ASTM E751/E751M-17

(Practice)Standard Practice for Acoustic Emission Monitoring During Resistance Spot-Welding

Standard Practice for Acoustic Emission Monitoring During Resistance Spot-Welding

SIGNIFICANCE AND USE

5.1 The AE produced during the production of a spot-weld can be related to weld quality parameters such as the strength and size of the nugget, the amount of expulsion, and the amount of cracking. Therefore, in-process AE monitoring can be used both as an examination method, and as a means for providing feedback control.

SCOPE

1.1 This practice describes procedures for the measurement, processing, and interpretation of the acoustic emission (AE) response associated with selected stages of the resistance spot-welding process.

1.2 This practice also provides recommendations for feedback control by utilizing the measured AE response signals during the spot-welding process.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E751/E751M − 17

Standard Practice for

Acoustic Emission Monitoring During Resistance Spot-

1

Welding

This standard is issued under the fixed designation E751/E751M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive

1.1 This practice describes procedures for the measurement,

Testing Personnel Qualification and Certification

processing, and interpretation of the acoustic emission (AE)

ANSI/ASNT CP-189 Standard for Qualification and Certifi-

response associated with selected stages of the resistance

cation of Nondestructive Testing Personnel

spot-welding process.

4

2.3 AIA Standard:

1.2 This practice also provides recommendations for feed-

NAS-410 Certification and Qualification of Nondestructive

back control by utilizing the measured AE response signals

Personnel (Quality Assurance Committee)

during the spot-welding process. 5

2.4 ISO Standard:

ISO 9712 Non-Destructive Testing: Qualification and Certi-

1.3 Units—The values stated in either SI units or inch-

pound units are to be regarded separately as standard. The fication of NDT Personnel

values stated in each system may not be exact equivalents;

3. Terminology

therefore, each system shall be used independently of the other.

3.1 Definitions—For definitions of terms relating to acoustic

Combining values from the two systems may result in non-

emission testing, see Section B of Terminology E1316.

conformance with the standard.

1.4 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

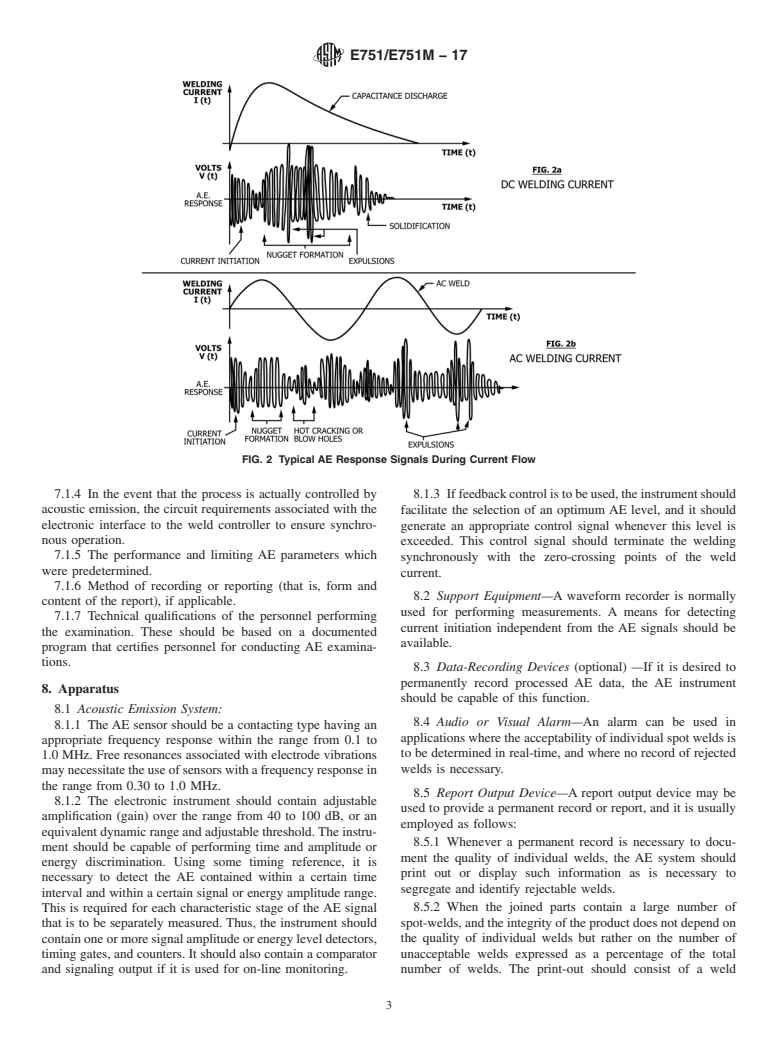

4.1 The resistance spot-welding process consists of several

responsibility of the user of this standard to establish appro-

stages. These are the set-down of the electrodes, squeeze,

priate safety and health practices and determine the applica-

current flow, forging, hold time, and lift-off. Various types of

bility of regulatory limitations prior to use.

acoustic emission signals are produced during each of these

1.5 This international standard was developed in accor-

stages. Often, these signals can be identified with respect to the

dance with internationally recognized principles on standard-

nature of their source. The individual signal elements may be

ization established in the Decision on Principles for the

greatly different, or totally absent, in various materials,

Development of International Standards, Guides and Recom-

thicknesses, and so forth. Fig. 1 is a schematic representation

mendations issued by the World Trade Organization Technical

showing typical signal elements which may be present in the

Barriers to Trade (TBT) Committee.

AE signature from a given spot-weld.

