ASTM E1742-00

(Practice)Standard Practice for Radiographic Examination

Standard Practice for Radiographic Examination

SCOPE

1.1 This practice establishes the minimum requirements for radiographic examination for metallic and nonmetallic materials.

1.2 Applicability -The criteria for the radiographic examination in this practice are applicable to all types of metallic and nonmetallic materials. The requirements expressed in this practice are intended to control the quality of the radiographic images and are not intended to establish acceptance criteria for parts and materials.

1.3 Basis of Application -There are areas in this practice that may require agreement between the cognizant engineering organization and the supplier, or specific direction from the cognizant engineering organization. These items should be addressed in the purchase order or the contract.

1.3.1 DoD contracts, 2.10.

1.3.2 Personnel qualification, 5.1.1.

1.3.3 Agency qualification, 5.1.2.

1.3.4 Digitizing techniques, 5.4.5.

1.3.5 Alternate image quality indicator (IQI) types, 5.5.3.

1.3.6 Examination sequence, 6.6.

1.3.7 Non-film techniques, 6.7.

1.3.8 Radiographic quality levels, 6.9.

1.3.9 Film density, 6.10.

1.3.10 IQI qualification exposure, 6.13.3.

1.3.11 Non-requirement for IQI, 6.18.4.

1.3.12 Examination coverage for welds, A2.2.2.

1.3.13 Electron beam welds, A2.3.

1.3.14 Geometric unsharpness, 6.23.

1.3.15 Responsibility for examination, 6.27.1.

1.3.16 Examination report, 6.27.2.

1.3.17 Retention of radiographs, 6.27.8.

1.3.18 Storage of radiographs, 6.27.9.

1.3.19 Reproduction of radiographs, 6.27.10 and 6.27.10.1.

1.3.20 Acceptable parts, 6.28.1.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1742–00

Standard Practice for

Radiographic Examination

This standard is issued under the fixed designation E1742; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 This standard does not purport to address all of the

2 safety concerns, if any, associated with its use. It is the

1.1 Thispractice establishestheminimumrequirementsfor

responsibility of the user of this standard to establish appro-

radiographic examination for metallic and nonmetallic materi-

priate safety and health practices and determine the applica-

als.

bility of regulatory limitations prior to use.

1.2 Applicability—The criteria for the radiographic exami-

nationinthispracticeareapplicabletoalltypesofmetallicand

2. Referenced Documents

nonmetallic materials. The requirements expressed in this

2.1 The following documents form a part of this practice to

practice are intended to control the quality of the radiographic

the extent specified herein:

imagesandarenotintendedtoestablishacceptancecriteriafor

2.2 ASTM Standards:

parts and materials.

E543 Practice for Agencies Performing Nondestructive

1.3 Basis of Application—There are areas in this practice

Testing

thatmayrequireagreementbetweenthecognizantengineering

E 747 Practice for Design, Manufacture, and Material

organization and the supplier, or specific direction from the

Grouping Classification of Wire Image Quality Indicators

cognizant engineering organization. These items should be

(IQI) Used for Radiology

addressed in the purchase order or the contract.

E801 Practice for Controlling Quality of Radiological Ex-

1.3.1 DoD contracts, .

amination of Electronic Devices

1.3.2 Personnel qualification, 5.1.1.

E999 Guide for Controlling the Quality of Industrial Ra-

1.3.3 Agency qualification, 5.1.2.

diographic Film Processing

1.3.4 Digitizing techniques, 5.4.5.

E1025 Practice for Design, Manufacturer, and Material

1.3.5 Alternate image quality indicator (IQI) types, 5.5.3.

Grouping Classification of Hole-Type Image Quality Indi-

1.3.6 Examination sequence, 6.6.

cators (IQI) Used for Radiology

1.3.7 Non-film techniques, 6.7.

E1030 Test Method for Radiographic Examination of Me-

1.3.8 Radiographic quality levels, 6.9.

tallic Castings

1.3.9 Film density, 6.10.

E1032 Test Method for Radiographic Examination of

1.3.10 IQI qualification exposure, 6.13.3.

Weldments

1.3.11 Non-requirement for IQI, 6.18.4.

E1079 Practice for Calibration of Transmission Densitom-

1.3.12 Examination coverage for welds, A2.2.2.

eters

1.3.13 Electron beam welds, A2.3.

E1165 Test Method for Measurement of Focal Spots of

1.3.14 Geometric unsharpness, 6.23.

Industrial X-Ray Tubes by Pinhole Imaging

1.3.15 Responsibility for examination, 6.27.1.

E1254 Guide for Storage of Radiographs and Unexposed

1.3.16 Examination report, 6.27.2.

Industrial Radiographic Film

1.3.17 Retention of radiographs, 6.27.8.

E1255 Practice for Radioscopy

1.3.18 Storage of radiographs, 6.27.9.

E1316 Terminology for Nondestructive Examinations

1.3.19 Reproduction of radiographs, 6.27.10 and 6.27.10.1.

E1390 Guide for Illuminators Used for Viewing Industrial

1.3.20 Acceptable parts, 6.28.1.

Radiographs

E1411 Practice for Qualification of Radioscopic Systems

E1416 Test Method for Radioscopic Examination ofWeld-

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

ments

structive Testing and is the direct responsibility of Subcommittee E07.01 on

Radiology (X and Gamma) Method.

