ASTM D5687/D5687M-95

(Guide)Standard Guide for Preparation of Flat Composite Panels with Processing Guidelines for Specimen Preparation

Standard Guide for Preparation of Flat Composite Panels with Processing Guidelines for Specimen Preparation

SCOPE

1.1 This document provides guidelines to facilitate the proper preparation of laminates and test specimens from fiber-reinforced organic matrix composite prepregs. The scope is limited to organic matrices and fiber reinforcement in unidirectional (tape) or orthagonal weave patterns. Other forms may require deviations from these general guidelines. Other processing techniques for test coupon preparation, for example, pultrusion, filament winding and resin-transfer molding, are not addressed.

1.2 Specimen preparation is modeled as an 8-step process that is presented in Fig. 1 and Section 8. Laminate consolidation techniques are assumed to be by press or autoclave. This practice assumes that the materials are properly handled by the test facility to meet the requirements specified by the material supplier(s) or specification, or both. Identification and information gathering guidelines are modeled after Guide E1309. Test specimens shall be directly traceable to material used as designated in Guide E1434. Proper test specimen identification also includes designation of process equipment, process steps, and any irregularities identified during processing.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5687/D 5687M – 95

Standard Guide for

Preparation of Flat Composite Panels with Processing

Guidelines for Specimen Preparation

This standard is issued under the fixed designation D 5687/D 5687M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This document provides guidelines to facilitate the

proper preparation of laminates and test specimens from

fiber-reinforced organic matrix composite prepregs. The scope

is limited to organic matrices and fiber reinforcement in

unidirectional (tape) or orthagonal weave patterns. Other forms

may require deviations from these general guidelines. Other

processing techniques for test coupon preparation, for example,

pultrusion, filament winding and resin-transfer molding, are

not addressed.

