ASTM G5-94(2004)

(Test Method)Standard Reference Test Method for Making Potentiostatic and Potentiodynamic Anodic Polarization Measurements

Standard Reference Test Method for Making Potentiostatic and Potentiodynamic Anodic Polarization Measurements

SCOPE

1.1 This test method covers an experimental procedure for checking experimental technique and instrumentation. If followed, this test method will provide repeatable potentiostatic and potentiodynamic anodic polarization measurements that will reproduce data determined by others at other times and in other laboratories provided all laboratories are testing reference samples from the same lot of Type 430 stainless steel.

1.2 Values stated in SI units are to be regarded as the standard. Inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G5–94 (Reapproved 2004)

Standard Reference Test Method for

Making Potentiostatic and Potentiodynamic Anodic

Polarization Measurements

This standard is issued under the fixed designation G5; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Samples of a standard ferritic Type 430 stainless steel

(UNS S43000) used in obtaining standard reference plot are

1.1 This test method covers an experimental procedure for

available for those who wish to check their own test procedure

checking experimental technique and instrumentation. If fol-

and equipment.

lowed, this test method will provide repeatable potentiostatic

3.3 Standard potentiostatic and potentiodynamic polariza-

and potentiodynamic anodic polarization measurements that

tion plots are supplied with the purchase of the reference

will reproduce data determined by others at other times and in

material. These reference data are based on the results from

otherlaboratoriesprovidedalllaboratoriesaretestingreference

different laboratories that followed the standard procedure,

samples from the same lot of Type 430 stainless steel.

using that material in 1.0 N H SO . Maximum and minimum

2 4

1.2 Values stated in SI units are to be regarded as the

current values are shown at each potential to indicate the

standard. Inch-pound units given in parentheses are for infor-

acceptable range of values.

mation only.

3.4 Thistestmethodmaynotbeappropriateforpolarization

1.3 This standard does not purport to address all of the

testing of all materials or in all environments.

safety concerns, if any, associated with its use. It is the

3.5 This test method is intended for use in evaluating the

responsibility of the user of this standard to establish appro-

accuracy of a given electrochemical test apparatus, not for use

priate safety and health practices and determine the applica-

in evaluating materials performance. Therefore, the use of the

bility of regulatory limitations prior to use.

plots in Figs. 1 and 2 orAppendix X2 is not recommended to

2. Referenced Documents evaluate alloys other than Type 430, or lots of Type 430 other

than those available throughASTM.The use of the data in this

2.1 ASTM Standards:

test method in this manner is beyond the scope and intended

E1338 Guide for Identification of Metals and Alloys in

useofthistestmethod.Usersofthistestmethodareadvisedto

Computerized Material Property Databases

evaluate test results relative to the scatter bands corresponding

G3 Practice for ConventionsApplicable to Electrochemical

to the particular lot of Type 430 stainless steel that was tested.

Measurements in Corrosion Testing

G107 Guide for Formats for Collection and Compilation of

4. Apparatus

Corrosion Data for Metals for Computerized Database

4.1 The test cell should be constructed to allow the follow-

Input

ing items to be inserted into the solution chamber: the test

3. Significance and Use electrode, two auxiliary electrodes, a Luggin capillary with

salt-bridge connection to the reference electrode, inlet and

3.1 The availability of a standard procedure, standard ma-

outletforaninertgas,andathermometer.Thetestcellshallbe

terial, and a standard plot should make it easy for an investi-

constructed of materials that will not corrode, deteriorate, or

gator to check his techniques. This should lead to polarization

otherwise contaminate the test solution.

curves in the literature which can be compared with confi-

dence.

NOTE 1—Borosilicate glass and TFE-fluorocarbon have been found

suitable.

