ISO/ASTM 51939:2002

(Main)Practice for blood irradiation dosimetry

Practice for blood irradiation dosimetry

ISO/ASTM 51939 outlines irradiator installation qualification and dosimetric procedures to be followed in the irradiation of blood and blood products by the blood-banking community. If followed, these procedures will help to ensure that the products processed with ionizing radiation from gamma, bremsstrahlung X-rays or electron sources receive absorbed doses within a predetermined range. ISO/ASTM 51939 covers dosimetry for the irradiation of blood for the following types of irradiators: self-contained dry-storage 137Cs or 60Co irradiators (free-standing irradiators), tele-therapy units, self-contained bremsstrahlung X-ray units and electron accelerators. The absorbed dose range for blood irradiation is typically 15 Gy to 50 Gy. This International Standard also covers the use of radiation-sensitive indicators for the visual and qualitative indication that the product has been irradiated. It is intended for use by technically and non-technically oriented people and, therefore, contains more tutorial information than many other ISO/ASTM dosimetry standards.

Guide de la dosimétrie pour l'irradiation du sang

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO/ASTM

STANDARD 51939

First edition

2002-03-15

Practice for blood irradiation dosimetry

Pratique de la dosimétrie pour l’irradiation du sang

Reference number

ISO/ASTM 51939:2002(E)

© ISO/ASTM International 2002

---------------------- Page: 1 ----------------------

ISO/ASTM 51939:2002(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe’s licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe’s licensing policy. Neither the ISO Central

Secretariat nor ASTM International accepts any liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies

and ASTM members. In the unlikely event that a problem relating to it is found, please inform the ISO Central Secretariat or ASTM

International at the addresses given below.

© ISO/ASTM International 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s member body in the country of the

requester. In the United States, such requests should be sent to ASTM International.

ISO copyright office ASTM International, 100 Barr Harbor Drive, PO Box C700,

Case postale 56 • CH-1211 Geneva 20 West Conshohocken, PA 19428-2959, USA

Tel. +41 22 749 01 11 Tel. +610 832 9634

Fax +41 22 749 09 47 Fax +610 832 9635

E-mail copyright@iso.ch E-mail khooper@astm.org

Web www.iso.ch Web www.astm.org

Printed in the United States

ii © ISO/ASTM International 2002 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/ASTM 51939:2002(E)

