ASTM E1815-08

(Test Method)Standard Test Method for Classification of Film Systems for Industrial Radiography

Standard Test Method for Classification of Film Systems for Industrial Radiography

SIGNIFICANCE AND USE

This test method provides a relative means for classification of film systems used for industrial radiography. The film system consists of the film and associated processing system (the type of processing and processing chemistry). Section 9 describes specific parameters used for this test method. In general, the classification for hard X-rays, as described in Section 9, can be transferred to other radiation energies and metallic screen types, as well as screens without films. The usage of film system parameters outside the energy ranges specified may result in changes to a film/system performance classification.

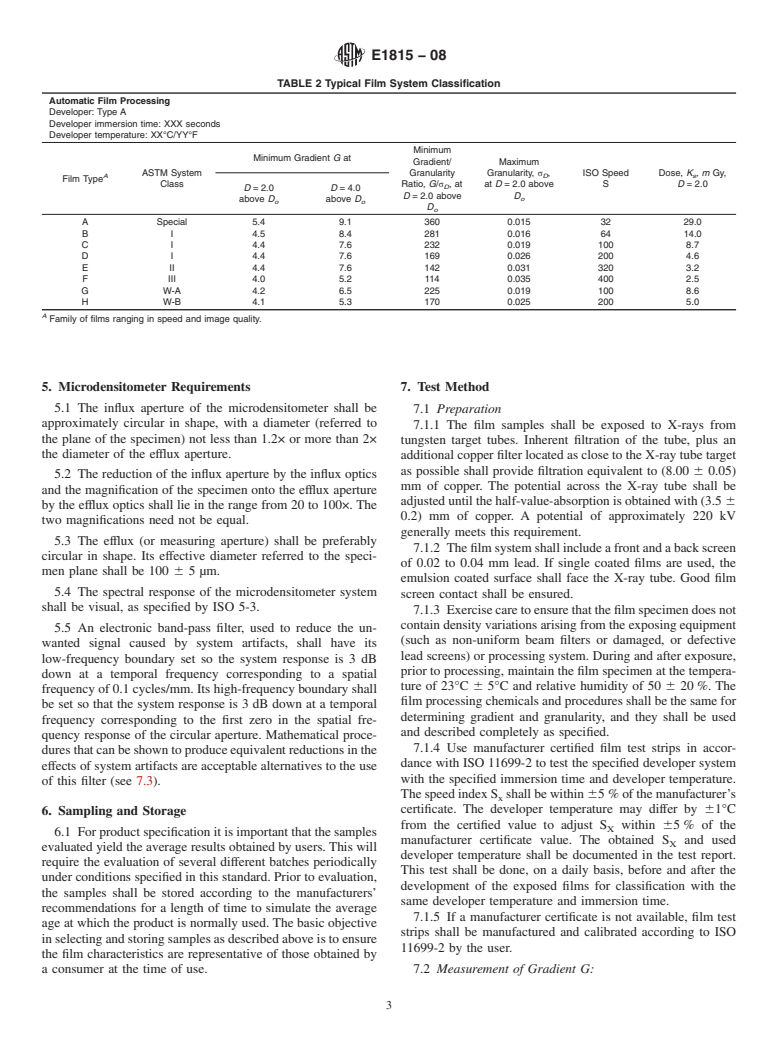

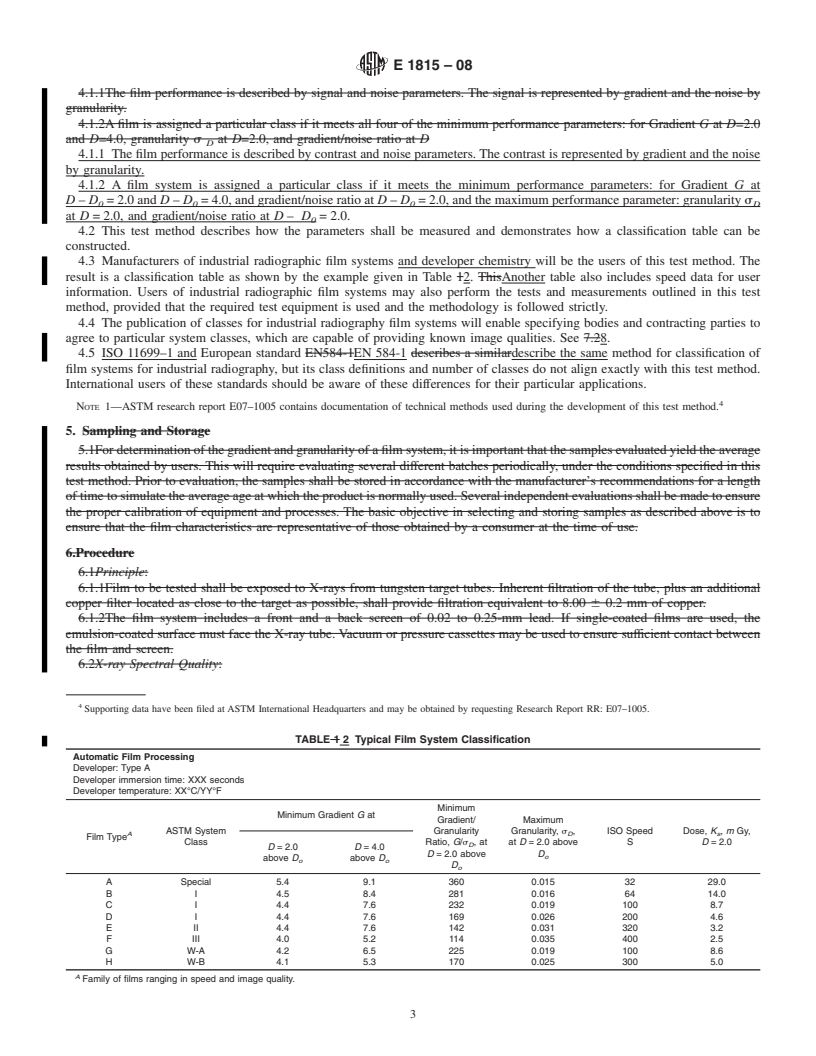

The film performance is described by contrast and noise parameters. The contrast is represented by gradient and the noise by granularity.

A film system is assigned a particular class if it meets the minimum performance parameters: for Gradient G at D – D0 = 2.0 and D – D0 = 4.0, and gradient/noise ratio at D – D0 = 2.0, and the maximum performance parameter: granularity σD at D = 2.0, and gradient/noise ratio at D – D0 = 2.0.

This test method describes how the parameters shall be measured and demonstrates how a classification table can be constructed.

Manufacturers of industrial radiographic film systems and developer chemistry will be the users of this test method. The result is a classification table as shown by the example given in Table 2. Another table also includes speed data for user information. Users of industrial radiographic film systems may also perform the tests and measurements outlined in this test method, provided that the required test equipment is used and the methodology is followed strictly.

The publication of classes for industrial radiography film systems will enable specifying bodies and contracting parties to agree to particular system classes, which are capable of providing known image qualities. See 8.

ISO 11699–1 and European standard EN 584-1 describe the same method for classification of film systems for industrial r...

SCOPE

1.1 This test method covers a procedure for determination of the performance of film systems used for industrial radiography. This test method establishes minimum requirements that correspond to system classes.

