ASTM D4084-94(1999)

(Test Method)Standard Test Method for Analysis of Hydrogen Sulfide in Gaseous Fuels (Lead Acetate Reaction Rate Method)

Standard Test Method for Analysis of Hydrogen Sulfide in Gaseous Fuels (Lead Acetate Reaction Rate Method)

SCOPE

1.1 This test method covers the determination of hydrogen sulfide (H 2 S) in gaseous fuels. It is applicable to the measurement of H 2 S in natural gas, liquefied petroleum gas (LPG), substitute natural gas, and mixtures of fuel gases. Air does not interfere. The applicable range is 0.1 to 16 parts per million by volume (ppm/v) (approximately 0.1 to 22 mg/m ) and may be extended to 100% H 2 S by manual or automatic volumetric dilution.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4084 – 94 (Reapproved 1999)

Standard Test Method for

Analysis of Hydrogen Sulfide in Gaseous Fuels (Lead

Acetate Reaction Rate Method)

This standard is issued under the fixed designation D 4084; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope H Sreactswithleadacetatetoformabrownstainonthepaper.

The rate of reaction and resulting rate of color change is

1.1 This test method covers the determination of hydrogen

proportional to the concentration of H S in the sample. An

sulfide (H S) in gaseous fuels. It is applicable to the measure-

optical system, photodetectors, a means to obtain the first

ment of H S in natural gas, liquefied petroleum gas (LPG),

derivativeofthephotodetectorsignal,andameanstoobtainan

substitute natural gas, and mixtures of fuel gases.Air does not

output from the differentiation process comprises the analyzer.

interfere. The applicable range is 0.1 to 16 parts per million by

When there is no change in the color of the tape, and no

volume (ppm/v) (approximately 0.1 to 22 mg/m ) and may be

resulting change in photodetector output, E, the first derivative,

extended to 100 % H S by manual or automatic volumetric

dE/dt, is zero. This results in an analyzer that automatically

dilution.

zeroes when there is no H S.

1.2 This standard does not purport to address all of the 2

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 This test method is useful in determining the concentra-

priate safety and health practices and determine the applica-

tionofhydrogensulfideingaseoussamplestoverifythatlimits

bility of regulatory limitations prior to use.

setforH Sintheproductgasarecompliedwith.Theautomatic

2. Referenced Documents operation of this method allows unattended measurement of

H S concentration.

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

5. Apparatus

D 1914 Practice for Conversion Units and Factors Relating

3 5.1 Volumetric Measuring Devices—a graduated 10-L cyl-

to Sampling and Analysis of Atmospheres

inder (see Fig. 1) having a movable piston for volumetrically

D 2420 Test Method for Hydrogen Sulfide in Liquefied

4 measuring test gas. Gastight syringes of 0.1- and 0.5-mL

Petroleum (LP) Gases (Lead Acetate Method)

volumeforvolumetricallymeasuring100 %H S.Thesegradu-

D 3609 Practice for Calibration Techniques Using Perme-

3 ated devices are not needed if the permeation tube method of

ation Tubes

dynamic mixing is used to prepare the reference sample as this

3. Summary of Test Method method may be used to generate reference mixture.

5.2 Sample Pump—a pump capable of providing more than

3.1 Measurement of H S is accomplished by ratiometrically

8 mL/s (approximately 1 ft /h) at 70 kPa (approximately 10.15

comparing a reading of an unknown sample with that of a

psig). Gas-wetted parts are to be either aluminum or polytet-

known standard sample using a colorimetric analysis method.

rafluorethylene (PTFE). Stainless steel is less preferable but

Pure H S is used as a primary standard and mixed volumetri-

may be used for the purpose of improving safety if applicable.

callywithasulfurfreecarriergasthatisofthesametypeasthe

5.3 Colorimetric Rate of Reaction Sensor—select a device

gas to be analyzed. A gaseous sample at constant flow is

of sufficient sensitivity to measure a minimum rate of change

humidified and passed over lead-acetate-impregnated paper.

