ASTM E1495-97

(Guide)Standard Guide for Acousto-Ultrasonic Assessment of Composites, Laminates, and Bonded Joints

Standard Guide for Acousto-Ultrasonic Assessment of Composites, Laminates, and Bonded Joints

SCOPE

1.1 This guide explains the rationale and basic technology for the acousto-ultrasonic (AU) method. Guidelines are given for nondestructive evaluation (NDE) of flaws and physical characteristics that influence the mechanical properties and relative strength of composite structures (for example, filament-wound pressure vessels), adhesive bonds (for example, joints between metal plates), and interlaminar and fiber/matrix bonds in man-made composites and natural composites (for example, wood products).

1.2 This guide covers technical details and rules that must be observed to ensure reliable and reproducible quantitative AU assessments of laminates, composites, and bonded structures. The underlying principles, prototype apparatus, instrumentation, calibration, testing methods, and data analysis for such assessments are covered. Limitations of the AU method and guidelines for taking advantage of its capabilities are cited.

1.3 The objective of AU is to assess subtle flaws and associated strength variations in composite structures and bonded joints. Discontinuities such as large voids, disbonds, or extended lack of contact at interfaces can be assessed by other NDE methods such as conventional ultrasonics.

1.4 Additional information may be found in the publications cited in the list of references at the end of this guide. The referenced works provide background on research, applications, and various aspects of signal acquisition, processing, and interpretation.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: E 1495 – 97

Standard Guide for

Acousto-Ultrasonic Assessment of Composites, Laminates,

1

and Bonded Joints

This standard is issued under the fixed designation E 1495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

2

1. Scope E 1316 Terminology for Nondestructive Examinations

2.2 ASNT Standard:

1.1 This guide explains the rationale and basic technology

Practice SNT-TC-1A Personnel Qualifications and Certifi-

for the acousto-ultrasonic (AU) method. Guidelines are given

3

cation in Nondestructive Testing

for nondestructive evaluation (NDE) of flaws and physical

characteristics that influence the mechanical properties and

3. Terminology

relative strength of composite structures (for example,

3.1 Definitions:

filament-wound pressure vessels), adhesive bonds (for ex-

3.1.1 acousto-ultrasonics (AU)—a nondestructive examina-

ample, joints between metal plates), and interlaminar and

tion method that uses induced stress waves to detect and assess

fiber/matrix bonds in man-made composites and natural com-

the diffuse defect states, damage conditions, and variations of

posites (for example, wood products).

mechanical properties of a test structure. The AU method

1.2 This guide covers technical details and rules that must

combines aspects of acoustic emission (AE) signal analysis

be observed to ensure reliable and reproducible quantitative

with ultrasonic materials characterization methods (Terminol-

AU assessments of laminates, composites, and bonded struc-

ogy E 1316).

tures. The underlying principles, prototype apparatus, instru-

3.1.2 Additional related definitions may be found in Termi-

mentation, calibration, testing methods, and data analysis for

nology E 1316.

such assessments are covered. Limitations of the AU method

3.2 Definitions of Terms Specific to This Standard:

and guidelines for taking advantage of its capabilities are cited.

3.2.1 stress wave factor (SWF)—a generic measure of the

1.3 The objective of AU is to assess subtle flaws and

relative energy loss (attenuation) or propagation efficiency of

associated strength variations in composite structures and

stress waves generated by the AU method. There are many

bonded joints. Discontinuities such as large voids, disbonds, or

ways to define and calculate the SWF. Several of these are

extended lack of contact at interfaces can be assessed by other

described in Section 11 of this guide.

NDE methods such as conventional ultrasonics.