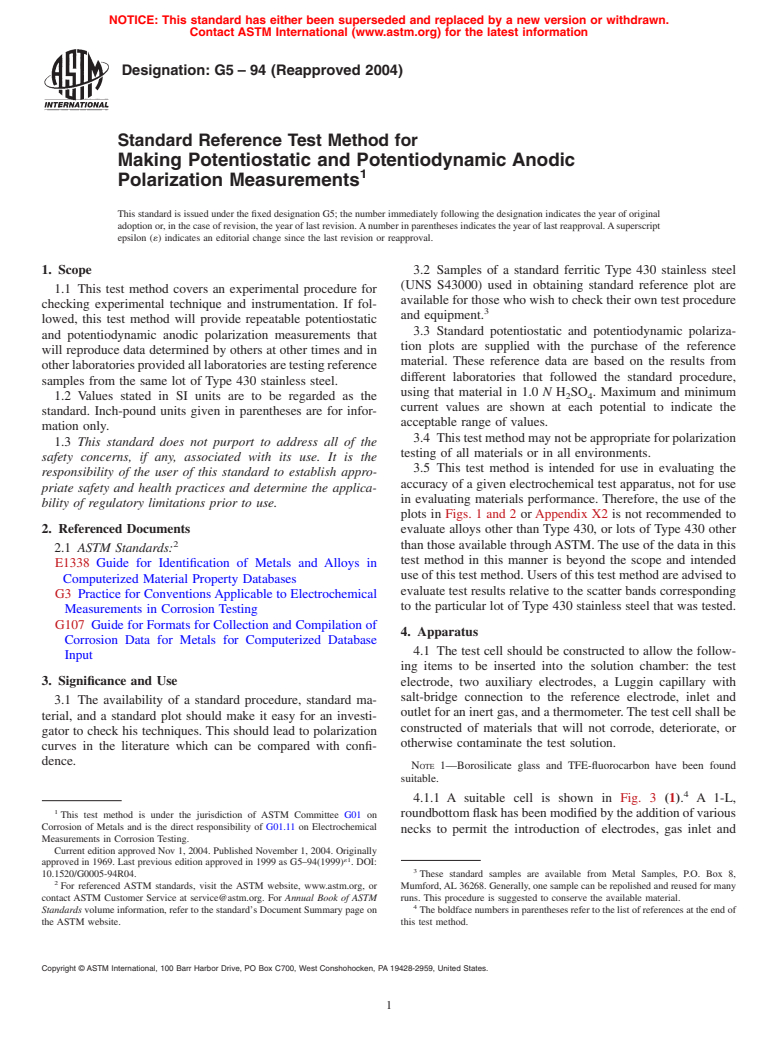

4.1.1 A suitable cell is shown in Fig. 3 (1). A 1-L,

This test method is under the jurisdiction of ASTM Committee G01 on roundbottomflaskhasbeenmodifiedbytheadditionofvarious

Corrosion of Metals and is the direct responsibility of G01.11 on Electrochemical

necks to permit the introduction of electrodes, gas inlet and

Measurements in Corrosion Testing.

Current edition approved Nov 1, 2004. Published November 1, 2004. Originally

´1

approved in 1969. Last previous edition approved in 1999 as G5–94(1999) . DOI:

10.1520/G0005-94R04. These standard samples are available from Metal Samples, P.O. Box 8,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Mumford,AL36268. Generally, one sample can be repolished and reused for many

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM runs. This procedure is suggested to conserve the available material.

Standards volume information, refer to the standard’s Document Summary page on Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the ASTM website. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G5–94 (2004)

CURRENT DENSITY (µA/cm )

FIG. 1 Typical Standard Potentiostatic Anodic Polarization Plot

CURRENT DENSITY (µA/cm )

FIG. 2 Typical Standard Potentiodynamic Anodic Polarization Plot

outlet tubes, and a thermometer. The Luggin probe-salt bridge specimen supplied, the potentiostat should have a potential

separates the bulk solution from the saturated calomel refer- range from−0.6 to 1.6 V and an anodic current output range

enceelectrode,andtheprobetipcanbeeasilyadjustedtobring from 1.0 to 10 µA.

it in close proximity with the working electrode. 4.3 Potential-Measuring Instruments (Note 2):

4.2 Potentiostat (Note 2): 4.3.1 The potential-measuring circuit should have a high

11 14

4.2.1 Apotentiostatthatwillmaintainanelectrodepotential input impedance on the order of 10 to 10 V to minimize

within 1 mV of a preset value over a wide range of applied current drawn from the system during measurements. Such

currents should be used. For the type and size of standard circuits are provided with most potentiostats. Instruments

G5–94 (2004)

the logarithm of the current as a voltage, which allows direct

plotting of the potential log current curve using an X-Y

recorder.

