ISO 28901:2011

(Main)Soil quality - Guidance for burial of animal carcasses to prevent epidemics

Soil quality - Guidance for burial of animal carcasses to prevent epidemics

ISO 28901:2011 provides guidance on environment-friendly burial methods of animal carcasses to prevent epidemics, to curtail the spread of the disease, to destroy the causative agents, and to dispose of the carcasses. ISO 28901:2011 does not apply to the burial of animal carcasses resulting from natural death or by accident. Other methods of disposal are outside the scope of ISO 28901:2011.

Qualité du sol — Lignes directrices pour l'enfouissement des carcasses d'animaux pour éviter une épidémie

General Information

Overview

ISO 28901:2011 - Soil quality: Guidance for burial of animal carcasses to prevent epidemics provides practical, environment‑focused guidance for the burial of infected animal carcasses during disease outbreaks. The standard aims to curtail disease spread, destroy causative agents and ensure safe disposal while limiting soil, groundwater and surface‑water contamination. It does not apply to carcasses from natural death or accidental mortality, and other disposal methods (incineration, rendering, composting) are outside its scope.

Key topics and technical requirements

- Objectives & constraints: priorities include limiting pathogen spread, safe disposal, site rehabilitation and rapid response under constrained resources and local ground conditions.

- Planning of burial programmes: timing of burial, species/disease considerations, and burial volume planning (the document includes an indicative table of average livestock weights and planning assumptions).

- Site selection: guidance to prefer onsite burial (to reduce transport risks) when feasible; sites must be controllable, away from water sources, principal aquifers, main roads and residential areas, not flood‑prone or soft ground.

- Methods of burial: descriptions and evaluation of simple burial, aerobic burial and anaerobic (lined) burial approaches, with discussion of their environmental and biosecurity implications.

- Construction of burial pits: stepwise guidance on site preparation, excavation, lining materials and drainage (including placement of perforated pipes), carcass placement and final coverage.

- Post‑burial maintenance & monitoring: measures for safety, odour and gas control, leachate management, surface regrading, ongoing monitoring, and rules for reuse of burial sites.

- Record keeping & reporting: documentation requirements for burial operations.

- Informative annexes: examples of national specifications, a list of diseases (aligned with the World Organisation for Animal Health/OIE), and design examples for protection layers around drainage pipes.

Practical applications and users

ISO 28901:2011 is designed for use in emergency animal disease management and environmental protection contexts. Typical users include:

- Veterinary authorities and animal‑health emergency response teams

- Farm managers and biosecurity officers responsible for on‑farm carcass disposal

- Environmental regulators and public‑health agencies overseeing site safety and monitoring

- Waste management contractors and civil engineers planning burial pits and drainage controls

- Soil scientists and land managers assessing suitability and rehabilitation of burial sites

Use cases include rapid mass carcass disposal during outbreaks (FMD, avian influenza, etc.), planning burial programmes, selecting safe burial locations, designing pits with leachate control, and establishing monitoring and record‑keeping protocols.

Related standards

ISO 28901 references soil and geotechnical test standards such as ISO 10390, ISO 10694, ISO 11260, ISO 11272, ISO 11277, ISO 13536, ISO 14688‑2 and ISO 25177, which support site assessment and monitoring activities.

Frequently Asked Questions

ISO 28901:2011 is a standard published by the International Organization for Standardization (ISO). Its full title is "Soil quality - Guidance for burial of animal carcasses to prevent epidemics". This standard covers: ISO 28901:2011 provides guidance on environment-friendly burial methods of animal carcasses to prevent epidemics, to curtail the spread of the disease, to destroy the causative agents, and to dispose of the carcasses. ISO 28901:2011 does not apply to the burial of animal carcasses resulting from natural death or by accident. Other methods of disposal are outside the scope of ISO 28901:2011.

ISO 28901:2011 provides guidance on environment-friendly burial methods of animal carcasses to prevent epidemics, to curtail the spread of the disease, to destroy the causative agents, and to dispose of the carcasses. ISO 28901:2011 does not apply to the burial of animal carcasses resulting from natural death or by accident. Other methods of disposal are outside the scope of ISO 28901:2011.

ISO 28901:2011 is classified under the following ICS (International Classification for Standards) categories: 13.080.99 - Other standards related to soil quality. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ISO 28901:2011 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 28901