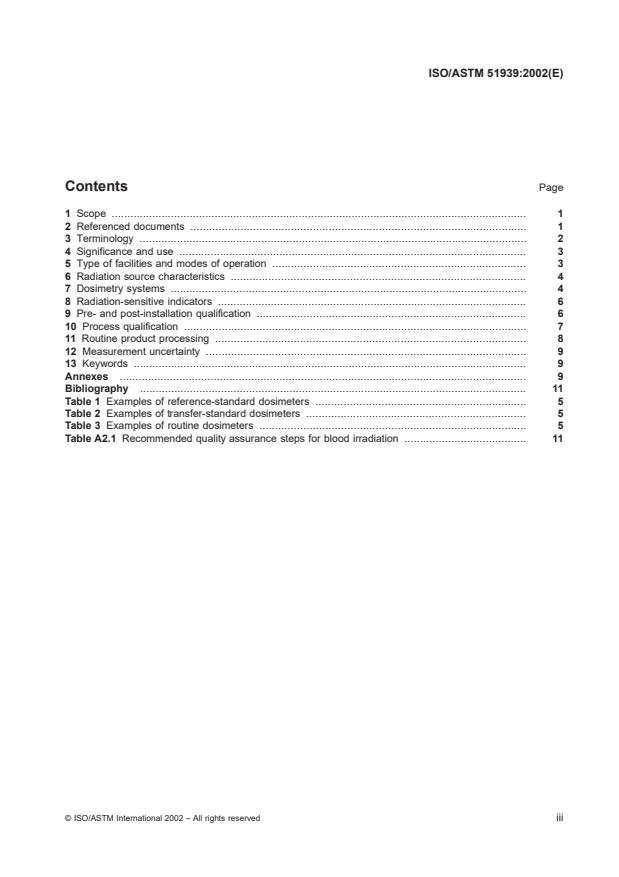

Contents Page

1 Scope . 1

2 Referenced documents . 1

3 Terminology . 2

4 Significance and use . 3

5 Type of facilities and modes of operation . 3

6 Radiation source characteristics . 4

7 Dosimetry systems . 4

8 Radiation-sensitive indicators . 6

9 Pre- and post-installation qualification . 6

10 Process qualification . 7

11 Routine product processing . 8

12 Measurement uncertainty . 9

13 Keywords . 9

Annexes . 9

Bibliography . 11

Table 1 Examples of reference-standard dosimeters . 5

Table 2 Examples of transfer-standard dosimeters . 5

Table 3 Examples of routine dosimeters . 5

Table A2.1 Recommended quality assurance steps for blood irradiation . 11

© ISO/ASTM International 2002 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/ASTM 51939:2002(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are circulated to the member bodies for

voting. Publication as an International Standard requires approval by at least 75% of the member bodies

casting a vote.

ASTM International is one of the world’s largest voluntary standards development organizations with global

participation from affected stakeholders. ASTM technical committees follow rigorous due process balloting

procedures.

A pilot project between ISO and ASTM International has been formed to develop and maintain a group of

ISO/ASTM radiation processing dosimetry standards. Under this pilot project, ASTM Subcommittee E10.01,

Dosimetry for Radiation Processing, is responsible for the development and maintenance of these dosimetry

standards with unrestricted participation and input from appropriate ISO member bodies.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. Neither ISO nor ASTM International shall be held responsible for identifying any or all such

patent rights.

International Standard ISO/ASTM 51939 was developed by ASTM Committee E10, Nuclear Technology and

Applications, through Subcommittee E10.01, and by Technical Committee ISO/TC 85, Nuclear Energy.

Annexes A1 and A2 of this International Standard are for information only.

iv © ISO/ASTM International 2002 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/ASTM 51939:2002(E)

Standard Practice for

1

Blood Irradiation Dosimetry

This standard is issued under the fixed designation ISO/ASTM 51939; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision.

1. Scope E 668 Practice for Application of Thermoluminescence-

Dosimetry (TLD) Systems for Determining Absorbed Dose

1.1 This practice outlines irradiator installation qualification

2

in Radiation-Hardness Testing of Electronic Devices

and dosimetric procedures to be followed in the irradiation of

E 1026 Practice for Using the Fricke Reference Standard

blood and blood products by the blood-banking community. If

2

Dosimetry System

followed, these procedures will help to ensure that the products

2.2 ISO/ASTM Standards:

processed with ionizing radiation from gamma, bremsstrahlung

51261 Guide for Selection and Calibration of Dosimetry

X-rays or electron sources receive absorbed doses within a

2

Systems for Radiation Processing

predetermined range.

51275 Practice for Use of a Radiochromic Film Dosimetry

1.2 This practice covers dosimetry for the irradiation of

2

System

blood for these types of irradiators: self-contained dry-storage

137 60

51538 Practice for Use of the Ethanol-Chlorobenzene Do-

Cs or Co irradiators (free-standing irradiators), tele-

2

simetry System

therapy units, self-contained bremsstrahlung X-ray units and

2

51539 Guide for the Use of Radiation-Sensitive Indicators

electron accelerators. The absorbed dose range for blood

51540 Practice for Use of a Radiochromic Liquid Dosim-

irradiation is typically 15 Gy to 50 Gy.

2

etry System

1.3 This practice also covers the use of radiation-sensitive

51607 Practice for Use of the Alanine-EPR Dosimetry

indicators for the visual and qualitative indication that the

2

System

product has been irradiated.

51608 Practice for Dosimetry in an X-ray (Bremsstrahlung)

1.4 This practice is intended for use by technically and

2

Facility for Radiation Processing

non-technically oriented people. It, therefore, contains more

51707 Guide for Estimating Uncertainties in Dosimetry for

tutorial information than many other ASTM and ISO/ASTM

2

Radiation Processing

dosimetry standards.

