ASTM D2270-93(1998)

(Practice)Standard Practice for Calculating Viscosity Index From Kinematic Viscosity at 40 and 100°C

Standard Practice for Calculating Viscosity Index From Kinematic Viscosity at 40 and 100°C

SCOPE

1.1 This practice specifies the procedures for calculating the viscosity index of petroleum products, such as lubricating oils, and related materials from their kinematic viscosities at 40 and 100°C.

1.1.1 Procedure A -For petroleum products of viscosity index up to and including 100.

1.1.2 Procedure B -For petroleum products of which the viscosity index is 100 or greater.

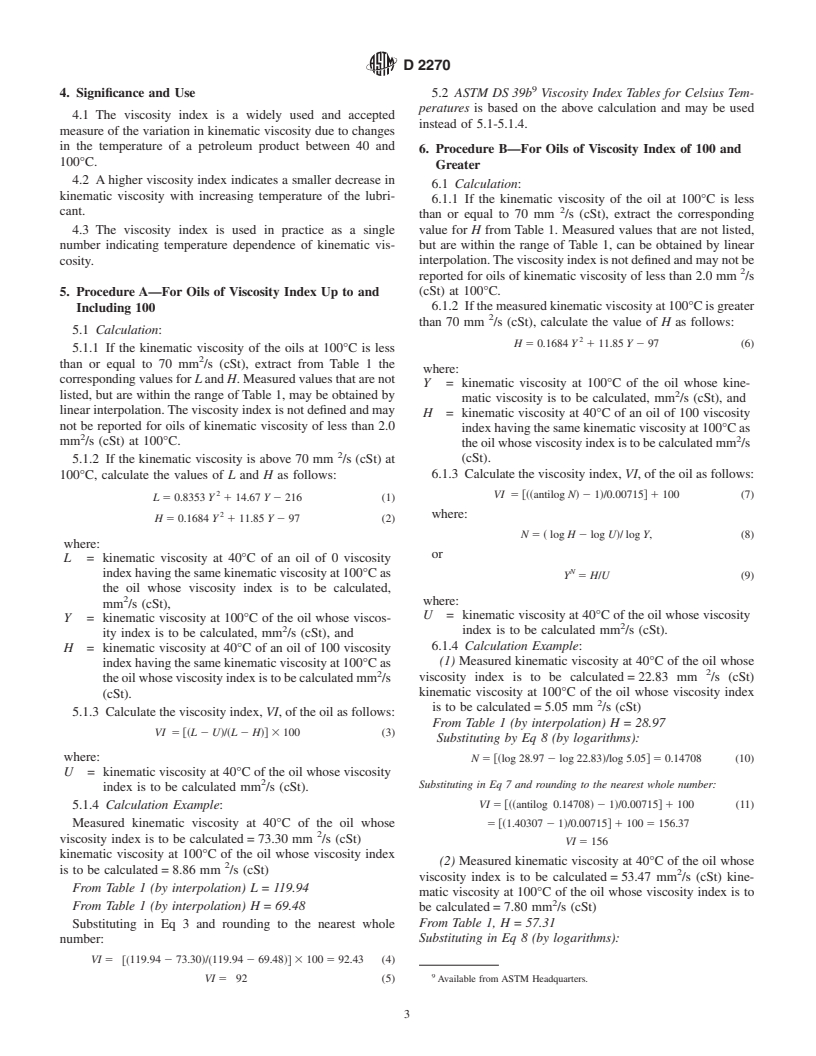

1.2 Table 1 given in this practice applies to petroleum products with kinematic viscosities between 2 and 70 mm /s (cSt) at 100°C. Equations are provided for calculating viscosity index for petroleum products having kinematic viscosities above 70 mm /s (cSt) at 100°C.

1.3 The kinematic viscosity values are determined with reference to a value of 1.0038 mm /s (cSt) at 20.00°C for distilled water. The determination of the kinematic viscosity of a petroleum product shall be carried out in accordance with Test Methods D445, IP 71, ISO 3104, or ISO 2909.