Current edition approved July 10, 2000. Published September 2000. Originally

published as E1742–95. Last previous edition E1742–95.

2 3

This practice replaced MIL-STD-453. Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1742–00

E1815 Test Method for Classification of Film Systems, for 3.2.1 cognizant engineering organization—the company,

Industrial Radiography government agency, or other authority responsible for the

2.3 AWS Document: design, or end use, of the system or component for which

AWS A2.4 Symbols for Welding and Nondestructive Test- radiographic examination is required. This, in addition to

ing design personnel, may include personnel from engineering,

2.4 Aerospace Industries Association Document: material and process engineering, stress analysis, NDT, or

NAS 410 Certification & Qualification of Nondestructive quality groups and others, as appropriate.

Test Personnel 3.2.2 component—the part(s) or element of a system, as-

2.5 ASNT Documents: sembled or processed to the extent specified by the drawing,

SNT-TC-1A Recommended Practice for Personnel Qualifi- purchase order, or contract.

cation and Certification in Nondestructive Testing 3.2.3 energy—a property of radiation that determines its

ANSI/ASNT-CP-189 ASNT Standard for Qualification and penetrating ability. In X-ray radiography, energy machine

Certification of Nondestructive Testing Personnel rating is determined by kilovolts (kV), million electronvolts

2.6 NCRP Documents: (MeV).Ingammarayradiography,energyisacharacteristicof

NCRP 51 Radiation Protection Design Guidelines for the source used.

0.1–100 MeV Particle Accelerator Facilities 3.2.4 like section—a separate section of material that is

NCRP 91 Recommendations on Limits for Exposures to similar in shape and cross section to the component or part

Ionizing Radiation being radiographed, and is made of the same or radiographi-

2.7 ANSI Standards: cally similar material.

ANSI IT 9.1 Imaging Media (Film)—Silver-Gelatin Type 3.2.5 material group—materials that have the same pre-

Specifications for Stability dominant alloying elements and which can be examined using

ANSIPH4.8 Photography(Chemicals)—ResidualThiosul- the same IQI.Alisting of common material groups is given in

phate and Other Chemicals in Films, Plates, and Papers— Practice E1025.

Determination and Measurement 3.2.6 NDT facility—the NDT facility performing the radio-

2.8 Government Standard: graphic examination.

MIL-STD-410 Nondestructive Testing Personnel Qualifica- 3.2.7 radiographic quality level—The ability of a radio-

tion and Certification (Eddy Current, Liquid Penetrant, graphic procedure to demonstrate a certain IQI sensitivity.

Magnetic Particle, Radiographic and Ultrasonic)

4. Significance and Use

2.9 Other Government Documents:

4.1 This practice establishes the basic parameters for the

NIST Handbook 114 General Safety Standard for Installa-

application and control of the radiographic method. This

tions Using Non-Medical X-Ray and Sealed Gamma Ray

practice is written so it can be specified on the engineering

Sources, Energies up to 10 MeV

drawing, specification, or contract. It is not a detailed how-to

NOTE 1—DoD Contracts:Unless otherwise specified, the issues of the

procedure to be used by the NDT facility and, therefore, must

documents that are DoD adopted are those listed in the issue of the

be supplemented by a detailed procedure (see 6.1). Test

DoDISS (Department of Defense Index of Specifications and Standards)

Methods E1030, E1032, and E1416 contain information to

cited in the solicitation.

NOTE 2—Order of Precedence:In the event of conflict between the text

help develop detailed technique/procedure requirements.

of this practice and the references cited herein, the text of this practice

takesprecedence.Nothinginthispractice,however,supersedesapplicable 5. General Practice

laws and regulations unless a specific exemption has been obtained.

5.1 Qualification:

5.1.1 Personnel Qualification—Personnel performing ex-

3. Terminology

aminationsinaccordancewiththispracticeshallbequalifiedin

3.1 Definitions—Definitionsrelatingtoradiographicexami-

accordance with MIL-STD-410, NAS 410, ANSI/ASNT-CP-

nation,whichappearinTerminologyE1316,shallapplytothe

189,orSNT-TC-1Aandcertifiedbytheemployerorcertifying

terms used in this practice.

agencyasapplicable.Otherequivalentqualificationdocuments

3.2 Definitions of Terms Specific to This Standard:

may be used when specified in the contract or purchase order.

