ASTM E751-01

(Practice)Standard Practice for Acoustic Emission Monitoring During Resistance Spot-Welding

Standard Practice for Acoustic Emission Monitoring During Resistance Spot-Welding

SCOPE

1.1 This practice describes procedures for the measurement, processing, and interpretation of the acoustic emission (AE) response associated with selected stages of the resistance spot-welding process.

1.2 This practice also provides guidelines for feedback control by utilizing the measured AE response signals during the spot-welding process.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E751–01

Standard Practice for

Acoustic Emission Monitoring During Resistance Spot-

1

Welding

This standard is issued under the fixed designation E 751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice describes procedures for the measurement, 4.1 The AE produced during the production of a spot-weld

processing, and interpretation of the acoustic emission (AE) can be related to weld quality parameters such as the strength

response associated with selected stages of the resistance and size of the nugget, the amount of expulsion, and the

spot-welding process. amount of cracking. Therefore, in-process AE monitoring can

1.2 This practice also provides guidelines for feedback be used both as an examination method, and as a means for

control by utilizing the measured AE response signals during providing feedback control.

the spot-welding process.

5. Basis of Application

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 5.1 Personnel Qualification—

5.1.1 If specified in the contractual agreement, personnel

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- performing examinations to this standard shall be qualified in

accordance with a nationally recognized NDT personnel quali-

bility of regulatory limitations prior to use.

fication practice or standard such as ANSI/ASNT CP-189,

2. Referenced Documents

SNT-TC-1A, MIL-STD-410, NAS-410 or a similar document

2.1 ASTM Standards: and certified by the employer or certifying agency, as appli-

E 543 Practice for Agencies Performing Nondestructive cable. The practice or standard used and its applicable revision

2

Testing shall be specified in the contractual agreement between the

2

E 1316 Terminology for Nondestructive Examinations using parties.

3

2.2 ASNT Standards: 5.2 Qualification of Nondestructive Agencies—If specified

SNT-TC-1A Recommended Practice for Nondestructive in the contractual agreement, NDT agencies shall be qualified

Testing Personnel Qualification and Certification and evaluated in accordance with Practice E 543. The appli-

ANSI/ASNT CP-189 Standard for Qualification and Certi- cable edition of Practice E 543 shall be specified in the

fication of Nondestructive Testing Personnel contractual agreement.

2.3 Military Standard: 5.3 Procedures and Techniques—The procedures and tech-

MIL-STD-410 Nondestructive Testing Personnel Qualifica- niques to be used shall be as described in this practice unless

4

tion and Certification otherwisespecified.Specifictechniquesmaybespecifiedinthe

contractual agreement.

3. Terminology

6. Ordering Information

3.1 Definitions—Fordefinitionsoftermsrelatingtoacoustic

emission testing, see Section B of Terminology E 1316. 6.1 If the spot-weld monitoring or process control methods

described in this practice are performed as a service, the

following items should be addressed in the purchase specifi-

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

cation, and are subject to agreement between the purchaser and

structive Testing and is the direct responsibility of Subcommittee E07.04 on

the supplier:

Acoustic Emission.

Current edition approved July 10, 2001. Published September 2001. Originally 6.1.1 Description of the welded parts in terms of geometry,

published as E 751 – 80. Last previous edition E 751 – 96.

dimensions, number and position of welds, and materials.

2

Annual Book of ASTM Standards, Vol 03.03.

3

Available from American Society for Nondestructive Testing, 1711 Arlingate

Plaza, P.O. Box 28518, Columbus, OH 43228-0518.

4

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E751–01

6.1.2 Description of the welding machine, type and dimen- current initiation can be related to the initial resistance, and the

sions of the electrodes, type of weld controller, welding cleanliness of the part. For example, burning through of certain

schedule, and distance between the welding head and the oxide layers contributes to the acoustic emission response

controller. during this time.

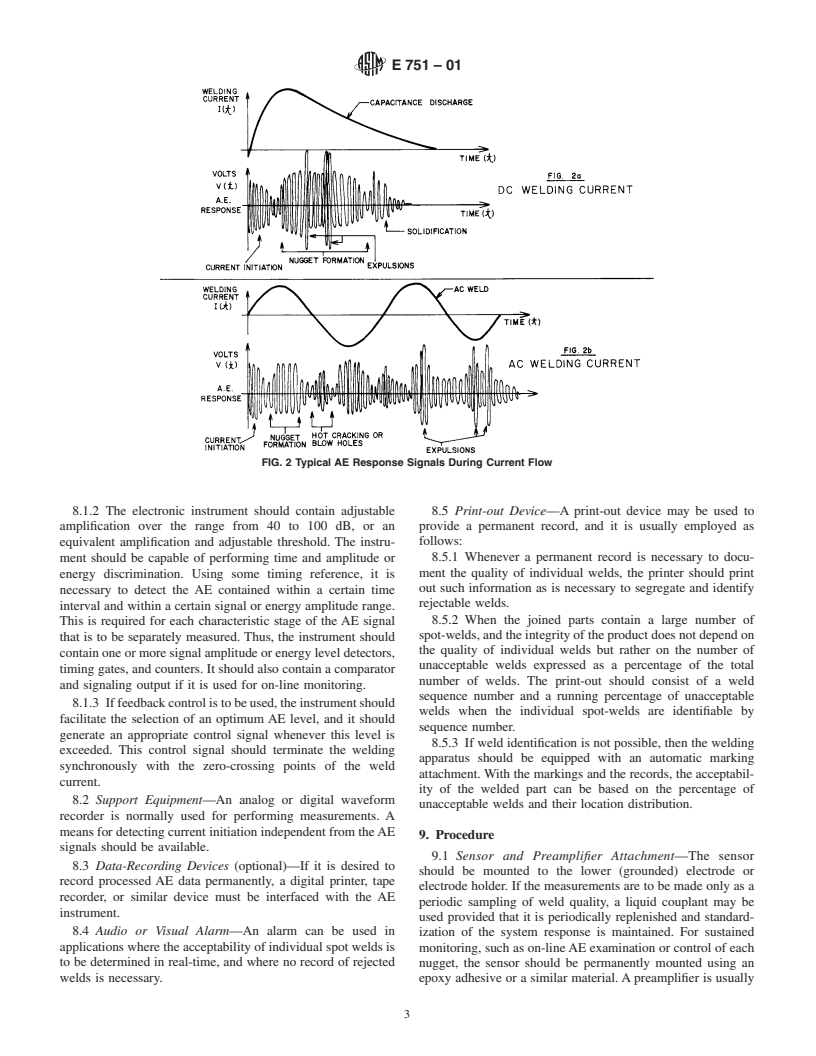

6.1.3 Location and mounting method for the acoustic emis- 7.2.1 During current flow, plastic deformation, nugget ex-

sion sensors, and design of the mounting fixture, as appropri- pansion, friction, melting,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.