ASTM D6270-98(2004)

(Practice)Standard Practice for Use of Scrap Tires in Civil Engineering Applications

Standard Practice for Use of Scrap Tires in Civil Engineering Applications

SIGNIFICANCE AND USE

This practice is intended for use of scrap tires including tire chips or tire shreds comprised of pieces of scrap tires, tire chip/soil mixtures, tire sidewalls, and whole scarp tires in civil engineering applications. This practice includes the use of tire chips, tire shreds, and tire chip/soil mixtures as lightweight embankment fill, lightweight retaining wall backfill, drainage layers, thermal insulation to limit frost penetration beneath roads, insulating backfill to limit heat loss from buildings, and replacement for soil or rock in other fill applications. Use of whole scrap tires and tire sidewalls includes construction of retaining walls and drainage culverts, as well as use as fill when whole tires have been compressed into bales. It is the responsibility of the design engineer to determine the appropriateness of using scrap tires in a particular application and to select applicable tests and specifications to facilitate construction and environmental protection. This practice is intended to encourage wider utilization of scrap tires in civil engineering applications.

Three tire shred fills with thicknesses in excess of 7 m have experienced a serious heating reaction; however, more than 70 fills with a thickness less than 3 m have been constructed with no evidence of a deleterious heating reaction (1)6 . Guidelines have been developed to minimize internal heating of tire shred fills (2) as discussed in 6.10. The guidelines are applicable to fills less than 3 m thick; thus, this practice should be applied only to tire shred fills less than 3 m thick.

SCOPE

1.1 This practice provides guidance for testing the physical properties and gives data for assessment of the leachate generation potential of processed or whole scrap tires in lieu of conventional civil engineering materials, such as stone, gravel, soil, sand, or other fill materials. In addition, typical construction practices are outlined.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6270 – 98 (Reapproved 2004)

Standard Practice for

Use of Scrap Tires in Civil Engineering Applications

This standard is issued under the fixed designation D 6270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice provides guidance for testing the physical 3.1 Definitions:

properties and gives data for assessment of the leachate 3.1.1 baling, n—a method of volume reduction whereby

generation potential of processed or whole scrap tires in lieu of tires are compressed into bales.

conventional civil engineering materials, such as stone, gravel, 3.1.2 bead,n—theanchoringpartofthetirewhichisshaped

soil, sand, or other fill materials. In addition, typical construc- to fit the rim and is constructed of bead wire wrapped by the

tion practices are outlined. plies.

3.1.3 bead wire, n—a high tensile steel wire surrounded by

2. Referenced Documents

rubber, which forms the bead of a tire that provides a firm

2.1 ASTM Standards: contact to the rim.

C 127 Test Method for Specific Gravity and Absorption of

3.1.4 belt wire, n—abrassplatedhightensilesteelwirecord

Coarse Aggregate used in steel belts.

D 422 Test Method for Particle-Size Analysis of Soils

3.1.5 buffıng rubber, n—vulcanized rubber usually obtained

D 698 Test Method for Laboratory Compaction Character- from a worn or used tire in the process of removing the old

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

tread in preparation for retreading.

kN-m/m )) 3.1.6 carcass, n—see casing.

D 1557 Test Method for Laboratory Compaction Character-

3.1.7 casing, n—the basic tire structure excluding the tread

istics of Soil Using Modified Effort (56,000 ft-lbf/ft (Syn. carcass).

(2,700 kN-m/m ))

3.1.8 granulated rubber, n—particulaterubbercomposedof

D 2434 Test Method for Permeability of Granular Soils mainly nonspherical particles that span a broad range of

(Constant Head)

maximumparticledimension,frombelow425µm(40mesh)to

D 3080 Test Method for Direct Shear Test of Soils Under

12 mm (also refer to particulate rubber).

Consolidated Drained Conditions 3.1.9 ground rubber, n—particulate rubber composed of

D 4253 TestMethodsforMaximumIndexDensityandUnit

mainly nonspherical particles that span a range of maximum

Weight of Soils Using a Vibratory Table particle dimensions, from below 425 µm (40 mesh) to 2 mm

2.2 AASHTO Standard:

(also refer to particulate rubber).

