ASTM D2657-97

(Practice)Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

Standard Practice for Heat Fusion Joining of Polyolefin Pipe and Fittings

SCOPE

1.1 This practice describes general procedures for making joints with polyolefin pipe and fittings by means of heat fusion joining techniques in either a shop or field environment. These procedures should be regarded as general ones. Manufacturers should be requested to supply specific recommendations for heat fusion joining their materials or products.

1.2 The techniques covered are applicable only to joining polyolefin pipe and fittings of related polymer chemistry, for example, polyethylenes to polyethylenes, polypropylenes to polypropylenes, or polybutylenes to polybutylenes. Material, density, and flow rate shall be taken into consideration in order to develop uniform melt viscosities and formation of a good fusion bond, when joining the same material to itself or to other materials of related polymer chemistry.

1.3 The heat fusion joining techniques described can produce sound joints between polyolefin pipe and fittings, provided that the parts are within the dimensional tolerances given in present ASTM specifications.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The text of this practice references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the practice.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See specific safety precautions in 4.2, 5.1.1, 8.2.3.1, Notes 8 and 9, and A1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2657 – 97

Standard Practice for

Heat Fusion Joining of Polyolefin Pipe and Fittings

This standard is issued under the fixed designation D 2657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope F 1056 Specification for Socket Fusion Tools for Use in

Socket Fusion Joining Polyethylene Pipe or Tubing and

1.1 This practice describes general procedures for making

Fittings

joints with polyolefin pipe and fittings by means of heat fusion

joining techniques in either a shop or field environment. These

3. Summary of Practice

procedures are general ones. Specific instructions for heat

3.1 Heat-fusionjoiningusesacombinationofheatandforce

fusion joining are obtained from product manufacturers.

resulting in two melted surfaces flowing together to produce a

1.2 The techniques covered are applicable only to joining

joint. Fusion bonding occurs when the joint cools below the

polyolefin pipe and fittings of related polymer chemistry, for

melt temperature of the material. There is a temperature range

example, polyethylenes to polyethylenes, polypropylenes to

within which any particular material is satisfactorily joined.

polypropylenes, or polybutylenes to polybutylenes. Material,

The specific temperature used requires consideration of the

density, and flow rate shall be taken into consideration in order

propertiesofthespecificmaterial,andthejoiningenvironment.

to develop uniform melt viscosities and formation of a good

With Techniques II or III (3.3.2 or 3.3.3), there is also an

fusion bond when joining the same material to itself or to other

appropriate force to be applied which depends upon the

materials of related polymer chemistry.

material, the fusion equipment being used, and fusion tempera-

1.3 Parts that are within the dimensional tolerances given in

ture.

present ASTM specifications are required to produce sound

3.1.1 Electrically powered heat fusion tools and equipment

joints between polyolefin pipe and fittings when using the

are usually not explosion proof. When performing heat fusion

joining techniques described in this practice.

in a potentially combustible atmosphere such as in an excava-

1.4 The values stated in inch-pound units are to be regarded

tion where gas is present, all electrically powered tools and

as the standard. The values given in parentheses are for

equipment that will be used in the combustible atmosphere

information only.

shall be disconnected from the electrical power source and

1.5 The text of this practice references notes, footnotes, and

operated manually to prevent explosion and fire. For the

appendixes which provide explanatory material. These notes

heating tool, this requires bringing the heating tool up to or

and footnotes (excluding those in tables and figures) shall not

slightly above temperature in a safe area, then disconnecting it

be considered as requirements of the practice.

from electrical power immediately before use. This procedure

1.6 This standard does not purport to address all of the

is limited to smaller sizes where heating is accomplished

safety concerns, if any, associated with its use. It is the

before the heating tool drops below acceptable temperature.

responsibility of the user of this standard to establish appro-

3.2 Adequate joint strength for testing is attained when all

priate safety and health practices and determine the applica-

of the joint material cools to ambient temperature. The joint

bility of regulatory limitations prior to use. See specific safety

shall not be disturbed or moved until it has cooled.

precautions in 3.1.1, 5.2, 8.2.3.1, Note 8 and Note 9, andA1.1.