First edition

2011-09-15

Soil quality — Guidance for burial of

animal carcasses to prevent epidemics

Qualité du sol — Lignes directrices pour l’enfouissement des carcasses

d’animaux pour éviter une épidémie

Reference number

©

ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

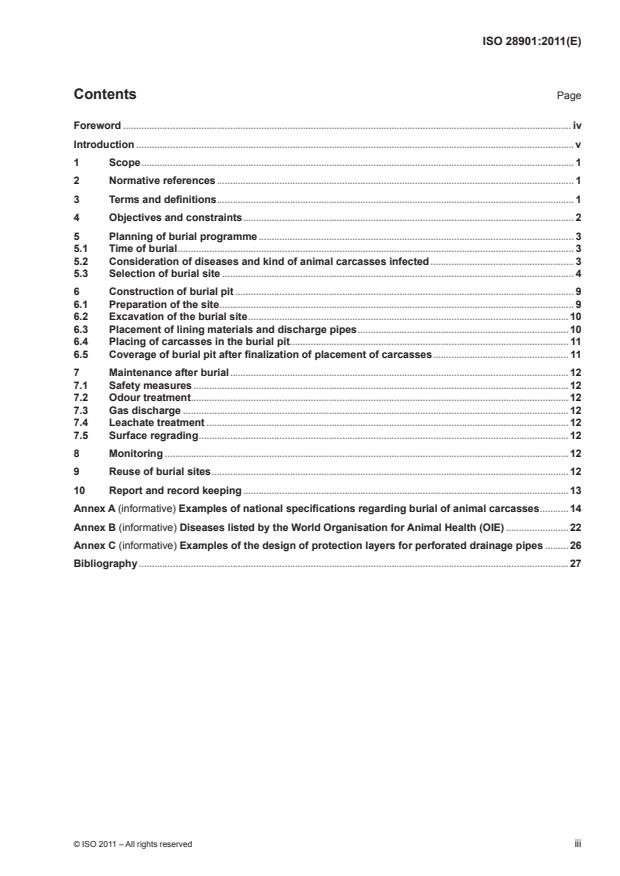

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Objectives and constraints . 2

5 Planning of burial programme . 3

5.1 Time of burial . 3

5.2 Consideration of diseases and kind of animal carcasses infected . 3

5.3 Selection of burial site . 4

6 Construction of burial pit . 9

6.1 Preparation of the site . 9

6.2 Excavation of the burial site .10

6.3 Placement of lining materials and discharge pipes .10

6.4 Placing of carcasses in the burial pit . 11

6.5 Coverage of burial pit after finalization of placement of carcasses . 11

7 Maintenance after burial .12

7.1 Safety measures .12

7.2 Odour treatment .12

7.3 Gas discharge .12

7.4 Leachate treatment .12

7.5 Surface regrading .12

8 Monitoring .12

9 Reuse of burial sites .12

10 Report and record keeping .13

Annex A (informative) Examples of national specifications regarding burial of animal carcasses .14

Annex B (informative) Diseases listed by the World Organisation for Animal Health (OIE) .22

Annex C (informative) Examples of the design of protection layers for perforated drainage pipes .26

Bibliography .27

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 28901 was prepared by Technical Committee ISO/TC 190, Soil quality, Subcommittee SC 7, Soil and

site assessment.

iv © ISO 2011 – All rights reserved

Introduction

The incidence of livestock epidemics such as bovine spongiform encephalopathy (BSE), swine fever, foot and

mouth disease (FMD), Newcastle disease and avian influenza (AI) are becoming increasingly more frequent

and geographically widespread. These epidemics spread quickly across country borders due to rapid exchange

of people, animals and products between countries. Epidemics threaten the welfare of human beings through

secondary infection on other livestock, economic loss and public health. Preventing the spread of epidemics

to other areas where livestock are raised is the priority. However, when this fails and the epidemic has spread,

rapid and effective action should be taken to prevent the further spread of infection. Slaughter followed by

disposal of infected livestock is an essential means of preventing the spread of the epidemic.

Disposal methods for slaughtered livestock include: incineration, rendering, composting and burial. Burial is a

method that has long been used, as it is relatively economical and does not require specialized techniques or

equipment. However, it does have the potential to contaminate the receiving environment. Leachate from the

buried animal carcass can pollute the soil and the surrounding waters (groundwater and surface water), and

the gas caused by the decomposition of the carcass produces foul. Despite such drawbacks, burial continues

to be used widely, because it can limit the spread of an epidemic when massive amount of carcasses must

be disposed rapidly. The objectives of this International Standard are to curtail the spread of the disease, to

destroy the causative agents, and to dispose of the carcasses by burial.

INTERNATIONAL STANDARD ISO 28901:2011(E)

Soil quality — Guidance for burial of animal carcasses to

prevent epidemics

1 Scope

This International Standard provides guidance on environment-friendly burial methods of animal carcasses to prevent

epidemics, to curtail the spread of the disease, to destroy the causative agents, and to dispose of the carcasses.

This International Standard does not apply to the burial of animal carcasses resulting from natural death

or by accident.

Other methods of disposal are outside the scope of this International Standard.

NOTE In some countries, infected animals or parts of animals cannot be buried on farms due to legislation but are

subject to handling by licensed commercial landfills or incinerations.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced document

(including any amendments) applies.

ISO 10390, Soil quality — Determination of pH

ISO 10694, Soil quality — Determination of organic and total carbon after dry combustion (elementary analysis)

ISO 11260, Soil quality — Determination of effective cation exchange capacity and base saturation level using

barium chloride solution

ISO 11272, Soil quality — Determination of dry bulk density

ISO 11277, Soil quality — Determination of particle size distribution in mineral soil material — Method by

sieving and sedimentation

ISO 13536, Soil quality — Determination of the potential cation exchange capacity and exchangeable cations

using barium chloride solution buffered at pH = 8,1

ISO 14688-2:2004, Geotechnical investigation and testing — Identification and classification of soil — Part 2:

Principles for a classification

ISO 25177, Soil quality — Field soil description

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

affected animal

animal which has been infectious or is at present infectious or is suspected of soon becoming infectious and

which is to be killed to prevent epidemics

3.2

animal carcass

dead body of an animal or parts thereof, or products of animal origin

NOTE Animal excreta are included in this definition.