5.1.2 Agency Evaluation—If specified in the contractual

agreement, NDT agencies shall be qualified and evaluated in

Available from American Welding Society (AWS), P.O. Box 351040, Miami,

accordance with Practice E543. The applicable revision of

FL 33135.

Practice E543 shall be specified in the contractual agreement.

Available from Aerospace Industries Association, 1050 Eye St. N.W., Wash-

5.2 Laboratory Installations:

ington, DC 20005.

Available from American Society for Nondestructive Testing, 1711 Arlingate

5.2.1 Safety—The premises and equipment shall present no

Plaza, P.O. Box 28518, Columbus, OH 43228-0518.

hazardstothesafetyofpersonnelorproperty.NCRP51,NCRP

Available from National Council on Radiation Protection and Measurements,

91 and NIST Handbook 114 may be used as guides to ensure

NCRP Publications, 7910 Woodmount Ave., Suite 800, Bethesda, MD 20814.

that radiographic procedures are performed so that personnel

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

shall not receive a radiation dosage exceeding the maximum

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

permitted by city, state, or national codes.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

5.2.2 Radiographic Exposure Areas—Radiographic expo-

Available from National Institute of Standards and Technology (NIST),

Gaithersburg, MD 20899. sure areas shall be clean and equipped so that acceptable

E1742–00

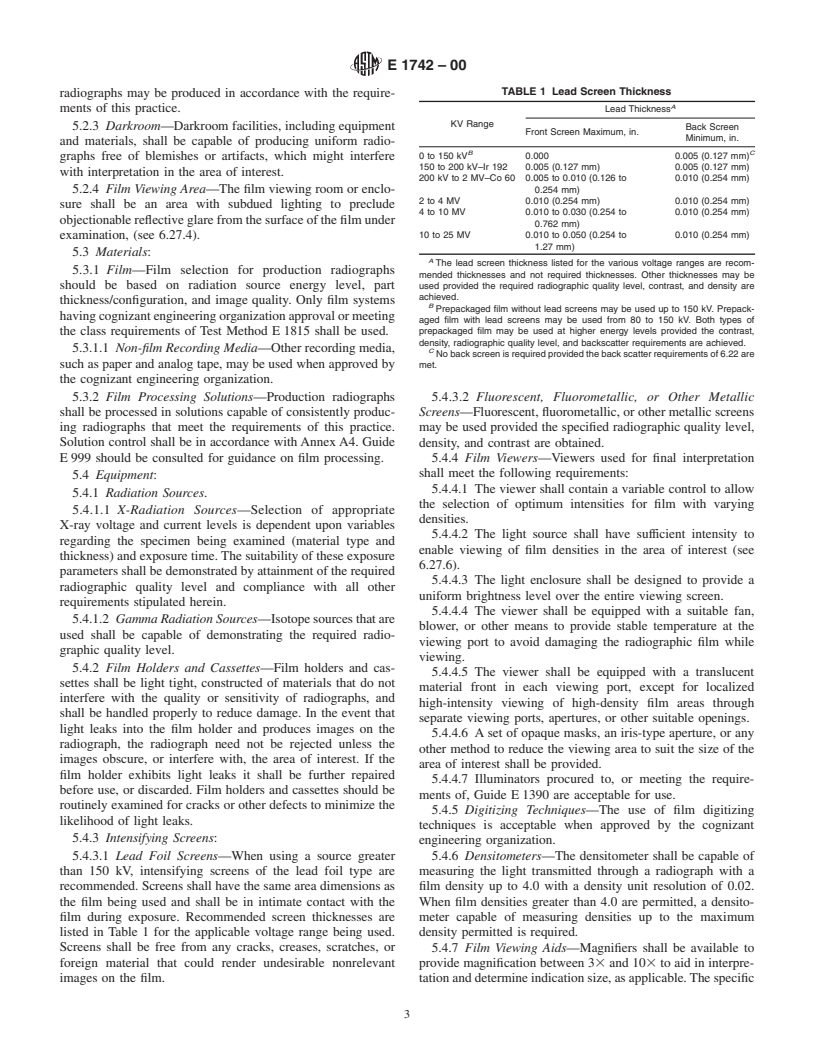

TABLE 1 Lead Screen Thickness

radiographs may be produced in accordance with the require-

A

ments of this practice. Lead Thickness

KV Range

5.2.3 Darkroom—Darkroom facilities, including equipment Back Screen

Front Screen Maximum, in.

