ASTM D2582-03

(Test Method)Standard Test Method for Puncture-Propagation Tear Resistance of Plastic Film and Thin Sheeting

Standard Test Method for Puncture-Propagation Tear Resistance of Plastic Film and Thin Sheeting

SCOPE

1.1 This test method covers the determination of the dynamic tear resistance of plastic film and thin sheeting subjected to end-use snagging-type hazards.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no equivalent ISO test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D2582–03

Standard Test Method for

Puncture-Propagation Tear Resistance of Plastic Film and

1

Thin Sheeting

This standard is issued under the fixed designation D 2582; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Significance and Use

1.1 This test method covers the determination of the dy- 4.1 The puncture-propagation of tear test measures the

namic tear resistance of plastic film and thin sheeting subjected resistance of a material to snagging, or more precisely, to

to end-use snagging-type hazards. dynamic puncture and propagation of that puncture resulting in

1.2 The values stated in SI units are to be regarded as the a tear. Failures due to snagging occur in a variety of end uses,

standard. The values given in parentheses are for information including industrial bags, liners, and tarpaulins. The units

only. reported in this test method are Newtons (tear resistance).

1.3 This standard does not purport to address all of the 4.2 Experience has shown that for many materials puncture

safety concerns, if any, associated with its use. It is the does not contribute significantly to the force value determined,

responsibility of the user of this standard to establish appro- due to the sharpness of the propagating probe used. However,

priate safety and health practices and determine the applica- comparing the results of prepunctured test specimens with

bility of regulatory limitations prior to use. normal nonpunctured specimens will give an indication of the

extent of any puncture resistance in the reported result.

NOTE 1—There is no equivalent ISO test method.

4.3 For many materials, there may be a specification that

requires the use of this test method, but with some procedural

2. Referenced Documents

2 modifications that take precedence when adhering to the

2.1 ASTM Standards:

specification. Therefore, it is advisable to refer to that material

D 618 Practice for Conditioning Plastics for Testing

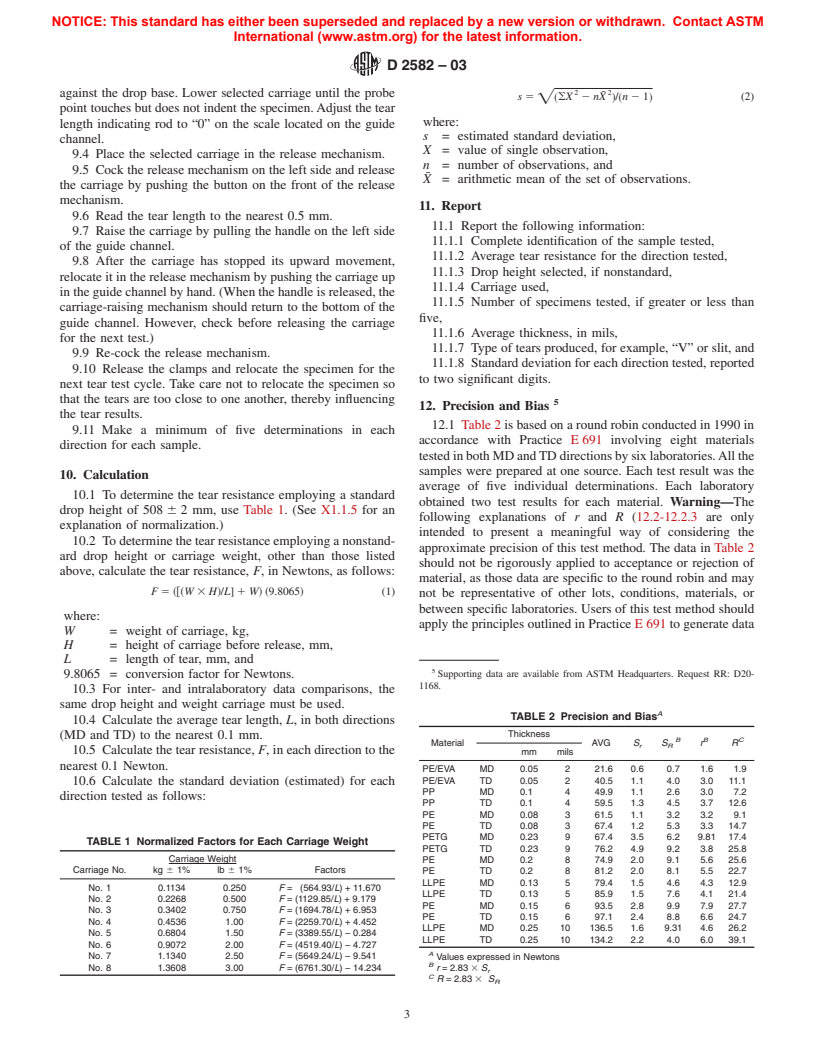

specification before using this test method. Table 1 of Classi-

D 883 Terminology Relating to Plastics

fication System D 4000 lists the current ASTM materials

D 4000 Classification System for Specifying Plastic Mate-

standards.

rials

3

D 4805 Terminology for Plastics Standards

4

5. Apparatus

D 5947 Test Methods for Physical Dimensions of Solid

5.1 As shown in Fig. 1, the instrument consists of:

Plastic Specimens

5.1.1 Carriages of different weight, each with a pointed

E 691 Practice for Conducting an Interlaboratory Study to

probe. Each carriage weight shall have a tolerance of 61%of

Determine the Precision of a Test Method

the weight desired.

5.1.2 A test stand including:

3. Terminology

5.1.2.1 Carriage release mechanism,

3.1 Descriptions of Terms Specific to This Standard:

5.1.2.2 Scale marked in millimetres,

3.1.1 slit tear—a single tear parallel to the direction of the

5.1.2.3 Curved specimen holder with a tear slot and five

falling carriage.

clamps,

3.1.2 “V” tear—atearthathastwoindividualtearlegs(not

5.1.2.4 Drop base with a guide channel to accommodate the

necessarily of equal length) radiating approximately 645°

carriage wheels, and

from the point the tear was initiated.

5.1.2.5 Bubble level to level the base.

5.2 Thestandarddropheightis508mm[20.0in.];however,

1

it can be varied to suit the desired end-use-rate condition. See

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

Current edition approved March 10, 2003. Published April 2003. Originally

approved in 1967. Last previous edition approved in 2000 as D 2582 – 00.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The sole source of supply of the apparatus known to the committee at this time

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM isTestingMachines,Inc.,2910ExpresswayDrive,South,Islandia,NY11749.If

Standards volume information, refer to the standard’s Document Summary page on you are aware of alternative suppliers, please provide this information to ASTM

the ASTM website. International Headquarters. Your comments will receive careful consideration at a

3

1

Withdrawn. meeting of the responsible technical committee , which you may attend.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.