ASTM D7414-09

(Test Method)Standard Test Method for Condition Monitoring of Oxidation in In-Service Petroleum and Hydrocarbon Based Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry

Standard Test Method for Condition Monitoring of Oxidation in In-Service Petroleum and Hydrocarbon Based Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry

SIGNIFICANCE AND USE

A large number of compounds, such as aldehydes, ketones, esters, and carboxylic acids, are produced when oils react with atmospheric oxygen. Oxidation is measured using a common FT-IR spectral feature between 1800 and 1670 cm-1 caused by the absorption of the carbonyl group present in most oxidation compounds. These oxidation products may lead to increased viscosity (causing oil thickening problems), acidity (causing acidic corrosion), and formation of sludge and varnish (leading to filter plugging, fouling of critical oil clearances and valve friction). Monitoring of oxidation products is therefore an important parameter in determining overall machinery health and should be considered in conjunction with data from other tests such as atomic emission (AE) and atomic absorption (AA) spectroscopy for wear metal analysis (Test Method D 5185), physical property tests (Test Methods D 445 and D 6304), base reserve (Test Method D 2896 and D 4739), acid number tests (Test Methods D 664 and D 974) and other FT-IR oil analysis methods for nitration (Practice E 2412), sulfate by-products (Test Method D 7415), additive depletion (Test Method D 7412), breakdown products and external contaminants (Practice E 2412), which also assess elements of the oil’s condition, see Refs (1-6).

SCOPE

1.1 This test method covers monitoring oxidation in in-service petroleum and hydrocarbon based lubricants such as in diesel crankcase, motor, hydraulic, gear and compressor oils, as well as other types of lubricants that are prone to oxidation.

1.2 This test method uses Fourier Transform Infrared (FT-IR) spectrometry for monitoring build-up of oxidation products in in-service petroleum and hydrocarbon based lubricants as a result of normal machinery operation. Petroleum and hydrocarbon based lubricants react with oxygen in the air to form a number of different chemical species, including aldehydes, ketones, esters, and carboxylic acids. This test method is designed as a fast, simple spectroscopic check for monitoring of oxidation in in-service petroleum and hydrocarbon based lubricants with the objective of helping diagnose the operational condition of the machine based on measuring the level of oxidation in the oil.

1.3 Acquisition of FT-IR spectral data for measuring oxidation in in-service oil and lubricant samples is described in Practice D 7418. In this test method, measurement and data interpretation parameters for oxidation using both direct trend analysis and differential (spectral subtraction) trend analysis are presented.

1.4 This test method is based on trending of spectral changes associated with oxidation of in-service petroleum and hydrocarbon based lubricants. Warnings or alarm limits can be set on the basis of a fixed minimum value for a single measurement or, alternatively, can be based on a rate of change of the response measured, see Ref (1).

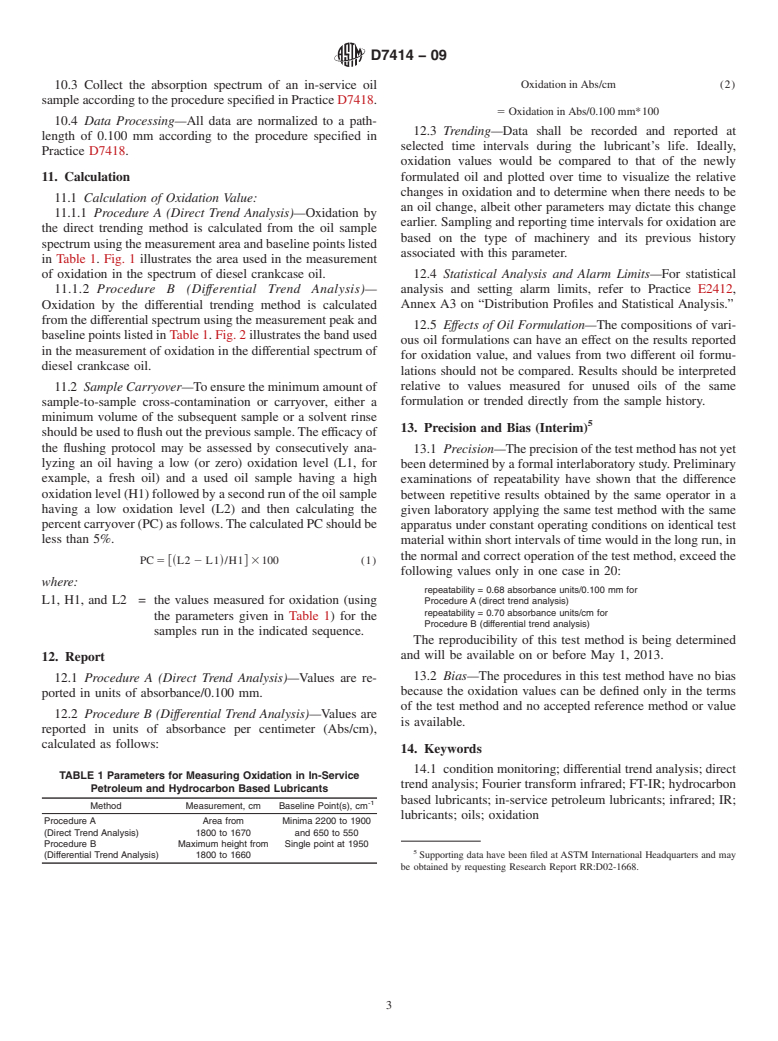

1.4.1 For direct trend analysis, values are recorded directly from absorption spectra and reported in units of absorbance per 0.1 mm pathlength.

