ASTM E1025-98

(Practice)Standard Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used for Radiology

Standard Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used for Radiology

SCOPE

1.1 This practice covers the design, material grouping classification, and manufacture of hole-type image quality indicators (IQI) used to indicate the quality of radiologic images.

1.2 This practice is applicable to X-ray and gamma-ray radiology.

1.3 The values stated in inch-pound units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1025 – 98

Standard Practice for

Design, Manufacture, and Material Grouping Classification

of Hole-Type Image Quality Indicators (IQI) Used for

Radiology

This standard is issued under the fixed designation E1025; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers the design, material grouping 3.1 Definitions—Thedefinitionsoftermsrelatingtogamma

classification, and manufacture of hole-type image quality andx-radiologyinTerminologyE1316,SectionD,shallapply

indicators (IQI) used to indicate the quality of radiologic to the terms used in this practice.

images.

4. Hole-Type IQI Requirements

1.2 This practice is applicable to X-ray and gamma-ray

4.1 Image quality indicators (IQIs) used to determine

radiology.

1.3 Thevaluesstatedininch-poundunitsaretoberegarded radiologic-image quality levels shall conform to the following

requirements.

as standard.

1.4 This standard does not purport to address all of the 4.1.1 Standard Hole-Type IQIs:

4.1.1.1 Image quality indicators (IQIs) shall be fabricated

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- from materials or alloys identified or listed in accordance with

7.3. Other materials may be used in accordance with 7.4.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.1.1.2 Image quality indicators (IQIs) shall dimensionally

conform to the requirements of Fig. 1.

2. Referenced Documents

4.1.1.3 Both the rectangular and the circular IQI shall be

2.1 ASTM Standards: identified with number(s) made of lead or a material of similar

B139 Specification for Phosphor Bronze Rod, Bar, and radiation opacity. The number shall be bonded to the rectan-

Shapes gular IQI’s and shall be placed adjacent to circular IQI’s to

B150 Specification for Aluminum Bronze Rod, Bar, and provide identification of the IQI on the image. The identifica-

Shapes tion numbers shall indicate the thickness of the IQI in

B161 Specification for Nickel Seamless Pipe and Tube thousandths of an inch, that is, a number 10 IQI is 0.010 in.

B164 Specification for Nickel-CopperAlloy Rod, Bar, and thick, a number 100 IQI is 0.100 in. thick, etc. Additional

Wire identification requirements are provided in 7.2.

B 166 Specification for Nickel-Chromium-Iron Alloys 4.1.1.4 Alloy-group identification shall be in accordance

(UNS N06600, N06601, and N06690) and Nickel- with Fig. 2. Rectangular IQI’s shall be notched. Image quality

Chromium-Cobalt-Molybdenum Alloy (UNS N06617) indicators (IQI’s) shall be vibrotooled or etched as specified.

Rod, Bar, and Wire 4.1.2 Modified Hole-Type IQI:

E1316 Terminology for Nondestructive Examinations 4.1.2.1 The rectangular IQI may be modified in length and

width as necessary for special applications, provided the hole

size(s) and IQI thickness conform to Fig. 1.

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

4.1.2.2 The IQI’s shall be identified as specified in 4.1.1.3,

structive Testing and is the direct responsibility of Subcommittee E07.01 on

except that the identification numbers may be placed adjacent

Radiographic Practice and Penetrameters.

to the IQI if placement on the IQI is impractical.

Current edition approved July 10, 1998. Published December 1998. Originally

published as E1025–84. Last previous edition E1025–95.

4.1.2.3 When modified IQI’s are used, details of the modi-

For ASME Boiler and Pressure Vessel Code applications see related Practice

fication shall be documented in the records accompanying the

SE-1025 in Section II of that Code.

examination results.

Annual Book of ASTM Standards, Vol 02.01.

