ASTM D665-14

(Test Method)Standard Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

Standard Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

SIGNIFICANCE AND USE

5.1 In many instances, such as in the gears of a steam turbine, water can become mixed with the lubricant, and rusting of ferrous parts can occur. This test indicates how well inhibited mineral oils aid in preventing this type of rusting. This test method is also used for testing hydraulic and circulating oils, including heavier-than-water fluids. It is used for specification of new oils and monitoring of in-service oils.

Note 3: This test method was used as a basis for Test Method D3603. Test Method D3603 is used to test the oil on separate horizontal and vertical test rod surfaces, and can provide a more discriminating evaluation.

SCOPE

1.1 This test method covers the evaluation of the ability of inhibited mineral oils, particularly steam-turbine oils, to aid in preventing the rusting of ferrous parts should water become mixed with the oil. This test method is also used for testing other oils, such as hydraulic oils and circulating oils. Provision is made in the procedure for testing heavier-than-water fluids.

Note 1: For synthetic fluids, such as phosphate ester types, the plastic holder and beaker cover should be made of chemically resistant material suitable for the type of fluid tested.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.4 – 7.6.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D665 − 14

Designation:135/06

Standard Test Method for

Rust-Preventing Characteristics of Inhibited Mineral Oil in

the Presence of Water

This standard is issued under the fixed designation D665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Vessels and for General Applications

D91 Test Method for Precipitation Number of Lubricating

1.1 This test method covers the evaluation of the ability of

Oils

inhibited mineral oils, particularly steam-turbine oils, to aid in

D1193 Specification for Reagent Water

preventing the rusting of ferrous parts should water become

D2422 Classification of Industrial Fluid Lubricants by Vis-

mixed with the oil. This test method is also used for testing

cosity System

other oils, such as hydraulic oils and circulating oils. Provision

D3603 Test Method for Rust-Preventing Characteristics of

is made in the procedure for testing heavier-than-water fluids.

Steam Turbine Oil in the Presence of Water (Horizontal

NOTE 1—For synthetic fluids, such as phosphate ester types, the plastic

Disk Method)

holder and beaker cover should be made of chemically resistant material

D4057 Practice for Manual Sampling of Petroleum and

suitable for the type of fluid tested.

Petroleum Products

1.2 The values stated in SI units are to be regarded as

E1 Specification for ASTM Liquid-in-Glass Thermometers

standard. No other units of measurement are included in this

2.2 Other Documents:

standard.

Motor Fuels, Section I, Annex A2, Table 32, Reference

1.3 This standard does not purport to address all of the

Materials and Blending Accessories

safety concerns, if any, associated with its use. It is the Specifications-IP Standard Thermometers, Vol 2, Appendix

responsibility of the user of this standard to establish appro-

A

priate safety and health practices and determine the applica- Specifications for IP Standard Reference Liquids, Appendix

bility of regulatory limitations prior to use. For specific B

warning statements, see 7.4 – 7.6.

SAE Standard J405 Chemical Composition of SAEWrought

Stainless Steels

2. Referenced Documents

BS 871 Specification for abrasive papers and cloths

BS 970 Part 1: Carbon and Carbon Manganese Steels

2.1 ASTM Standards:

Including Free Cutting Steels

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

Finished

3. Terminology

A240/A240M Specification for Chromium and Chromium-

3.1 Definitions of Terms Specific to This Standard:

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

3.1.1 rust,n—aspecialcaseofcorrosionthatcanbevisually

observed on the surface of round steel test rods as reddish-

This test method is under the jurisdiction of ASTM Committee D02 on

brown discoloration or small black spots.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.C0.02 on Corrosion and Water/Air Separability.

4. Summary of Test Method

Current edition approved Oct. 1, 2014. Published November 2014. Originally

approved in 1942. Last previous edition approved in 2012 as D665 – 12. DOI:

4.1 Amixture of 300 mLof the oil under test is stirred with

10.1520/D0665-14.

30 mL of distilled water or synthetic sea water, as required, at

This standard has been developed through the cooperative effort betweenASTM

International and the Energy Institute, London. The EI and ASTM International

logos imply that the ASTM International and EI standards are technically See 1996 Annual Book of ASTM Standards, Vol 05.04.

equivalent, but does not imply that both standards are editorially identical. AnnualBookofIPStandardMethodsforAnalysisandTestingofPetroleumand

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Related Products, Vol 2. Available from Energy Institute, 61 New Cavendish St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM London, WIG 7AR, U.K.

