ASTM D2657-07

(Practice)Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

SIGNIFICANCE AND USE

The procedures described in Sections 7, 8, and 9, when implemented using suitable equipment and procedures in either a shop or field environment, produce strong pressure-tight joints equal to the strength of the piping material. Some materials are more adaptable to one technique than another. Melt characteristics, average molecular weight and molecular weight distribution are influential factors in establishing suitable fusion parameters; therefore, consider the manufacturer’instructions in the use or development of a specific fusion procedure.

SCOPE

1.1 This practice describes general procedures for making joints with polyolefin pipe and fittings (excluding polyethylene pipe and fittings) by means of heat fusion joining techniques in either a shop or field environment. These procedures are general ones. Specific instructions for heat fusion joining are obtained from product manufacturers. See Practice F 2620 for heat fusion joining of polyethylene pipe and fittings.

1.2 The techniques covered are applicable only to joining polyolefin pipe and fittings of related polymer chemistry, for example, polypropylenes to polypropylenes, or polybutylenes to polybutylenes. Material, density, and flow rate shall be taken into consideration in order to develop uniform melt viscosities and formation of a good fusion bond when joining the same material to itself or to other materials of related polymer chemistry.

1.3 Parts that are within the dimensional tolerances given in present ASTM specifications are required to produce sound joints between polyolefin pipe and fittings when using the joining techniques described in this practice.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The text of this practice references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the practice.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See specific safety precautions in 3.1.1, 5.2, 8.2.3.1, Note 8 and Note 9, and A1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2657 −07 AnAmerican National Standard

Standard Practice for

1

Heat Fusion Joining of Polyolefin Pipe and Fittings

This standard is issued under the fixed designation D2657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice describes general procedures for making

F1056 Specification for Socket Fusion Tools for Use in

joints with polyolefin pipe and fittings (excluding polyethylene

Socket Fusion Joining Polyethylene Pipe or Tubing and

pipe and fittings) by means of heat fusion joining techniques in

Fittings

either a shop or field environment. These procedures are

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe

general ones. Specific instructions for heat fusion joining are

and Fittings

obtained from product manufacturers. See Practice F2620 for

heat fusion joining of polyethylene pipe and fittings.

3. Summary of Practice

1.2 The techniques covered are applicable only to joining

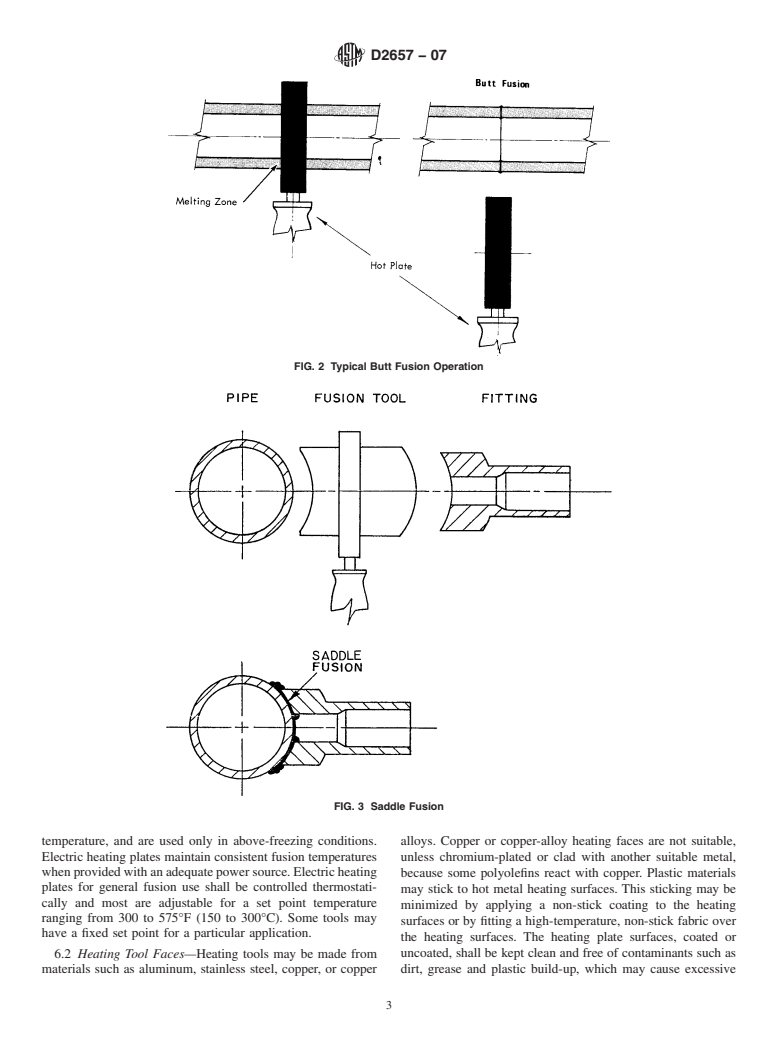

3.1 Heat-fusionjoiningusesacombinationofheatandforce

polyolefin pipe and fittings of related polymer chemistry, for

resulting in two melted surfaces flowing together to produce a

example, polypropylenes to polypropylenes, or polybutylenes

joint. Fusion bonding occurs when the joint cools below the

topolybutylenes.Material,density,andflowrateshallbetaken

melt temperature of the material. There is a temperature range

into consideration in order to develop uniform melt viscosities within which any particular material is satisfactorily joined.

and formation of a good fusion bond when joining the same The specific temperature used requires consideration of the

material to itself or to other materials of related polymer propertiesofthespecificmaterial,andthejoiningenvironment.

chemistry. With Techniques II or III (3.3.2 or 3.3.3), there is also an

appropriate force to be applied which depends upon the

1.3 Parts that are within the dimensional tolerances given in

material, the fusion equipment being used, and fusion tempera-

present ASTM specifications are required to produce sound

ture. See Practice F2620 for heat fusion procedure for poly-

joints between polyolefin pipe and fittings when using the

ethylene pipe and fittings.

joining techniques described in this practice.

3.1.1 Electrically powered heat fusion tools and equipment

are usually not explosion proof. When performing heat fusion

1.4 The values stated in inch-pound units are to be regarded

in a potentially combustible atmosphere such as in an excava-

as the standard. The values given in parentheses are for

tion where gas is present, all electrically powered tools and

information only.

equipment that will be used in the combustible atmosphere

1.5 The text of this practice references notes, footnotes, and

shall be disconnected from the electrical power source and

appendixes which provide explanatory material. These notes

operated manually to prevent explosion and fire. For the

and footnotes (excluding those in tables and figures) shall not

heating tool, this requires bringing the heating tool up to or

be considered as requirements of the practice.

slightly above temperature in a safe area, then disconnecting it

from electrical power immediately before use. This procedure

1.6 This standard does not purport to address all of the

is limited to smaller sizes where heating is accomplished

safety concerns, if any, associated with its use. It is the

before the heating tool drops below acceptable temperature.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.2 Adequate joint strength for testing is attained when all

bility of regulatory limitations prior to use. See specific safety of the joint material cools to ambient temperature. The joint

precautions in 3.1.1, 5.2, 8.2.3.1, Note 8 and Note 9, andA1.1.

shallnotbedisturbedormoveduntilithascooled.SeePractice

F2620 for heat fusion procedure for polyethylene pipe and

fittings.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2007. Published May 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2003 as D2657 – 03. DOI: Standards volume information, refer to the standard’s Document Summary page on

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.