T 274 Standard Method of Test for Resilient Modulus of 3.1.10 nominal size, n—the average size product (chip) that

Subgrade Soils

comprises 50 % or more of the through put in a scrap tire

2.3 USEPA Standard: processing operation; scrap tire processing operations generate

Method 1311 Toxicity Characteristics Leaching Procedure

products (chips) above and below the nominal size.

3.1.11 particulate rubber, n—raw, uncured, compounded or

vulcanized rubber that has been transformed by means of a

This practice is under the jurisdiction of ASTM Committee D34 on Biotech-

mechanicalsizereductionprocessintoacollectionofparticles,

nology and is the direct responsibility of Subcommittee D34.03.03 on Industrial

Recovery and Reuse. with or without a coating of a partitioning agent to prevent

Current edition approved June 10, 1998. Published August 1998.

agglomeration during production, transportation, or storage

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(also see definition of buffing rubber, granulated rubber,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ground rubber, and powdered rubber).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3.1.12 passenger car tire, n—atirewithlessthana457-mm

Standard Specifications for Transportation Materials and Methods of Sampling

rim diameter for use on cars only.

and Testing, Part II: Methods of Sampling and Testing, American Association of

State Highway and Transportation Officials, Washington, D.C.

4 rd

Test Methods for Evaluating Solid Waste: Physical/Chemical Methods, 3 ed.,

Report No. EPA530/SW-846, U.S. Environmental ProtectionAgency, Washington,

D.C. The defined term is the responsibility of Committee D11 on Rubber.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6270 – 98 (2004)

3.1.13 powdered rubber, n—particulaterubbercomposedof whole scrap tires and tire sidewalls includes construction of

mainly nonspherical particles that have a maximum particle retaining walls and drainage culverts, as well as use as fill

dimension equal to or below 425 µm (40 mesh) (also refer to when whole tires have been compressed into bales. It is the

particulate rubber). responsibility of the design engineer to determine the appro-

3.1.14 rough shred, n—a piece of a shredded tire that is priateness of using scrap tires in a particular application and to

larger than 50 mm by 50 mm by 50 mm, but smaller than 762 select applicable tests and specifications to facilitate construc-

mm by 50 mm by 100 mm. tion and environmental protection. This practice is intended to

3.1.15 rubber fines, n—smallparticlesofgroundrubberthat encourage wider utilization of scrap tires in civil engineering

result as a by-product of producing shredded rubber. applications.

3.1.16 scrap tire, n—a tire, which can no longer be used for 4.2 Three tire shred fills with thicknesses in excess of 7 m

its original purpose due to wear or damage. have experienced a serious heating reaction; however, more

3.1.17 shred sizing, n—a term which generally refers to the than 70 fills with a thickness less than 3 m have been

process of particles passing through a rated screen opening constructed with no evidence of a deleterious heating reaction

rather than those which are retained on the screen. (1) . Guidelines have been developed to minimize internal

3.1.18 shredded tire, n—a size reduced scrap tire where the heating of tire shred fills (2) as discussed in 6.10. The

reductioninsizewasaccomplishedbyamechanicalprocessing guidelines are applicable to fills less than 3 m thick; thus, this

device, commonly referred to as a shredder. practice should be applied only to tire shred fills less than 3 m

3.1.19 shredded rubber, n—pieces of scrap tires resulting thick.

from mechanical processing.

5. Material Characterization

3.1.20 sidewall, n—the side of a tire between the tread

shoulder and the rim bead.

5.1 The specific gravity and water absorption capacity of

3.1.21 single pass shred, n—a shredded tire that has been

tire shreds should be determined in accordance with Test

processed by one pass through a shear type shredder and the

Method C 127; however, the specific gravity of tire shreds is

resulting pieces have not been classified by size.

less than half the value obtained for common earthen coarse

3.1.22 steel belt, n—rubber coated steel cords that run

aggregate, so it is permissible to use a minimum weight of test

diagonallyunderthetreadofsteelradialtiresandextendacross

sample that is half of the specified value. The particle density

the tire approximately the width of the tread.

or density of solids of tire shreds (r ) may be determined from

s

3.1.23 tire chips, n—Pieces of scrap tires that have a basic

the apparent specific gravity using the following equation:

geometrical shape and are generally between 12 mm and 50

r 5 S ~r ! (1)

s a w

mm in size and have most of the wire removed (Syn. chipped

tire). where:

3.1.24 tire shreds, n—Pieces of scrap tires that have a basic S = apparent specific gravity, and

a

r = density of water.

geometrical shape and are generally between 50 mm and 305

w

5.2 The gradation of tires shreds should be determined in

mm in size.