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1025–98

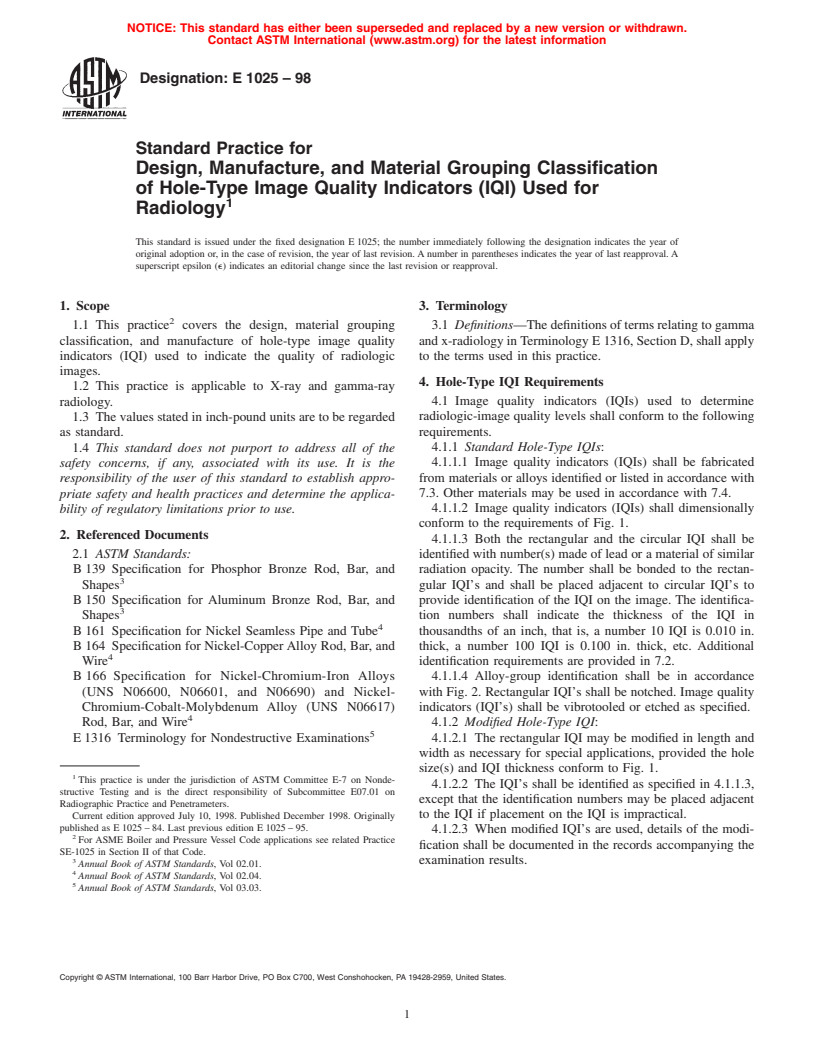

NOTE 1—All dimensions in inches (Note 6).

NOTE 2—Tolerances for IQI thickness and hole diameter.

NOTE 3—XX identification number equals T in .001 inches.

NOTE 4—IQIs No. 1 through 9 are not 1T,2T, and 4T.

NOTE 5—Holes shall be true and normal to the IQI. Do not chamfer.

NOTE 6—To convert inch dimensions to metric, multiply by 25.4.

Identification

Number T Tolerances

(Note 3) A B C D E F (Note 2)

1–4 1.500 0.750 0.438 0.250 0.500 0.250 610%

60.015 60.015 60.015 60.015 60.015 60.030

5–20 1.500 0.750 0.438 0.250 0.500 0.250 60.0005

60.015 60.015 60.015 60.015 60.015 60.030

21–50 . . . . . . 60.0025

Over 50–160 2.250 1.375 0.750 0.375 1.000 0.375 60.005

60.030 60.030 60.030 60.030 60.030 60.030

Over 160 1.330T 0.830T . . . . 60.010

60.005 60.005

FIG. 1 IQI Design

5. IQI Procurement 5.1.2 Determine the thickness or thickness range of the

material(s) to be examined.

5.1 When selecting IQI’s for procurement, the following

factors should be considered: 5.1.3 Select the applicable IQI’s that represent the required

5.1.1 Determine the alloy group(s) of the material to be

IQI thickness and alloy(s).

examined.

