ASTM D4532-97

(Test Method)Standard Test Method for Respirable Dust in Workplace Atmospheres

Standard Test Method for Respirable Dust in Workplace Atmospheres

SCOPE

1.1 This test method is useful for the determination of respirable dust (see Terminology D 1356) in a range from 0.5 to 10 mg/m in workplace atmospheres.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4532 – 97

Standard Test Method for

Respirable Dust in Workplace Atmospheres

This standard is issued under the fixed designation D 4532; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5.2 The limitations on the test method are a minimum

weight of 0.2 mg of dust on the filter, and a maximum loading

1.1 This test method is useful for the determination of

of 0.3 mg/cm on the filter. The test method may be used at

respirable dust (see Terminology D 1356) in a range from 0.5

higher loadings if the flow rate can be maintained constant.

to 10 mg/m in workplace atmospheres.

1.2 This standard does not purport to address all of the

6. Apparatus

safety concerns, if any, associated with its use. It is the

6.1 The sampling unit consists of a pump and a sampling

responsibility of the user of this standard to consult and

head. The sampling head consists of a 10-mm cyclone and a

establish appropriate safety and health practices and deter-

filter assembly.

mine the applicability of regulatory limitations prior to use.

6.1.1 Pump—A personal sampling pump with a flow rate

2. Referenced Documents accurate to 65 %. Pump pulsation not to exceed6 20 % of the

mean flow. The pump must be capable of maintaining the mean

2.1 ASTM Standards:

flow constant to within 65 % during the sampling period.

D 1356 Terminology Relating to Sampling and Analysis of

2 Calibrate the sampling pump using Practice D 5337.

Atmospheres

6.1.2 Sampling Head—The sampling head consists of a

D 3195 Practice for Rotameter Calibration

10-mm cyclone, a filter, a filter-support pad, and a filter holder

D 5337 Practice for Flow Rate for Calibration of Personal

with suitable caps (see Fig. 1).