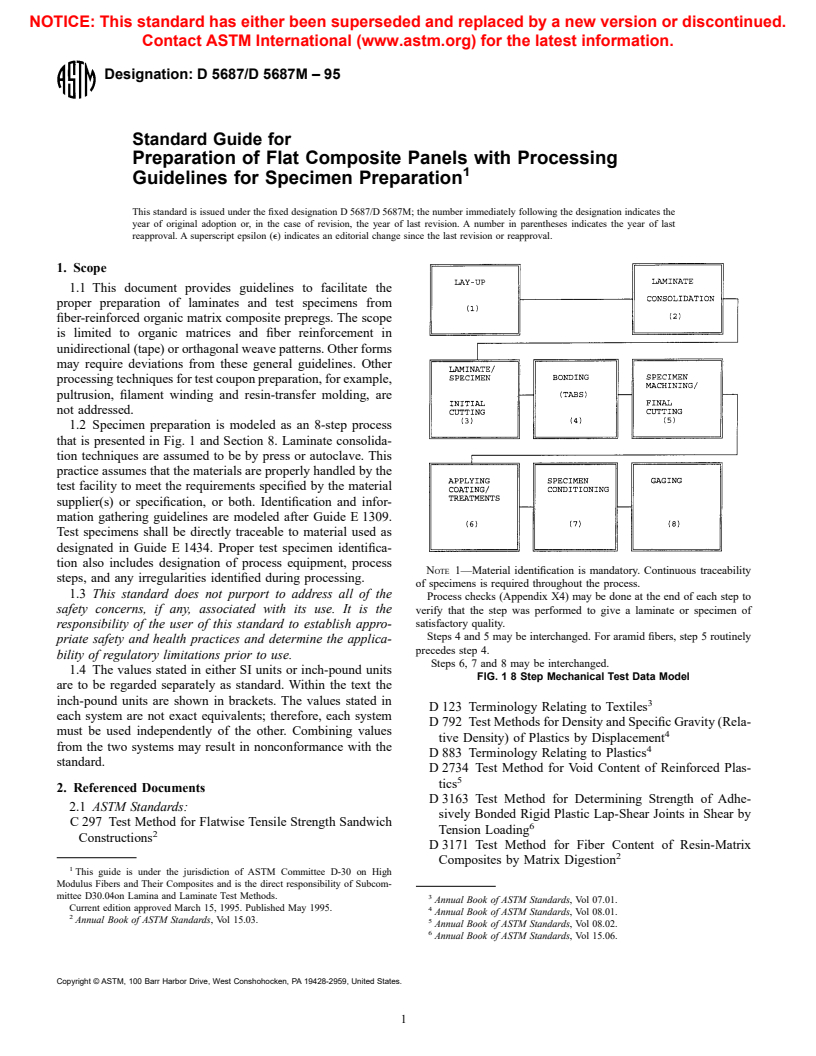

1.2 Specimen preparation is modeled as an 8-step process

that is presented in Fig. 1 and Section 8. Laminate consolida-

tion techniques are assumed to be by press or autoclave. This

practice assumes that the materials are properly handled by the

test facility to meet the requirements specified by the material

supplier(s) or specification, or both. Identification and infor-

mation gathering guidelines are modeled after Guide E 1309.

Test specimens shall be directly traceable to material used as

designated in Guide E 1434. Proper test specimen identifica-

tion also includes designation of process equipment, process

NOTE 1—Material identification is mandatory. Continuous traceability

steps, and any irregularities identified during processing.

of specimens is required throughout the process.

1.3 This standard does not purport to address all of the

Process checks (Appendix X4) may be done at the end of each step to

safety concerns, if any, associated with its use. It is the

verify that the step was performed to give a laminate or specimen of

satisfactory quality.

responsibility of the user of this standard to establish appro-

Steps 4 and 5 may be interchanged. For aramid fibers, step 5 routinely

priate safety and health practices and determine the applica-

precedes step 4.

bility of regulatory limitations prior to use.

Steps 6, 7 and 8 may be interchanged.

1.4 The values stated in either SI units or inch-pound units

FIG. 1 8 Step Mechanical Test Data Model

are to be regarded separately as standard. Within the text the

inch-pound units are shown in brackets. The values stated in

D 123 Terminology Relating to Textiles

each system are not exact equivalents; therefore, each system

D 792 Test Methods for Density and Specific Gravity (Rela-

must be used independently of the other. Combining values

tive Density) of Plastics by Displacement

from the two systems may result in nonconformance with the

D 883 Terminology Relating to Plastics

standard.

D 2734 Test Method for Void Content of Reinforced Plas-

tics

2. Referenced Documents

D 3163 Test Method for Determining Strength of Adhe-

2.1 ASTM Standards:

sively Bonded Rigid Plastic Lap-Shear Joints in Shear by

C 297 Test Method for Flatwise Tensile Strength Sandwich

Tension Loading

Constructions

D 3171 Test Method for Fiber Content of Resin-Matrix

Composites by Matrix Digestion

This guide is under the jurisdiction of ASTM Committee D-30 on High

Modulus Fibers and Their Composites and is the direct responsibility of Subcom-

mittee D30.04on Lamina and Laminate Test Methods.

Annual Book of ASTM Standards, Vol 07.01.

Current edition approved March 15, 1995. Published May 1995.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 15.03.

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 15.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5687/D 5687M

D 3531 Test Method for Resin Flow of Carbon Fiber-Epoxy 3.2.9 fiber washing, n—the tendency of fibers to change

Prepreg orientation due to resin flow from the original lay-up direction.

D 3878 Terminology of High-Modulus Reinforcing Fibers Fiber washing may occur during the laminate consolidation

and Their Composites process mainly at the sides of a laminate.

D 3990 Terminology Relating to Fabric Defects 3.2.10 fill, n—(1) Fiber inserted by the shuttle during

D 4850 Terminology Relating to Fabric

weaving also designated as filling. See Terminology D 123. (2)

D 5229/D 5229M Test Method for Moisture Absorption The direction of fiber running perpendicular to the warp fibers.

Properties and Equilibrium Conditioning of Polymer Ma-

3.2.11 flip/flop, v—the process of alternating plies through

trix Composite Materials

an angle orientation of 180° during laminate lay-up. This

E 1237 Guide for Installing Bonded Resistance Strain

practice is commonly used if material of the same width as the

Gages

laminate has a reoccurring flaw. The process changes the

E 1309 Guide for the Identification of Composite Materials

location of the flaw so that it does not unduly affect the

in Computerized Material Property Databases

laminate structure.

E 1434 Guide for the Development of Standard Data

3.2.12 flaw, n—a material defect, typically occurring in the

Records for Computerization of Mechanical Test Data for

discrete fiber reinforcement, but possible in the matrix.

