ASTM D245-00e1

(Practice)Standard Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber

Standard Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber

SCOPE

1.1 This practice (1,2) covers the basic principles for establishing related unit stresses and stiffness values for design with visually-graded solid sawn structural lumber. This practice starts with property values from clear wood specimens and includes necessary procedures for the formulation of structural grades of any desired strength ratio.

1.2 The grading provisions used as illustrations herein are not intended to establish grades for purchase, but rather to show how stress-grading principles are applied. Detailed grading rules for commercial stress grades which serve as purchase specifications are established and published by agencies which formulate and maintain such rules and operate inspection facilities covering the various species.

1.3 The material covered in this practice appears in the following order: SectionScope 1Significance and Use3Basic Principles of Strength Ratios4Estimation and Limitation of Growth Characteristics5Allowable Properties for Timber Design6Modification of Allowable Properties for Design Use7Example of Stress-Grade Development8

1.4 The values given in parentheses are provided for information purposes only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 245 – 00

Standard Practice for

Establishing Structural Grades and Related Allowable

1

Properties for Visually Graded Lumber

This standard is issued under the fixed designation D 245; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Footnote 1 was editorially corrected in April 2001.

3

1. Scope D 9 Terminology Relating to Wood

2

D 143 Methods of Testing Small Clear Specimens of Tim-

1.1 This practice (1,2) covers the basic principles for

3

ber

establishing related unit stresses and stiffness values for design

D 2555 Test Methods for Establishing Clear-Wood Strength

with visually-graded solid sawn structural lumber. This prac-

3

Values

tice starts with property values from clear wood specimens and

4

E 105 Practice for Probability Sampling of Materials

includes necessary procedures for the formulation of structural

E 380 Practice for Use of the International System of Units

grades of any desired strength ratio.

5

(SI) (the Modernized Metric System)

1.2 The grading provisions used as illustrations herein are

not intended to establish grades for purchase, but rather to

3. Significance and Use

show how stress-grading principles are applied. Detailed grad-

3.1 Need for Lumber Grading:

ing rules for commercial stress grades which serve as purchase

3.1.1 Individual pieces of lumber, as they come from the

specifications are established and published by agencies which

saw, represent a wide range in quality and appearance with

formulate and maintain such rules and operate inspection

respect to freedom from knots, cross grain, shakes, and other

facilities covering the various species.

characteristics. Such random pieces likewise represent a wide

1.3 The material covered in this practice appears in the

range in strength, utility, serviceability, and value. One of the

following order:

obvious requirements for the orderly marketing of lumber is

Section

the establishment of grades that permit the procurement of any

Scope 1

Significance and Use 3

required quality of lumber in any desired quantity. Maximum

Basic Principles of Strength Ratios 4

economy of material is obtained when the range of quality-

Estimation and Limitation of Growth Characteristics 5

determining characteristics in a grade is limited and all pieces

Allowable Properties for Timber Design 6

Modification of Allowable Properties for Design Use 7

are utilized to their full potential. Many of the grades are

Example of Stress-Grade Development 8

established on the basis of appearance and physical character-

1.4 The values given in parentheses are provided for infor- istics of the piece, but without regard for mechanical proper-

mation purposes only. ties. Other grades, called structural or stress grades, are

1.5 This standard does not purport to address all of the established on the basis of features that relate to mechanical

safety concerns, if any, associated with its use. It is the properties. The latter designate near-minimum strength and

responsibility of the user of this standard to establish appro- near-average stiffness properties on which to base structural

priate safety and health practices and determine the applica- design.

bility of regulatory limitations prior to use. 3.1.2 The development of this practice is based on extensive

research covering tests of small clear specimens and of

2. Referenced Documents

full-sized structural members. Detailed studies have included

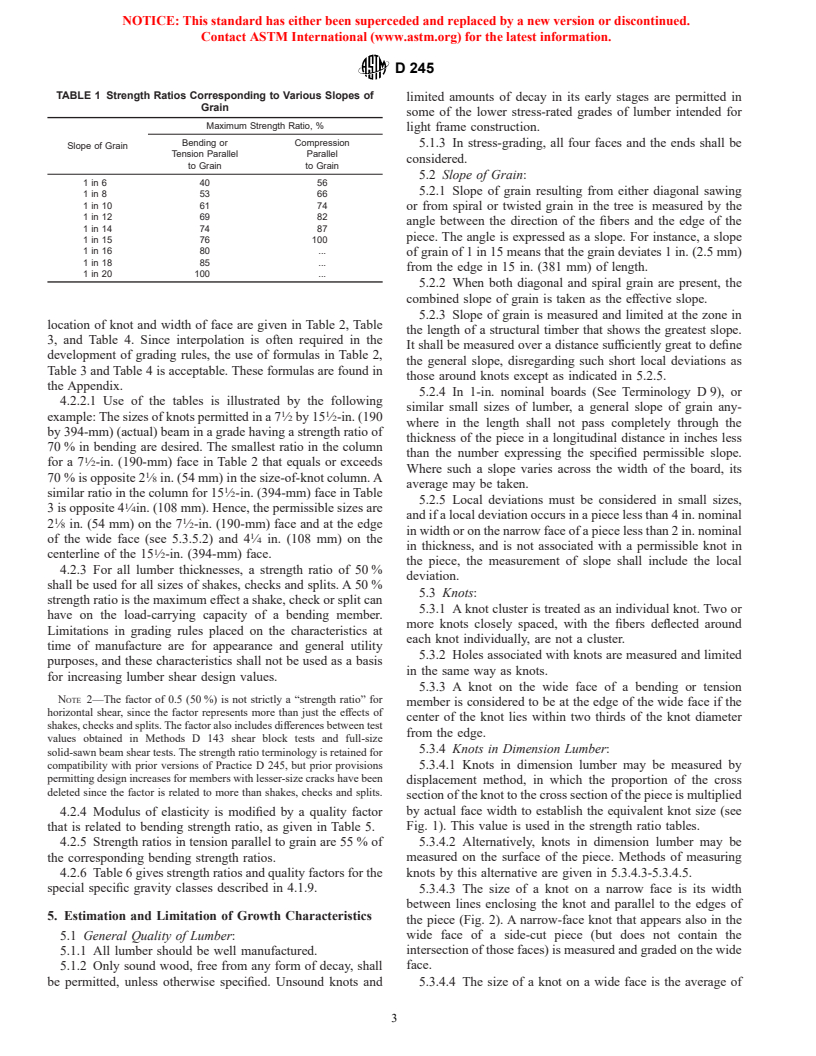

2.1 ASTM Standards: the strength and variability of clear wood, and the effect on

strength from various factors such as density, knots (See

Terminology D 9), and other defects, seasoning, duration of

1

This practice is under the jurisdiction of ASTM Committee D07 on Wood and

stress, and temperature.

is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered

Wood Products.

Current edition approved April 10, 2000. Published June 2000. Originally

3

published as D 245 – 26. Last previous edition D 245 – 99. Annual Book of ASTM Standards, Vol 04.10.

2 4

The boldface numbers in parentheses refer to references at the end of this Annual Book of ASTM Standards, Vol 14.02.

5

practice. Annual Book of ASTM Standards, Vol 14.02 (excerpts in Vol 04.10).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.