1.4 The values stated in SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D2270–93 (Reapproved 1998) British Standard 4459

Designation: 226/91(95)

Standard Practice for

Calculating Viscosity Index From Kinematic Viscosity at 40

and 100°C

This standard is issued under the fixed designation D2270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This is also a standard of the Institute of Petroleum issued under the fixed designation IP 226. The final number indicates the year of

last revision.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D341 Viscosity-Temperature Charts for Liquid Petroleum

2 Products

1.1 This practice specifies the procedures for calculating

D445 Test Method for Kinematic Viscosity of Transparent

the viscosity index of petroleum products, such as lubricating

and Opaque Liquids (and the Calculation of Dynamic

oils,andrelatedmaterialsfromtheirkinematicviscositiesat40

Viscosity)

and 100°C.

D1695 Terminology of Cellulose and Cellulose Deriva-

1.1.1 Procedure A—For petroleum products of viscosity

tives

index up to and including 100.

2.2 ISO Standards:

1.1.2 Procedure B—For petroleum products of which the

ISO 2909 Petroleum products—Calculation of Viscosity

viscosity index is 100 or greater.

Index from kinematic viscosity

1.2 Table 1 given in this practice applies to petroleum

ISO 3104 Petroleum products—Transparent and opaque

products with kinematic viscosities between 2 and 70 mm /s

liquids—Determination of kinematic viscosity and calcu-

(cSt) at 100°C. Equations are provided for calculating viscos-

lation of dynamic viscosity

ity index for petroleum products having kinematic viscosities

2.3 IP Document:

above 70 mm /s (cSt) at 100°C.

IP71

1.3 The kinematic viscosity values are determined with

reference to a value of 1.0038 mm /s (cSt) at 20.00°C for

3. Terminology

distilledwater.Thedeterminationofthekinematicviscosityof

3.1 Definitions of Terms Specific to This Standard:

a petroleum product shall be carried out in accordance with

3.1.1 viscosity index, n—an arbitrary number used to char-

Test Methods D445, IP 71, ISO 3104, or ISO 2909.

acterize the variation of the kinematic viscosity of a petroleum

1.4 The values stated in SI units are to be regarded as the

product with temperature.

standard.

3.1.1.1 Discussion—For oils of similar kinematic viscosity,

2. Referenced Documents the higher the viscosity index the smaller the effect of tem-

perature on its kinematic viscosity.

2.1 ASTM Standards:

NOTE 1—Viscosity index is also used in Terminology D1695 in a

definition unrelated to that in 3.1.1.

This practice is under the jurisdiction ofASTM Committee D-2 on Petroleum

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.07on

Flow Properties.

IntheIP,thispracticeisunderthejurisdictionoftheStandardizationCommittee.

Current edition approved March 15, 1993. Published May 1993. Originally

published as D2270–64. Last previous edition D2270–91.

2 5

MetricationofViscosityIndexSystemMethodD2270isavailablefromASTM Annual Book of ASTM Standards, Vol 05.01.

Headquarters. Request RR: D02-1009. Annual Book of ASTM Standards, Vol 06.03.

3 7

The results obtained from the calculation of VI from kinematic viscosities AvailablefromAmericanNationalStandardsInstitute,11W.42ndSt.,13thFl.,

determinedat40and100°Carevirtuallythesameasthoseobtainedfromtheformer New York, NY 10036.