2.3 National Council on Radiation Protection and Mea-

1.5 This standard does not purport to address all of the

5

surements (NCRP) Publications

safety concerns, if any, associated with its use. It is the

NCRP Report No. 58, A Handbook of Radioactivity Mea-

responsibility of the user of this standard to establish appro-

surement Procedures, 1985.

priate safety and health practices and to determine the

NCRP Report No. 69, Dosimetry of X-ray and Gamma-Ray

applicability or regulatory limitations prior to use.

Beams for Radiation Therapy in the Energy Range 10 keV

2. Referenced Documents to 50 MeV, December 1981.

2.4 International Commission on Radiation Units and

2.1 ASTM Standards:

6

Measurements Reports (ICRU)

E 170 Terminology Relating to Radiation Measurements

2

ICRU 14 Radiation Dosimetry: X-rays and Gamma Rays

and Dosimetry

with Maximum Photon Energies Between 0.6 and 50 MeV

E 177 Practice for Use of the Terms Precision and Bias in

3,4

ICRU 17 Radiation Dosimetry: X-rays Generated at Poten-

ASTM Test Methods

,

3 4

tials of 5 to 150 kV

E 456 Terminology Relating to Quality and Statistics

ICRU 30 International Comparison of Radiological Units

E 666 Practice for Calculating Absorbed Dose from Gamma

2

and Measurements Quantitative Concepts and Dosimetry

or X Radiation

in Radiobiology

ICRU 34 The Dosimetry of Pulsed Radiation

ICRU 35 Radiation Dosimetry: Electron Beams with Ener-

1

This practice is under the jurisdiction of ASTM Committee E10 on Nuclear

gies Between 1 and 50 MeV

Technology and Applications and is the direct responsibility of Subcommittee

E10.01 on Dosimetry for Radiation Processing, and is also under the jurisdiction of

ISO/TC 85/WG 3.

Current edition approved Jan. 22, 2002. Published March 15, 2002. Originally

5

published as ASTM E 1939–98. Last previous ASTM edition E 1939–98. Available from the National Council on Radiation Protection and Measure-

2

Annual Book of ASTM Standards, Vol 12.02. ments, 7910 Woodmont Ave., Suite 800, Bethesda, MD 20814 U.S.A.

3 th 6

ASTM Standards on Precision and Bias for Various Applications,4 ed., 1992. Available from the International Commission on Radiation Units and Measure-

4

Annual Book of ASTM Standards, Vol 14.02. ments, 7910 Woodmont Ave., Suite 800, Bethesda, MD 20814 U.S.A.

© ISO/ASTM International 2002 – All rights reserved

1

---------------------- Page: 5 ----------------------

ISO/ASTM 51939:2002(E)

ICRU 60 Radiation Quantities and Units 3.1.5 dose uniformity ratio—ratio of maximum to minimum

2.5 Guidelines on Blood Irradiation absorbed dose within the irradiated blood or blood product.

Guidelines on Gamma Irradiation of Blood Components for This concept is also referred to as the “max/min ratio.”

the Prevention of Transfusion-associated Graft-versus-

3.1.5.1 Discussion—The central plane/minimum ratio is not

host Disease, Prepared by the BCSH Blood Transfusion

used in this standard.

7

Task Force.

3.1.6 dosimeter—a device that, when irradiated, exhibits a

Recommendations Regarding License Amendments and

quantifiable change in some property of the device which can

Procedures for Gamma Irradiation of Blood Products.

be related to absorbed dose in a given material using appro-

8

(1993) US Food and Drug Administration.

priate analytical instrumentation and techniques.

3.1.6.1 Discussion—A dosimeter must exhibit the reproduc-

3. Terminology

ible and quantifiable properties that allow it to be calibrated

3.1 Definitions:

and compared to national standards.

