ASTM C1243-93(2015)e2

(Test Method)Standard Test Method for Relative Resistance to Deep Abrasive Wear of Unglazed Ceramic Tile by Rotating Disc

Standard Test Method for Relative Resistance to Deep Abrasive Wear of Unglazed Ceramic Tile by Rotating Disc

SIGNIFICANCE AND USE

4.1 This test method provides the means to measure the potential resistance to wear of unglazed ceramic tile intended for floor coverings. This test method does not consider physical appearance but is intended to measure durability. See Test Method C1027 for the determination of visible abrasion resistance of glazed ceramic tile.

4.1.1 See Test Method C501 for an alternative method to determine deep abrasion.

SCOPE

1.1 This test method covers the deep abrasive wear by measuring the loss of volume resulting from abrasion of unglazed ceramic tile under given conditions by means of a rotating disc and the use of abrasive material.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´2

Designation:C1243 −93 (Reapproved 2015)

Standard Test Method for

Relative Resistance to Deep Abrasive Wear of Unglazed

Ceramic Tile by Rotating Disc

This standard is issued under the fixed designation C1243; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected Eq 1 editorially in Nov. 2019.

1. Scope 3. Terminology

1.1 This test method covers the deep abrasive wear by 3.1 Definitions:

measuring the loss of volume resulting from abrasion of 3.1.1 For definitions of terms used in this test method, see

unglazed ceramic tile under given conditions by means of a Terminology C242.

rotating disc and the use of abrasive material.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 4.1 This test method provides the means to measure the

standard. potential resistance to wear of unglazed ceramic tile intended

forfloorcoverings.Thistestmethoddoesnotconsiderphysical

1.3 This standard does not purport to address all of the

appearance but is intended to measure durability. See Test

safety concerns, if any, associated with its use. It is the

Method C1027 for the determination of visible abrasion

responsibility of the user of this standard to establish appro-

resistance of glazed ceramic tile.

priate safety, health, and environmental practices and deter-

4.1.1 See Test Method C501 for an alternative method to

mine the applicability of regulatory limitations prior to use.

determine deep abrasion.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Apparatus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