of color density corresponding to 0.1-ppm H S by volume in

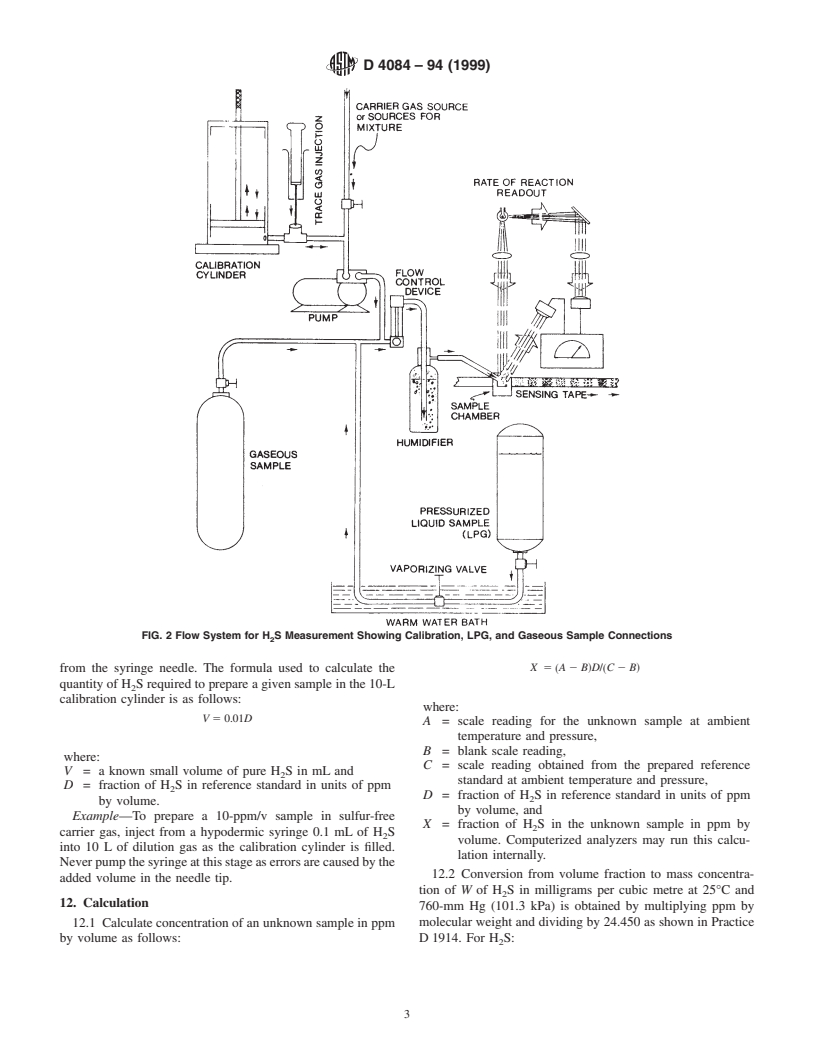

the sample gas. (See Fig. 2.)

This test method is under the jurisdiction ofASTM Committee D-3 on Gaseous

5.4 Recorder, having an adjustable span of 1- to 10-V full

Fuels and is the direct responsibility of Subcommittee D03.05 on Determination of

scale with an input impedance of 1 MV or higher.Aprinter or

Special Constituents of Gaseous Fuels.

Current edition approved Feb. 15, 1994. Published April 1984. Originally

published as D 4084 – 81. Last previous edition D 4084 – 82 (1988).

Annual Book of ASTM Standards, Vol 11.01.

3 5

Annual Book of ASTM Standards, Vol 11.03. A suitable apparatus is available from EnviroTech Controls, Inc., 22001

Annual Book of ASTM Standards, Vol 05.01. Northpark Dr., Kingwood, TX 77339-3804.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4084 – 94 (1999)

sample, when at atmospheric pressure, is convenient for analysis and will

normally not deteriorate appreciably within 1 h. Slow instrument response

to changes in H S concentration indicates the need for thorough cleaning

of the flow system. (See Appendix X1 for cleaning procedure.) Errors

caused by ambient temperature and pressure changes are compensated by

comparison to a reference standard prepared at the time of analysis.

Preparation of the reference sample is described in Section 11. An

approximatesampleconcentrationisindicatedbytheprocedureinSection

10.

8. Preparation of Instrument

8.1 Fill the humidifier bubbler to the full mark with acetic

acid solution. The acetic acid minimizes interference from

mercaptans. Set the range of the analyzer for the range

FIG. 1 Calibration Sample Preparation Cylinder with Movable

expected in the sample. Connect the pump and set the

Piston

flowmeter for a nominal flow of 8 mL/s (approximately 1

ft /h). Obtain a blank reading by flowing dilution gas through

other output means can be used with digital and computerized

the analyzer. Record the reading of the blank sample as B in

rate of reaction sensors.

12.1. Do not adjust the instrument zero until verification is

obtained, by scrubbing out H S, that the room air or the carrier

6. Reagents and Materials

gas does not contain H S. Absorption on activated charcoal

will remove H S.

6.1 Acetic Acid Solution—Add 50 mL of glacial acid

(CH COOH) to distilled water to make 1 L of solution (5 %).

9. Calibration

Type II distilled water as specified in Specification D 1193 is

satisfactory for the dilution. 9.1 Immediately after having prepared a calibration stan-

dard, obtain its response on the analyzer. Practice D 3609 is

6.2 Hydrogen Sulfide, Lecture Bottle Size—99.5 % by vol-

ume purity or better. An alternative H S source is an H S acceptable as an alternative method for preparation of a

2 2

mixture obtained using permeation tube procedures. Hydrogen reference standard. The analyzer response is recorded as C in

sulfide generated from a solid heated to generate H S may be 12.1.

used instead of the lecture bottle of compressed H S if desired,

10. Sample Measurement Procedure

as a safety precaution.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.