3.1.25 tread, n—that portion of the tire which contacts the accordance with Test Method D 422; however, the specific

gravity of tire shreds is less than half the values obtained for

road.

3.1.26 truck tire, n—a tire with a rim diameter of 500 mm common earthen materials so it is permissible to use a

minimum weight of test sample that is half of the specified

or larger.

3.1.27 waste tire, n—a tire which is no longer capable of value.

5.3 The laboratory compacted dry density, or bulk density,

beingusedforitsoriginalpurposebutwhichhasbeendisposed

of in such a manner that it cannot be used for any other of tire chips and tire chip/soil mixtures with less than 30 %

retained on the 19.0-mm sieve can be determined in accor-

purpose.

dance with Test Method D 698 or D 1557. Tire Shred and tire

3.1.28 whole tire, n—a scrap tire that has been removed

shred/soil mixtures used for civil engineering applications,

from a rim but which has not been processed.

however, almost always have more than 30 % retained on the

3.1.29 x-mm minus, n—pieces of classified, size reduced

19.0-mm sieve, so these methods generally are not applicable.

scrap tires where the maximum size of 95 % of the pieces is

Alarger compaction mold should be used to accommodate the

less than x-mm in any dimension (that is, 25-mm minus;

larger size of the tire shreds. The sizes of typical compaction

50-mm minus; 75-mm minus, etc).

moldsaresummarizedinTable1.Thelargermoldrequiresthat

4. Significance and Use

the number of layers, or the number of blows of the rammer/

4.1 This practice is intended for use of scrap tires including

layer, or both, be increased to produce the desired compactive

tire chips or tire shreds comprised of pieces of scrap tires, tire

energy/unit volume. Compactive energies ranging from 60 %

3 3

chip/soil mixtures, tire sidewalls, and whole scarp tires in civil

ofTest Method D 698 (60 % 3 600 kN-m/m = 360 kN-m/m )

engineering applications. This practice includes the use of tire

to 100 % of Test Method D 1557 (2,700 kN-m/m ) have been

chips, tire shreds, and tire chip/soil mixtures as lightweight

used. Compaction energy only has a small effect on the

embankment fill, lightweight retaining wall backfill, drainage

layers, thermal insulation to limit frost penetration beneath

roads, insulating backfill to limit heat loss from buildings, and

The boldface numbers in parentheses refer to the list of references at the end of

replacement for soil or rock in other fill applications. Use of this standard.

D 6270 – 98 (2004)