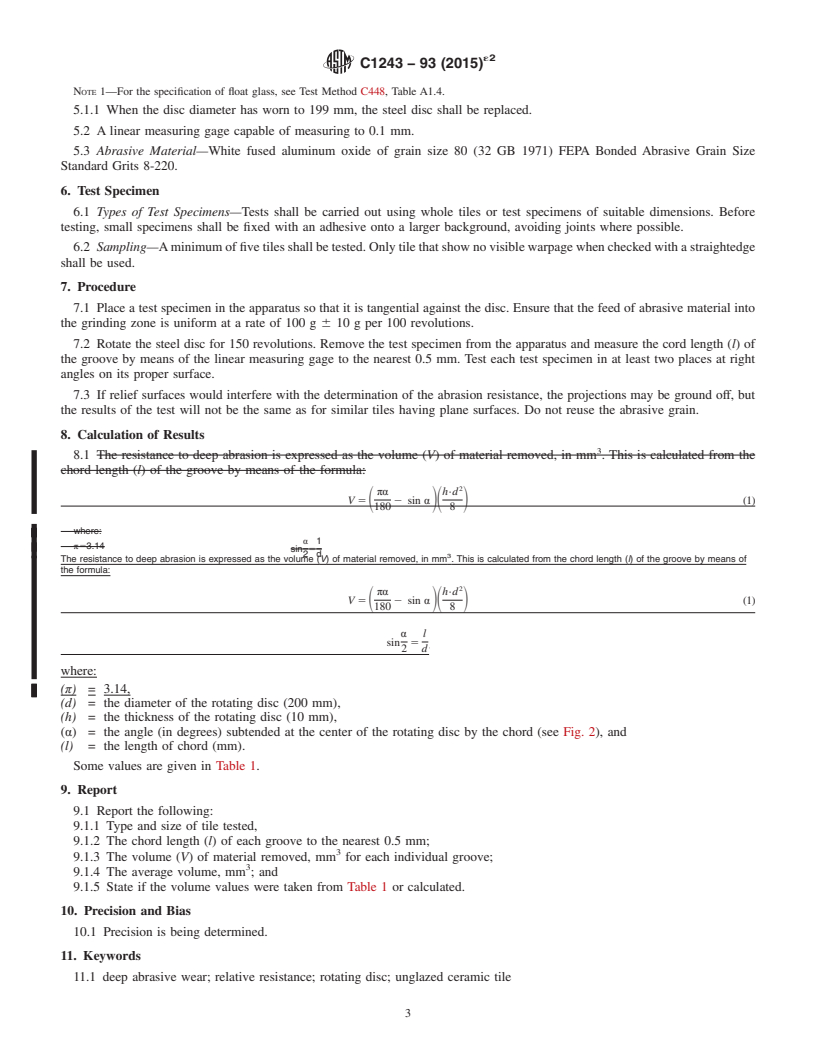

5.1 Abrasion apparatus (see Fig. 1) consisting essentially of

mendations issued by the World Trade Organization Technical

a rotating disc, a storage hopper with a dispensing device for

Barriers to Trade (TBT) Committee.

the abrasive material, a test specimen support, and a counter-

weight.ThediscismadeofFe360Asteel(ISO630-1980)with

2. Referenced Documents

a diameter of 200 6 0.2 mm and thickness at the edge of 10 6

0.1 mm, and with a rate of revolution of 75 r/min.The pressure

2.1 ASTM Standards:

with which test specimens are held against the steel disc is

C242 Terminology of Ceramic Whitewares and Related

determined by calibrating the apparatus against float glass

Products

(bathside). The pressure is adjusted such that, after 150

C448 Test Methods for Abrasion Resistance of Porcelain

revolutions, a chord of 24 6 0.5 mm is produced.

Enamels

C501 Test Method for Relative Resistance to Wear of

NOTE 1—For the specification of float glass, see Test Method C448,

Unglazed Ceramic Tile by the Taber Abraser

Table A1.4.

C1027 Test Method for Determining Visible Abrasion Re-

5.1.1 When the disc diameter has worn to 199 mm, the steel

sistance of Glazed Ceramic Tile

disc shall be replaced.

5.2 A linear measuring gage capable of measuring to 0.1

1 mm.

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Whitewares and Related Productsand is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile.

Current edition approved Dec. 15, 2015. Published December 2015. Originally

approved in 1993. Last previous edition approved in 2015 as C1243 – 93 (2015). The sole source of supply of the apparatus known to the committee at this time

DOI: 10.1520/C1243-93R15E02. is Gabrielli S.R.L., Box 218, 50019 Sesto Florentino, Florence, Italy, Fax:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 55-42-15-654. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

theASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

C1243−93 (2015)

7.2 Rotate the steel disc for 150 revolutions. Remove the

t

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´2

Designation: C1243 − 93 (Reapproved 2015)

Standard Test Method for

Relative Resistance to Deep Abrasive Wear of Unglazed

Ceramic Tile by Rotating Disc

This standard is issued under the fixed designation C1243; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected Eq 1 editorially in Nov. 2019.

1. Scope 3. Terminology

1.1 This test method covers the deep abrasive wear by 3.1 Definitions:

measuring the loss of volume resulting from abrasion of 3.1.1 For definitions of terms used in this test method, see

unglazed ceramic tile under given conditions by means of a Terminology C242.

rotating disc and the use of abrasive material.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 4.1 This test method provides the means to measure the

standard. potential resistance to wear of unglazed ceramic tile intended

for floor coverings. This test method does not consider physical

1.3 This standard does not purport to address all of the

appearance but is intended to measure durability. See Test

safety concerns, if any, associated with its use. It is the

Method C1027 for the determination of visible abrasion

responsibility of the user of this standard to establish appro-

resistance of glazed ceramic tile.

priate safety, health, and environmental practices and deter-

4.1.1 See Test Method C501 for an alternative method to

mine the applicability of regulatory limitations prior to use.

determine deep abrasion.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Apparatus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.1 Abrasion apparatus (see Fig. 1) consisting essentially of

mendations issued by the World Trade Organization Technical

a rotating disc, a storage hopper with a dispensing device for

Barriers to Trade (TBT) Committee.

the abrasive material, a test specimen support, and a counter-

weight. The disc is made of Fe 360A steel (ISO 630-1980) with

2. Referenced Documents

a diameter of 200 6 0.2 mm and thickness at the edge of 10 6

0.1 mm, and with a rate of revolution of 75 r/min. The pressure

2.1 ASTM Standards:

with which test specimens are held against the steel disc is

C242 Terminology of Ceramic Whitewares and Related

determined by calibrating the apparatus against float glass

Products

(bathside). The pressure is adjusted such that, after 150

C448 Test Methods for Abrasion Resistance of Porcelain

revolutions, a chord of 24 6 0.5 mm is produced.