1.2 This test method is to be used only for direct exposure-type film exposed with lead intensifying screens. The performance of films exposed with fluorescent (light-emitting) intensifying screens cannot be determined accurately by this test method.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1815 −08

StandardTest Method for

1

Classification of Film Systems for Industrial Radiography

This standard is issued under the fixed designation E1815; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ISO 11699-2Non-Destructive Testing—Industrial Radio-

graphic Film—Part 2: Control of Film Processing by

1.1 This test method covers a procedure for determination

Means of Reference Values

of the performance of film systems used for industrial radiog-

ISO/IEC 17025General Requirements for the Competence

raphy.Thistestmethodestablishesminimumrequirementsthat

of Testing and Calibration Laboratories

correspond to system classes.

3

2.3 European CEN Standard:

1.2 This test method is to be used only for direct exposure-

EN 584-1 Non-Destructive Testing—Industrial Radio-

type film exposed with lead intensifying screens. The perfor-

graphic Film—Part 1: Classification of Film Systems for

manceoffilmsexposedwithfluorescent(light-emitting)inten-

Industrial Radiography

sifying screens cannot be determined accurately by this test

method.

3. Terminology

1.3 The values stated in SI units are to be regarded as

3.1 Definitions—For definitions of terms used in this test

standard. The values given in parentheses are for information

method, refer to Terminology E1316.

only.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

3.2.1 characteristic curve—curve showing the relationship

safety concerns, if any, associated with its use. It is the

between the common logarithm of exposure logK, and the

responsibility of the user of this standard to establish appro-

optical density D.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.2.2 diffuse density—quantitative measure of film blacken-

ing (optical density) as determined by a densitometer. It is the

2. Referenced Documents

sum of all transmitted and scattered light into the half sphere

2

2.1 ASTM Standards:

behind the film.

E94Guide for Radiographic Examination

3.2.3 film gradient G—the slope of the characteristic curve

E1316Terminology for Nondestructive Examinations

at a specified optical density, D, and a measure of the contrast

3

2.2 ISO Standards:

of the film system.