1.4.2 For differential trend analysis, values are recorded from the differential spectra (spectrum obtained by subtraction of the absorption spectrum of the reference oil from that of the in-service oil) and reported in units of 100*absorbance per 0.1 mm pathlength (or equivalently absorbance units per centimetre).

1.4.3 In either case, maintenance action limits should be determined through statistical analysis, history of the same or similar equipment, round robin tests or other methods in conjunction with the correlation of oxidation changes to equipment performance.

Note 1—It is not the intent of this test method to establish or recommend normal, cautionary, warning or alert limits for any machinery. Such limits should be established in conjunction with advice and guidance from the machinery manufacturer and maintenance group.

1.5 This test method is for petroleum and hydrocarbon based lubricants and is...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7414 − 09

Standard Test Method for

Condition Monitoring of Oxidation in In-Service Petroleum

and Hydrocarbon Based Lubricants by Trend Analysis

1

Using Fourier Transform Infrared (FT-IR) Spectrometry

This standard is issued under the fixed designation D7414; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4.2 For differential trend analysis, values are recorded

from the differential spectra (spectrum obtained by subtraction

1.1 This test method covers monitoring oxidation in in-

of the absorption spectrum of the reference oil from that of the

service petroleum and hydrocarbon based lubricants such as in

in-service oil) and reported in units of 100*absorbance per 0.1

diesel crankcase, motor, hydraulic, gear and compressor oils,

mm pathlength (or equivalently absorbance units per centime-

as well as other types of lubricants that are prone to oxidation.

tre).

1.2 This test method uses Fourier Transform Infrared (FT-

1.4.3 In either case, maintenance action limits should be

IR)spectrometryformonitoringbuild-upofoxidationproducts

determined through statistical analysis, history of the same or

in in-service petroleum and hydrocarbon based lubricants as a

similar equipment, round robin tests or other methods in

result of normal machinery operation. Petroleum and hydro-

conjunction with the correlation of oxidation changes to

carbon based lubricants react with oxygen in the air to form a

equipment performance.

number of different chemical species, including aldehydes,

NOTE 1—It is not the intent of this test method to establish or

ketones, esters, and carboxylic acids. This test method is

recommend normal, cautionary, warning or alert limits for any machinery.

designed as a fast, simple spectroscopic check for monitoring

Suchlimitsshouldbeestablishedinconjunctionwithadviceandguidance

of oxidation in in-service petroleum and hydrocarbon based

from the machinery manufacturer and maintenance group.

lubricants with the objective of helping diagnose the opera-

1.5 This test method is for petroleum and hydrocarbon

tionalconditionofthemachinebasedonmeasuringthelevelof

based lubricants and is not applicable for ester based oils,

oxidation in the oil.

including polyol esters or phosphate esters.

1.3 Acquisition of FT-IR spectral data for measuring oxida-

1.6 The values stated in SI units are to be regarded as

tion in in-service oil and lubricant samples is described in

standard. No other units of measurement are included in this

Practice D7418. In this test method, measurement and data

standard.

interpretation parameters for oxidation using both direct trend

-1

1.6.1 Exception—The unit for wave numbers is cm .

analysis and differential (spectral subtraction) trend analysis

1.7 This standard does not purport to address all of the

are presented.

safety concerns, if any, associated with its use. It is the

1.4 This test method is based on trending of spectral

responsibility of the user of this standard to establish appro-

changes associated with oxidation of in-service petroleum and

priate safety and health practices and determine the applica-

hydrocarbon based lubricants. Warnings or alarm limits can be

bility of regulatory limitations prior to use.

set on the basis of a fixed minimum value for a single

measurement or, alternatively, can be based on a rate of change

2. Referenced Documents

2

of the response measured, see Ref (1).

3

2.1 ASTM Standards:

1.4.1 For direct trend analysis, values are recorded directly

D445 Test Method for Kinematic Viscosity of Transparent

fromabsorptionspectraandreportedinunitsofabsorbanceper

and Opaque Liquids (and Calculation of Dynamic Viscos-

0.1 mm pathlength.

ity)

D664 Test Method for Acid Number of Petroleum Products

1

This test method is under the jurisdiction of ASTM Committee D02 on by Potentiometric Titration

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.96.03 on FTIR Testing Practices and Techniques Related to

In-Service Lubricants.

3

Current edition approved July 1, 2009. Published August 2009. DOI: 10.1520/ For referenced ASTM standards, visit the ASTM website, www.astm.org, or

D7414-09. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Pag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.