3.3

burial

act of burying an animal carcass

3.4

discharge

action of releasing a substance such as a liquid or gas; a substance that is expelled from a defined area or location

3.5

disposal

collective noun for any operation to remove and discard waste

3.6

epidemic

large number of cases of a particular disease, usually infectious, occurring at the same time in a particular community

3.7

infectious waste

substance containing viable microorganisms or their toxins which is known or reliably believed to cause disease

in man or other living organisms

[EN 13965-1:2004]

3.8

leachate

liquid percolated through a soil and containing substances in solution or suspension

3.9

livestock

domesticated animals, usually kept on a farm

EXAMPLES Cattle, sheep, horses, pigs, chickens.

3.10

permeability

measure of the ease with which gases, liquids, or plant roots penetrate or pass through a bulk mass of soil

3.11

quicklime

liming material consisting mainly of calcium oxide or a mixture of calcium oxide and possibly magnesium oxide,

produced by the calcination of limestone, magnesian limestone or dolomitic limestone

[EN 12944-3:2001]

3.12

soil texture

relative proportions of the various particle size fractions (i.e. sand, silt, clay) in a soil according to a soil

classification system

3.13

wildlife animal

all non-domesticated animals

EXAMPLES Deer, wild boar, rodents.

4 Objectives and constraints

In the event of an epidemic in which an infectious disease either kills animals directly or causes them to be

killed, urgent action is required to

— curtail the spread of the disease,

2 © ISO 2011 – All rights reserved

— destroy the causative agents,

— rehabilitate those persons affected by the epidemic,

— return the land to profitable agriculture or other use,

— dispose of the carcasses, and

— dispose of excreta and other obnoxious material.

Four factors will constrain the work:

a) The need for urgency arises because there will be a multiplicity of pathways by which the causative agents

can be transmitted from live or dead animals within the area affected to animals in remote locations. The

causative agent can be spread by birds, other wildlife, or transported by wind or wind-blown dust, and

water. All of these mechanisms are difficult to control.

b) In an attempt to arrest some of these pathways, the site shall be quarantined, with movements of people

and other animals onsite and offsite being minimized, controlled and disinfected.

c) As a consequence, the work shall be constrained by what is in hand or can readily be obtained.

d) Further adaptation should be made to suit local ground conditions.

The number of animals involved shall also be considered.

NOTE For example, in one small outbreak in 2007, over 350 cattle were slaughtered on one day, and 800 pigs and

50 more cattle were slaughtered on the following day.

5 Planning of burial programme

5.1 Time of burial

Carcasses should be buried as soon as possible after their death. However, it should be noted that postmortem

livestock will gas up and increase volume by up to half. Therefore, if they are placed in a burial pit too soon and

covered over, the carcasses will subsequently rapidly degas, causing large voids to form and causing cracking

of cover material. Therefore, either the stock should not be covered immediately or the carcasses should be

pierced to prevent them gassing up.

Once buried, decomposition and degradation processes will intensify after 24 h to 72 h (depending on the

ambient temperature), which will pose additional threats to health and the environment.

Each country may have a specified time frame within which carcasses shall be buried.

5.2 Consideration of diseases and kind of animal carcasses infected

When livestock are sufficiently believed to be infected by an epidemic, owners of livestock in the area where

the epidemic has spread or may spread can be ordered to immediately eradicate the livestock. Livestock

eradication requirements can differ on a national scale, depending on the form of the epidemic. Diseases listed

by the World Organisation for Animal Health (OIE) are given in Annex B.

5.2.1 Consideration of volume of carcasses to be buried

It might be necessary to bury the following:

a) carcasses and parts thereof;

b) excreta, including: urine, dung, sweat, saliva, snot (nasal mucus), tears, earwax, milk, semen, “afterbirth”;

c) miscellaneous droppings, for example: hair, scurf, skin, blood;

d) infected straw, bedding mixed with dung, farmyard manure (if infected), etc.

Depending on the disease, some or perhaps all of these can transmit viable causative agents.

Burial volume is generally determined by the livestock’s species and size. If the burial volume is uncertain, it

should be assumed that no more than 300 kg of carcass per 1 m will be permitted. Table 1 gives an indication

of average livestock weight.

Table 1 — Average livestock weight

Type Kind of animal Weight

kg

Beef cattle Cows and bulls 550

Feeder cattle 450

Replacement heifers 360

Calves 135

Dairy cattle Cows and bulls 600

Replacement heifers 450

Calves 135

Hog Boars or sows 150

Feeder pigs 100

Weanling pigs 16

Poultry Hens, cockerels, capons 1,8

Chicks, broilers 1,5

Hen turkeys, geese, ducks 8

Sheep 50

5.3 Selection of burial site

5.3.1 Deciding between onsite or offsite burial

In general, to avoid further spreading of the disease due to transport and handling, the infected livestock should

be buried at the site where they are found.