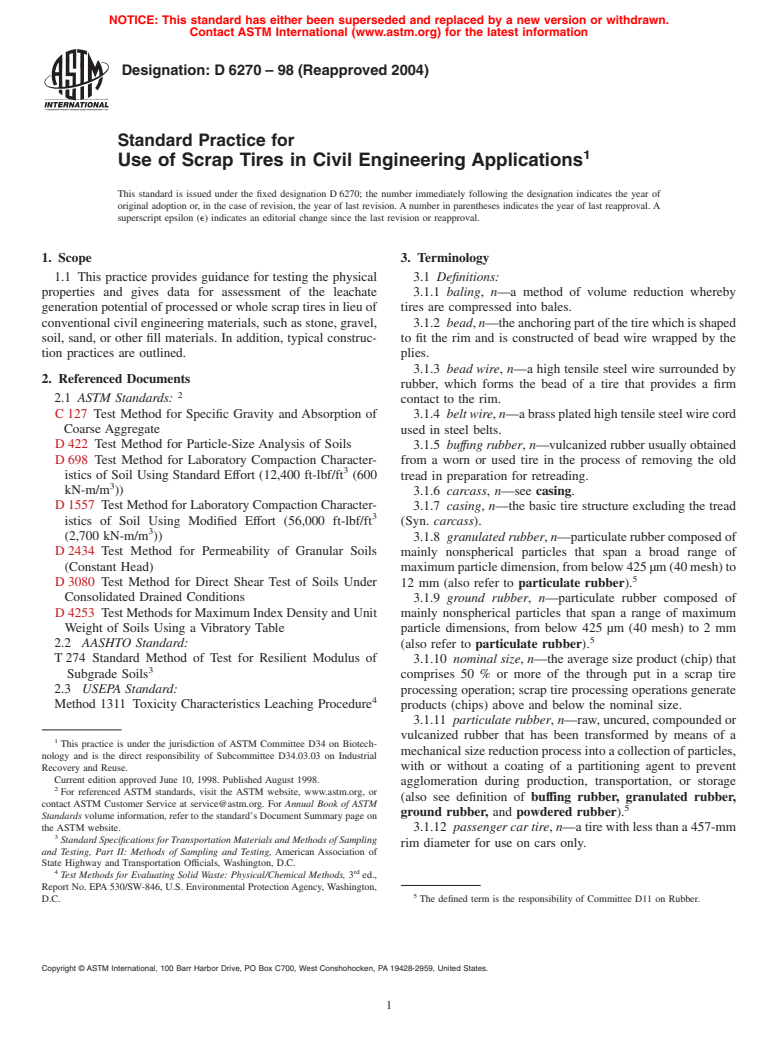

TABLE 1 Size of Compaction Molds Used to Determine Dry

cylinder with a diameter several times greater than the largest

Density of Tire Shreds

particlesizeandthenmeasuringtheverticalstraincausedbyan

Maximum Particle Mold Diameter Mold Volume Reference

increasing vertical stress. If it is desired to calculate the

Size (mm) (mm) (m )

coefficient of lateral earth pressure at rest K , the cylinder can

O

75 254 0.0125 (3)

be instrumented to measure the horizontal stress of the tire

75 305 0.0146 (4)

A

shreds acting on the wall of the cylinder.

51 203 and 305 N.R. (5)