NOTE 1—Polybutylene undergoes a crystalline transformation for sev-

2. Referenced Documents

eral days after cooling below its melt temperature.Although this phenom-

enon has an effect on the ultimate physical properties of the material, its

2.1 ASTM Standards:

effect on testing of joints has not been found to be significant. If there is

F 905 Practice for Qualification of Polyethylene Saddle

2 anyquestionofitseffect,acomparisonshouldbemadebetweenjointsthat

Fusion Joints

havebeenconditionedfordifferentperiodsoftimeinordertoestablishthe

conditioning-time relationship.

3.3 Three fusion techniques are covered in this practice as

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

follows:

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

3.3.1 Procedure 1, Socket Fusion—The socket-fusion tech-

Current edition approved May 10, 1997. Published November 1997. Originally

nique involves simultaneously heating the outside surface of a

published as D 2657 – 67. Last previous edition D 2657 – 96.

Annual Book of ASTM Standards, Vol 08.04. pipe end and the inside of a fitting socket, which is sized to be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2657

smallerthanthesmallestoutsidediameterofthepipe.Afterthe 5. Operator Experience

proper melt has been generated at each face to be mated, the

5.1 Skill and knowledge on the part of the operator are

twocomponentsarejoinedbyinsertingonecomponentintothe

required to obtain a good quality joint. This skill and knowl-

other. See Fig. 1. The fusion bond is formed at the interface

edge is obtained by making joints in accordance with proven

resulting from the interference fit. The melts from the two

procedures under the guidance of skilled operators. Evaluate

components flow together and fuse as the joint cools. Optional

operator proficiency by testing sample joints.

alignment devices are used to hold the pipe and socket fitting

5.2 These procedures require the use of heating and cutting

in Logitudinal alignment during the joining process; especially

equipment. The person actually responsible for the joining of

with pipe sizes 3 in. IPS (89 mm) and larger.