The principal advantages of burial over incineration are that burial tools are simple, and movements off the site

where infected animal carcasses occur are minimized.

When a suitable location for burial is not available on the farm, burial would have to be off the farm.

If the carcasses are buried on the farm, continuing maintenance and monitoring of the burial area are required

(in relation to an existing national specification, if available); see also Clause 8. This area should be taken out

of production.

NOTE The presence of the pit, even if landscaped, can reduce the value of the land.

5.3.2 Methods of burial

The following methods of burial are distinguished.

Simple burial: The carcasses are laid into a pit and soil is placed directly on top of them, perhaps with the

addition of some quicklime. In this method, earth-dwelling worms, insects, and bacteria have direct access

to the carcasses and assist in their disintegration. However, large volumes of obnoxious effluent are to be

expected, and the causative agents are likely to escape with the effluent, meaning that complete disposal of

4 © ISO 2011 – All rights reserved

the carcasses cannot be assured. Although this method has been used in the past, it should now be regarded

as unacceptable.

Aerobic burial: Although there appears to be a view that burial under carefully controlled aerobic conditions

(presumably without earth-dwelling worms, insects and bacteria) would ensure complete disintegration

and disposal of the carcasses, there appears to be little in the way of either scientific evidence or practical

experience to support this view.

Anaerobic burial: Recent practice seems to have been to envelop the carcasses in impermeable membranes

with a view to collecting the leachate. It seems probable that anaerobic conditions have developed in many

cases when such systems have been used but there is some doubt as to whether disintegration does occur

under anaerobic conditions.

5.3.3 Requirements for the burial site

Burial sites are limited to areas where human or livestock access can be controlled, and shall not be in the

vicinity of water sources, surface water and principal aquifers, main roads or residential areas. In addition,

other aspects, such as environmental designation, archaeological site history, existing underground services,

field drains, statutory and legal issues, need to be considered.

When the candidate site is in the vicinity of a principal aquifer, the site should only be used for burial if the

results of a trial pit and other investigations show that the site is safe.

The area selected should not be liable to flooding or become submerged during flood events.

Soft ground should be avoided in selecting sites.

Characteristics of the soil of the burial site, such as soil texture, permeability, slope, groundwater depth and its

topography, should be taken into consideration. Escarpments and sandy soils shall be avoided.

In selecting a site for burial, soil information obtained from trial pits can be useful. A trial pit is a shallow

excavation made to a depth of not greater than 5 m. The trial pit is to be used extensively at the surface for soil

sampling and detection of services prior to borehole excavation (see, for example, ISO 10381-4).

SAFETY PRECAUTIONS — An important safety point to note is that all pits below a depth of 1,2 m shall

be supported.

When preparing a trial pit, a log including such information as soil type, structure and groundwater levels

should be made.

The basic characteristic parameters given in Table 2 should be considered to evaluate the potential contamination

of soil and groundwater at the burial sites.

NOTE For more information regarding groundwater protection, ISO 15175 can be considered.

Table 2 — Substances and parameters to be considered in selecting sites for burial

Substance/parameter Method International Standard

Distance to water source — —

Distance to main roads — —

Distance to residential area — —

Depth of groundwater table — ISO 25177

Possibility of submergence in case of — —

flooding

Slope — ISO 25177

Soil texture Sieving, sedimentation ISO 11277

Permeability — —

Bulk density Direct measurement of undisturbed ISO 11272

soil samples estimation from soil

water-retention curves

pH pH-electrode ISO 10390

Organic carbon Dry combustion ISO 10694

Cation exchange capacity, BASCOMP, BaCl ISO 11260

exchangeable cations

ISO 13536

Bearing capacity Cone penetration test —

Trial pit — ISO 14688-2:2004

5.3.4 Seasonal high groundwater level

Burial pits should be located on sites with soils having a seasonal high groundwater table not less than 1,5 m

below the bottom of the planned burial pit.

Some difficulty will be experienced in establishing the seasonal high groundwater level. Usually, this would

require observations to be taken from dip wells or the like, over the course of at least 1 year. However, usually

neither is the time available, nor is it advisable to drill holes from severely contaminated land down to the

water table. If this information is not already available, it might be possible to obtain a reasonable estimate

of seasonable high groundwater level from a desk study or from indirect observations. Otherwise, the best

possible estimate should be made and the possibility of error should be accepted.

Because a relatively deep excavation is being made without a thorough investigation, there is a small possibility

of breaking into an artesian aquifer. Should this happen, the excavation shall immediately be refilled with

compacted soil.

In the worst cases, it will be necessary to exhume the carcasses and start again.

5.3.5 Selection of the kind of pit

Usually onsite burial is preferable to offsite burial, given the potential of transmitting infection via transportation.

However, site-specific circumstances will usually dictate the best approach.

