance or calibrates the electronically applied force signal.

This method may be used for research and development, quality control, manufacturing or regulatory applications.

Other thermomechanical analyzer calibration functions include temperature by Test Method E1363 and length change by Test Method E2113.

SCOPE

1.1 This test method describes the calibration or performance confirmation of the electronically applied force signal for thermomechanical analyzers over the range of 0 to 1 N.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 There is no ISO method equivalent to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2206 − 11

StandardTest Method for

1

Force Calibration of Thermomechanical Analyzers

This standard is issued under the fixed designation E2206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope conformance, precision, relative standard deviation,

repeatability, reproducibility, and thermomechanical analyzer.

1.1 This test method describes the calibration or perfor-

mance confirmation of the electronically applied force signal

4. Summary of Test Method

for thermomechanical analyzers over the range of 0 to 1N.

4.1 The electronic force signal generated by a thermome-

1.2 The values stated in SI units are to be regarded as

chanical analyzer is compared to that exerted by gravity on a

standard. No other units of measurement are included in this

known mass. The thermomechanical analyzer may be said to

standard.

be in conformance if the performance is within established

limits, typically 1%. Alternatively, the force signal may be

1.3 There is no ISO method equivalent to this standard.

calibrated using a two-point calibration method.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Most thermomechanical analysis experiments are car-

priate safety and health practices and determine the applica-

ried out with some force applied to the test specimen. This

bility of regulatory limitations prior to use.

force is often created electronically. It may be constant or

changed during the experiment.

2. Referenced Documents

2

2.1 ASTM Standards: 5.2 Thismethoddemonstratesconformanceorcalibratesthe

electronically applied force signal.

E4Practices for Force Verification of Testing Machines

E473Terminology Relating to Thermal Analysis and Rhe-

5.3 Thismethodmaybeusedforresearchanddevelopment,

ology

quality control, manufacturing or regulatory applications.

E617Specification for Laboratory Weights and Precision

5.4 Other thermomechanical analyzer calibration functions

Mass Standards

include temperature by Test Method E1363 and length change

E831Test Method for Linear Thermal Expansion of Solid

by Test Method E2113.

Materials by Thermomechanical Analysis

E1142Terminology Relating to Thermophysical Properties

6. Apparatus

E1363Test Method forTemperature Calibration ofThermo-

6.1 Thermomechanical Analyzer—The essential instrumen-

mechanical Analyzers

tationrequiredtoprovideaminimumthermomechanicalanaly-

E2113Test Method for Length Change Calibration of Ther-

sis or thermodilatometric capability for this method includes:

momechanical Analyzers

6.1.1 Rigid Specimen Holder, inert, low expansivity mate-

E2161Terminology Relating to Performance Validation in

rial [typically <0.6µm/(m·K)] to center the specimen in the

Thermal Analysis

furnace and to fix the specimen to mechanical ground.

3. Terminology

NOTE 1—Materials of construction with greater expansivity may be

used but shall be reported.

3.1 The technical terms used in this standard are defined in

Terminologies E473, E1142, and E2161 including calibration,

6.1.2 Rigid (Expansion or Compression) Probe, inert, low

expansivity material [typically <0.6µm/(m·K)] which con-

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

tactsthespecimenwithanappliedcompressiveforce(seeNote

Measurements and is the direct responsibility of Subcommittee E37.10 on

1).

Fundamental, Statistical and Mechanical Properties.

6.1.3 Sensing Element, linear over a minimum range of

Current edition approved Aug. 1, 2011. Published August 2011. Originally

2mmtomeasurethedisplacementoftherigidprobeto 61µm

approved in 2002. Last previous edition approved in 2006 as E2206–06. DOI:

10.1520/E2206-11.

resulting from changes in length of the specimen.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.4 Programmable Force Transducer, to generate a con-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

stant force (61.0%) of up to 1.0N that is applied through the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. rigid probe to the specimen.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2206 − 11

NOTE 2—Other force ranges may be used but shall be reported.