3.1.1 absorbed dose (D)—Quantity of ionizing radiation

3.1.7 dosimeter batch—Quantity of dosimeters made from a

energy imparted per unit mass of a specified material. The SI

specific mass of material with uniform composition, fabricated

unit of absorbed dose is the gray (Gy), where 1 gray is

in a single production run under controlled, consistent condi-

equivalent to the absorption of 1 joule per kilogram of the

tions and having a unique identification code.

specified material (1 Gy = 1 J/kg). The mathematical relation-

3.1.8 dosimetry system—a system used for determining

ship is the quotient of de¯ by dm, where de¯ is the mean

absorbed dose, consisting of dosimeters, measurement instru-

incremental energy imparted by ionizing radiation to matter of

ments and their associated reference standards, and procedures

incremental mass dm (see ICRU 60).

for the system’s use.

D 5 de¯ dm (1)

/

3.1.9 irradiator turntable—device used to rotate the canis-

3.1.1.1 Discussion—

ter during the irradiation process to improve the dose unifor-

mity ratio.

1. The discontinued unit for absorbed dose is the rad (1 rad = 100

erg/g = 0.01 Gy). 3.1.9.1 Discussion—An irradiator turntable is often referred

2. Absorbed dose is sometimes referred to simply as dose.

to as a turntable. Some irradiator geometries e.g. with a circular

3. For a photon source under conditions of charged particle equilib-

array of radiation sources surrounding the product, may not

rium, the absorbed dose, D, may be expressed as follows:

need a turntable.

D5F@E~μ /r!#, (2)

en

3.1.10 measurement quality assurance plan—A docu-

mented program for the measurement process that ensures on

where:

2

a continuing basis that the overall uncertainty meets the

F = particle fluence (particles/m ),

requirements of the specific application. This plan requires

E = energy of the ionizing radiation (J), and

2

traceability to, and consistency with, nationally- or

μ /r = mass energy absorption coefficient (m /kg).

en

internationally-recognized standards.

4. If bremsstrahlung production within the specified material is

3.1.11 radiation-sensitive indicator—a material such as

negligible, the mass energy absorption coefficient (μ /r) is equal to the

en

coated or impregnated adhesive-back substrates, inks, or coat-

mass energy transfer coefficient (μ /r), and absorbed dose is equal to

tr

kerma. ings which may be affixed to or printed on the blood product or

blood component product and which undergo a visual change

˙

3.1.2 absorbed-dose rate (D)—the absorbed dose in a

when exposed to ionizing radiation (see ISO/ASTM Guide

material per incremental time interval, ie. the quotient of dD by

51539).

dt.

3.1.11.1 Discussion—Radiation-sensitive indicators are of-

˙

D 5 dD dt (3)

/

ten referred to as “indicators.” Radiation-sensitive indicators

–1

Unit: Gy·s . cannot be classified as a “label” under the U.S. FDA “Guide-

3.1.2.1 Discussion—The absorbed-dose rate can be speci- lines for the Uniform Labeling of Blood and Blood Products”

8

fied in terms of average value of D over long-time intervals, for (August, 1985). Indicators may be used to show that products

–1 –1

example, in units of Gy·min or Gy·h . have been exposed to ionizing radiation. They can be used to

3.1.3 blood product—a unit of blood or specific blood provide a visual and qualitative indication of radiation expo-

component. sure and can be used to distinguish between irradiation-

3.1.4 canister—a container, usually an aluminum or steel processed blood products and unprocessed blood products.

cylinder, used to house the blood product, or blood-equivalent Indicators cannot be used as a substitute for proper dosimetry.

product during the irradiation process.

3.1.12 reference–standard dosimeter—a dosimeter of high

metrological quality, used as a standard to provide measure-

ments traceable to and consistent with measurements made

7

with primary–standard dosimeters (see ISO/ASTM Guide

Available from the National Blood Transfusion Service, East Anglian Blood

Transfusion Centre, Long Road, Cambridge, CB2 2PT United Kingdom, Tel (0223)

51261).

245921, Fax (0223) 411618.