VI system using kinematic viscosities determined at 37.78 and 98.89°C. Available from Institute of Petroleum, 61 New Cavendish St., London W1M

4 2 −6 2

1 cSt=1 mm/s=10 m /s. 8AR, United Kingdom.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2270

TABLE 1 Basic Values for L and H for Kinematic Viscosity in 40–100°C System

Kinematic

Kinematic Kinematic Kinematic Kinematic Kinematic

Viscosity

Viscosity Viscosity Viscosity Viscosity Viscosity

at

LH at 100°C, LH at 100°C, LH at 100°C, LH at 100°C, LH at 100°C, LH

100°C,

2 2 2 2 2

mm /s mm /s mm /s mm /s mm /s

mm /s

(cSt) (cSt) (cSt) (cSt) (cSt)

(cSt)

2.00 7.994 6.394 7.00 78.00 48.57 12.0 201.9 108.0 17.0 369.4 180.2 24.0 683.9 301.8 42.5 1935 714.9

2.10 8.640 6.894 7.10 80.25 49.61 12.1 204.8 109.4 17.1 373.3 181.7 24.2 694.5 305.6 43.0 1978 728.2

2.20 9.309 7.410 7.20 82.39 50.69 12.2 207.8 110.7 17.2 377.1 183.3 24.4 704.2 309.4 43.5 2021 741.3

2.30 10.00 7.944 7.30 84.53 51.78 12.3 210.7 112.0 17.3 381.0 184.9 24.6 714.9 313.0 44.0 2064 754.4

2.40 10.71 8.496 7.40 86.66 52.88 12.4 213.6 113.3 17.4 384.9 186.5 24.8 725.7 317.0 44.5 2108 767.6

2.50 11.45 9.063 7.50 88.85 53.98 12.5 216.6 114.7 17.5 388.9 188.1 25.0 736.5 320.9 45.0 2152 780.9

2.60 12.21 9.647 7.60 91.04 55.09 12.6 219.6 116.0 17.6 392.7 189.7 25.2 747.2 324.9 45.5 2197 794.5

2.70 13.00 10.25 7.70 93.20 56.20 12.7 222.6 117.4 17.7 396.7 191.3 25.4 758.2 328.8 46.0 2243 808.2

2.80 13.80 10.87 7.80 95.43 57.31 12.8 225.7 118.7 17.8 400.7 192.9 25.6 769.3 332.7 46.5 2288 821.9

2.90 14.63 11.50 7.90 97.72 58.45 12.9 228.8 120.1 17.9 404.6 194.6 25.8 779.7 336.7 47.0 2333 835.5

3.00 15.49 12.15 8.00 100.0 59.60 13.0 231.9 121.5 18.0 408.6 196.2 26.0 790.4 340.5 47.5 2380 849.2

3.10 16.36 12.82 8.10 102.3 60.74 13.1 235.0 122.9 18.1 412.6 197.8 26.2 801.6 344.4 48.0 2426 863.0

3.20 17.26 13.51 8.20 104.6 61.89 13.2 238.1 124.2 18.2 416.7 199.4 26.4 812.8 348.4 48.5 2473 876.9

3.30 18.18 14.21 8.30 106.9 63.05 13.3 241.2 125.6 18.3 420.7 201.0 26.6 824.1 352.3 49.0 2521 890.9

3.40 19.12 14.93 8.40 109.2 64.18 13.4 244.3 127.0 18.4 424.9 202.6 26.8 835.5 356.4 49.5 2570 905.3

3.50 20.09 15.66 8.50 111.5 65.32 13.5 247.4 128.4 18.5 429.0 204.3 27.0 847.0 360.5 50.0 2618 919.6

3.60 21.08 16.42 8.60 113.9 66.48 13.6 250.6 129.8 18.6 433.2 205.9 27.2 857.5 364.6 50.5 2667 933.6

3.70 22.09 17.19 8.70 116.2 67.64 13.7 253.8 131.2 18.7 437.3 207.6 27.4 869.0 368.3 51.0 2717 948.2

3.80 23.13 17.97 8.80 118.5 68.79 13.8 257.0 132.6 18.8 441.5 209.3 27.6 880.6 372.3 51.5 2767 962.9

3.90 24.19 18.77 8.90 120.9 69.94 13.9 260.1 134.0 18.9 445.7 211.0 27.8 892.3 376.4 52.0 2817 977.5