Standards volume information, refer to the standard’s Document Summary page on 1995 SAE Handbook, Vol 1. Available from Society of Automotive Engineers

the ASTM website. (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D665 − 14

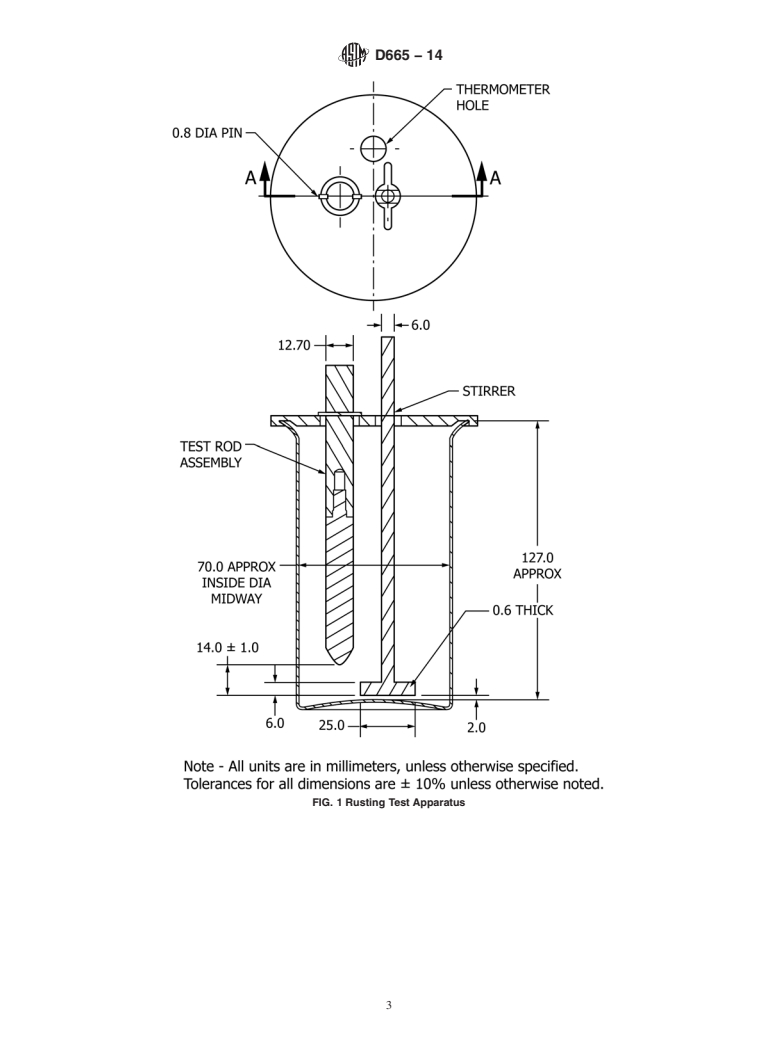

for the beaker which has been found to be suitable.An optional feature is

a temperature of 60 °C 6 1 °C with a cylindrical steel test rod

shown, consisting of a slot, 1.6 mm by 27 mm, which is centered on a

completelyimmersedtherein.Itisrecommendedtorunthetest

diameter of the stirrer hole at right angles to the cover diameter through

for 4 h; however, the test period may, at the discretion of the

the test rod hole and stirrer hole. This feature allows withdrawal of the

contracting parties, be for a shorter or longer period. The test

stirrerwhilethebeakercoverisinplace.Whenthetestmethodtestisused

rod is observed for signs of rusting and, if desired, degree of

for other fluids such as synthetics, the beaker cover should be made from

chemically resistant material such as polymonochlorotrifluoroethylene

rusting.

(PCTFE).

NOTE 2—Until 1999 it was customary to run the test for 24 h.Around

6.4 The plastic holder shall be made of PMMA resin in

robin with comparisons of different test times showed that no statistically

accordance with the dimensions shown in Fig. 3 (two types of

significant differences in rating were found for any sample, between the

4 h and 24 h results. holders are illustrated). When testing synthetic fluids, the

plastic holder should be made from chemically resistant

5. Significance and Use

material such as polytetrafluoroethylene (PTFE).

5.1 In many instances, such as in the gears of a steam

6.5 Stirrer—A stirrer constructed entirely from stainless

turbine, water can become mixed with the lubricant, and

steel (Note 6 and Note 7) in the form of an inverted T. A flat

rusting of ferrous parts can occur. This test indicates how well

blade (25 by 6) mm by 0.6 mm shall be attached to a rod with

inhibited mineral oils aid in preventing this type of rusting.

a diameter of 6 mm in such a way that the blade is symmetrical

This test method is also used for testing hydraulic and

with the rod and has its flat surface in the vertical plane.

circulating oils, including heavier-than-water fluids. It is used

NOTE 6—A suitable material is an 18 % chromium, 8 % nickel alloy

for specification of new oils and monitoring of in-service oils.

steel conforming toType 304, of Specification A240/A240M, or SAE No.

