ASTM C1093-95(2001)

(Practice)Standard Practice for Accreditation of Testing Agencies for Unit Masonry

Standard Practice for Accreditation of Testing Agencies for Unit Masonry

SCOPE

1.1 This practice covers the minimum requirements for laboratory personnel, for establishing and maintaining a quality system, and it establishes minimum qualifications for agencies engaged in the testing of masonry materials.

1.2 Criteria are provided for evaluating the capability of an agency to properly perform designated tests on masonry materials, and for establishing guidelines pertaining to an agency's organization, personnel, facilities, and quality system. This practice may be supplemented by more specific criteria and requirements for particular projects.

1.3 This practice can be used as a basis to evaluate testing agencies, and it is intended for use for the qualifying or accrediting of testing agencies, or both, public or private, engaged in the testing of masonry materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1093–95 (Reapproved 2001)

Standard Practice for

Accreditation of Testing Agencies for Unit Masonry

This standard is issued under the fixed designation C 1093; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope masonry materials. The criteria may be supplemented by more

specific criteria and requirements. It can be used as a guide for

1.1 This practice covers the minimum requirements for

internal audits by individual users.

laboratorypersonnel,forestablishingandmaintainingaquality

3.2 Theintentofthispracticeistoprovideaconsensusbasis

system, and it establishes minimum qualifications for agencies

for evaluating a testing agency, with respect to that agency’s

engaged in the testing of masonry materials.

capability to objectively and competently provide the specific

1.2 Criteria are provided for evaluating the capability of an

services needed by the user.

agency to properly perform designated tests on masonry

3.3 This practice may be used as a basis for accreditation.

materials, and for establishing guidelines pertaining to an

agency’sorganization,personnel,facilities,andqualitysystem.

4. Responsibilities and Duties

This practice may be supplemented by more specific criteria

4.1 The agency shall ensure that only tests for which it is

and requirements for particular projects.

adequately equipped and staffed are performed.

1.3 This practice can be used as a basis to evaluate testing

4.2 The agency shall ensure that personnel perform only

agencies, and it is intended for use for the qualifying or

tests for which they are adequately trained, qualified, and

accrediting of testing agencies, or both, public or private,

certified in accordance with applicable specifications.

engaged in the testing of masonry materials.

4.3 The agency shall ensure that all equipment is properly

1.4 This standard does not purport to address all of the

maintained in good operating condition and is calibrated as

safety concerns, if any, associated with its use. It is the

applicable.

responsibility of the user of this standard to establish appro-

4.4 The agency shall perform all testing in accordance with

priate safety and health practices and determine the applica-

appropriate standards and quality control criteria. Documents

bility of regulatory limitations prior to use.

unique to the user shall be furnished to the agency.

2. Terminology

5. General Capabilities

2.1 Definition:

5.1 Laboratory Testing—The laboratory testing services of

2.1.1 quality system—the organizational structure, respon-

the masonry materials testing agency shall include some or all

sibilities, procedures, processes, capabilities, and resources for

of the following capabilities:

implementing quality management.

5.1.1 Testing of masonry units in the laboratory,

2.2 Definitions of Terms Specific to This Standard:

5.1.2 Testing of masonry mortars in the laboratory, and

2.2.1 agency—the organization engaged to test masonry

5.1.3 Testing of aggregates for compliance with specifica-

materials as required by a specification or contract.

tion requirements.

2.2.2 quality system manual (QSM)—a manual describing

and documenting an agency’s quality system.

NOTE 1—Since the requirements for construction control can vary from

2.2.3 user—the person or organization engaging the agency project to project depending upon the nature of the type, location, and

intended use of the masonry in the project, the capability of the agency for

to provide tests; or using this practice to evaluate or accredit

testing should be that necessary to accomplish construction control for the

the agency.

user’s specific project or special requirements.