NOTE 2—The instrumental requirements are based upon values typical

of the instruments in 15 laboratories.

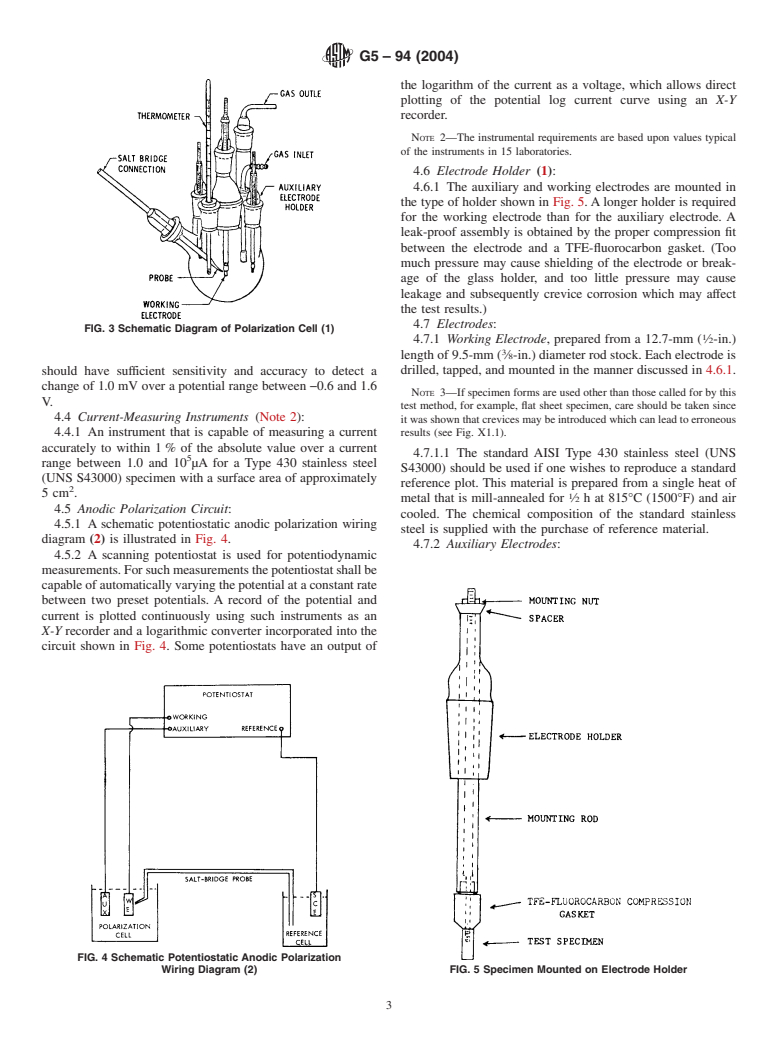

4.6 Electrode Holder (1):

4.6.1 The auxiliary and working electrodes are mounted in

the type of holder shown in Fig. 5.Alonger holder is required

for the working electrode than for the auxiliary electrode. A

leak-proof assembly is obtained by the proper compression fit

between the electrode and a TFE-fluorocarbon gasket. (Too

much pressure may cause shielding of the electrode or break-

age of the glass holder, and too little pressure may cause

leakage and subsequently crevice corrosion which may affect

the test results.)