NOTE 3—This test method was used as a basis for Test Method D3603.

30304 (see SAE J405), or BS 970: Part 1: 1983: 302S31.

Test Method D3603 is used to test the oil on separate horizontal and

NOTE 7—If stainless steel is not obtainable, stirrers made of heat-

vertical test rod surfaces, and can provide a more discriminating evalua-

resistant glass and having approximately the same dimensions as the

tion.

stainless steel stirrers specified can be used.

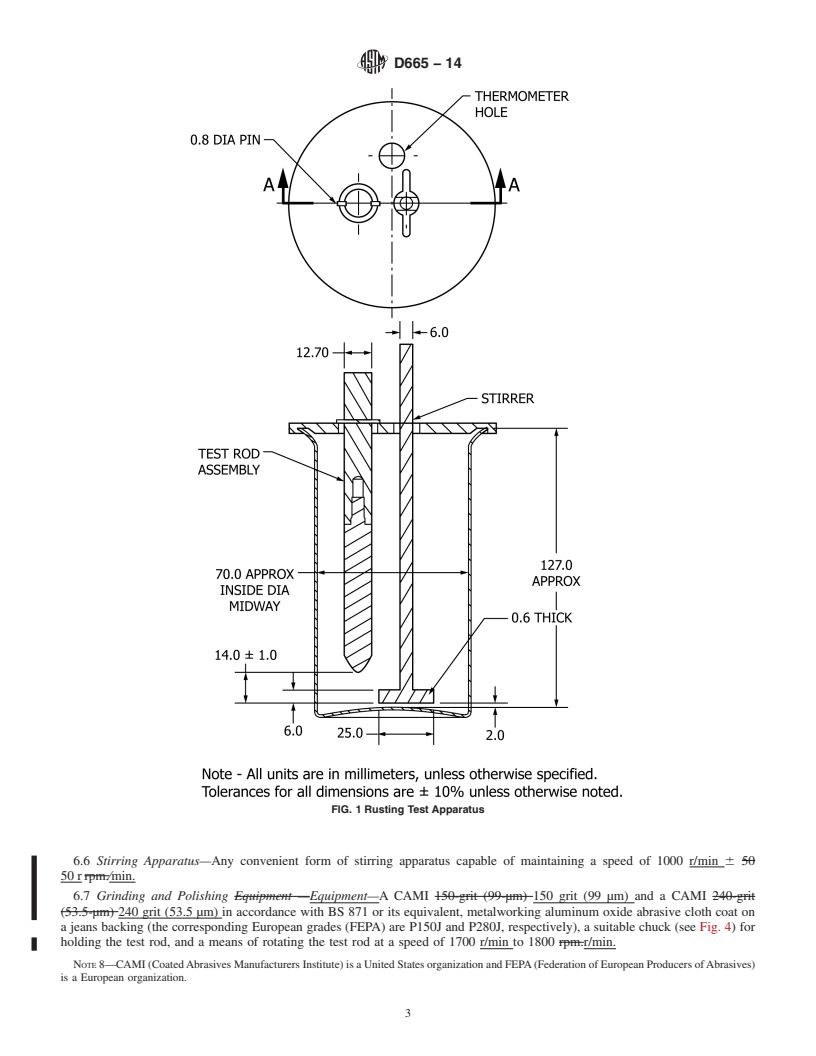

6.6 Stirring Apparatus—Any convenient form of stirring

6. Apparatus

apparatus capable of maintaining a speed of 1000 r/min 6

6.1 Oil Bath—A thermostatically controlled liquid bath

50 r⁄min.

capable of maintaining the test sample at a temperature of

6.7 Grinding and Polishing Equipment—A CAMI 150 grit

60 °C 6 1 °C (see Note 4). An oil having a viscosity of

(99 µm) and a CAMI 240 grit (53.5 µm) in accordance with BS

approximately ISO VG 32 (see Classification D2422)is

871 or its equivalent, metalworking aluminum oxide abrasive

suitable for the bath. The bath shall have a cover with holes to

cloth coat on a jeans backing (the corresponding European

accommodate the test beakers.

grades (FEPA) are P150J and P280J, respectively), a suitable

NOTE 4—ASTMThermometer 9C, as prescribed in Specification E1,or

chuck (see Fig. 4) for holding the test rod, and a means of

IP Thermometer 21C in accordance with IP Standard Thermometers,

rotating the test rod at a speed of 1700 r/min to 1800 r/min.