2. Referenced Documents 4.2 Most of the depictedAE signal features can be related to

2

factors of weld quality. TheAE occurring during set-down and

2.1 ASTM Standards:

squeeze can often be related to the condition of the electrodes

E543 Specification for Agencies Performing Nondestructive

and the surface of the parts. The large, often brief, signal at

Testing

current initiation can be related to the initial resistance, and the

E1316 Terminology for Nondestructive Examinations

cleanliness of the part. For example, burning through of certain

oxide layers contributes to the acoustic emission response

during this time.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

3

Acoustic Emission Method. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Current edition approved June 1, 2017. Published June 2017. Originally 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

approved in 1980. Last previous edition approved in 2012 as E751 - 12. DOI: Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

10.1520/E0751-17. WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), ISO

Standards volume information, refer to the standard’s Document Summary page on Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

the ASTM website. Geneva, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. Unite

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E751/E751M − 12 E751/E751M − 17

Standard Practice for

Acoustic Emission Monitoring During Resistance Spot-

1

Welding

This standard is issued under the fixed designation E751/E751M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice describes procedures for the measurement, processing, and interpretation of the acoustic emission (AE)

response associated with selected stages of the resistance spot-welding process.

1.2 This practice also provides guidelinesrecommendations for feedback control by utilizing the measured AE response signals

during the spot-welding process.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E1316 Terminology for Nondestructive Examinations

3

2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Nondestructive Testing Personnel Qualification and Certification

ANSI/ASNT CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

4

2.3 AIA Standard:

NAS-410 Certification and Qualification of Nondestructive Personnel (Quality Assurance Committee)

5

2.4 ISO Standard:

ISO 9712 Non-Destructive Testing: Qualification and Certification of NDT Personnel

3. Terminology

3.1 Definitions—For definitions of terms relating to acoustic emission testing, see Section B of Terminology E1316.

4. Summary of Practice

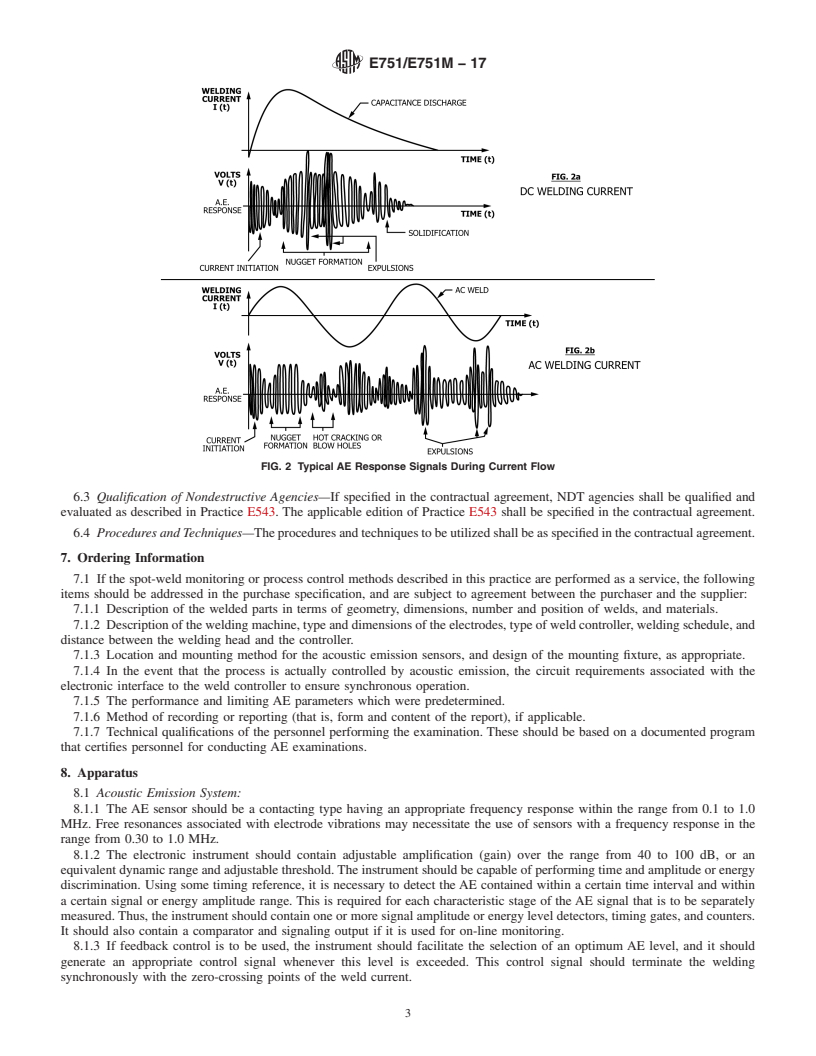

4.1 The resistance spot-welding process consists of several stages. These are the set-down of the electrodes, squeeze, current

flow, forging, hold time, and lift-off. Various types of acoustic emission signals are produced during each of these stages. Often,

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.04 on Acoustic Emission

Method.

Current edition approved June 15, 2012June 1, 2017. Published July 2012June 2017. Originally approved in 1980. Last previous edition approved in 20072012 as

E751 - 07.E751 - 12. DOI: 10.1520/E0751-12.10.1520/E0751-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

Available from Aerospace Industries Association of America, Inc. (AIA), 1000 Wilson Blvd., Suite 1700, Arlington, VA 22209-3928, http://www.aia-aerospace.org.

5

Available from International Organization for Standardization (ISO), ISO Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E751/E751M − 17

FIG. 1 Typical AE Response Signals During Resistance Spot Welding

these signals can be identified with respect to the nature of their source. The individual signal elements may be greatly different,

or totally absent, in various materials, thicknesses, and so forth. Fig. 1 is a schematic representation showing typical signal

elements which may be prese

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.