1.4 Additional information may be found in the publications

4. Summary of Guide

cited in the list of references at the end of this guide. The

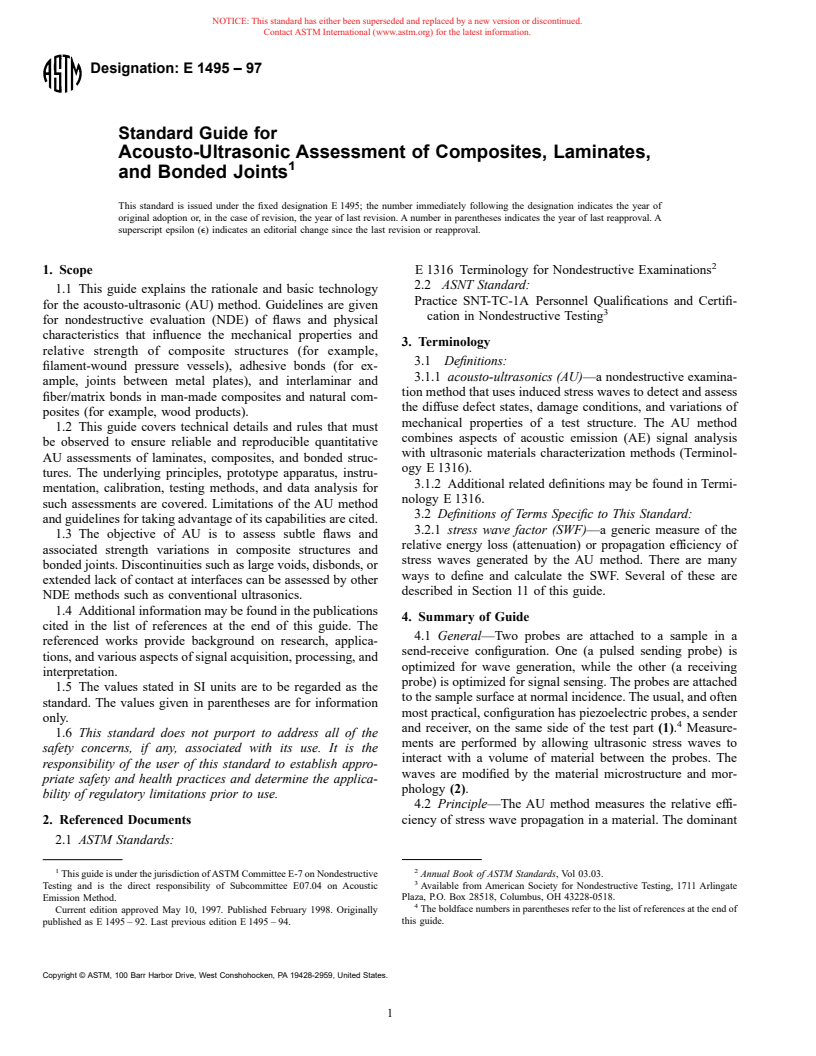

4.1 General—Two probes are attached to a sample in a

referenced works provide background on research, applica-

send-receive configuration. One (a pulsed sending probe) is

tions, and various aspects of signal acquisition, processing, and

optimized for wave generation, while the other (a receiving

interpretation.

probe) is optimized for signal sensing. The probes are attached

1.5 The values stated in SI units are to be regarded as the

to the sample surface at normal incidence. The usual, and often

standard. The values given in parentheses are for information

most practical, configuration has piezoelectric probes, a sender

only.

4

and receiver, on the same side of the test part (1). Measure-

1.6 This standard does not purport to address all of the

ments are performed by allowing ultrasonic stress waves to

safety concerns, if any, associated with its use. It is the

interact with a volume of material between the probes. The

responsibility of the user of this standard to establish appro-

waves are modified by the material microstructure and mor-

priate safety and health practices and determine the applica-

phology (2).

bility of regulatory limitations prior to use.

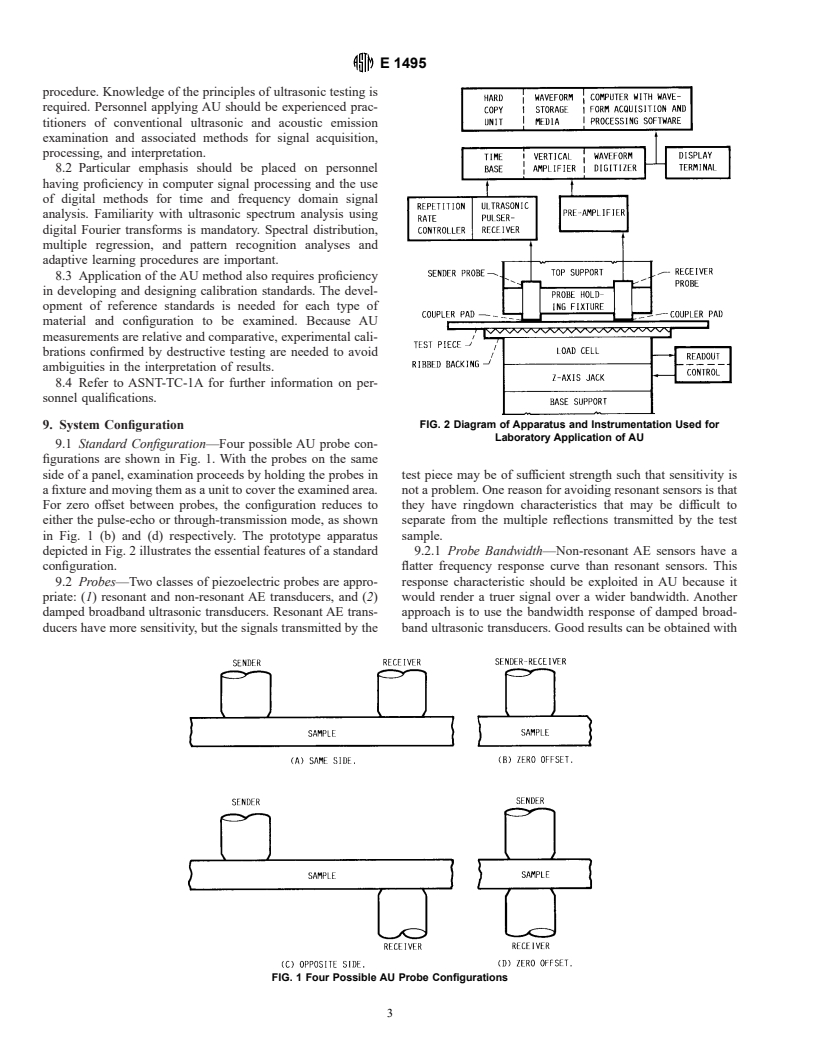

4.2 Principle—The AU method measures the relative effi-

ciency of stress wave propagation in a material. The dominant

2. Referenced Documents

2.1 ASTM Standards:

1 2

This guide is under the jurisdiction of ASTM Committee E-7 on Nondestructive Annual Book of ASTM Standards, Vol 03.03.

3

Testing and is the direct responsibility of Subcommittee E07.04 on Acoustic Available from American Society for Nondestructive Testing, 1711 Arlingate

Emission Method. Plaza, P.O. Box 28518, Columbus, OH 43228-0518.

4

Current edition approved May 10, 1997. Published February 1998. Originally The boldface numbers in parentheses refer to the list of references at the end of

published as E 1495 – 92. Last previous edition E 1495 – 94. this guide.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 1495

attribute measured is stress wave attenuation. Lower attenua- coupling with elastomer pads attached to the pro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.