ASTM F1437-01

(Practice)Standard Practice for Inclined Cargo Tank Ladders

Standard Practice for Inclined Cargo Tank Ladders

SCOPE

1.1 This practice provides design, construction, and installation criteria for inclined ladders to be installed within cargo tanks.

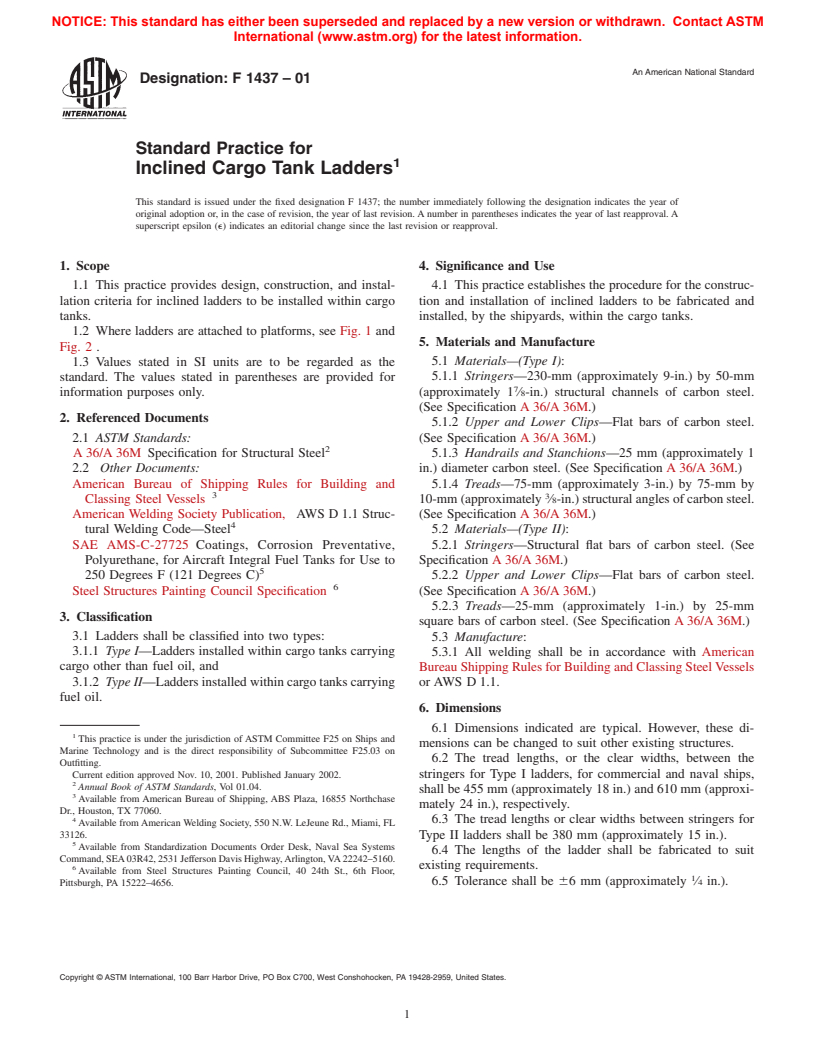

1.2 Where ladders are attached to platforms, see Figs. 1 and 2.

1.3 Values stated in SI units are to be regarded as the standard. The values stated in parentheses are provided for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation: F 1437 – 01

Standard Practice for

1

Inclined Cargo Tank Ladders

This standard is issued under the fixed designation F 1437; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice provides design, construction, and instal- 4.1 This practice establishes the procedure for the construc-

lation criteria for inclined ladders to be installed within cargo tion and installation of inclined ladders to be fabricated and

tanks. installed, by the shipyards, within the cargo tanks.

1.2 Where ladders are attached to platforms, see Fig. 1 and

5. Materials and Manufacture

Fig. 2 .