High-Modulus Fiber-Reinforced Composite Materials

3.2.13 flow, n—the movement of uncured matrix under

pressure during laminate consolidation.

3. Terminology

3.2.14 harness, n—a weaving designation of how many fill

3.1 Definitions—Terminology D 3878 defines terms relating

fibers a warp float crosses in a satin weave. Typical weaves are

to high-modulus fibers and their composites. Terminology

5-Harness and 8-Harness.

D 883 defines terms relating to plastics. Terminology D 123

3.2.15 joint, n—a location where two edges of prepreg

defines textile related terms. Terminology D 4850 defines

meet. Two common types of joints used in lay-up are a butt

terms relating to fabric. In the event of a conflict between

joint (where 2 plies are aligned edge to edge) and an overlap

terms, Terminology D 3878 shall have precedence over the

joint (where the edge of each ply is overlapped some specified

other standards.

width with another ply).

3.2 Description of Trems Used in This Standard—The terms

3.2.16 lay-up, n—the finished product of ply stacking and

used in this guide may conflict with general usage. There is not

bagging operations.

yet an established consensus concerning the use of these terms.

3.2.17 matrix, n—the continuous constituent of a composite

The following descriptions are intended only for use in this

material.

guide.

3.2.18 mold, n—the support structure that holds the lami-

3.2.1 bag, v—the process of enclosing the ply layers within

nate or lay-up during the laminate consolidation process.

a flexible container. See lay-up.

3.2.19 non-perforated TFE, n—a non-porous tetrafluoroet-

3.2.2 base plate, n—a flat plate on which a laminate is laid

hylene film.

up [usually made of aluminum and 6 mm [0.25 in.] or thicker

3.2.20 panel, n—a uniformly contoured composite lami-

with a flatness requirement of 0.05 mm [0.002 in.] or less].

nate, typically flat.

3.2.3 breather string, n—a glass string connected from the

3.2.21 peel ply, n—a cloth with release capabilities. Usually

laminate to a breather in the autoclave bag. It is used as a

used in conjunction with laminates requiring secondary bond-

degassing aid; providing a path for gasses to be transferred

ing.

from the laminate.

3.2.22 perforated TFE, n—a porous tetrafluoroethylene film

3.2.4 caul plate, n—a flat plate used to provide a flat surface

used in the bagging process that allows gasses or excess matrix

to the top of the laminate during laminate consolidation

materials to escape from a laminate during laminate consoli-

[usually made of aluminum and 3 mm [0.125 in.] thick or

dation, while protecting the laminate from physical bonding to

thicker with a flatness requirement of 0.05 mm [0.002 in.] or

other items such as base plates or caul plates.

less].

3.2.23 ply, n—a single layer of prepreg used in lay-up.

3.2.5 cloth, n—a piece of textile fabric containing woven

3.2.24 press, n—equipment consisting of heated, flat [usu-

reinforcement without a load transferring matrix.

ally within a tolerance of 0.3 mm [0.01 in.] or less] platens that

3.2.6 dam, n—a solid material (such as silicone rubber, steel

supply pressure against a surface.

or aluminum) used in the autoclave bag to contain the matrix

3.2.25 satin, adj—a weave pattern in which warp floats pass

material within defined boundaries during laminate consolida-

over several yarns before crossing under a single yarn. It is

tion.

characterized by parallel fibers and no diagonal pattern.

3.2.7 debulk, v—process of decreasing voids between

lamina before laminate consolidation through use of vacuum or 3.2.26 sealant, n—a high temperature material used to seal

by mechanical means. Laminae can be debulked at ambient or the edges of a vacuum bag to the base plate during a

elevated temperatures. consolidation or debulking cycle.

3.2.8 doubler, n—an unbonded tab used to hold the lami- 3.2.27 staggered, adj—the description of ply placement

nate specimen in a grip or fixture. See tab.

where the joints are not positioned in the same inplane location

through some specified thickness of the laminate.

7 3.2.28 tab, n—a piece of material used to hold the laminate

Annual Book of ASTM Standards, Vol 07.02.

Annual Book of ASTM Standards, Vol 03.01. specimen in a grip or fixture for testing so that the laminate is

D 5687/D 5687M

not damaged, and is adequately supported. It is bonded to the ment for test specimens that identically duplicates that of larger

specimen. An unbonded tab is termed a doubler. scale processes.