8

3.1.13 routine dosimeter—dosimeter calibrated against a

Available from the Office of Blood Research and Review, US Food and Drug

Administration, 1401 Rockville Pike, Rockville, MD 20852, USA. primary–, reference-, or transfer-standard dosimeter and used

© ISO/ASTM International 2002 – All rights reserved

2

---------------------- Page: 6 ----------------------

ISO/ASTM 51939:2002(E)

for routine absorbed-dose measurement (see ISO/ASTM Guide volume is measured by the manufacturer as part of acceptance

51261). testing using a reference-standard dosimetry system. That

3.1.14 simulated product—a mass of material with attenu- reference-standard measurement must be used to calculate the

ation and scattering properties similar to those of the product, timer setting required to deliver the specified absorbed dose to

material or substance to be irradiated. the center of the blood or blood component, or other reference

3.1.14.1 Discussion—Simulated product is used during ir- position of the container filled with blood products. Either

radiator characterization as a substitute for the actual product, relative or absolute absorbed-dose measurements are per-

material or substance to be irradiated. When used for absorbed- formed within the blood- or blood-equivalent volume for

dose mapping, simulated product is sometimes referred to as a determining the absorbed-dose distribution. Accurate radiation

phantom material. dosimetry at a reference position which could be the position of

3.1.15 transfer–standard dosimeter—a dosimeter, often a the maximum absorbed dose (Dmax) or minimum absorbed

reference–standard dosimeter, suitable for transport between dose (Dmin) offers a quantitative, independent method to

different locations for use as an intermediary to compare monitor the radiation process.

absorbed-dose measurements (see ISO/ASTM Guide 51261).

4.6 Dosimetry is part of a measurement quality assurance

3.1.16 transit dose—absorbed dose delivered to product

program that is applied to ensure that the radiation process

while the product moves from the load/unload position to the meets predetermined specifications (4).

irradiate position, and back to the load/unload position.

4.7 Absorbed-dose mapping is often performed using simu-

3.1.17 validation—establishment of documented evidence

lated product.

which provides a high degree of assurance that a specified

4.8 Proper documentation and record keeping are critical

process will consistently produce a product meeting its prede-

components of radiation processing. This standard does not

termined specifications and quality attributes.

address this issue since minimum requirements must be set by

3.2 Definitions of other terms used in this standard that

the pertinent governing bodies.

pertain to radiation measurement and dosimetry may be found

in ASTM Terminology E 170. Definitions in ASTM E 170 are

5. Type of Facilities and Modes of Operation

compatible with ICRU 60; that document, therefore, may be

5.1 Self-Contained Blood Irradiators. (5) The majority of

used as an alternative reference.

blood components are irradiated by gamma rays from either

137 60

Cs or Co self-contained dry storage irradiators. These

4. Significance and Use

devices house the radiation source in a protective lead shield

4.1 Blood products include whole blood, red cells, frozen

(or other appropriate high atomic number material), and

cells, platelet concentrates, apheresis platelets, granulocyte

usually have a mechanism to rotate or lower the canister from

concentrates, and fresh (frozen) plasma. The assurance that

the load/unload position to the irradiation position.

blood or blood products have been properly irradiated is of

5.1.1 The most common method used to ensure a uniform

crucial importance for patient health. The irradiator operator

absorbed-dose distribution in the blood product is to rotate the

must demonstrate by means of accurate absorbed-dose mea-

canister holding the blood product on an irradiator turntable in

surements on the product, or in simulated product, that the

front of the radiation source.

specified absorbed dose has been achieved throughout the

5.1.2 A second method is to distribute the source in a

product.

circular array. The blood product is located at the center of the

4.2 Blood and various blood products are irradiated at

array, resulting in a relatively uniform absorbed-dose distribu-

pre-determined doses to inactivate viable lymphocytes to help

tion. In this design, irradiator turntables would not normally be

prevent transfusion-induced graft-versus-host disease (GVHD)

necessary.

in selected immunocompromised patients and those receiving

60

5.2 Teletherapy Equipment. Co equipment and linear

9

related-donor products (1,2).