4.7 Electrodes:

FIG. 3 Schematic Diagram of Polarization Cell (1)

4.7.1 Working Electrode, prepared from a 12.7-mm ( ⁄2-in.)

lengthof9.5-mm( ⁄8-in.)diameterrodstock.Eachelectrodeis

drilled, tapped, and mounted in the manner discussed in 4.6.1.

should have sufficient sensitivity and accuracy to detect a

change of 1.0 mVover a potential range between−0.6 and 1.6

NOTE 3—If specimen forms are used other than those called for by this

V.

test method, for example, flat sheet specimen, care should be taken since

4.4 Current-Measuring Instruments (Note 2):

itwasshownthatcrevicesmaybeintroducedwhichcanleadtoerroneous

4.4.1 An instrument that is capable of measuring a current results (see Fig. X1.1).

accurately to within 1% of the absolute value over a current

4.7.1.1 The standard AISI Type 430 stainless steel (UNS

range between 1.0 and 10 µA for a Type 430 stainless steel

S43000) should be used if one wishes to reproduce a standard

(UNS S43000) specimen with a surface area of approximately

reference plot. This material is prepared from a single heat of

5cm .

metal that is mill-annealed for ⁄2 h at 815°C (1500°F) and air

4.5 Anodic Polarization Circuit:

cooled. The chemical composition of the standard stainless

4.5.1 A schematic potentiostatic anodic polarization wiring

steel is supplied with the purchase of reference material.

diagram (2) is illustrated in Fig. 4.

4.7.2 Auxiliary Electrodes:

4.5.2 A scanning potentiostat is used for potentiodynamic

measurements.Forsuchmeasurementsthepotentiostatshallbe

capableofautomaticallyvaryingthepotentialataconstantrate

between two preset potentials. A record of the potential and

current is plotted continuously using such instruments as an

X-Y recorder and a logarithmic converter incorporated into the

circuit shown in Fig. 4. Some potentiostats have an output of

FIG. 4 Schematic Potentiostatic Anodic Polarization

Wiring Diagram (2) FIG. 5 Specimen Mounted on Electrode Holder

G5–94 (2004)

4.7.2.1 Twoplatinumauxiliaryelectrodesarepreparedfrom oxygen-free gas such as hydrogen, argon, or nitrogen at a rate

high-purity rod stock. Each electrode is drilled, tapped, and of 150 cm /min for a minimum of ⁄2 h.

mounted with a TFE-fluorocarbon gasket in the same manner 5.5 Prepare the working electrode surface within1hofthe

as the working electrode. A large platinum sheet sealed into a experiment.Wetgrindwith240-gritSiCpaper,wetpolishwith

glass holder is also acceptable. 600-gritSiCpaperuntilpreviouscoarsescratchesareremoved,

4.7.2.2 A platinized surface may be utilized because of the rinse, and dry. (Drilled and tapped specimens can be threaded

increased surface area. This may be accomplished by cleaning onto an electrode holder rod and secured in a lathe or electric

the surface in hot aqua regia (3 parts concentrated HCl and 1 drill for this operation.)

part concentrated HNO ), washing, and then drying. Both 5.6 Determinethesurfaceareabymeasuringalldimensions

electrodes are platinized by immersing them in a solution of to the nearest 0.01 mm, subtracting the area under the gasket

3%platinicchlorideand0.02%leadacetateandelectrolyzing (usually 0.20 to 0.25 cm ).

at a current density of 40 to 50 mA/cm for4or5min (1, 3). 5.7 Mount the specimen on the electrode holder as de-

The polarity is reversed every minute. Occluded chloride is scribedin4.6.1.Tightentheassemblybyholdingtheupperend

removed by electrolyzing in a dilute (10%) sulfuric acid of the mounting rod in a vise or clamp while tightening the

solution for several minutes with a reversal in polarity every mounting nut until the gasket is properly compressed.

5.8 Degrease the specimen just prior to immersion and then

minute.Electrodesarerinsedthoroughlyandstoredindistilled

water until ready for use. Since certain ions can poison these rinse in distilled water.