3.2.29 TFE coated cloth, n—a cloth coated with a tetrafluo- 5.5 Tolerances are guidelines based on current lab practices.

This guide does not attempt to give detailed instructions due to

roethylene coating. This is used in the bagging process to allow

gases or excess matrix material to escape during the laminate the variety of possible panels and specimens that could be

made. The tolerances should be used as a starting reference

consolidation. It differs from perforated TFE in that it gives a

textured surface to the laminate. from which refinements can be made.

3.2.30 traveler, n—a coupon with the same nominal thick-

6. Interferences

ness and width as the test specimen, made of the same material

6.1 Specimen preparation practices should reflect those used

and processed similarly to the specimen except usually without

on an applicable part, to the greatest extent practical. However,

tabs or gages. The traveler is used to measure mass changes

due to scaling effects, processing requirements for test lami-

during environmental conditioning when it is impractical to

nates may not exactly duplicate the processes used in larger

measure these changes on the actual specimen.

scale components. The user should attempt to understand and

3.2.31 vacuum bag, n—a low gas permeable material used

control those critical process parameters that may produce a

to enclose and seal the laminate during a consolidation or

difference in material response between the test coupon and the

debulking cycle.

structure. Critical process parameters are material, application,

3.2.32 vacuum couple, n—the mechanical connection that

and process dependent and are beyond the scope of this guide.

seals the vacuum source to the lay-up during a consolidation or

6.2 Laminate quality is directly related to the prevention of

debulking cycle.

contamination during lay-up and processing.

3.2.33 warp surface, n—the ply surface which shows the

larger area of warp tows with respect to filling tows. Fabrics

7. Apparatus and Materials

where both surfaces show an equal area of warp tows with

NOTE 1—This section provides a listing of apparatus and material items

respect to filling tows do not have a warp surface.

that have been shown to be acceptable. The list is not meant to be all

3.2.34 warp nested, n—warp plies alternated in the pattern

inclusive, but may be helpful to novice users.

warp surface up, warp surface down.

7.1 Equipment:

7.1.1 Lay-up Environment/Tools:

4. Summary of Guide

7.1.1.1 Tables—Tables should be1m[3ft] in height (or

4.1 This guide describes the general process flow for prepa-

adjustable tables) with ample area for lay-up. The table should

ration of flat composite panels and provides specific recom-

be accessible from all sides. The table surface should have a

mended techniques that are generally suitable to laminated

fully supported metal or wood undersurface. The table surface

fibrous organic polymer matrix composites for each of the

should be of (1) safety glass with edges protected by aluminum

process steps to test specimen fabrication.

angle plate or (2) A toughened transparent plastic sheet.

4.2 The specific techniques included in this guide are the

7.1.1.2 Convenient accessibility of lay-up materials—Wall

minimum recommended for common composite material sys-

racks hold bulk cloth, TFE, and other expendable bagging

tems as represented in the scope of this guide. For a given

materials. These racks typically consist of a steel rod which can

application other techniques may need to be added or substi-

hold a roll of material. The rods should be able to accommo-

tuted for those described by this guide.

date material rolls up to 1.5 m [60 in.] wide. The spacing

between racks should be a minimum of 0.4 m [15 in.] spacing

5. Significance and Use

between rods with the bottom rod being no closer than 0.6 m

5.1 The techniques described in this guide, if properly used

[25 in.] to the floor and the top rod being no higher than 2.2 m

in conjunction with a knowledge of behavior of particular

[85 in.] from the floor. Cabinets and drawers hold other lay-up

material systems, will aid in the proper preparation of consoli-

materials such as sealants, spare tape, vacuum couples, hoses,

dated laminates for mechanical property testing.

caul plates, thermocouple wire etc. These should be compart-

5.2 The techniques described are recommended to facilitate

mentalized for easy access.

the consistent production of satisfactory test specimens by

7.1.1.3 Vacuum Supply—Overhead piping for vacuum with

minimizing uncontrolled processing variance during specimen

a flexible hose reel over the table has been found to be

fabrication.

satisfactory. The vacuum pump should be located within 45 m

5.3 Steps 3 through 8 of the 8-step process may not be [150 ft] of the lay-up site.

required for particular specimen or test types. If th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.