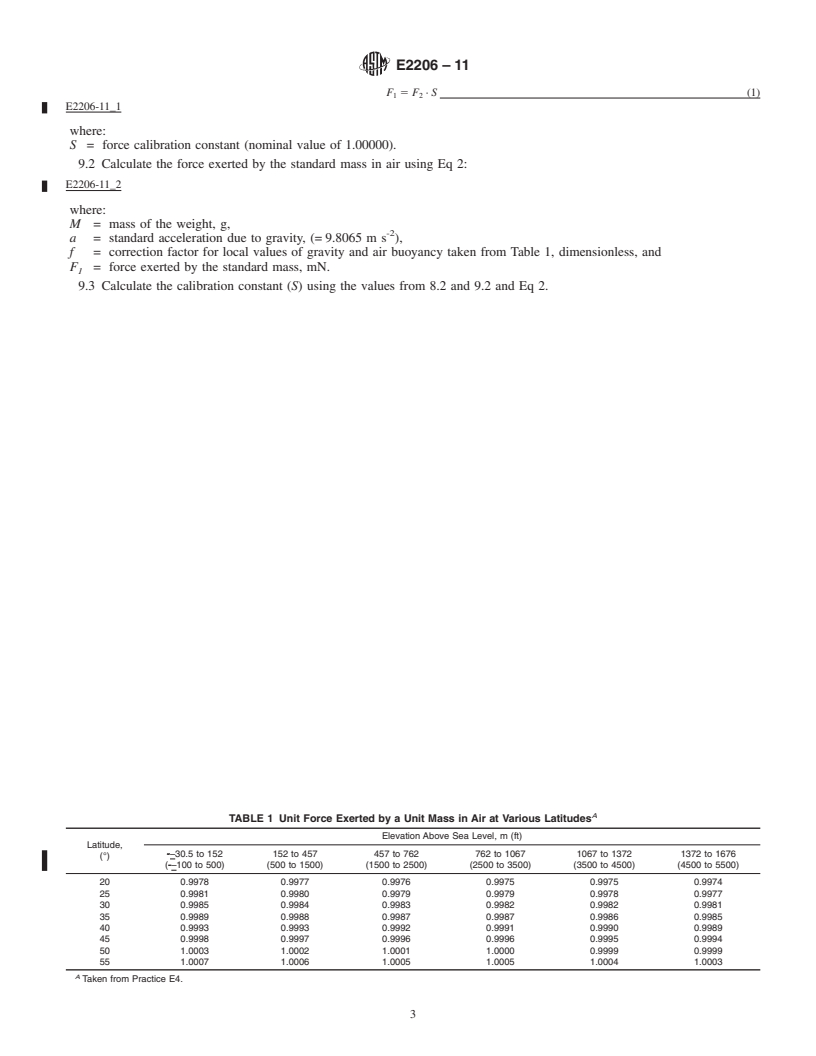

8. Procedure

6.1.5 Furnace, capable of providing uniform controlled

8.1 With no specimen present, lower the probe so that it

heating (cooling) of the specim

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2206–06 Designation:E2206–11

Standard Test Method for

Force Calibration Of Thermomechnical AnalyzersForce

1

Calibration of Thermomechanical Analyzers

This standard is issued under the fixed designation E2206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes the calibration or performance confirmation of the electronically applied force signal for

thermomechanical analyzers over the range of 0 to 1N.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 There is no ISO method equivalent to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E473 Terminology Relating to Thermal Analysis and Rheology

E617 Specification for Laboratory Weights and Precision Mass Standards

E831 Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

E1142 Terminology Relating to Thermophysical Properties

E1363 Test Method for Temperature Calibration of Thermomechanical Analyzers

E2113 Test Method for Length Change Calibration of Thermomechanical Analyzers Test Method for Length Change

Calibration of Thermomechanical Analyzers

E2161 Terminology Relating to Performance Validation in Thermal Analysis

3. Terminology

3.1 The technical terms used in this standard are defined in Terminologies E473and , E1142, and E2161 including calibration,

conformance, precision, relative standard deviation, repeatability, reproducibility, and thermomechanical analyzer.

4. Summary of Test Method

4.1 The electronic force signal generated by a thermomechanical analyzer is compared to that exerted by gravity on a known

mass. The thermomechanical analyzer may be said to be in conformance if the performance is within established limits, typically

1%. Alternatively, the force signal may be calibrated using a two-point calibration method.

5. Significance and Use

5.1 Most thermomechanical analysis experiments are carried out with some force applied to the test specimen. This force is

often created electronically. It may be constant or changed during the experiment.

5.2 This method demonstrates conformance or calibrates the electronically applied force signal.

5.3 This method may be used for research and development, quality control, manufacturing or regulatory applications.

5.4 Other thermomechanical analyzer calibration functions include temperature by Test Method E1363 and length change by

Test Method E2113.

1

This test method is under the jurisdiction ofASTM Committee E37 onThermal Measurements and is the direct responsibility of Subcommittee E37.10 on Fundamental,

Statistical and Mechanical Properties.

Current edition approved MarchAug. 1, 2006.2011. Published April 2006.August 2011. Originally approved in 2002. Last previous edition approved in 20022006 as

E2206–026. DOI: 10.1520/E2206-06.10.1520/E2206-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2206–11

6. Apparatus

6.1 Thermomechanical Analyzer—The essential instrumentation required to provide a minimum thermomechanical analysis or

thermodilatometric capability for this method includes:

6.1.1 Rigid Specimen Holder, inert, low expansivity material [typically <0.6µm/(m·K)] to center the specimen in the furnace

and to fix the specimen to mechanical ground.

NOTE 1—Materials of construction with greater expansivity may be used but shall be reported.

6.1.2 Rigid (Expansion or Compression) Probe, inert, low expansivity material [typically <0.6µm/(m·K)] which contacts the

specimen with an applied compressive force (see Note 1).

6.1.3 Sensing Element, linear over a minimum rang

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.