4.00 25.32 19.56 9.00 123.3 71.10 14.0 263.3 135.4 19.0 449.9 212.7 28.0 904.1 380.6 52.5 2867 992.1

4.10 26.50 20.37 9.10 125.7 72.27 14.1 266.6 136.8 19.1 454.2 214.4 28.2 915.8 384.6 53.0 2918 1007

4.20 27.75 21.21 9.20 128.0 73.42 14.2 269.8 138.2 19.2 458.4 216.1 28.4 927.6 388.8 53.5 2969 1021

4.30 29.07 22.05 9.30 130.4 74.57 14.3 273.0 139.6 19.3 462.7 217.7 28.6 938.6 393.0 54.0 3020 1036

4.40 30.48 22.92 9.40 132.8 75.73 14.4 276.3 141.0 19.4 467.0 219.4 28.8 951.2 396.6 54.5 3073 1051

4.50 31.96 23.81 9.50 135.3 76.91 14.5 279.6 142.4 19.5 471.3 221.1 29.0 963.4 401.1 55.0 3126 1066

4.60 33.52 24.71 9.60 137.7 78.08 14.6 283.0 143.9 19.6 475.7 222.8 29.2 975.4 405.3 55.5 3180 1082

4.70 35.13 25.63 9.70 140.1 79.27 14.7 286.4 145.3 19.7 479.7 224.5 29.4 987.1 409.5 56.0 3233 1097

4.80 36.79 26.57 9.80 142.7 80.46 14.8 289.7 146.8 19.8 483.9 226.2 29.6 998.9 413.5 56.5 3286 1112

4.90 38.50 27.53 9.90 145.2 81.67 14.9 293.0 148.2 19.9 488.6 227.7 29.8 1011 417.6 57.0 3340 1127

5.00 40.23 28.49 10.0 147.7 82.87 15.0 296.5 149.7 20.0 493.2 229.5 30.0 1023 421.7 57.5 3396 1143

5.10 41.99 29.46 10.1 150.3 84.08 15.1 300.0 151.2 20.2 501.5 233.0 30.5 1055 432.4 58.0 3452 1159

5.20 43.76 30.43 10.2 152.9 85.30 15.2 303.4 152.6 20.4 510.8 236.4 31.0 1086 443.2 58.5 3507 1175

5.30 45.53 31.40 10.3 155.4 86.51 15.3 306.9 154.1 20.6 519.9 240.1 31.5 1119 454.0 59.0 3563 1190

5.40 47.31 32.37 10.4 158.0 87.72 15.4 310.3 155.6 20.8 528.8 243.5 32.0 1151 464.9 59.5 3619 1206

5.50 49.09 33.34 10.5 160.6 88.95 15.5 313.9 157.0 21.0 538.4 247.1 32.5 1184 475.9 60.0 3676 1222

5.60 50.87 34.32 10.6 163.2 90.19 15.6 317.5 158.6 21.2 547.5 250.7 33.0 1217 487.0 60.5 3734 1238

5.70 52.64 35.29 10.7 165.8 91.40 15.7 321.1 160.1 21.4 556.7 254.2 33.5 1251 498.1 61.0 3792 1254

5.80 54.42 36.26 10.8 168.5 92.65 15.8 324.6 161.6 21.6 566.4 257.8 34.0 1286 509.6 61.5 3850 1270

5.90 56.20 37.23 10.9 171.2 93.92 15.9 328.3 163.1 21.8 575.6 261.5 34.5 1321 521.1 62.0 3908 1286

6.00 57.97 38.19 11.0 173.9 95.19 16.0 331.9 164.6 22.0 585.2 264.9 35.0 1356 532.5 62.5 3966 1303

6.10 59.74 39.17 11.1 176.6 96.45 16.1 335.5 166.1 22.2 595.0 268.6 35.5 1391 544.0 63.0 4026 1319