polyolefin pipe and fittings shall ensure that detailed proce-

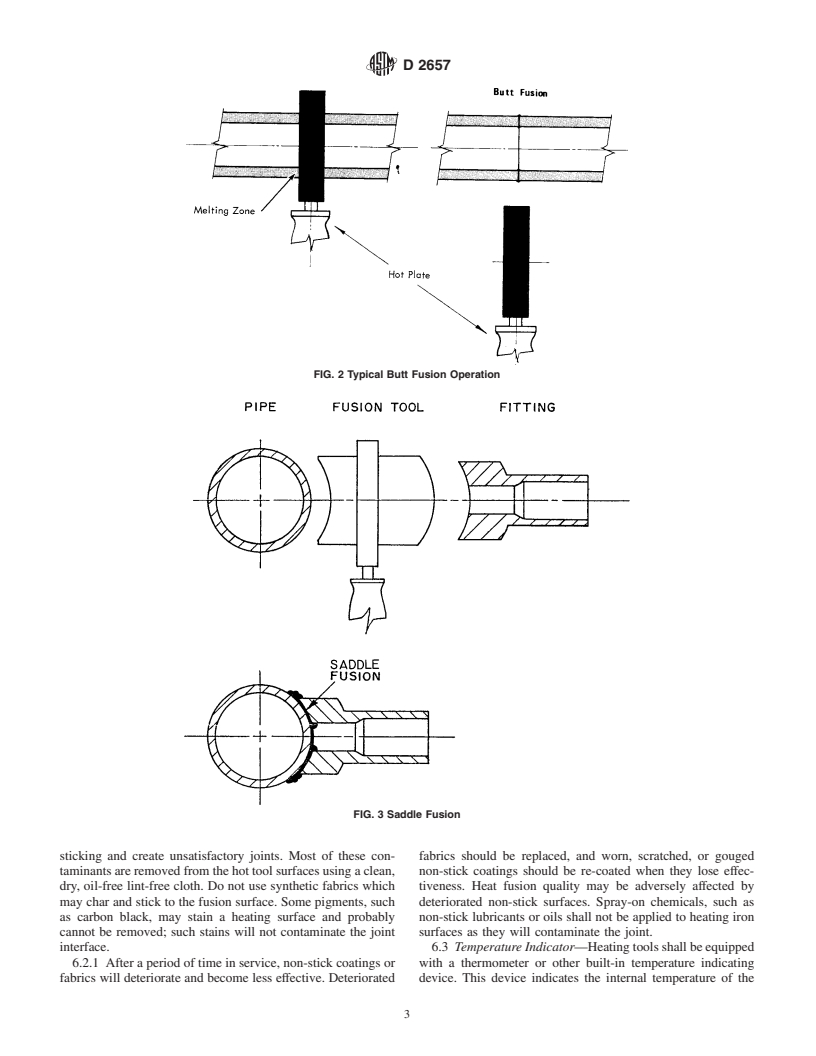

3.3.2 Procedure 2, Butt Fusion—The butt-fusion technique

dures developed in conjunction with the manufacturers of the

in its simplest form consists of heating the squared ends of two

pipe, fittings, and the joining equipment involved, including

pipes, a pipe and a fitting, or two fittings, by holding them

the safety precautions to be followed, are issued before actual

againstaheatedplate,removingtheplatewhenthepropermelt

joining operations begin.

is obtained, promptly bringing the ends together, and allowing

6. Apparatus: General Recommendations

the joint to cool while maintaining the appropriate applied

force. See Fig. 2. An alignment jig shall be used to obtain and

6.1 Heating Tool—The tool may be heated by gas or

maintain suitable alignment of the ends during the fusion

electricity. Gas-fired heaters shall have heat sinks of sufficient

operation.

capacity to prevent excessive draw down of the tool tempera-

3.3.3 Procedure 3, Saddle Fusion—The saddle-fusion tech-

ture. Electric heating plates maintain consistent fusion tem-

nique involves melting the concave surface of the base of a

peratures when provided with an adequate power source.

saddle fitting, while simultaneously melting a matching pattern

Electricheatingplatesforgeneralfusionuseshallbecontrolled

on the surface of the pipe, bringing the two melted surfaces

thermostatically and adjusted over a temperature range from

together and allowing the joint to cool while maintaining the

300 to 575°F (150 to 300°C). Some tools may have a fixed set

appropriate applied force. See Fig. 3.

point for a particular application.

6.2 Heating Tool Faces—Heating tools may be made from

4. Significance and Use

materials such as aluminum, stainless steel, copper, or copper

4.1 The procedures described in Sections 7, 8, and 9, when alloys. Copper or copper-alloy heating faces are not suitable,

implementedusingsuitableequipmentandproceduresineither unless chromium-plated or clad with another suitable metal,

a shop or field environment, produce strong pressure-tight because some polyolefins react with copper. Plastic materials

joints equal to the strength of the piping material. Some may stick to hot metal heating surfaces. This sticking may be

materials are more adaptable to one technique than another. minimized by applying a non-stick coating to the heating

Average molecular weight and molecular weight distribution surfaces or by fitting a high-temperature, non-stick fabric over

are influential factors in establishing suitable fusion param- the heating surfaces. The heating plate surfaces, coated or

eters; therefore, consider the manufacturer’s instructions in the

uncoated, shall be kept clean and free of contaminants such as

use or development of a specific fusion procedure. dirt, grease and plastic build-up, which may cause excessive

FIG. 1 Socket Fusion

D 2657

FIG. 2 Typical Butt Fusion Operation

FIG. 3 Saddle Fusion

sticking and create unsatisfactory joints. Most of these con- fabrics should be replaced, and worn, scratched, or gouged

taminantsareremovedfromthehottoolsurfacesusingaclean, non-stick coatings should be re-coated when they lose effec-

dry, oil-free lint-free cloth. Do not use synthetic fabrics which tiveness. Heat fusion quality may be adversely affected by

may char and stick to the fusion surface. Some pigments, such deteriorated non-stick surfaces. Spray-on chemicals, such as

as carbon black, may stain a heating surface and probably non-stick lubricants or oils shall not be applied to heating iron

cannot be removed; such stains will not contaminate the joint surfaces as they will contaminate the joint.

interface. 6.3 TemperatureIndicator—Heatingtoolsshallbeequipped

6.2.1 After a period of time in service, non-stick coatings or with a thermometer or other built-in temperature indicating

fabrics will deteriorate and become less effective. Deteriorated device. This device indicates the internal temperature of the