accelerator teletherapy equipment (in electron or bremsstrahl-

4.3 Blood products may be treated with ionizing radiation,

137 60 ung X-ray modes) are used primarily for the treatment of

such as gamma rays from Cs or Co sources, and from

tumors. These units may also be used to irradiate blood

self-contained bremsstrahlung X-ray units and medical linear

products. In both types of equipment, radiation is emitted or

X-ray and electron accelerators used primarily for radio-

generated and directed at the blood products placed beneath the

therapy.

collimator. The collimator is used to create a highly defined

4.4 Blood irradiation specifications include a lower limit of

beam of radiation.

absorbed dose, and may include an upper limit or central target

5.3 Electron Accelerator (Electron and Bremsstrahlung

dose. For a given application, any of these values may be

X-ray modes). Accelerator-generated radiation is in the form of

prescribed by regulations that have been established on the

electrons or bremsstrahlung X-rays. Teletherapy accelerators

basis of available scientific data.

can be used for this purpose.

4.5 For each blood irradiator, an absorbed-dose rate at a

5.3.1 For an electron accelerator, the two principal beam

reference dose position within the blood- or blood-equivalent

characteristics are the energy spectrum and the average beam

current. The electron energy spectrum affects the variation of

9

absorbed dose with depth in a given material, and the average

The boldface numbers in parentheses refer to the bibliography at the end of this

standard. beam current affects the absorbed-dose rate.

© ISO/ASTM International 2002 – All rights reserved

3

---------------------- Page: 7 ----------------------

ISO/ASTM 51939:2002(E)

5.3.2 A bremsstrahlung X-ray accelerator emits short- (fields) and other dosimeters. The two most commonly used

wavelength electromagnetic radiation, similar in energy to primary–standard dosimeters are ionization chambers and

gamma radiation. Although their effects on materials are calorimeters (see ISO/ASTM Guide 51261, ICRU Reports 14,

generally similar, these kinds of radiation differ in their energy 17, 34 and 35 and NCRP Report 69).

spectra, angular distributions, and absorbed-dose rates. 7.1.2.2 Reference–Standard Dosimeters: Reference–stan-

5.3.3 Some blood components are irradiated using a self-

dard dosimeters are used to calibrate radiation environments

contained portable bremsstrahlung X-ray blood irradiator. The and routine dosimeters. Reference–standard dosimeters may

bremsstrahlung X-rays are produced in a conventional manner,

also be used as routine dosimeters. Examples of reference-

but the unit is totally self-contained (free standing). Spectrum

–standard dosimeters used in blood irradiation, along with their

filtration is used to reduce the low energy component of the useful dose ranges are given in Table 1.

radiation, thus improving the dose uniformity ratio. In some

7.1.2.3 Transfer–Standard Dosimeters: Transfer–standard

cases, irradiator turntables are used.

dosimeters are specially selected dosimeters used for transfer-

ring absorbed-dose information from an accredited or national

6. Radiation Source Characteristics

standards laboratory to an irradiation facility in order to

6.1 The radiation source used in a facility considered in this

establish traceability for that facility. These dosimeters should

60 137

practice consists of sealed elements of Co or Cs which

be used under conditions that are carefully controlled by the

are typically linear rods or “pencils” arranged in one or more

issuing laboratory. Transfer–standard dosimeters may be se-

planar or cylindrical arrays, bremsstrahlung X-rays, or elec-

lected from either reference–standard dosimeters or routine

trons.

dosimeters and shall have performance characteristics that

6.2 Cobalt-60 emits photons with energies of approximately

meet the requirements listed in a table in ISO/ASTM Guide

1.17 and 1.33 MeV in nearly equal proportions. Cesium-137

51261. Examples of transfer-standard dosimeters used in blood

produces photons with energies of approximately 0.662 MeV

irradiation are given in Table 2.

(3).