3. Significance and Use

6. Personnel Qualifications

3.1 This practice provides the basic minimum criteria for

6.1 Management and Supervision—The testing services of

use in evaluating the qualifications of testing agencies for

the agency shall be under the direction of a person charged

with scientific or engineering managerial responsibility. This

This practice is under the jurisdiction of ASTM Committee C15 on Manufac- person shall be a registered engineer and a full-time employee

tured Masonry Units and is the direct responsibility of Subcommittee C15.07 on

of the agency and shall have a minimum of five years

Standards for Laboratory Accreditation.

experience in inspecting and testing of masonry materials and

Current edition approved Oct. 10, 1995. Published January 1996. Originally

construction; or, in place of being a registered engineer, a

published as C 1093 – 88. Last previous edition C 1093 – 88.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1093

person with equivalent science-oriented education and experi- calibrated or verified at the intervals specified in the agency’s

ence in having satisfactorily directed testing or inspection QSM. The intervals specified in the QSM shall be no greater

services, or both, of masonry is acceptable. than those indicated in Table 1 (see Note 4). Newly acquired

6.2 Supervising Laboratory Technician—The supervising equipment without manufacturer’s certification and equipment

laboratory technician shall have at least five years experience that has not been calibrated or verified because it has been

performing tests on materials. This person shall be able to removed from service shall be calibrated or verified before

demonstrate, either by oral or written examination, or both, the being placed in service. The agency shall have detailed written

ability to perform the tests normally required in the manner procedures for all in-house calibration and verification activi-

stipulated under ASTM or other governing procedures and ties not addressed in standards.These procedures shall indicate

shall be capable of evaluating the test results in terms of the equipment required to perform the calibration or verifica-

specification compliance. tion.

NOTE 4—When a maximum calibration or verification interval for a

7. Quality System Criteria

specific piece of test equipment is specified in a standard, the maximum

7.1 The agency shall establish and implement a quality

interval specified by this practice is intended to be the same as the

maximum interval specified by the standard.

system that meets the following criteria:

7.1.1 Quality System Manual (QSM)—The agency shall

7.1.5 Inspection of Facilities—The agency shall have its

establish and maintain a QSM that conforms to the require-

laboratory procedures and equipment evaluated at intervals of

ments in Section 8. Each document in the QSM shall indicate

approximately two years by an evaluation authority (see Note

its preparation date. If a document is revised, the date of

5) as evidence of its competence to perform the required test.

revision shall be indicated on the document. The QSM shall be

Within 30 days of the receipt of the evaluation authority’s

available for use by laboratory staff.

written report, the agency shall address or correct any deficien-

7.1.2 Quality System Management—The agency shall des-

cies cited in the report. The laboratory shall report corrections

ignate a person(s) having responsibility for the quality system

made to the evaluation authority or include a plan of action to

and its implementation. The quality manager ensures that

implement the corrections in response to the on-site inspection

activities are being conducted by agency staff in the manner

report.

specified in the agency’s quality system manual and has

NOTE 5—The AASHTO Material Reference Laboratory (AMRL), Ce-

responsibility for maintaining and revising it. This individu-

ment and Concrete Reference Laboratory (CCRL), the National Institute

al(s) shall have direct access to top management (see Note 2).

ofStandardsandTechnologyNationalVoluntaryLaboratoryAccreditation

Program (NVLAP), and the American Association for Laboratory Ac-

NOTE 2—This individual(s) may have other responsibilities (for ex-

creditation (AALA) are qualified evaluation authorities.

ample, laboratory manager).

7.1.6 Agency Accreditation—The agency shall possess a

7.1.3 Laboratory Procedure Manual—A written laboratory

certificate of accreditation, (see Note 6) from a national

procedure manual outlining the method or inspection proce-

authority as evidence that it meets the requirement of this

dure for each test or service performed by the laboratory.

practice.