D 2657

heating iron which is usually higher than temperature of the 7.2.4 Bring the preheated tool faces into contact with the

fusion surfaces. Use a pyrometer periodically to verify the outside surface of the end of the pipe and the inside surface of

temperature of the tool surfaces within the pipe or fitting the socket.

contact area. Select multiple checkpoints to ensure uniform 7.2.5 Heat the pipe end and the fitting socket for the time

surface temperature.

required to obtain a proper melt. Proper melt is a function of

material, time, tool temperature, and the size of the parts. Pipe

NOTE 2—Asignificant temperature variation, that is, cold spots, on the

and fittings of larger diameters require more time to reach the

fusion surfaces may indicate a faulty heating iron which may need to be

proper melt consistency than those of smaller diameters.

serviced before it can be used.

Underheated or overheated materials will not form a good

bond.

7. Procedure 1—Socket Fusion

7.2.6 At the end of the heating time, simultaneously remove

7.1 Apparatus—Socket fusion tools manufactured in accor-

the pipe and fitting straight out from the tool, using a snap

dance with Specification F 1056 should be used for joining

action. Immediately insert the pipe straight into the socket of

polyethylene pipe, tubing, and fittings.

the fitting so the rounding clamp is flush against the end of the

7.1.1 Heating Tool—In order to obtain a proper melt, it is

fitting socket. Hold or block the joint in place until the melts of

necessary for a uniform temperature to be maintained across

the mating surfaces have solidified. The exact cooling time

the heating surface. Therefore, gas-fired tools are generally

depends on the size of the pipe and the material being fused.

restricted to use with pipe sizes of 2 in. IPS (63 mm) or less.

7.2.7 Remove the rounding clamp, and inspect the melt

7.1.2 Heating Tool Faces—Consisting of two parts, a male

patternattheendofthesocketforacompleteimpressionofthe

end for the interior socket surface and a female end for the

rounding clamp in the melt surface.There shall no gaps, voids,

exterior pipe surface. Both parts shall be made to such

or unbonded areas. Clean the heating tool of any residual

tolerances as to cause an interference fit.

material using a wood stick or a clean, dry, oil-free, lint-free,

7.1.3 Alignment Jig—The alignment jig is an optional tool

non-synthetic cloth. Take care not to damage the heating

which consists of two sets of devices holding the components

surfaces. Plastic left on the tool tends to char when reheated,

in alignment to each other. One set of holding devices is fixed,

causing a loss of heater efficiency and joint contamination.

and the other allows longitudinal movement for making the

7.2.8 Allow for extremes in weather when making field

joint.

joints. Heating times, operation of alignment jig, dimensional

7.1.4 Rounding Clamps, (cold ring) to maintain roundness

changes, and the like, are affected by extreme conditions.

of the pipe and control the depth of pipe insertion into the

7.3 Testing—Evaluate sample joints in order to verify the

socket during the joining operation.

skill and knowledge of the fusion operator. Cut joints into

7.1.5 Depth Gage, for proper positioning of the rounding

straps, (see Fig. 4) and visually examine and test for bond

clamp.

continuity and strength. Bending, peeling, and elongation tests

7.1.6 Chamfering Tool, to bevel the end of the pipe.

are useful for this purpose.

NOTE 3—The depth gage and chamfering tool may be combined into a

8. Procedure 2—Butt Fusion

single tool.

8.1 Apparatus:

7.1.7 Tubing Cutter, to obtain a square end cut on the pipe.

8.1.1 Heating Tool—The heating tool shall have sufficient

7.1.8 FittingPuller, an optional tool to assist in the removal

area to adequately cover the ends of the size of pipe to be

of the fitting from the heating tool and to hold the fitting during

joined.

assembly.

8.1.2 Alignment Jig—The alignment jig is three basic parts:

7.2 Procedure:

(1) a stationary clamping fixture and a movable clamping

7.2.1 Attach the proper size heater faces to the heating tool,

fixture for holding each of the two parts to be fused in

and heat the tool to the fusion temperature for the material.

alignment; (2) a facer for simultaneously preparing the ends of

7.2.2 Cut the pipe end squarely, and clean the pipe end and

thepartstobejoined(Note6);and(3)appropriateadaptersfor

fitting, both inside and outside, by wiping with a clea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.