6.20 61.52 40.15 11.2 179.4 97.71 16.2 339.2 167.7 22.4 604.3 272.3 36.0 1427 555.6 63.5 4087 1336

6.30 63.32 41.13 11.3 182.1 98.97 16.3 342.9 169.2 22.6 614.2 275.8 36.5 1464 567.1 64.0 4147 1352

6.40 65.18 42.14 11.4 184.9 100.2 16.4 346.6 170.7 22.8 624.1 279.6 37.0 1501 579.3 64.5 4207 1369

6.50 67.12 43.18 11.5 187.6 101.5 16.5 350.3 172.3 23.0 633.6 283.3 37.5 1538 591.3 65.0 4268 1386

6.60 69.16 44.24 11.6 190.4 102.8 16.6 354.1 173.8 23.2 643.4 286.8 38.0 1575 603.1 65.5 4329 1402

6.70 71.29 45.33 11.7 193.3 104.1 16.7 358.0 175.4 23.4 653.8 290.5 38.5 1613 615.0 66.0 4392 1419

6.80 73.48 46.44 11.8 196.2 105.4 16.8 361.7 177.0 23.6 663.3 294.4 39.0 1651 627.1 66.5 4455 1436

6.90 75.72 47.51 11.9 199.0 106.7 16.9 365.6 178.6 23.8 673.7 297.9 39.5 1691 639.2 67.0 4517 1454

40.0 1730 651.8 67.5 4580 1471

40.5 1770 664.2 68.0 4645 1488

41.0 1810 676.6 68.5 4709 1506

41.5 1851 689.1 69.0 4773 1523

42.0 1892 701.9 69.5 4839 1541

70.0 4905 1558

D2270

4. Significance and Use 5.2 ASTM DS 39b Viscosity Index Tables for Celsius Tem-

peratures is based on the above calculation and may be used

4.1 The viscosity index is a widely used and accepted

instead of 5.1-5.1.4.

measure of the variation in kinematic viscosity due to changes

in the temperature of a petroleum product between 40 and

6. Procedure B—For Oils of Viscosity Index of 100 and

100°C.

Greater

4.2 Ahigher viscosity index indicates a smaller decrease in

6.1 Calculation:

kinematic viscosity with increasing temperature of the lubri-

6.1.1 If the kinematic viscosity of the oil at 100°C is less

cant.

than or equal to 70 mm /s (cSt), extract the corresponding

4.3 The viscosity index is used in practice as a single value for H from Table 1. Measured values that are not listed,

number indicating temperature dependence of kinematic vis- but are within the range of Table 1, can be obtained by linear

cosity. interpolation.Theviscosityindexisnotdefinedandmaynotbe

reported for oils of kinematic viscosity of less than 2.0 mm /s

(cSt) at 100°C.

5. Procedure A—For Oils of Viscosity Index Up to and

6.1.2 Ifthemeasuredkinematicviscosityat100°Cisgreater

Including 100

than 70 mm /s (cSt), calculate the value of H as follows:

5.1 Calculation:

H 50.1684 Y 111.85 Y 297 (6)

5.1.1 If the kinematic viscosity of the oils at 100°C is less

than or equal to 70 mm /s (cSt), extract from Table 1 the

where:

correspondingvaluesfor Land H.Measuredvaluesthatarenot

Y = kinematic viscosity at 100°C of the oil whose kine-

listed, but are within the range of Table 1, may be obtained by

matic viscosity is to be calculated, mm /s (cSt), and

linearinterpolation.Theviscosityindexisnotdefinedandmay

H = kinematic viscosity at 40°C of an oil of 100 viscosity

not be reported for oils of kinematic viscosity of less than 2.0

indexhavingthesamekinematicviscosityat100°Cas

mm /s (cSt) at 100°C.

theoilwhoseviscosityindexistobecalculatedmm /s

(cSt).

