ISO 22762-2:2018

(Main)Elastomeric seismic-protection isolators — Part 2: Applications for bridges — Specifications

Elastomeric seismic-protection isolators — Part 2: Applications for bridges — Specifications

This document specifies minimum requirements and test methods for elastomeric seismic isolators used for bridges, as well as rubber material used in the manufacture of such isolators. It is applicable to elastomeric seismic isolators used to provide bridges with protection from earthquake damage. The isolators covered consist of alternate elastomeric layers and reinforcing steel plates, which are placed between a superstructure and its substructure to provide both flexibility for decoupling structural systems from ground motion and damping capability to reduce displacement at the isolation interface and the transmission of energy from the ground into the structure at the isolation frequency.

Appareils d'appuis structuraux en élastomère pour protection sismique — Partie 2: Applications pour ponts — Spécifications

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22762-2

Third edition

2018-10

Elastomeric seismic-protection

isolators —

Part 2:

Applications for bridges —

Specifications

Appareils d'appuis structuraux en élastomère pour protection

sismique —

Partie 2: Applications pour ponts — Spécifications

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

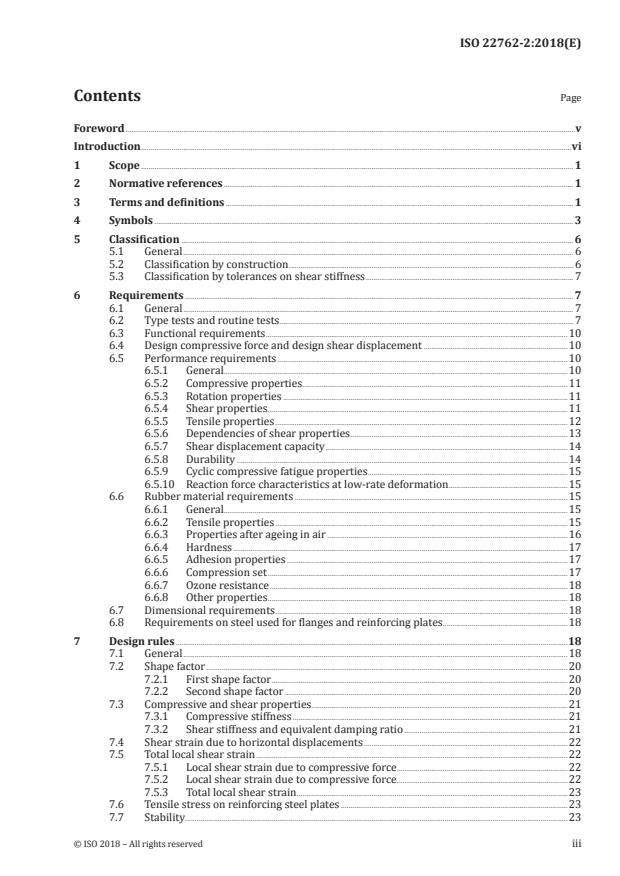

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 3

5 Classification . 6

5.1 General . 6

5.2 Classification by construction . 6

5.3 Classification by tolerances on shear stiffness . 7

6 Requirements . 7

6.1 General . 7

6.2 Type tests and routine tests. 7

6.3 Functional requirements .10

6.4 Design compressive force and design shear displacement .10

6.5 Performance requirements .10

6.5.1 General.10

6.5.2 Compressive properties .11

6.5.3 Rotation properties .11

6.5.4 Shear properties .11

6.5.5 Tensile properties .12

6.5.6 Dependencies of shear properties .13

6.5.7 Shear displacement capacity .14

6.5.8 Durability .14

6.5.9 Cyclic compressive fatigue properties .15

6.5.10 Reaction force characteristics at low-rate deformation.15

6.6 Rubber material requirements .15

6.6.1 General.15

6.6.2 Tensile properties .15

6.6.3 Properties after ageing in air .16

6.6.4 Hardness .17

6.6.5 Adhesion properties .17

6.6.6 Compression set .17

6.6.7 Ozone resistance .18

6.6.8 Other properties .18

6.7 Dimensional requirements .18

6.8 Requirements on steel used for flanges and reinforcing plates .18

7 Design rules .18

7.1 General .18

7.2 Shape factor .20

7.2.1 First shape factor .20

7.2.2 Second shape factor .20

7.3 Compressive and shear properties .21

7.3.1 Compressive stiffness .21

7.3.2 Shear stiffness and equivalent damping ratio .21

7.4 Shear strain due to horizontal displacements .22

7.5 Total local shear strain .22

7.5.1 Local shear strain due to compressive force .22

7.5.2 Local shear strain due to compressive force .22

7.5.3 Total local shear strain . .23

7.6 Tensile stress on reinforcing steel plates .23

7.7 Stability .23

7.7.1 Maximum compressive stress in non-seismic condition .23

7.7.2 Rotation performance check .23

7.7.3 Buckling check .24

7.7.4 Tensile stress on isolator .24

7.8 Force, moment and deformation affecting structures .24

7.8.1 Shear force affecting structures due to movement .24

7.8.2 Resistance to rotation .24

7.8.3 Compressive displacement due to compressive force .25

7.9 Design of fixings .25

7.9.1 External forces affecting joint members .25

7.9.2 Fixings and stresses to be checked .25

7.9.3 Allowable stress .26

8 Manufacturing tolerances .26

8.1 General .26

8.2 Measuring instruments .26

8.3 Plan dimensions of isolator body .27

8.3.1 Measurement method (see Figure 1) .27

8.3.2 Tolerances .27

8.4 Product height .28

8.4.1 Measurement method .28

8.4.2 Tolerances .29

8.5 Flatness of products .30

8.5.1 Measurement method .30

8.5.2 Tolerances .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.