NOTE For example, in an area where a high density of farms has been affected, it might be more appropriate to have

one centralized and professionally managed disposal point, with carcasses transported to this point under appropriate

conditions. The advantage of this approach is that a more engineered design of the burial pit can be used, together with

more stringent monitoring of the disposal process. This approach reduces the number of smaller on-farm burial sites,

which for practical and financial reasons are invariably not well engineered or as closely monitored.

6 © ISO 2011 – All rights reserved

5.3.6 Design of the burial pit

There is no “one size fits all” design for burial pits. For centralized and professionally managed sites, a landfill-

like design (as given in Figure 1) may be appropriate. In contrast, on small and medium-sized individual farms,

it is unlikely that this approach can be used.

The design (and later construction) of the burial pit should be supervised by a competent civil engineer.

The depth of the pit should be such that the distance between the top of the carcass (once buried) and the

ground surface should be more than 2 m. The sides and the bottom of the pit should be covered with waterproof

material such as HDPE (high-density polyethylene) sheet.

Table 3 indicates the amount by which soil is likely to bulk up; i.e. increase in volume due to its lower compaction.

NOTE Loose soil is unlikely to settle to its original volume. The amount of settlement to be expected when the pit

is backfilled will depend, inter alia, on the nature of the soil, the thickness of the soil layer (self-loading), whether any

compaction is carried out, the moisture content and the amount of rainfall. Guidance on settlement processes can be

found in geotechnical guidance documents.

Table 3 — Examples of swelling behaviour of different materials

Material Swell

%

Clay 40

Loam 25

Sand 12

Gravel 12

Where no water courses are located nearby and no underlying aquifers are present, encapsulation with

impermeable materials or specialized capping materials may not be required. However, a site-specific

assessment of the appropriateness of the burial site would need to be made.

Dimensions in millimetres

Key

1 waterproof material: 6.3 Bringing in lining materials and discharge pipes

2 soil: 6.2 Execution of the excavation

3 perforated pipe: 6.3 Bringing in lining materials and discharge pipes

4 quicklime: 5.3.9 Use of lime, 6.2 Execution of the excavation

5 carcass: 6.4 Placing of carcasses in the burial pit

6 quicklime: 5.3.9 Use of lime, 6.5 Coverage of burial pit after finalization of placement of carcasses

7 filling: 6.5 Coverage of burial pit after finalization of placement of carcasses

8 bentonite: 6.5 Coverage of burial pit after finalization of placement of carcasses

9 soil: 6.5 Coverage of burial pit after finalization of placement of carcasses

10 leachate discharge pipe: 5.3.8 Effluent collection, 6.5 Coverage of burial pit after finalization of placement of

carcasses

11 leachate treatment system: 7.4 Leachate treatment

12 gas discharge pipe: 5.3.8 Installation of pipes for gas discharge, 6.5 Coverage of burial pit after finalization of

placement of carcasses

13 UV lamp: 5.3.8 Installation of pipes for gas discharge

14 drainage: 6.5 Coverage of burial pit after finalization of placement of carcasses

15 groundwater

Figure 1 — Schematic diagram of an animal carcass burial pit

5.3.7 Leachate collection

One or more perforated pipes shall be laid along the bottom of the pit to collect and remove leachate from the

carcasses, together with any other liquids entering the pit. Care shall be taken to ensure that no leakage can

occur at the point or points where such pipes leave the pit.

The top of the perforated pipe(s) should be covered with gravel to prevent their breakage and blockage by

leachate and carcass. Examples of the design of protection layers are given in Annex C.

Leachate should be removed and disposed of in a manner in keeping with current appropriate guidance within

each country.

8 © ISO 2011 – All rights reserved

5.3.8 Installation of pipes for gas discharge

Pipes should be installed to discharge gas produced from carcass decay. The gas discharge pipes should be

greater than 100 mm in diameter, perforated and U-shaped and face towards the ground surface in order to

reduce stench and to prevent inflow of rainwater. At least 5 pipes should be installed every 90 m of the burial

pit. The pipe should be placed on a layer made from gravel to prevent blockage. For reasons of public health

and safety a suitable device for gas treatment should be installed at the end of each pipe. For example, a gas

sterilization filter (0,2 µm) or solar-cell-operated UV lamp can be used for this purpose.

5.3.9 Use of lime

The use of lime in an animal carcass burial site should be decided according to the national and local situation.

The principal reasons for adding lime are as follows:

a) to mop up excess water by conversion of calcium oxide to calcium hydroxide (i.e. slaked lime); this is

sometimes used on construction sites on which the surface soil has become too wet;

b) to alter the adsorption complex on clay with a view to modifying the behaviour of the clay;

c) to stabilize clayey soils by reaction with the clay;

d) to kill bacteria, probably by extracting water from them;

e) to convert foul-smelling gases to a less obnoxious form; for this to be successful, it is necessary to ensure

that the gases passed through the lime rather than escaping along preferential flow paths around it;

f) to convert foul effluent and leachate to less noxious forms;

g) to control the pH to promote bacterial and/or chemical disintegration of the carcasses;

h) to encourage earthworms; this would presumably apply only in cases of simple burial.