5.1.2 If the kinematic viscosity is above 70 mm /s (cSt) at

6.1.3 Calculatetheviscosityindex, VI,oftheoilasfollows:

100°C, calculate the values of L and H as follows:

VI 5 @~~antilog N! 21!/0.00715# 1100 (7)

L 50.8353 Y 114.67 Y 2216 (1)

where:

H 50.1684 Y 111.85 Y 297 (2)

N 5 ~ log H 2log U!/log Y, (8)

where:

or

L = kinematic viscosity at 40°C of an oil of 0 viscosity

N

indexhavingthesamekinematicviscosityat100°Cas

Y 5 H/U (9)

the oil whose viscosity index is to be calculated,

where:

mm /s (cSt),

U = kinematic viscosity at 40°C of the oil whose viscosity

Y = kinematic viscosity at 100°C of the oil whose viscos-

index is to be calculated mm /s (cSt).

ity index is to be calculated, mm /s (cSt), and

6.1.4 Calculation Example:

H = kinematic viscosity at 40°C of an oil of 100 viscosity

(1) Measured kinematic viscosity at 40°C of the oil whose

indexhavingthesamekinematicviscosityat100°Cas

viscosity index is to be calculated=22.83 mm /s (cSt)

theoilwhoseviscosityindexistobecalculatedmm /s

kinematic viscosity at 100°C of the oil whose viscosity index

(cSt).

is to be calculated=5.05 mm /s (cSt)

5.1.3 Calculatetheviscosityindex, VI,oftheoilasfollows:

From Table 1 (by interpolation) H = 28.97

VI 5 L 2 U / L 2 H 3100 (3)

@~ ! ~ !#

Substituting by Eq 8 (by logarithms):

where:

N 5 @~log28.97 2log22.83!/log5.05# 50.14708 (10)

U = kinematic viscosity at 40°C of the oil whose viscosity

Substituting in Eq 7 and rounding to the nearest whole number:

index is to be calculated mm /s (cSt).

VI 5 @~~antilog 0.14708! 21!/0.00715# 1100 (11)

5.1.4 Calculation Example:

Measured kinematic viscosity at 40°C of the oil whose 5 @~1.40307 21!/0.00715# 1100 5156.37

viscosity index is to be calculated=73.30 mm /s (cSt)

VI 5156

kinematic viscosity at 100°C of the oil whose viscosity index

(2) Measured kinematic viscosity at 40°C of the oil whose

is to be calculated=8.86 mm /s (cSt)

viscosity index is to be calculated=53.47 mm /s (cSt) kine-

From Table 1 (by interpolation) L = 119.94

matic viscosity at 100°C of the oil whose viscosity index is to

From Table 1 (by interpolation) H = 69.48

be calculated=7.80 mm /s (cSt)

Substituting in Eq 3 and rounding to the nearest whole From Table 1, H = 57.31

Substituting in Eq 8 (by logarithms):

number:

VI 5 @~119.94 273.30!/~119.94 269.48!# 3100 592.43 (4)

VI 5 92 (5) Available from ASTM Headquarters.

D2270

N 5 @~ log57.31 2log53.47!/log7.80# 50.03376 (12) be that based on the means of the appropriate kinematic

viscosity values. If the kinematic viscosity data do not meet

Substituting in Eq 7 and rounding to the nearest whole number:

acceptability limits in Test Method D445, the data should be

VI 5 @~~antilog0.03376! 21!/0.00715# 1100 (13)

examined and redetermined.

5 @~1.08084 21!/0.00715# 1100 5111

8. Precision and Bias

6.2 ASTM DS 39b —Viscosity Index Tables for Celsius

8.1 The calculation of viscosity index from kinematic vis-

Temperatures is based on the above calculation and may be

cositiesat40and100°Cisexact,andnoprecisionlimitscanbe

used instead of 6.1 through 6.1.4.

assigned to this calculation.

7. Report

8.2 The accuracy of the calculated viscosity index is depen-

dent only on the accuracy of the original viscosity determ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.