Sampling Pumps

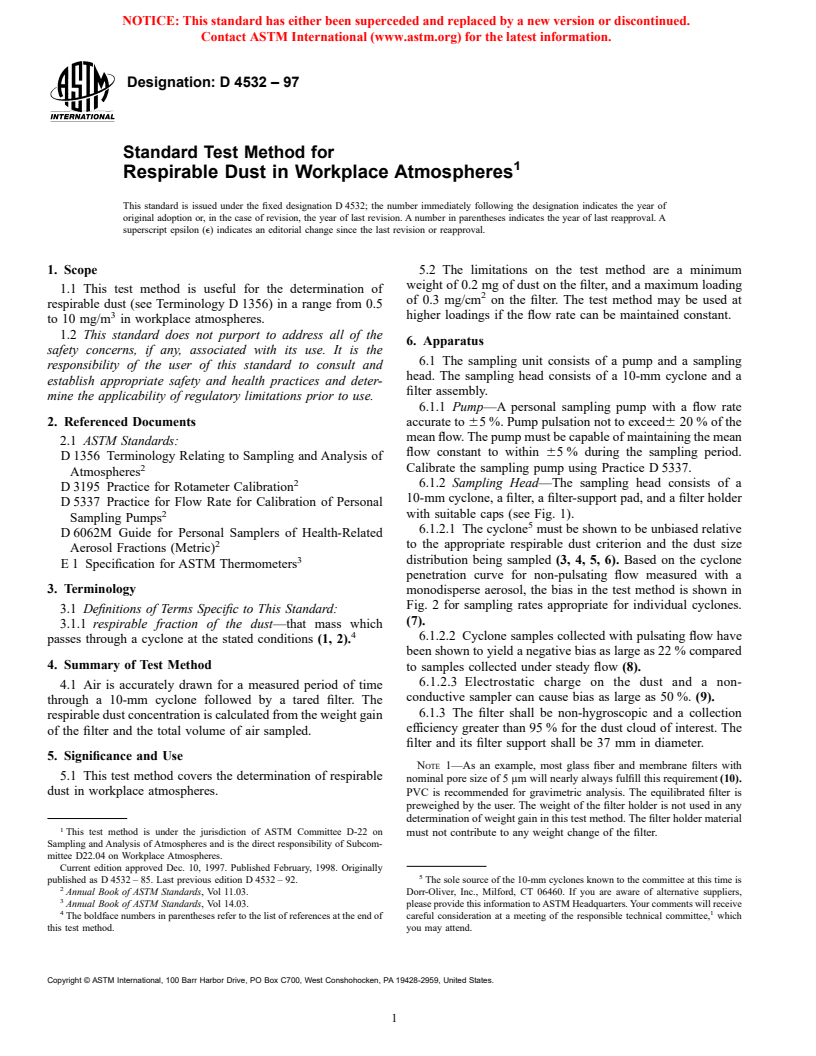

6.1.2.1 The cyclone must be shown to be unbiased relative

D 6062M Guide for Personal Samplers of Health-Related

to the appropriate respirable dust criterion and the dust size

Aerosol Fractions (Metric)

distribution being sampled (3, 4, 5, 6). Based on the cyclone

E 1 Specification for ASTM Thermometers

penetration curve for non-pulsating flow measured with a

3. Terminology monodisperse aerosol, the bias in the test method is shown in

Fig. 2 for sampling rates appropriate for individual cyclones.

3.1 Definitions of Terms Specific to This Standard:

(7).

3.1.1 respirable fraction of the dust—that mass which

6.1.2.2 Cyclone samples collected with pulsating flow have

passes through a cyclone at the stated conditions (1, 2).

been shown to yield a negative bias as large as 22 % compared

4. Summary of Test Method

to samples collected under steady flow (8).

6.1.2.3 Electrostatic charge on the dust and a non-

4.1 Air is accurately drawn for a measured period of time

conductive sampler can cause bias as large as 50 %. (9).

through a 10-mm cyclone followed by a tared filter. The

6.1.3 The filter shall be non-hygroscopic and a collection

respirable dust concentration is calculated from the weight gain

efficiency greater than 95 % for the dust cloud of interest. The

of the filter and the total volume of air sampled.

filter and its filter support shall be 37 mm in diameter.

5. Significance and Use

NOTE 1—As an example, most glass fiber and membrane filters with

5.1 This test method covers the determination of respirable

nominal pore size of 5 μm will nearly always fulfill this requirement (10).

dust in workplace atmospheres. PVC is recommended for gravimetric analysis. The equilibrated filter is

preweighed by the user. The weight of the filter holder is not used in any

determination of weight gain in this test method. The filter holder material

This test method is under the jurisdiction of ASTM Committee D-22 on must not contribute to any weight change of the filter.

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom-

mittee D22.04 on Workplace Atmospheres.

Current edition approved Dec. 10, 1997. Published February, 1998. Originally

published as D 4532 – 85. Last previous edition D 4532 – 92. The sole source of the 10-mm cyclones known to the committee at this time is

Annual Book of ASTM Standards, Vol 11.03. Dorr-Oliver, Inc., Milford, CT 06460. If you are aware of alternative suppliers,

Annual Book of ASTM Standards, Vol 14.03. please provide this information to ASTM Headquarters. Your comments will receive

4 1

The boldface numbers in parentheses refer to the list of references at the end of careful consideration at a meeting of the responsible technical committee, which

this test method. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4532

6.11 Manometer, 0 to 250 mm of water (0 to 0.25 kPa) for

measuring the pressure drop across the sampling head.

6.12 Flexible Tube with Two Clips, one near the sampling

head, if the sampling head does not have a clip, and the other

midway between the sampling head and the pump. The length

of the tube is dependent on how the sampling unit is worn. A

length of 0.7 to 0.9 m is suitable if the pump is attached to the

worker’s belt.