NOTE 3—Inspection and testing procedures may reference published

standards. NOTE 6—Accreditation programs offered by AASHTO (Accreditation

Program—AAP), the American Association for Laboratory Accreditation

7.1.4 Equipment Calibration and Verification—The agency

(AALA), and the National Voluntary Laboratory Accreditation Program

shall calibrate or verify all significant testing equipment

(NVLAP) are examples of programs offered by national authorities.

associated with tests covered by the scope of this standard

7.1.7 Proficiency Sample Testing—The agency shall partici-

which the agency performs. As a minimum, the equipment

pate in applicable proficiency sample programs, (see Note 7).

listed in Table 1 shall be included if it is associated with tests

performed by the agency. Applicable equipment shall be

NOTE 7—The Cement and Concrete Reference Laboratory offers a

proficiency sample program for physical testing of masonry mortar. The

AASHTO Materials Reference Laboratory offers a proficiency sample

TABLE 1 Masonry Test Equipment

program for testing of fine aggregates.

Intervals

Equipment—Test Method Requirements

7.1.8 Test Records—The agency shall maintain test records

Months

that contain sufficient information to permit verification of any

Analytical balances and weights Verify 24

test reports. Records pertaining to testing shall include trace-

Brass and plastic cube molds Check critical dimensions 12

Compression test machine Verify load indications 18

ability of sample from source to agency, original observations,

Flexural bond apparatus Calibrate 12

calculations, derived data, and an identification of personnel

General purpose balances, scales, Verify 12

involved in sampling and testing. The agency shall prepare test

and weights

Mechanical shakers Check sieving thoroughness 12

reports that clearly, accurately, and unambiguously present the

Mixers Check paddle to bowl clearance 24

information specified in Table 2. The procedure for amending

Molds, cylindrical Check critical dimensions 12

reports shall require that the previously existing report be

Molds and tampers Check critical dimensions 12

Ovens Verify temperature setting 4

clearlyreferencedwhenanamendmentismade.Thereferences

Sieves Check physical condition 6

Thermometers Calibrate 6

Timers Check dial and timer accuracy 6

Water retention Calibrate vacuum 12 American Association for State Highway Transportation Officials (AASHTO),