E1025–98

quality levels specified in 6.1 and Table 1. The equivalent sensitivity can

Group 03 IQI

be computed from data furnished in Appendix X1.

for Magnesium

6.2 Typical image quality level designations are shown in

Table 1. The level of inspection specified should be based on

Group 02 IQI

service requirements of the product. Care should be taken in

for Aluminum

specifying image quality levels 2-1T, 1-1T, and 1-2T by first

determining that these levels can be maintained in production.

6.3 In specifying image quality levels, the contract, pur-

Group 01 IQI

chase order, product specification, or drawing should state the

for Titanium

propertwo-partexpressionandclearlyindicatethethicknessof

the metal to which the level refers. In place of a designated

two–partexpression,theIQInumberandminimumdiscernible

Group 1 IQI

hole size shall be specified.

for Carbon Alloy and

Stainless Steel

7. Material Groups

7.1 General:

Group 2 IQI 7.1.1 Materials have been designated in eight groups based

for Aluminum Bronze

on their radiation absorption characteristics: Groups 03, 02,

and 01 for light metals and Groups 1 through 5 for heavy

metals.

Group 3 IQI

7.1.2 The light metal groups, magnesium (Mg), aluminum

for Nickel-Chromium-Iron

(A1), and titanium (Ti) are identified 03, 02, and 01 respec-

tivelyfortheirpredominantalloyingconstituent.Thematerials

are listed in order of increasing radiation absorption.

Group 4 IQI

7.1.3 The heavy metal groups, steel, copper base, nickel

for Nickel-Copper (70-30)

base, and kindred alloys are identified 1 through 5. The

materials increase in radiation absorption with increasing

numerical designation.

Group 5 IQI

for Tin Bronze

NOTE 3—These groups were established experimentally at 180 kV on

⁄4-in.(19-mm)thickspecimens.Theyapplyfrom125kVtothemultivolt

range.

Detail of Notch

7.1.4 Common trade names or alloy designations have been

used for clarification of the pertinent materials.

7.1.5 The materials from which the IQI for the group are to

⁄16 in. (1.588

mm) be made are designated in each case, and these IQI’s are

applicableforallmaterialslistedinthatgroup.Inaddition,any

group IQI may be used for any material with a higher group

NOTCH TOLERANCES

number, provided the applicable quality level is maintained.

Width +15°

−0°

7.2 Identification System:

Depth + ⁄16 in. (1.588mm)

7.2.1 A notching system has been designated for the eight

− ⁄32 in. (.794mm)

groups of IQI’s and is shown in Fig. 2.

FIG. 2 Rectangular IQI Notch Identification and Material Grouping

7.2.2 For circular IQI’s, a group designation shall be vibro-

tooled or chemically etched on the IQI to identify it by using

NOTE 1—ThispracticedoesnotrecommendorsuggestspecificIQIsets

to be procured. Section 5 is an aid in selecting IQI’s based on specific

TABLE 1 Typical Image Quality Levels

needs.

Standard Image Quality Levels

Minimum

6. Image Quality Levels

Image Quality Preceptible Equivalent IQI

IQI Thickness

A

6.1 Image quality levels are designated by a two part

Levels Hole Sensitivity, %

Diameter

expression X-YT.Thefirstpartoftheexpression Xreferstothe

2-1T ⁄50 (2 %) of Specimen Thickness 1T 1.4

IQI thickness expressed as a percentage of the specimen

B

2-2T 2T 2.0

thickness. The second part of the expression YT refers to the

2-4T 4T 2.8

Special Image Quality Levels

diameter of the hole and is expressed as a multiple of the IQI

1-1T ⁄100 (1 %) of Specimen Thickness 1T 0.7

thickness, T. The image quality level 2-2T means that the IQI

1-2T 2T 1

thickness T is 2% of the specimen thickness and that the 1

4-2T ⁄25 (4 %) of Specimen Thickness 2T 4

A

diameter of the IQI imaged hole is 2 3the IQI thickness.

Equivalent IQI sensitivity is that thickness of the IQI, expressed as a percent-

age of the part thickness, in which the 2T hole would be visible under the same

NOTE 2—Image Quality Indicators (IQI’s) less than number 10 have

conditions.

B

hole sizes 0.010, 0.020, and 0.040 in. diameter regardless of the IQI 1

For Level 2-2T Radiologic—The 2Tholeinan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.