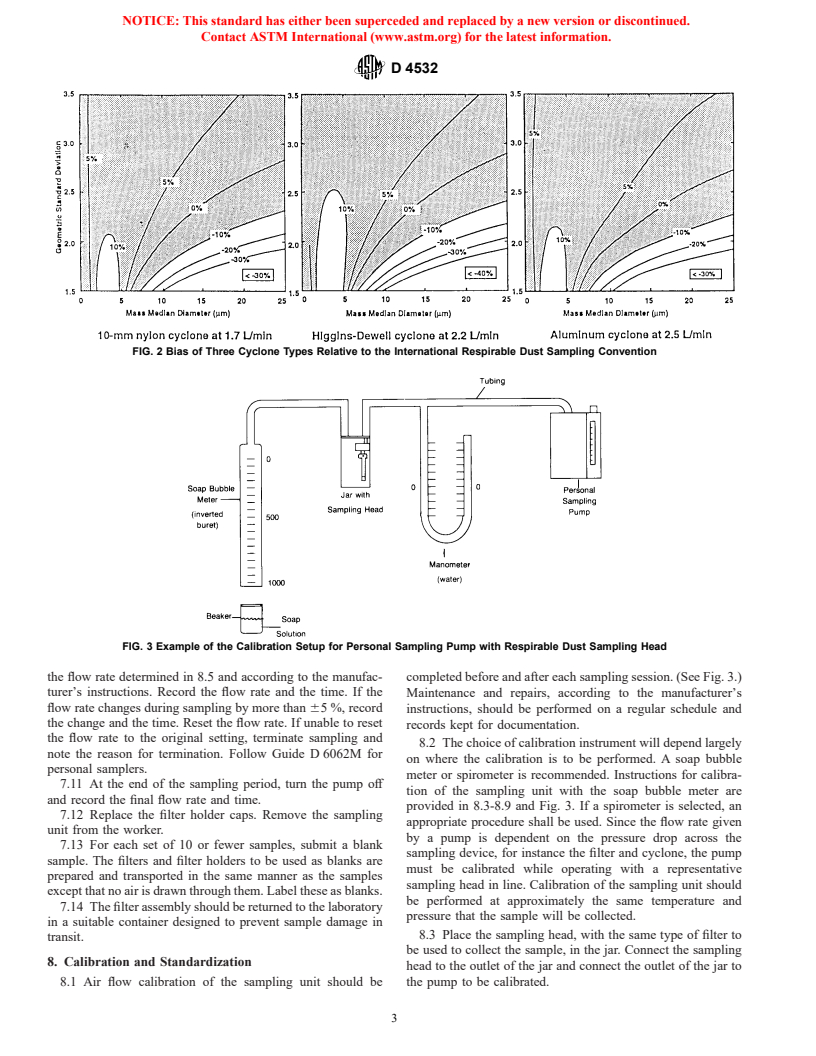

6.13 Jar, leakproof, of suitable size to contain the sampling

head during calibration of sampling system. (See and Fig. 3).

7. Sampling

7.1 Clean and inspect the interior of the cyclone. If the

inside surfaces are visibly scored, replace the cyclone since the

dust separation characteristics might be altered.

7.2 Condition all filters to a constant weight. Record the

filter weight.

7.3 Place the tared filter and filter support in the filter holder,

close firmly, and tape the circumference of the filter holder. If

necessary, use the press described in 6.8. Suitably cover the

assembly to avoid contamination if it is held for any time prior

to use.

7.4 Assemble sampling apparatus as shown in Fig. 1.

7.5 Run the pump for 5 min to stabilize the flow rate.

7.6 Remove the filter holder caps and connect the filter

holder to the cyclone as required by the manufacturer. Connect

the outlet of the sampling head to the pump’s inlet with a piece

of flexible tubing. Check to be sure all connections are free of

leaks by closing off the filter inlet. Flow should stop in 10 to 15

s.

