ASTM A941-03

(Terminology)Standard Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

Standard Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

SCOPE

1.1 This standard is a compilation of definitions of terms related to steel, stainless steel, related alloys, and ferroalloys.

1.2 When a term is used in an ASTM document for which Committee A01 is responsible, it is included herein only when judged, after review by Subcommittee A01.92, to be a generally usable term.

1.3 Some definitions include a discussion section, which is a mandatory part of the definition and contains additional information that is relevant to the meaning of the defined term.

1.4 Definitions of terms specific to a particular standard will appear in that standard and will supersede any definitions of identical terms in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 941 – 03

Terminology Relating to

1

Steel, Stainless Steel, Related Alloys, and Ferroalloys

This standard is issued under the fixed designation A 941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* manganese, but does not prescribe a minimum limit for

chromium, cobalt, molybdenum, nickel, niobium (colum-

1.1 This standard is a compilation of definitions of terms

bium), tungsten (wolfram), vanadium, or zirconium.

related to steel, stainless steel, related alloys, and ferroalloys.

1.2 When a term is used in an ASTM document for which

DISCUSSION—Except as required above, it is permissible for carbon

Committee A01 is responsible, it is included herein only when steel specifications to prescribe limits (minimum or maximum, or both)

for each specified alloying element, subject to the following restrictions

judged, after review by Subcommittee A01.92, to be a gener-

for the heat analysis limits in mass percent:

ally usable term.

(a) for wrought carbon steel products, the specified maximum limit is

1.3 Some definitions include a discussion section, which is

not to exceed: 0.10 for aluminum, 0.60 for silicon, and 0.050 for

a mandatory part of the definition and contains additional

titanium;

information that is relevant to the meaning of the defined term.

(b) for carbon steel castings, the specified maximum limit is not to

1.4 Definitions of terms specific to a particular standard will

exceed: 0.10 for aluminum, 1.00 for silicon, and 0.050 for titanium.

appear in that standard and will supersede any definitions of (c) for carbon steels that are required to be rephosphorized, the

specified minimum limit for phosphorus is not to be less than 0.040;

identical terms in this standard.

(d) for carbon steels that are required to be resulfurized, the specified

minimum limit for sulfur is not to be less than 0.060;

2. Referenced Documents

(e) for carbon steels that are not required to be rephosphorized or

2.1 ASTM Standards:

resulfurized, the specified maximum limit is not to exceed: 0.60 for

2

E 112 Test Methods for Determining Average Grain Size

copper, 0.050 for phosphorus, and 0.060 for sulfur; and

(f) for carbon steels that are required to contain boron, copper, or lead,

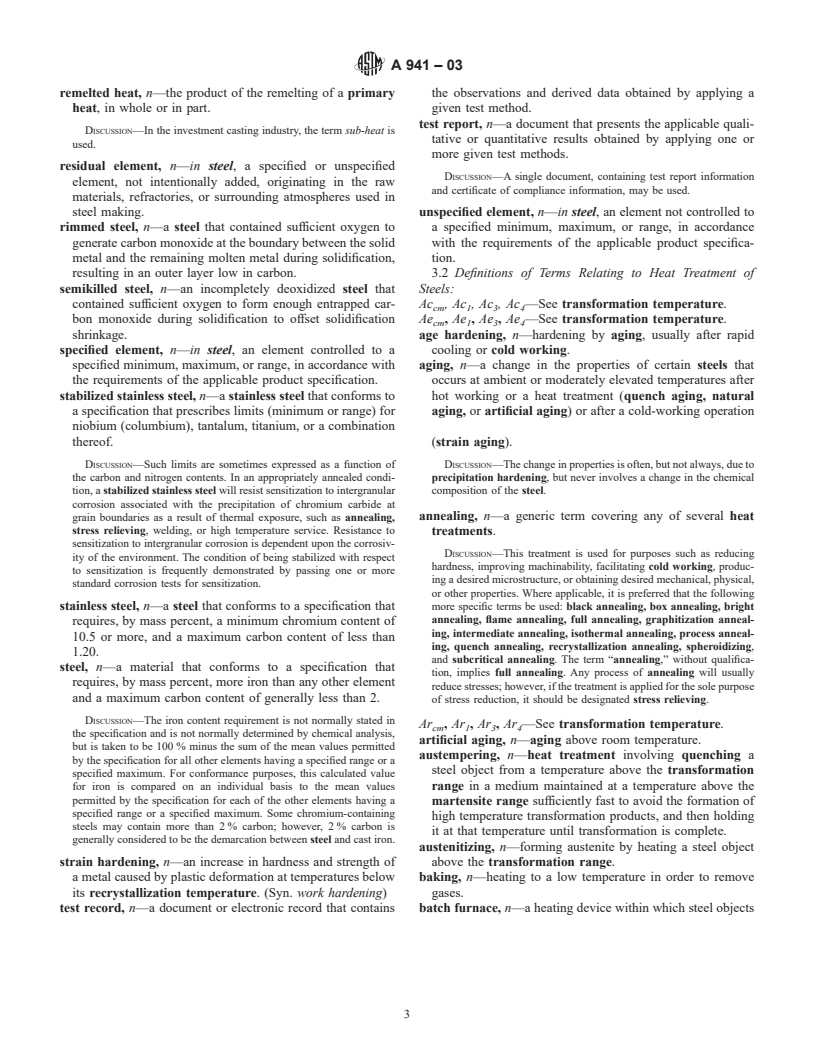

3. Terminology

the specified minimum limit is not to exceed: 0.0005 for boron, 0.35 for

copper, and 0.25 for lead.

3.1 Definitions of General Terms:

cast analysis—Deprecated term. Use the preferred term heat

alloy steel, n—a steel, other than a stainless steel, that

analysis.

conforms to a specification that requires one or more of the

certificate of compliance, n—in manufactured products,a

following elements, by mass percent, to have a minimum

document that states that the product was manufactured,

content equal to or greater than: 0.30 for aluminum; 0.0008

sampled, tested, and inspected in accordance with the

for boron; 0.30 for chromium; 0.30 for cobalt; 0.40 for

requirements of the specification (including year of issue)

copper; 0.40 for lead; 1.65 for manganese; 0.08 for molyb-

and any other requirements specified in the purchase order or

denum; 0.30 for nickel; 0.06 for niobium (columbium); 0.60

contract, and has been found to meet such requirements.

for silicon; 0.05 for titanium; 0.30 for tungsten (wolfram);

0.10 for vanadium; 0.05 for zirconium; or 0.10 for any other

DISCUSSION—A single document, containing test report information

alloying element, except sulphur, phosphorus, carbon, and

and certificate of compliance information, may be used.

nitrogen.

certifying organization, n—in product specifications, the

capped steel, n—a rimmed steel in which, during ingot

entity responsible for the conformance and certification of

solidification, the rimming action was limited by mechanical

the product to the specification requirements.

or chemical means.

coarse grain practice, n—a steelmaking practice for other

carbon steel, n—a steel that conforms to a specification that

than stainless steel that is intended to produce a killed steel

prescribes a maximum limit, by heat analysis in mass

in which aluminum, niobium (columbium), titanium, and

percent, of not more than: 2.00 for carbon and 1.65 for

vanadium are residual elements.

cold working, n—mechanical deformation of a metal at

1

This terminology is under the jurisdiction of ASTM Committee A01 on Steel, temperatures below its recrystallization temperature.

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

defect, n—an imperfection of sufficient magnitude to warrant

A01.92 on Terminology.

rejection based on the specified requirements.

Current edition approved July

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.