The disinfectant used to kill the causative agent for foot-and-mouth disease is acidic. On this basis, there is a

fear that the use of lime might help to preserve some causative agents. In addition, the high pH of the leachate

collected from the animal carcass burial site where lime is applied may cause problems in treating leachate.

5.3.10 Other aspects

When there are several burial pits at a site, the distance between the pits should be more than 6 m to enable

the movement of people and equipment.

6 Construction of burial pit

6.1 Preparation of the site

When the location of the burial pit has been decided, the following actions are desirable.

a) Exclude animals.

b) Collect debris and perhaps dung.

c) Disinfect the working area. This is intended to minimize the chance of survival of causative agents on or

in the topsoil.

d) If the land is arable, compact a strip 1 m wide along the upslope side of the pit to prevent water from flowing

through the topsoil and into the pit.

e) Draw a furrow across the upslope side of the pit to collect runoff.

f) Strip the topsoil from the area of the pit, and place this soil in a stockpile.

6.2 Excavation of the burial site

Take all necessary measures to ensure safe working inside the pit and within close vicinity of the pit.

Excavate the burial pit depending on the size necessary, using suitable equipment and machines.

Place excavated material at a sufficient distance from the excavation to ensure that no material can fall back

into the pit.

Whilst digging the pit, rake out any sharp stones protruding from the sides of the pit and inspect the sides in case

field drains, mole drains, or other sources of seepage are present. Should any such sources be discovered,

they shall be excavated for 0,5 m back from the side of the pit and replaced by well-rammed soil. In severe

cases, arrangements to intercept and divert the water will be required. In extreme cases, a new location for the

pit must be found.

If the material underlying the bottom of the pit appears to be permeable, remove another 0,6 m of material and

replace this with clay or such fine-grained material as can be found. In some cases, adding small quantities of

bentonite or cement to the material which has been excavated will be sufficient. This underlay shall be heavily

compacted whilst in a moist condition with a view to leaving it in an impermeable state (in civil engineering

terms, the material should be a few percent wet of optimum, but it is unlikely that there will be time to perform

compaction tests). It will be necessary to compact the underlay in a number of “lifts” (i.e. sub-layers), probably 2,

3 or 4, depending upon the type of machine used.

If the material underlying the bottom of the pit contains sharp stones or is in fact rock, it shall be covered with

a 150 mm layer of stone-free soil whose function is to protect the overlying impermeable membrane which

will be placed upon it. This layer of soil shall be given such compaction as seems necessary to stabilize it. Its

moisture content is unlikely to be critical but, if it seems to be too wet, adding a small quantity of quicklime may

dry it sufficiently.

The bottom of the burial site should be slanted to prevent leachate from collecting at the bottom of the pit. There

should be at least a 2 % slope to the perforated pipe where leachate is drained.

On top of the waterproof material, the pit shall be filled with a 1 m layer of soil. Then apply a layer made of 3 cm

of quicklime to prevent groundwater pollution from percolating leachate.

6.3 Placement of lining materials and discharge pipes

The bottom and sides of the pit shall be lined with heavy-duty impermeable material, such as high-density

polyethylene (HDPE) sheet. The joins between separate pieces of this material shall be made watertight.

Lay out one or more perforated pipes at the bottom of the pit, taking care to ensure that no leakage can occur

at the point or points where the pipes leave the pit. When the conceptual design calls for only one pipe, it will

often be prudent to lay a pair of pipes very close together.

NOTE Should a single perforated pipe become blocked, it would be difficult to clear. The reason for laying two pipes

is therefore that fluid in the blocked pipe could escape from one pipe into the other.

In order to protect the perforated pipes and the impermeable membrane at the bottom of the pit from traffic

within the pit, and to help to provide drainage paths from the carcasses to the perforated pipes, a bottom layer

of at least 0,6 m thickness shall be constructed. Three designs for this layer are suggested below.

a) Lay a thick permeable plastic layer over the impermeable layer at the bottom of the pit (the main purpose

of this is to protect the impermeable layer). Add 250 mm of lightly compacted gravel to provide cross-

drainage. Add 200 mm of moderately compacted sand to provide vertical drainage and to act as a graded

filter to keep material from the next layer out of the gravel. Add 150 mm of soil to filter out solid debris. If

necessary, add quicklime to reduce the moisture content and help to preserve any small soil aggregates

(i.e. crumbs) present. Compact this layer of soil sufficiently, so that serious rutting will not be caused by

a farm tractor when carrying a carcass. If necessary, protect the sand layer from disturbance by adding

another layer of soil.

10 © ISO 2011 – All rights reserved

b) Before the perforated pipes are laid, construct the entire bottom layer using 2, 3 or 4 sub-layers of soil.