7.1.2.4 Routine Dosimeters: Routine dosimeters may be

60 137

6.3 The half-lives for Co and Cs are approximately

used for quality control and process monitoring. Proper dosi-

5.2708 years (14) and 30.07 years (15, 16), respectively.

metric techniques, including calibration, shall be employed to

6.4 For gamma-ray sources, the only variation in the source

ensure that measurements are reliable and accurate. Examples

output is the known reduction in the activity caused by

of routine dosimeters used in blood irradiation, along with their

radioactive decay. The reduction in the source strength and the

useful dose ranges are given in Table 3.

required increase in the irradiation time may be calculated (see

7.2 Dosimeter Applications: In general, routine dosimeters

9.4.6) or obtained from tables provided by the irradiator

are used to monitor the radiation process on a routine basis as

manufacturer.

an integral part of process control, and may be used to perform

6.5 Direct-action electron accelerators which employ dc or

dose mapping to determine the absorbed-dose distribution

pulsed high-voltage generators typically produce electron en-

throughout the product or simulated product. The absorbed-

ergies up to 5 MeV. Indirect-action electron accelerators use

dose rate at a specific location, which will be used to determine

microwave or very high frequency (vhf) ac power to produce

the time interval for the irradiation (or the timer setting), must

electron energies typically from 5 MeV to 15 MeV.

be determined using higher-quality primary-, reference-, or

6.6 The continuous energy spectrum of the X-rays

transfer-standard dosimeters.

(bremsstrahlung) ranges from approximately 35 keV up to the

7.2.1 Timer Setting Calculations: The reference-standard

maximum energy of the electrons incident on the X-ray target

measurement must be used to calculate the timer setting

(see ISO/ASTM Practice 51608).

required to deliver the specified absorbed dose to the center of

6.7 Regulations in some countries limit the maximum elec-

the blood or blood component, or other reference position of

tron energy to 10 MeV and photon energy to 5 MeV.

the container filled with blood products. The reference–stan-

dard dosimeter most widely used is the ferrous sulfate (Fricke)

7. Dosimetry Systems

aqueous solution (see ASTM Practice E 1026 ). Other refer-

7.1 Description of Dosimeter Classes:

ence–standard dosimeters include ionization chambers (see

7.1.1 Dosimetry systems are used to measure absorbed

NCRP Report 69 and Ref (13)) and radiochromic solutions (see

dose. They consist of the dosimeters, measurement instruments

ISO/ASTM Practice 51540 and Ref (6)).

and their associated reference standards, and procedures for the

7.2.1.1 Precise and accurate absorbed-dose measurements

systems’ use.

are made in simulated product routine-processing conditions.

7.1.2 Dosimeters may be divided into four basic classes

The irradiation time to deliver the required absorbed dose can

according to their accuracy and areas of application: primary

then be accurately determined.

standard, reference standard, transfer standard, and routine

dosimeters. ISO/ASTM Guide 51261 provides detailed infor- NOTE 1—For reference standard dosimetry, the absorbed dose and

absorbed-dose rate can be expressed in water or other material which has

mation about the selection of dosimetry systems for different

similar absorption properties to that of blood and simulated-blood

applications.

products.

7.1.2.1 Primary–Standard Dosimeters: Primary–standard

dosimeters are established and maintained by national stan- 7.2.2 Quality Control and Routine Monitoring—Routine

dosimeters may be used for quality control and routine

dards laboratories for calibration of radiation environments

© ISO/ASTM International 2002 – All rights reserved

4

---------------------- Page: 8 ----------------------

ISO/ASTM 51939:2002(E)

TABLE 1 Examples of Reference-Standard Dosimeters

Dosimeter Readout System Useful Absorbed-dose Range (Gy) Reference

5

Alanine EPR Spectrometer 1 to 10 ISO/ASTM 51607

6

Ethanol-Chlorobenzene solution Spectrophotometer, color titration, high 10 to 2 3 10 ISO/ASTM 51538

frequency conductivity

Fricke UV Spectrophotometer 20 to 400 ASTM E 1026

Ionization Chamber Electrometer Can be easily applied to the Blood-irradiation Dose (13

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.