ISO 5-3Photography Density Measurements—Part 3: Spec-

3.2.4 film system—the film and associated film-processing

tral Conditions

requirements in accordance with the criteria established by the

ISO 7004Photography—Industrial Radiographic Film, De-

manufacturers of the film and processing chemicals.

termination of ISO Speed and Average Gradient When

Exposed to X and Gamma Radiation

3.2.5 filmsystemclass—classificationtakingintoaccountof

ISO 11699-1Non-Destructive Testing—Industrial Radio-

limiting values given in Table 1.

graphic Film—Part 1: Classification of Film Systems for

3.2.6 gradient/noise ratio—ratio of the gradient G and the

Industrial Radiography

granularity σ . It relates directly to the signal/noise ratio. All

D

further parameters determining the signal, such as the modu-

1

This test method is under the jurisdiction of ASTM Committee E07 on

lation transfer function or the energy of the radiation, are

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

considered to be constant.

Radiology (X and Gamma) Method.

3.2.6.1 Discussion—The limiting values given in this stan-

Current edition approved July 1, 2008. Published August 2008. Originally

approved in 1996. Last previous edition approved in 2006 as E1815-06. DOI:

dard are related to fixed radiation energies and specified

10.1520/E1815-08.

screens.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.7 granularity, σ —stochastic fluctuation in a radio-

D

Standards volume information, refer to the standard’s Document Summary page on

graphic image, superimposed on the image of the object and

the ASTM website.

3

typically caused by random, statistical groupings of individual

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. silver particles in processed film.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1815−08

TABLE 1 Limiting Values for Gradient, Gradient/Granularity Ratio, and Granularity

Minimum Gradient G at Minimum Maximum

Gradient/ Granularity,

ASTM

Granularity σ ,at D=2.0

D

System

Ratio, G/σ , above D

D

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1815–06 Designation: E 1815 – 08

Standard Test Method for

1

Classification of Film Systems for Industrial Radiography

This standard is issued under the fixed designation E1815; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determination of the performance of film systems used for industrial radiography.

This test method establishes minimum requirements that correspond to system classes.

1.2 This test method is to be used only for direct exposure-type film exposed with lead intensifying screens. The performance

of films exposed with fluorescent (light-emitting) intensifying screens cannot be determined accurately by this test method.

1.3 The values stated in SI units are to be regarded as standard. The values given in bracketsparentheses are for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E94 Guide for Radiographic Examination

E999Guide999 Guide for Controlling the Quality of Industrial Radiographic Film Processing

E1079Practice1079 Practice for Calibration of Transmission Densitometers

E1316 Terminology for Nondestructive Examinations

3

2.2 ANSI Standards:

PH 2.40Root IT2.40 Root Mean Square (rms) Granularity of Film (Images on One Side Only) Method of Measuring

3

2.3 ISO Standards:

ISO 5-2Photography5-2 Photography Density Measurements—Part 2: Geometric Conditions for Transmission Density

ISO 5-3 Photography Density Measurements—Part 3: Spectral Conditions

ISO 7004Photography—Industrial Radiographic Film, Determination of ISO Speed andAverage Gradient When Exposed to X

and Gamma Radiation Photography—Industrial Radiographic Film, Determination of ISO Speed and Average Gradient

When Exposed to X and Gamma Radiation

ISO 11699-1 Non-Destructive Testing—Industrial Radiographic Film—Part 1: Classification of Film Systems for Industrial

Radiography

ISO 11699-2 Non-Destructive Testing—Industrial Radiographic Film—Part 2: Control of Film Processing by Means of

Reference Values

3

2.4 DIN Standard:

EN584-1 Non-Destructive Testing—Industrial Radiographic Film—Classification of Film Systems

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology E1316.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 film system—the film and associated film-processing requirements in accordance with the criteria established by the

manufacturers of the film and processing chemicals. characteristic curve, n—curve showing the relationship between the common

logarithm of exposure logK, and the optical density D.

3.2.2 gradient G—the slope of the characteristic curve at a certain density, diffuse density—quantitative measure of film

1

This test method is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

(X and Gamma) Method.

Current edition approved Feb. 1, 2006. Published February 2006. Originally approved in 1996. Last previous edition approved in 2001 as E1815-96 (2001).

Current edition approved July 1, 2008. Published August 2008. Originally approved in 1996. Last previous edition approved in 2006 as E1815-06.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1815–08

blackening(opticaldensity)asdeterminedbyadensitometer.Itisthesumofalltransmittedandscatteredlightintothehalfsphere

behind the film.

3.2.3 film gradient G—the slope of the characteristic curve at a specified optical density, D, and a measure of the contrast of

the film system.

3.2.3granularity, s —nonuniformity of density in a radi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.