444 N. Capitol St. NW, Washington, DC 20001.

C1093

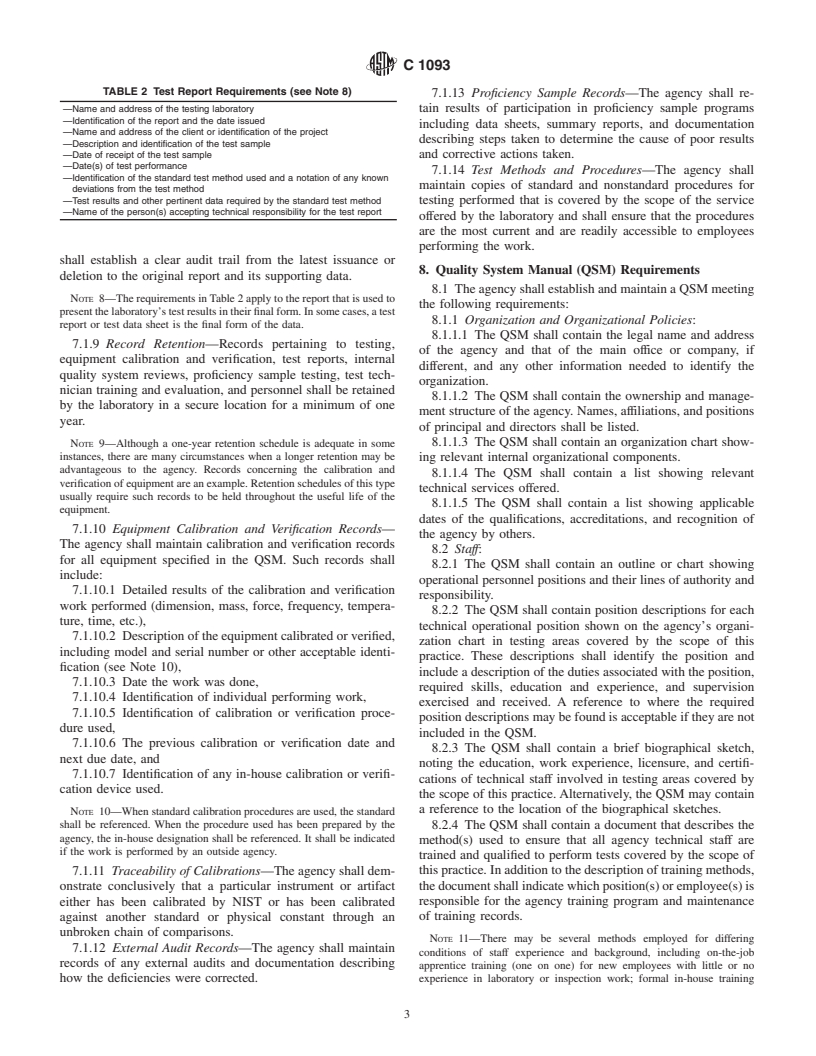

TABLE 2 Test Report Requirements (see Note 8)

7.1.13 Proficiency Sample Records—The agency shall re-

—Name and address of the testing laboratory tain results of participation in proficiency sample programs

—Identification of the report and the date issued

including data sheets, summary reports, and documentation

—Name and address of the client or identification of the project

describing steps taken to determine the cause of poor results

—Description and identification of the test sample

—Date of receipt of the test sample and corrective actions taken.

—Date(s) of test performance

7.1.14 Test Methods and Procedures—The agency shall

—Identification of the standard test method used and a notation of any known

maintain copies of standard and nonstandard procedures for

deviations from the test method

—Test results and other pertinent data required by the standard test method

testing performed that is covered by the scope of the service

—Name of the person(s) accepting technical responsibility for the test report

offered by the laboratory and shall ensure that the procedures

are the most current and are readily accessible to employees

performing the work.

shall establish a clear audit trail from the latest issuance or

8. Quality System Manual (QSM) Requirements

deletion to the original report and its supporting data.

8.1 The agency shall establish and maintain a QSM meeting

NOTE 8—The requirements in Table 2 apply to the report that is used to

the following requirements:

presentthelaboratory’stestresultsintheirfinalform.Insomecases,atest

8.1.1 Organization and Organizational Policies:

report or test data sheet is the final form of the data.

8.1.1.1 The QSM shall contain the legal name and address

7.1.9 Record Retention—Records pertaining to testing,

of the agency and that of the main office or company, if

equipment calibration and verification, test reports, internal

different, and any other information needed to identify the

quality system reviews, proficiency sample testing, test tech-

organization.

nician training and evaluation, and personnel shall be retained

8.1.1.2 The QSM shall contain the ownership and manage-

by the laboratory in a secure location for a minimum of one

ment structure of the agency. Names, affiliations, and positions

year.

of principal and directors shall be listed.

NOTE 9—Although a one-year retention schedule is adequate in some 8.1.1.3 The QSM shall contain an organization chart show-

instances, there are many circumstances when a longer retention may be

ing relevant internal organizational components.

advantageous to the agency. Records concerning the calibration and

8.1.1.4 The QSM shall contain a list showing relevant

verification of equipment are an example. Retention schedules of this type

technical services offered.

usually require such records to be held throughout the useful life of the

8.1.1.5 The QSM shall contain a list showing applicable

equipment.

dates of the qualifications, accreditations, and recognition of

7.1.10 Equipment Calibration and Verification Records—

the agency by others.

The agency shall maintain calibration and verification records

8.2 Staff:

for all equipment specified in the QSM. Such records shall

8.2.1 The QSM shall contain an outline or chart showing

include:

operational personnel positions and their lines of authority and

7.1.10.1 Detailed results of the calibration and verification

responsibility.

work performed (dimension, mass, force, frequency, tempera-

8.2.2 The QSM shall contain position descriptions for each

ture, time, etc.),

technical operational position shown on the agency’s organi-

7.1.10.2 Description of the equipmen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.