ASTM D1544-04

(Test Method)Standard Test Method for Color of Transparent Liquids (Gardner Color Scale)

Standard Test Method for Color of Transparent Liquids (Gardner Color Scale)

SIGNIFICANCE AND USE

This test method applies to drying oils, varnishes, fatty acids, polymerized fatty acids, and resin solutions. Its application to other materials has not been tested.

SCOPE

1.1 This test method covers the measurement of the color of transparent liquids by means of comparison with arbitrarily numbered glass standards.

1.2 Users of this method should have normal color vision.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D1544 – 04

Standard Test Method for

1

Color of Transparent Liquids (Gardner Color Scale)

This standard is issued under the fixed designation D1544; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

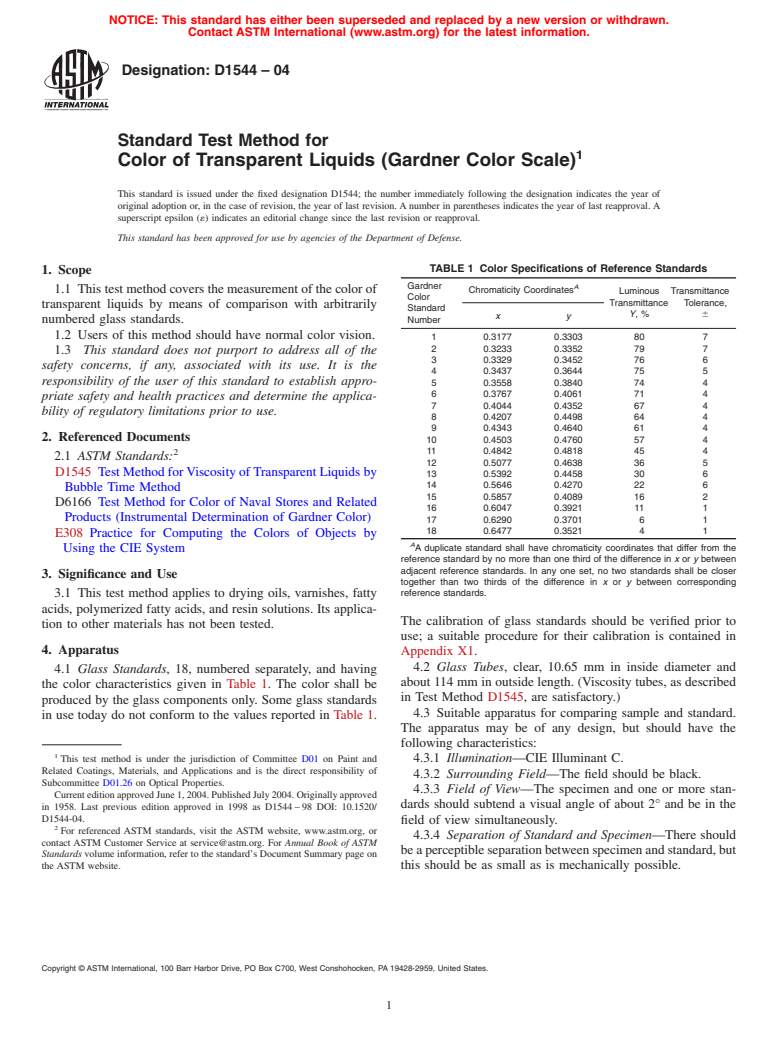

TABLE 1 Color Specifications of Reference Standards

1. Scope

Gardner A

1.1 Thistestmethodcoversthemeasurementofthecolorof Chromaticity Coordinates

Luminous Transmittance

Color

Transmittance Tolerance,

transparent liquids by means of comparison with arbitrarily

Standard

Y,% 6

xy

numbered glass standards. Number

1.2 Users of this method should have normal color vision.

1 0.3177 0.3303 80 7

2 0.3233 0.3352 79 7

1.3 This standard does not purport to address all of the

3 0.3329 0.3452 76 6

safety concerns, if any, associated with its use. It is the

4 0.3437 0.3644 75 5

responsibility of the user of this standard to establish appro-

5 0.3558 0.3840 74 4

6 0.3767 0.4061 71 4

priate safety and health practices and determine the applica-

7 0.4044 0.4352 67 4

bility of regulatory limitations prior to use.

8 0.4207 0.4498 64 4

9 0.4343 0.4640 61 4

2. Referenced Documents

10 0.4503 0.4760 57 4

11 0.4842 0.4818 45 4

2

2.1 ASTM Standards:

12 0.5077 0.4638 36 5

D1545 TestMethodforViscosityofTransparentLiquidsby

13 0.5392 0.4458 30 6

14 0.5646 0.4270 22 6

Bubble Time Method

15 0.5857 0.4089 16 2

D6166 Test Method for Color of Naval Stores and Related

16 0.6047 0.3921 11 1

Products (Instrumental Determination of Gardner Color)

17 0.6290 0.3701 6 1

18 0.6477 0.3521 4 1

E308 Practice for Computing the Colors of Objects by

A

A duplicate standard shall have chromaticity coordinates that differ from the

Using the CIE System

reference standard by no more than one third of the difference in x or y between

adjacent reference standards. In any one set, no two standards shall be closer

3. Significance and Use

together than two thirds of the difference in x or y between corresponding

reference standards.

3.1 This test method applies to drying oils, varnishes, fatty

acids, polymerized fatty acids, and resin solutions. Its applica-

The calibration of glass standards should be verified prior to

tion to other materials has not been tested.

use; a suitable procedure for their calibration is contained in

4. Apparatus

Appendix X1.

4.2 Glass Tubes, clear, 10.65 mm in inside diameter and

4.1 Glass Standards, 18, numbered separately, and having

about 114 mm in outside length. (Viscosity tubes, as described

the color characteristics given in Table 1. The color shall be

in Test Method D1545, are satisfactory.)

produced by the glass components only. Some glass standards

4.3 Suitable apparatus for comparing sample and standard.

in use today do not conform to the values reported in Table 1.

The apparatus may be of any design, but should have the

following characteristics:

1

This test method is under the jurisdiction of Committee D01 on Paint and

4.3.1 Illumination—CIE Illuminant C.

Related Coatings, Materials, and Applications and is the direct responsibility of

4.3.2 Surrounding Field—The field should be black.

Subcommittee D01.26 on Optical Properties.

4.3.3 Field of View—The specimen and one or more stan-

CurrenteditionapprovedJune1,2004.PublishedJuly2004.Originallyapproved

dards should subtend a visual angle of about 2° and be in the

in 1958. Last previous edition approved in 1998 as D1544–98 DOI: 10.1520/

D1544-04.

field of view simultaneously.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3.4 Separation of Standard and Specimen—There should

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

beaperceptibleseparationbetweenspecimenandstandard,but

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. this should be as small as is mechanically possible.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1544 – 04

5. Procedure 7.2 Repeatability—Two results obtained by a single opera-

torshouldbeconsideredsuspectiftheydifferbymorethantwo

5.1 Fill a glass tube with the material under test. If the

thirds of a color number.

material is perceptibly cloudy, first filter it.

7.3 Reproducibility—Two results, each of the mean of

5.2 Compare with glass standards, determining which stan-

duplicate measurements, made by operators in different labo-

dard most closely matches the specimen in brightness and

ratories should be considered suspect if they diffe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.