ASTM F1711-96(2008)

(Practice)Standard Practice for Measuring Sheet Resistance of Thin Film Conductors for Flat Panel Display Manufacturing Using a Four-Point Probe Method

Standard Practice for Measuring Sheet Resistance of Thin Film Conductors for Flat Panel Display Manufacturing Using a Four-Point Probe Method

SCOPE

1.1 This practice describes methods for measuring the sheet electrical resistance of sputtered thin conductive films deposited on large insulating substrates, used in making flat panel information displays. It is assumed that the thickness of the conductive thin film is much thinner than the spacing of the contact probes used to measure the sheet resistance.

1.2 This standard is intended to be used with Test Method F 390.

1.3 Sheet resistivity in the range 0.5 to 5000 ohms per square may be measured by this practice. The sheet resistance is assumed uniform in the area being probed.

1.4 This practice is applicable to flat surfaces only.

1.5 Probe pin spacings of 1.5 mm to 5.0 mm, inclusive (0.059 to 0.197 in inclusive) are covered by this practice.

1.6 The method in this practice is potentially destructive to the thin film in the immediate area in which the measurement is made. Areas tested should thus be characteristic of the functional part of the substrate, but should be remote from critical active regions. The method is suitable for characterizing dummy test substrates processed at the same time as substrates of interest.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1711 −96(Reapproved 2008)

Standard Practice for

Measuring Sheet Resistance of Thin Film Conductors for

Flat Panel Display Manufacturing Using a Four-Point Probe

1

Method

This standard is issued under the fixed designation F1711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice describes methods for measuring the sheet

F390Test Method for Sheet Resistance of Thin Metallic

electrical resistance of sputtered thin conductive films depos-

Films With a Collinear Four-Probe Array

ited on large insulating substrates, used in making flat panel

information displays. It is assumed that the thickness of the

3. Terminology

conductive thin film is much thinner than the spacing of the

contact probes used to measure the sheet resistance.

3.1 Definitions:

3.1.1 For definitions of terms used in this practice see Test

1.2 This standard is intended to be used with Test Method

Method F390.

F390.

1.3 Sheet resistivity in the range 0.5 to 5000 ohms per

4. Summary of Practice

square may be measured by this practice. The sheet resistance

4.1 This practice describes the preferred means of applying

is assumed uniform in the area being probed.

Test Method F390 to measure the electrical sheet resistance of

1.4 This practice is applicable to flat surfaces only. thinfilmsonverylargeflatsubstrates.Anarrayoffourpointed

probesisplacedincontactwiththefilmofinterest.Ameasured

1.5 Probe pin spacings of 1.5 mm to 5.0 mm, inclusive

electrical current is passed between two of the probes, and the

(0.059 to 0.197 in inclusive) are covered by this practice.

electrical potential difference between the remaining two

probes is determined. The sheet resistance is calculated from

1.6 The method in this practice is potentially destructive to

the measured current and potential values using correction

the thin film in the immediate area in which the measurement

factors associated with the probe geometry and the probe’s

is made. Areas tested should thus be characteristic of the

distance from the test specimen’s boundaries.

functional part of the substrate, but should be remote from

critical active regions. The method is suitable for characteriz-

4.2 The method of F390 is extended to cover staggered

ing dummy test substrates processed at the same time as

in-lineandsquareprobearrays.Inallthedesigns,however,the

substrates of interest.

probe spacings are nominally equal.

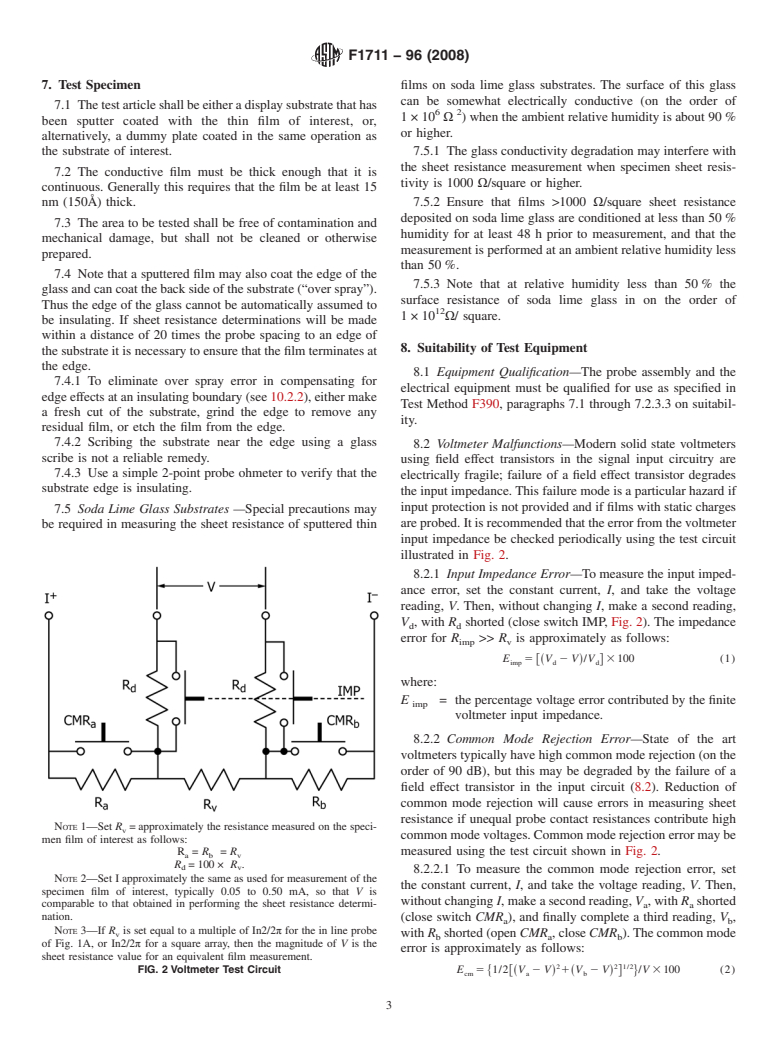

4.3 This practice includes a special electrical test for veri-

1.7 The values stated in SI units are to be regarded as the

fying the proper functioning of the potential measuring instru-

standard. The values given in parentheses are for information

ment (voltmeter), directions for making and using sheet resis-

only.

tance reference films, an estimation of measurement error

1.8 This standard does not purport to address all of the

caused by probe wobble in the probe supporting fixture, and a

safety concerns, if any, associated with its use. It is the

protocol for reporting film uniformity.

responsibility of the user of this standard to establish appro-

4.4 Two appendices indicate the computation methods em-

priate safety and health practices and determine the applica-

ployed in deriving numerical relationships and correction

bility of regulatory limitations prior to use.

factors employed in this practice, and in Test Method F390.

1

This practice is under the jurisdiction ofASTM Committee F01 on Electronics

2

and is the direct responsibility of Subcommittee F01.17 on Sputter Metallization. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 15, 2008. Published July 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2002 as F1711–96(2002). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1711-96R08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1711−96 (2008)

5. Significance and Use 5.1.4 It is difficult, given the conditions cited in 5.1.3,to

ensure that uniform probe spacing is not degraded by rough

5.1 ApplyingTestMethodF390tolargeflatpanelsubstrates

handlingoftheequipment.Thephasedsquarearray,described,

presents a number of serious difficulties not anticipated in the

averages out probe placement errors.

development of that standard. The following problems are

5.1.5 This practice is estimated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.