Each layer shall be compacted sufficiently to prevent serious rutting (as described above). To prevent

puddling and to improve the permeability, the soil should be moderately dry. Quicklime may be added to

reduce the water content. If the soil is clayey, quicklime may be mixed in with it to improve the structure

and the permeability of the soil. Quicklime reacts with clay to form cement. This reaction takes some time

so care will be required to avoid over-compacting the mixture. A rough guide is to add between 0,5 % and

1,0 % lime per 10 % clay. To improve passage of fluids from one sub-layer to the next, it will probably be

necessary to loosen the surface of each sub-layer before the next is added. When all of the soil is in place,

excavate trenches for the perforated pipes, lay the pipes, and backfill with gravel.

c) If no gravel is to hand, proceed as in b) above, taking extra care to make the layers as permeable as

possible. Then lay several permeable pipes at no more than 2 m apart, and backfill with lightly compacted

soil or turf.

Using plastic pipe enveloped in plastic filter material might be preferable to using gravel, especially if this

helped to minimize the number of movements onto and off the site. However, allowing either method to be used

would minimize delays if a difficulty in procurement arose.

6.4 Placing of carcasses in the burial pit

Carcasses of large animals shall be laid in an orderly fashion, to facilitate their exhumation if this becomes

necessary. The carcasses, especially of ruminants, will gas up and increase in volume. They are liable to

subsequently degas rapidly, leading to formation of large voids and the cracking of cover material. Thus, the

carcasses should be pierced to prevent gassing up, provided appropriate guidance is available on how to do

this. Regardless of the size of the animals, care shall be taken that the impermeable membrane at the side of

the pit is not pierced. Where applicable, consideration should be given to removing antlers, horns and tusks

from the carcasses. When the sides of the pit are sloping, the carcasses at the sides of the pit shall be laid

no closer to the original ground surface than 2 m. Carcasses in the centre of the pit may be laid at a higher

level based on an assumption of 20 % settlement, for example, except that no carcasses shall be closer to the

original ground surface than 2 m.

6.5 Coverage of burial pit after finalization of placement of carcasses

After burying the carcass, apply a 2 cm thick layer of quicklime to the surface to reduce leachate drainage and

prevent stench.

Other than the situation of conventional landfill, heavy compaction would be difficult and undesirable here.

Soil should not be used to fill the gaps between the carcasses. If exhumation becomes necessary, all that soil

becomes “infectious material requiring special treatment”.

Lay a heavy-duty permeable membrane over the carcasses with a view to enabling gases to move upwards

and to prevent soil from moving downwards. It will be necessary to cut holes in this membrane for the gas and

leachate discharge pipes. This should be done carefully, but a watertight and gastight seal is not required.

Backfill the previously excavated material to the pit about 2 m to reach surface level. On the surface, establish

a mound composed of 30 cm of bentonite and more than 1,2 m of soil to prevent rainfall infiltration, leachate

drainage and carcass damage by wild animals.

Complete the construction of the gas and leachate discharge pipes.

Spread the topsoil (which was excavated when the pit was dug) over the mound.

Disinfect the entire area.

Unless the topsoil consists mainly of viable turf, broadcast grass or “pasture-mixture” seeds over all bare

patches of soil as soon as the climatic conditions permit.

7 Maintenance after burial

7.1 Safety measures

A suitable warning sign with information on the buried carcass, such as the disease, species, number, burial

date and the possible date for excavation, should be erected at the site.

7.2 Odour treatment

Scatter deodorizer to eliminate stench from leachate and gas. Scatter sawdust in the ditch to absorb leachate,

and collect and dispose it regularly. Disinfect with quicklime.

7.3 Gas discharge

Install more gas discharge pipes where there is excess gas or leachate production. Where there is little or no

production of gas, reduce or eliminate the pipes.

7.4 Leachate treatment

In areas where heavy rainfall may occur very frequently, the site should be covered with material such as

HDPE sheet to prevent soil cover from being washed away or collapsing. Build a mound around the ditch

to prevent leachate overflow. The quantity of leachate will generally increase temporarily in case of rainfall,

and the quantity will depend on the amount of rainfall at the beginning. The amount of discharge will become

constant over time, with the carcass acting as a buffer. The collected leachate should be sterilized by using

treatment systems, such as sterilization by autoclaving, ionizing radiation, filtration and chemical treatment with

sterilizing agents. Leachate-treatment systems should be designed to accommodate daily changes in quantity

and quality accordingly.

7.5 Surface regrading

The surface of the mound of the burial pit can become undulated due to irregular collapse of the burial pit. In

that case, regrade the surface of the mound with the soil collected around the pit.

8 Monitoring

A monitoring program should be established according to national or international regulations to look for, and

then prevent or control evidence of protrusion, rupture or sinking due to a decaying carcass or gas.

After the site has been declared to be free from disease contamination (and after a minimum period of 6

months), construct dip wells and start to monitor the groundwater release of any contaminants from the pit. The

delay is intended to reduce the risk of viable causative agents being washed from the soil into the groundwater

from the construction of wells. It is recommended to install one dip well for every 100 m length of pit, one for

every pit less than 100 m in length and one for each group of pits. For this purpose, the length of a pit is to be

taken to include the carcasses and the cess pit, but excluding any ramps or slopes at the ends of the pit. For

very wide pits, measure in the direction which gives the largest dimension.