FIG. 1 Example of Personal Sampler for Respirable Dust

7.7 Check the sampling unit for proper operation, check for

6.1.4 Charger—Pump batteries shall be completely charged

leaks, and measure the flow rate.

with appropriate charger following the manufacturer’s instruc-

7.8 Sample at 1.7 L/min for the Dorr-Oliver 10-mm cy-

tions or disposable batteries may be used.

clone, or as directed by manufacturer of specific cyclones.

6.1.5 Suitable means is provided for separately attaching the

Depending on sample load, consecutive samples over the shift

pump and the sampling head to the appropriate person.

may be required. However, the sampling time should not

6.2 Buret, capacity of 1 L, used as a soap bubble meter for

exceed the operating life of the batteries or the prevailing “full

calibration of the sampling unit.

shift.” The nominal sampling period is 8 h. Sampling times

6.3 Barometer, capable of measuring atmospheric pressure

shorter than a full shift are permitted if the following occurs:

to 60.1 kPa.

7.8.1 The pressure drop across the filter exceeds the pump’s

6.4 Stopwatch, capable of measuring to 60.1 s.

capabilities; that is, the filter becomes clogged.

6.5 Weighing Room, with temperature and humidity control

7.8.2 Specific working operations of shorter duration are to

to allow weighing with an analytical balance to 60.01 mg.

be investigated.

6.6 Analytical Balance, capable of weighing 60.01 mg or

7.8.3 Determinations of variations of the exposure during a

better. Particular care must be given to the proper zeroing of

shift are made.

the balance. The same analytical balance and weights must be

7.9 Attach the sampling head to the worker so that it is

used for weighing filters before and after sample collection.

located in the breathing zone. The worker’s breathing zone

6.7 Charge Neutralizer, to eliminate static charge in the

consists of a hemisphere 300-mm radius extending in front of

balance case and on the filters during weighing. Replace

the face, and measured from a line bisecting the ears. The

Po-210 neutralizers 9 months after production date.

sampling head shall be placed in such a manner to prevent dust

6.8 Plane-Parallel Press, capable of giving a force of at

from falling into it and to avoid restricting the inlet. The pump

least 1000 N (may be required if plastic filter holders are used

can be attached to the worker’s belt.

that must be pressed together after insertion of the filter).

7.10 Initiate sampling by turning the pump on and setting

6.9 Tapered Tube Flow Meter, with precision 62% or

better within the range of the flow rate used. Calibrate the

The sole source for the 10-mm nylon cyclone calibrating jar known to the

meter using Practice D 3195.

committee at this time is Fischer Scientific, 711 Forbes Ave. If you are aware of

6.10 Thermometer, dry bulb, 0 to 50°C with divisions every

alternative suppliers, please provide this information to ASTM Headquarters. Your

0.1°C. (ASTM thermometers number 90C and 91C.) (See

comments will receive careful consideration at a meeting of the responsible

Specification E 1.) technical committee which you may attend.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 4532

FIG. 2 Bias of Three Cyclone Types Relative to the International Respirable Dust Sampling Convention

FIG. 3 Example of the Calibration Setup for Personal Sampling Pump with Respirable Dust Sampling Head

the flow rate determined in 8.5 and according to the manufac- completed before and after each sampling session. (See Fig. 3.)

turer’s instructions. Record the flow rate and the time. If the Maintenance and repairs, according to the manufacturer’s

flow rate changes during sampling by more than 65 %, record

instructions, should be performed on a regular schedule and

the change and the time. Reset the flow rate. If unable to reset

records kept for documentation.

the flow rate to the original setting, terminate sampling and

8.2 The choice of calibration instrument will depend largely

note the reason for termination. Follow Guide D 6062M for

on where the calibration is to be performed. A soap bubble

personal samplers.

meter or spirometer is recommended. Instructions for calibra-

7.11 At the end of the sampling period, turn the pump off

tion of the sampling unit with the soap bub

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.