5.9 Transfer the specimen to the test cell and adjust the

electrodes, periodic checks of platinized platinum potentials

against a known reference electrode should be made. salt-bridge probe tip so it is about 2 mm or 2 times the tip

diameter, whichever is larger from the specimen electrode.

4.7.2.3 Alternatively, graphite auxiliary electrodes can be

used, but material retained by the graphite may contaminate 5.10 Record the open-circuit specimen potential, that is, the

corrosion potential, after 55 min immersion. If platinum

subsequentexperiments.Thiscontaminationcanbeminimized

by using high-density graphite or avoided by routinely replac- counter electrodes and hydrogen gas are used, record the

platinum potential 50 min after immersion of the specimen.

ing the graphite electrode.

5.11 Potential Scan:

4.7.3 Reference Electrode (4):

5.11.1 Start the potential scan or step 1 h after specimen

4.7.3.1 Asaturated calomel electrode with a controlled rate

immersion, beginning at the corrosion potential (E ) for

of leakage (about 3 µL/h) is recommended. This type of

corr

potentiodynamic measurements and the nearest 50-mV incre-

electrode is durable, reliable, and commercially available.

ment above E for the potentiostatic measurements. Proceed

Precautions shall be taken to ensure that it is maintained in the

corr

through+1.60 V versus saturated calomel electrode (SCE)

propercondition.Thepotentialofthecalomelelectrodeshould

(active to noble).

be checked at periodic intervals to ensure the accuracy of the

5.11.2 In the potentiostatic method, use a potentiostatic

electrode. For other alloy-electrolyte combinations a different

potential step rate of 50 mVevery 5 min, recording the current

reference electrode may be preferred in order to avoid con-

at the end of each 5-min period at potential. These steps are

tamination of the reference electrode or the electrolyte.

repeated until a potential of+1.6 V SCE is reached.

4.7.3.2 Alternatively, a saturated calomel electrode utilizing

5.11.3 In the potentiodynamic method, use a potentiody-

a semi-permeable membrane or porous plug tip may be used.

namic potential sweep rate of 0.6 V/h (65%) recording the

These may require special care.

current continuously with change in potential from the corro-

sion potential to+1.6 V SCE.

5. Experimental Procedure

5.12 Plot anodic polarization data on semilogarithmic paper

5.1 Prepare 1 L of 1.0 N H SO fromA.C.S. reagent grade

2 4

in accordance with Practice G3, (potential-ordinate, current

acidanddistilledwater,forexample,byusing27.8mLof98%

density-abscissa).Ifapotentiostatwithalogarithmicconverter

H SO /Lof solution. Transfer 900 mLof solution to the clean

2 4

is used, this plot can be produced directly during the measure-

polarization cell.

ment.

5.2 Place the platinized auxiliary electrodes, salt-bridge

probe, and other components in the test cell and temporarily

6. Standard Reference Plots

close the center opening with a glass stopper. Fill the salt

6.1 Standard polarization plots prepared from data obtained

bridge with test solution.

by following the standard procedure discussed in this test

NOTE 4—When using a controlled leakage salt bridge, the levels of the

method are supplied with the purchase of reference material.

solutioninthereferenceandpolarizationcellsshouldbethesametoavoid

TypicaldataareshowninFig.1andFig.2 (5).Theplotsshow

siphoning. If this is impossible, a closed solution-wet (not greased)

a range of acceptable current density values at each potential.

stopcock can be used in the salt bridge to eliminate siphoning, or a

The average corrosion potential is−0.52 V, and the average

semi-permeable membrane or porous plug tip may be used on the salt

platinized platinum potential is−0.26 V.

bridge.

NOTE 5—The plots in Fig. 1 and Fig. 2 correspond to a lot ofType 430

5.3 Bring the temperature of the solution to 30 6 1°C by

stainless steel that is no longer available from ASTM (after July 1992).

immersing the test cell in a controlled-temperature water bath

Figs. 1 and 2 are presented primarily for the discussion of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.