9 Reuse of burial sites

For small on-farm sites, given the dominant use for agriculture, it is important that the pits be properly designed

and the land restored to a suitable standard. This includes reconnecting any severed field drains, provided

that the burial is deeper than agricultural operations (typically at least 1 m of topsoil and subsoil is required in

agricultural restorations following opencast operations). It is also important when excavating the pits that soil

layers be carefully separated to allow for correct reinstatement of soil horizons. In many cases, topsoil has

been buried with the livestock and rocky subsoil left on the surface, causing restoration problems.

12 © ISO 2011 – All rights reserved

10 Report and record keeping

The burial report shall include the following information:

a) a reference to this International Standard;

b) all information necessary for identification of the site;

c) complete information concerning the animal carcass and accompanying diseases;

d) a reference to the method used for burial;

e) any unusual features noted during the burial.

Annex A

(informative)

Examples of national specifications regarding burial of animal carcasses

A.1 Introduction

Many jurisdictions have produced guidance on the burial of animal carcasses. Although these differ at a

detailed level, they are similar in setting basic requirements relating to the surrounding environment and public

health, such as the distance from a water source (e.g. river, pond, lake, groundwater well), residential areas and

roads, and the depth to groundwater specified.

A.2 Examples

A.2.1 US EPA (Environmental Protection Agency)

Source Profile of the Agricultural Livestock Production Industry. Summary of operations, impacts and

pollution prevention opportunities for the agricultural livestock production industry, Section D:

Managing animal waste

Content — The impact of burying carcasses can be minimized by burying them deep below the

surface of the ground, well away and downgrade from any source of drinking water.

— Cover with a generous supply of quicklime to reduce soil pH before fill dirt is added.

— If the carcasses must be disposed of on-site, it is preferable to have:

— a burial area at least 100 m away from houses and watercourses;

— the pit base at least 38 inches above the level of the water table;

— heavy soil of low permeability and good stability;

— good access to the site for earthmoving machinery and stock transport unless the

stock are to be walked in for slaughter;

— It is important to avoid sites sloping toward watercourses and areas that are likely to drain

to surface water.

— Many states may have more strict statutes regulating the burial of dead animals.

14 © ISO 2011 – All rights reserved

A.2.2 Michigan, USA

Source State of Michigan, Department of Agriculture, Animal Industry Division, Bodies of dead animals,

R 287.652: Disposal of animal carcasses and disposal of residue from burning process of

carcasses.

Content — Animal carcasses, excluding restaurant grease, buried in individual graves shall be in

compliance with all of the following requirements:

— The carcass shall not come

...

ISO 28901:2011 is a standard that provides guidance on eco-friendly burial methods for animal carcasses to prevent epidemics. The purpose is to limit the spread of diseases, eliminate the causes, and dispose of the carcasses safely. It specifically does not cover the burial of carcasses resulting from natural death or accidents. Other disposal methods are not addressed in this standard.

ISO 28901:2011 - 토양 품질: 전염병 예방을 위한 동물 시체 매립에 대한 안내 는 전염병을 예방하기 위한 동물 시체의 친환경적인 매립 방법에 대한 안내를 제공한다. 이 표준은 질병의 전파를 제한하고 원인이 되는 요소를 제거하며 시체를 처리하기 위한 것이다. 이 표준은 자연사로 인해 발생한 동물 시체 또는 사고로 인한 동물 시체에는 적용되지 않는다. 다른 처리 방법은 ISO 28901:2011의 범위를 벗어난다.

ISO 28901:2011は、疫病の予防のために環境に優しい方法で動物の死体を埋葬するためのガイドラインを提供しています。目的は病気の拡散を制限し、原因を排除し、死体を安全に処分することです。ISO 28901:2011は自然死や事故による動物の死体の埋葬には適用されません。他の処分方法はこの規格の範囲外です。

ISO 28901:2011 is a standard that provides guidance on burying animal carcasses in an environmentally friendly way to prevent epidemics. The objective of this standard is to stop the spread of diseases, eliminate the agents responsible, and properly dispose of the carcasses. It is important to note that this standard does not cover the burial of animal carcasses resulting from natural death or accidents. Additionally, other methods of disposal are not included in the scope of ISO 28901:2011.

ISO 28901:2011は、疫病の予防に資するために環境に配慮した方法で動物の死骸を埋葬するためのガイドラインを提供しています。この規格の目的は、病気の拡散を防ぎ、原因となる微生物を排除し、死骸を適切に処理することです。なお、この規格は自然死や事故による動物の死骸の埋葬には適用されないことに注意が必要です。その他の処理方法はISO 28901:2011の範囲外です。

ISO 28901:2011은 전염병 예방을 위한 환경 친화적인 동물 시체 매장 방법에 대한 지침을 제공합니다. 목적은 질병의 확산을 제한하고 원인을 제거하며 시체를 안전하게 처분하는 것입니다. 자연적인 죽음이나 사고로 인해 발생하는 동물 시체의 매장은 이 표준의 적용 대상이 아닙니다. 다른 소각 방법은 ISO 28901:2011의 범위를 벗어납니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...