ASTM F2004-05

(Test Method)Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis

Standard Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis

SIGNIFICANCE AND USE

Differential scanning calorimetry provides a rapid method for determining the transformation temperature(s) of nickel-titanium shape memory alloys.

This test method uses small, stress-free, annealed samples to determine whether a sample of nickel-titanium alloy containing nominally 54.5 to 56.5 % nickel by weight is austenitic or martensitic at a particular temperature. Since chemical analysis of these alloys does not have sufficient precision to determine the transformation temperature by measuring the nickel to titanium ratio of the alloy, direct measurement of the transformation temperature of an annealed sample of known thermal history is recommended.

This test method is useful for quality control, specification acceptance, and research.

Transformation temperatures derived from differential scanning calorimetry (DSC) may not agree with those obtained by other test methods due to the effects of strain and load on the transformation.

SCOPE

1.1 This test method defines procedures for determining the transformation temperatures of nickel-titanium shape memory alloys.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2004–05

Standard Test Method for

Transformation Temperature of Nickel-Titanium Alloys by

1

Thermal Analysis

This standard is issued under the fixed designation F2004; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope monitored and recorded. Absorption of energy due to a phase

transformation in the specimen results in an endothermic peak

1.1 This test method defines procedures for determining the

on heating. Release of energy due to a phase transformation in

transformation temperatures of nickel-titanium shape memory

the specimen results in an exothermic peak on cooling.

alloys.

1.2 The values stated in SI units are to be regarded as the

5. Significance and Use

standard.

5.1 Differential scanning calorimetry provides a rapid

1.3 This standard does not purport to address all of the

method for determining the transformation temperature(s) of

safety concerns, if any, associated with its use. It is the

nickel-titanium shape memory alloys.

responsibility of the user of this standard to establish appro-

5.2 This test method uses small, stress-free, annealed

priate safety and health practices and to determine the

samplestodeterminewhetherasampleofnickel-titaniumalloy

applicability of regulatory limitations prior to use.

containing nominally 54.5 to 56.5 % nickel by weight is

2. Referenced Documents austenitic or martensitic at a particular temperature. Since

2

chemical analysis of these alloys does not have sufficient

2.1 ASTM Standards:

precision to determine the transformation temperature by

E473 Terminology Relating to Thermal Analysis and Rhe-

measuring the nickel to titanium ratio of the alloy, direct

ology

measurement of the transformation temperature of an annealed

E967 Test Method for Temperature Calibration of Differen-

sample of known thermal history is recommended.

tial Scanning Calorimeters and Differential Thermal Ana-

5.3 This test method is useful for quality control, specifica-

lyzers

tion acceptance, and research.

E1142 Terminology Relating to Thermophysical Properties

5.4 Transformation temperatures derived from differential

F2005 Terminology for Nickel-Titanium Shape Memory

scanning calorimetry (DSC) may not agree with those obtained

Alloys

byothertestmethodsduetotheeffectsofstrainandloadonthe

3. Terminology transformation.

3.1 Specific technical terms used in this test method are

6. Interferences

found in Terminologies E473, E1142, and F2005.

6.1 Make sure the material to be tested is homogeneous

4. Summary of Test Method

since milligram sample quantities are used.

6.2 Take care in preparing the sample. Cutting and grinding

4.1 This test method involves heating and cooling a test

cancausecoldwork,whichaffectsthetransformationtempera-

specimen at a controlled rate in a controlled environment

ture. Oxidation during heat treatment can change the thermal

through the temperature interval of the phase transformation.

conductance of the sample.

The difference in heat flow between the test material and a

6.3 Set the gas flow to provide adequate thermal conductiv-

reference material due to energy changes is continuously

ity in the test cell.

1

7. Apparatus

This test method is under the jurisdiction ofASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

7.1 Use a differential scanning calorimeter capable of heat-

F04.15 on Material Test Methods.

ing and cooling at rates up to 10°C/min and of automatically

Current edition approved Oct. 1, 2005. Published November 2005. Originally

published in 2000. Last previous edition published in 2003 as F2004 – 03. DOI:

recording the differential energy input between the specimen

10.1520/F2004-05.

and the reference to the required sensitivity and precision.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.2 Use sample capsules or pans composed of aluminum or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

other inert material of high thermal conductivity.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

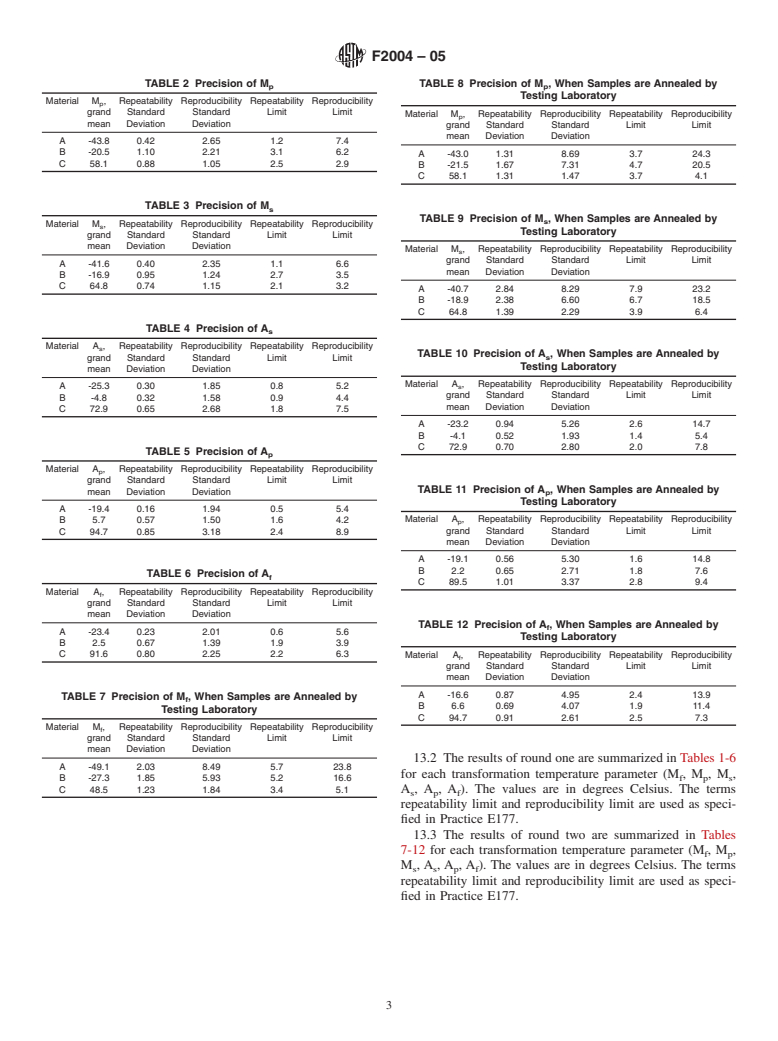

F2004–05

10.4.3 Cool the sample to a temperature of below M –

f

30°C; hold for a time sufficient to equilibrate the sample with

the furnace. Then, heat the sample to a temperature of at least

A + 30°C.

f

10.5 DataAcquisition—Record the resulting curve from the

heating and cooling program from A + 30°C to M – 30°C.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.