A

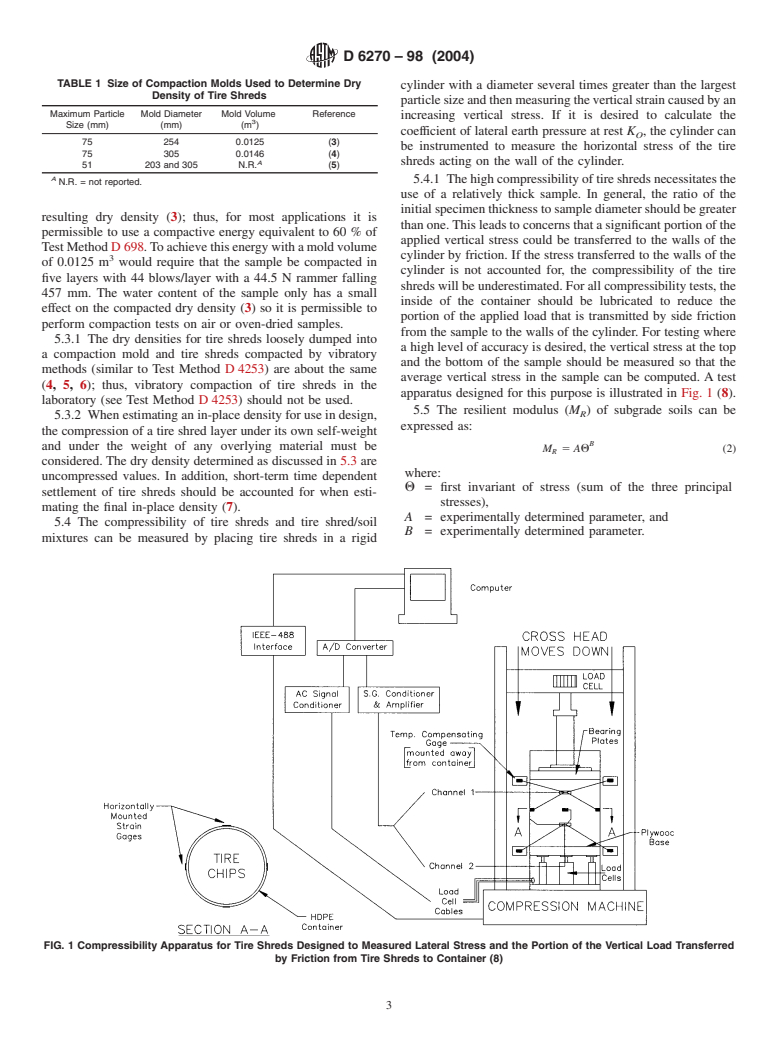

5.4.1 Thehighcompressibilityoftireshredsnecessitatesthe

N.R. = not reported.

use of a relatively thick sample. In general, the ratio of the

initialspecimenthicknesstosamplediametershouldbegreater

resulting dry density (3); thus, for most applications it is

thanone.Thisleadstoconcernsthatasignificantportionofthe

permissible to use a compactive energy equivalent to 60 % of

applied vertical stress could be transferred to the walls of the

TestMethodD 698.Toachievethisenergywithamoldvolume

cylinder by friction. If the stress transferred to the walls of the

of 0.0125 m would require that the sample be compacted in

cylinder is not accounted for, the compressibility of the tire

five layers with 44 blows/layer with a 44.5 N rammer falling

shreds will be underestimated. For all compressibility tests, the

457 mm. The water content of the sample only has a small

inside of the container should be lubricated to reduce the

effect on the compacted dry density (3) so it is permissible to

portion of the applied load that is transmitted by side friction

perform compaction tests on air or oven-dried samples.

from the sample to the walls of the cylinder. For testing where

5.3.1 The dry densities for tire shreds loosely dumped into

a high level of accuracy is desired, the vertical stress at the top

a compaction mold and tire shreds compacted by vibratory

and the bottom of the sample should be measured so that the

methods (similar to Test Method D 4253) are about the same

average vertical stress in the sample can be computed. A test

(4, 5, 6); thus, vibratory compaction of tire shreds in the

apparatus designed for this purpose is illustrated in Fig. 1 (8).

laboratory (see Test Method D 4253) should not be used.

5.5 The resilient modulus (M ) of subgrade soils can be

R

5.3.2 When estimating an in-place density for use in design,

expressed as:

the compression of a tire shred layer under its own self-weight

B

and under the weight of any overlying material must be

M 5 AQ (2)

R

considered. The dry density determined as discussed in 5.3 are

where:

uncompressed values. In addition, short-term time dependent

Q = first invariant of stress (sum of the three principal

settlement of tire shreds should be accounted for when esti-

stresses),

mating the final in-place density (7).

A = experimentally determined parameter, and

5.4 The compressibility of tire shreds and tire shred/soil

B = experimentally determined parameter.

mixtures can be measured by placing tire shreds in a rigid

FIG. 1 Compressibility Apparatus for Tire Shreds Designed to Measured Lateral Stress and the Portion of the Vertical Load Transferred

by Friction from Tire Shreds to Container (8)

D 6270 – 98 (2004)

TestsfortheparametersAandBcanbeconductedaccording wires would puncture the membrane used to surround the

to AASHTO T 274. The maximum particle size typically is specimen. The interface strength between tire shreds and

limited to 19 mm by the testing apparatus, which precludes the

geomembranecanbemeasuredinalargescaledirectsheartest

general applicability of this procedure to the larger size tire

apparatus (9).

chips and shreds typically used for civil engineering applica-

5.8 The hydraulic conductivity (permeability) of tire shreds

tions.

and tire shred/soils mixtures should be measured with a

5.6 The coefficient of lateral earth pressure at rest K and

O

constant head permeameter with a diameter several times

Poisson’s ratio µ can be determined from the results of

greater than the maximum particle size. Tire chips with a

confined compression tests where the horizontal stresses were

maximum size smaller than

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.