5.1 Materials—(Type I):

1.3 Values stated in SI units are to be regarded as the

standard. The values stated in parentheses are provided for 5.1.1 Stringers—230-mm (approximately 9-in.) by 50-mm

7

(approximately 1 ⁄8-in.) structural channels of carbon steel.

information purposes only.

(See Specification A 36/A 36M.)

2. Referenced Documents

5.1.2 Upper and Lower Clips—Flat bars of carbon steel.

2.1 ASTM Standards: (See Specification A 36/A 36M.)

2

A 36/A 36M Specification for Structural Steel 5.1.3 Handrails and Stanchions—25 mm (approximately 1

2.2 Other Documents: in.) diameter carbon steel. (See Specification A 36/A 36M.)

American Bureau of Shipping Rules for Building and 5.1.4 Treads—75-mm (approximately 3-in.) by 75-mm by

3

3

Classing Steel Vessels 10-mm (approximately ⁄8-in.) structural angles of carbon steel.

American Welding Society Publication, AWS D 1.1 Struc- (See Specification A 36/A 36M.)

4

tural Welding Code—Steel 5.2 Materials—(Type II):

SAE AMS-C-27725 Coatings, Corrosion Preventative, 5.2.1 Stringers—Structural flat bars of carbon steel. (See

Polyurethane, for Aircraft Integral Fuel Tanks for Use to Specification A 36/A 36M.)

5

250 Degrees F (121 Degrees C) 5.2.2 Upper and Lower Clips—Flat bars of carbon steel.

6

Steel Structures Painting Council Specification (See Specification A 36/A 36M.)

5.2.3 Treads—25-mm (approximately 1-in.) by 25-mm

3. Classification

square bars of carbon steel. (See Specification A 36/A 36M.)

3.1 Ladders shall be classified into two types:

5.3 Manufacture:

3.1.1 Type I—Ladders installed within cargo tanks carrying 5.3.1 All welding shall be in accordance with American

cargo other than fuel oil, and

Bureau Shipping Rules for Building and Classing SteelVessels

3.1.2 TypeII—Ladders installed within cargo tanks carrying or AWS D 1.1.

fuel oil.

6. Dimensions

6.1 Dimensions indicated are typical. However, these di-

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

mensions can be changed to suit other existing structures.

Marine Technology and is the direct responsibility of Subcommittee F25.03 on

6.2 The tread lengths, or the clear widths, between the

Outfitting.

Current edition approved Nov. 10, 2001. Published January 2002. stringers for Type I ladders, for commercial and naval ships,

2

Annual Book of ASTM Standards, Vol 01.04.

shall be 455 mm (approximately 18 in.) and 610 mm (approxi-

3

Available from American Bureau of Shipping, ABS Plaza, 16855 Northchase

mately 24 in.), respectively.

Dr., Houston, TX 77060.

4

6.3 The tread lengths or clear widths between stringers for

Available from American Welding Society, 550 N.W. LeJeune Rd., Miami, FL

33126.

Type II ladders shall be 380 mm (approximately 15 in.).

5

Available from Standardization Documents Order Desk, Naval Sea Systems

6.4 The lengths of the ladder shall be fabricated to suit

Command,SEA03R42,2531JeffersonDavisHighway,Arlington,VA22242–5160.

6 existing requirements.

Available from Steel Structures Painting Council, 40 24th St., 6th Floor,

1

6.5 Tolerance shall be 66 mm (approximately ⁄4 in.).

Pittsburgh, PA 15222–4656.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F 1437 – 01

FIG. 1 Type I Ladder Elevation

6.6 Type I ladders shall have the following dimensions: matelyequaltothenormaltreadspacing;andthedistancefrom

installed angle: 50 to 69° from the horizontal; tread depth: 175 the bottom tread to the lower walking surface is not to exceed

to 250 mm (approximately 7 to 10 in.) at 50°, tapering to 75 375 mm (approximately 15 in.).

mm (approximately 3 in.) at 69°; riser height 175 to 300 mm

7. Workmanship, Finish, and Appearance

1

(approximately 7 to 12 i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.