Enamels

C501 Test Method for Relative Resistance to Wear of

NOTE 1—For the specification of float glass, see Test Method C448,

Unglazed Ceramic Tile by the Taber Abraser

Table A1.4.

C1027 Test Method for Determining Visible Abrasion Re-

5.1.1 When the disc diameter has worn to 199 mm, the steel

sistance of Glazed Ceramic Tile

disc shall be replaced.

5.2 A linear measuring gage capable of measuring to 0.1

1 mm.

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic

Whitewares and Related Productsand is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile.

Current edition approved Dec. 15, 2015. Published December 2015. Originally

approved in 1993. Last previous edition approved in 2015 as C1243 – 93 (2015). The sole source of supply of the apparatus known to the committee at this time

DOI: 10.1520/C1243-93R15E02. is Gabrielli S.R.L., Box 218, 50019 Sesto Florentino, Florence, Italy, Fax:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 55-42-15-654. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

C1243 − 93 (2015)

7.2 Rotate the steel disc for 150 revolutions. Remove the

test specimen from the apparatus and measure the cord length

(l) of the groove by means

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´2 ´2

Designation: C1243 − 93 (Reapproved 2015) C1243 − 93 (Reapproved 2015)

Standard Test Method for

Relative Resistance to Deep Abrasive Wear of Unglazed

Ceramic Tile by Rotating Disc

This standard is issued under the fixed designation C1243; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected Eq 1 editorially in Feb. 2017.Nov. 2019.

1. Scope

1.1 This test method covers the deep abrasive wear by measuring the loss of volume resulting from abrasion of unglazed

ceramic tile under given conditions by means of a rotating disc and the use of abrasive material.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C242 Terminology of Ceramic Whitewares and Related Products

C448 Test Methods for Abrasion Resistance of Porcelain Enamels

C501 Test Method for Relative Resistance to Wear of Unglazed Ceramic Tile by the Taber Abraser

C1027 Test Method for Determining Visible Abrasion Resistance of Glazed Ceramic Tile

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, see Terminology C242.

4. Significance and Use

4.1 This test method provides the means to measure the potential resistance to wear of unglazed ceramic tile intended for floor

coverings. This test method does not consider physical appearance but is intended to measure durability. See Test Method C1027

for the determination of visible abrasion resistance of glazed ceramic tile.

4.1.1 See Test Method C501 for an alternative method to determine deep abrasion.

5. Apparatus

5.1 Abrasion apparatus (see Fig. 1) consisting essentially of a rotating disc, a storage hopper with a dispensing device for the

abrasive material, a test specimen support, and a counterweight. The disc is made of Fe 360A steel (ISO 630-1980) with a diameter

of 200 6 0.2 mm and thickness at the edge of 10 6 0.1 mm, and with a rate of revolution of 75 r/min. The pressure with which

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic Whitewares and Related Productsand is the direct responsibility of Subcommittee C21.06

on Ceramic Tile.

Current edition approved Dec. 15, 2015. Published December 2015. Originally approved in 1993. Last previous edition approved in 2015 as C1243 - 93C1243 – 93 (2015).

DOI: 10.1520/C1243-93R15E01.10.1520/C1243-93R15E02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The sole source of supply of the apparatus known to the committee at this time is Gabrielli S.R.L., Box 218, 50019 Sesto Florentino, Florence, Italy, Fax: 55-42-15-654.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting

of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´2

C1243 − 93 (2015)

FIG. 1 Abrasion Apparatus

FIG. 2 Definition of Chord

test specimens are held against the steel disc is determined by calibrating the apparatus against float glass (bathside). The pressure

is adjusted such that, after 150 revolutions, a chord of 24 6 0.5 mm is produced.

´2

C1243 − 93 (2015)

NOTE 1—For the specification of float glass, see Test Method C448, Table A1.4.

5.1.1 When the disc diameter has worn to 199 mm, the steel disc shall be replaced.

5.2 A linear measuring gage capable of measuring to 0.1 mm.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.