Minimum, in.

and materials, shall be capable of producing uniform radio-

B C

0 to 150 kV 0.000 0.005 (0.127 mm)

graphs free of blemishes or artifacts, which might interfere

150 to 200 kV–Ir 192 0.005 (0.127 mm) 0.005 (0.127 mm)

with interpretation in the area of interest.

200 kV to 2 MV–Co 60 0.005 to 0.010 (0.126 to 0.010 (0.254 mm)

5.2.4 Film Viewing Area—The film viewing room or enclo- 0.254 mm)

2 to 4 MV 0.010 (0.254 mm) 0.010 (0.254 mm)

sure shall be an area with subdued lighting to preclude

4 to 10 MV 0.010 to 0.030 (0.254 to 0.010 (0.254 mm)

objectionablereflectiveglarefromthesurfaceofthefilmunder

0.762 mm)

10 to 25 MV 0.010 to 0.050 (0.254 to 0.010 (0.254 mm)

examination, (see 6.27.4).

1.27 mm)

5.3 Materials:

A

The lead screen thickness listed for the various voltage ranges are recom-

5.3.1 Film—Film selection for production radiographs

mended thicknesses and not required thicknesses. Other thicknesses may be

should be based on radiation source energy level, part used provided the required radiographic quality level, contrast, and density are

achieved.

thickness/configuration, and image quality. Only film systems

B

Prepackaged film without lead screens may be used up to 150 kV. Prepack-

havingcognizantengineeringorganizationapprovalormeeting

aged film with lead screens may be used from 80 to 150 kV. Both types of

prepackaged film may be used at higher energy levels provided the contrast,

the class requirements of Test Method E1815 shall be used.

density, radiographic quality level, and backscatter requirements are achieved.

5.3.1.1 Non-film Recording Media—Otherrecordingmedia, C

No back screen is required provided the back scatter requirements of 6.22 are

such as paper and analog tape, may be used when approved by

met.

the cognizant engineering organization.

5.3.2 Film Processing Solutions—Production radiographs 5.4.3.2 Fluorescent, Fluorometallic, or Other Metallic

shall be processed in solutions capable of consistently produc-

Screens—Fluorescent, fluorometallic, or other metallic screens

ing radiographs that meet the requirements of this practice. may be used provided the specified radiographic quality level,

Solution control shall be in accordance withAnnexA4. Guide

density, and contrast are obtained.

E999 should be consulted for guidance on film processing. 5.4.4 Film Viewers—Viewers used for final interpretation

shall meet the following requirements:

5.4 Equipment:

5.4.4.1 The viewer shall contain a variable control to allow

5.4.1 Radiation Sources.

the selection of optimum intensities for film with varying

5.4.1.1 X-Radiation Sources—Selection of appropriate

densities.

X-ray voltage and current levels is dependent upon variables

5.4.4.2 The light source shall have sufficient intensity to

regarding the specimen being examined (material type and

enable viewing of film densities in the area of interest (see

thickness)andexposuretime.Thesuitabilityoftheseexposure

6.27.6).

parametersshallbedemonstratedbyattainmentoftherequired

5.4.4.3 The light enclosure shall be designed to provide a

radiographic quality level and compliance with all other

uniform brightness level over the entire viewing screen.

requirements stipulated herein.

5.4.4.4 The viewer shall be equipped with a suitable fan,

5.4.1.2 GammaRadiationSources—Isotopesourcesthatare

blower, or other means to provide stable temperature at the

used shall be capable of demonstrating the required radio-

viewing port to avoid damaging the radiographic film while

graphic quality level.

viewing.

5.4.2 Film Holders and Cassettes—Film holders and cas-

5.4.4.5 The viewer shall be equipped with a translucent

settes shall be light tight, constructed of materials that do not

material front in each viewing port, except for localized

interfere with the quality or sensitivity of radiographs, and

high-intensity viewing of high-density film areas through

shall be handled properly to reduce damage. In the event that

separate viewing ports, apertures, or other suitable openings.

light leaks into the film holder and produces images on the

5.4.4.6 Aset of opaque masks, an iris-type aperture, or any

radiograph, the radiograph need not be rejected unless the

other method to reduce the viewing area to suit the size of the

images obscure, or interfere with, the area of interest. If the

area of interest shall be provided.

film holder exhibits light leaks it shall be further repaired

5.4.4.7 Illuminators procured to, or meeting the require-

before use, or discarded. Film holders and cassettes should be

ments of, Guide E1390 are acceptable for use.

routinely examined for cracks or other defects to minimize the

5.4.5 Digitizing Techniques—The use of film digitizing

likelihood of light leaks.

techniques is accept

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.