Volume 2, Appendix A, is suitable to indicate the temperature.

Alternatively, calibrated thermocouples may be used.

NOTE 8—CAMI (CoatedAbrasives Manufacturers Institute) is a United

States organization and FEPA (Federation of European Producers of

6.2 Beaker—ABerzelius-type, tall-form heat-resistant glass

Abrasives) is a European organization.

beaker without pour-out, as shown in Fig. 1, approximately

6.8 Oven, capable of maintaining a temperature of 65 °C.

127 mm in height measured from the inside bottom center and

approximately 70 mm inside diameter measured at the middle.

7. Reagents and Materials

6.3 Beaker Cover—A flat beaker cover of glass or poly

7.1 Purity of Reagents—Reagent grade chemicals shall be

(methyl methacrylate) (PMMA) (Note 5), kept in position by

used in all tests. Unless otherwise indicated, it is intended that

suitable means such as a rim or groove. Two holes shall be

all reagents conform to the specifications of the Committee on

provided on any diameter of the cover; one for a stirrer 12 mm

Analytical Reagents of the American Chemical Society where

indiameterwithitscenter6.4mmfromthecenterofthecover;

such specifications are available. Other grades may be used,

andtheother,ontheoppositesideofthecenterofthecover,for

provided it is first ascertained that the reagent is of sufficiently

the test rod assembly (see Section 9), 18 mm in diameter with

high purity to permit its use without lessening the accuracy of

its center 16 mm from the center of the cover. In addition, a

the determination.

third hole 12 mm in diameter shall be provided for a tempera-

ture measuring device, with its center 22.5 mm from the center 7.2 PurityofWater—Unlessotherwiseindicated,references

to water shall be understood to mean reagent water as defined

of the cover and on a diameter of the cover at right angles to

the diameter through the other two holes. by Type II of Specification D1193.

NOTE 5—An inverted petri dish makes a suitable cover, as the sides of

the dish aid in keeping it in position. Fig. 2 shows a PMMA resin cover Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Supporting data (results of the cooperative test program with modified test Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

duration) have been filed atASTM International Headquarters and may be obtained and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

by requesting Research Report RR:D02-1474. MD.

D665 − 14

FIG. 1 Rusting Test Apparatus

D665 − 14

FIG. 2 Beaker Cover

7.3 The synthetic sea water shall have the following com-

Stock Solution No. 1:

MgCl ·6H O 3885 g

position: 2 2

CaCl ·2H O 538 g

2 2

Salt

SrCl ·6HO14g

2 2

Dissolve and dilute to 7 L

NaCl 24.54g/L

MgCl ·6H O 11.10g/L

2 2 Stock Solution No. 2:

Na SO 4.09g/L

2 4 KCl 483 g

CaCl ·2H O 1.54g/L

2 2 NaHCO 140 g

KCl 0.69g/L

KBr 70 g

NaHCO 0.20g/L

H BO 21 g

3 3

KBr 0.10g/L

NaF 2.1 g

H BO 0.03g/L

3 3

Dissolve and dilute to 7 L

SrCl ·6H O 0.04g/L

2 2

NaF 0.04g/L

7.3.2 To prepare the synthetic sea water, dissolve 245.4 g of

NaCl and 40.94 g of Na SO in a few litres of distilled water,

7.3.1 The solution can be conveniently prepared as follows.

2 4

add 200 mL of Stock Solution No. 1 and 100 mL of Stock

This procedure avoids any precipitation in concentrated solu-

Solution No. 2 and dilute to 10 L, stir and add 0.1 N Na CO

tions with subsequent uncertainty of complete resolution.

2 3

Using certified pure (cp) chemicals and distilled water, prepare solution until the pH is between 7.8 and 8.2. One or two

the following stock solutions: millilitres of the carbonate solution will be required.

D665 − 14

FIG. 3 Test Rod and Holders

D665 − 14

FIG. 4 Chuck for Polishing Test Rods

7.4 Precipitation Naphtha, as specified inTest Method D91. provided they are found to be satisfactory by comparative test

(Warning—Flammable. Health hazard.) using this Test Method D665 – IP 135.

7.5 Isooctane, as specified in Motor Fuels, Section I,Annex

NOTE 9—When making a check test, the steel test rod that showed rust

A2, Table 32, Reference Materials and Blending Accessories.

shouldnotbereused.Testrodsthatrepeatedlyshowrustintestsofvarious

oils can be imperfect. Such test rods should be used with oils known to

(Warning—Flammable. Health hazard.)

pass the test. If rusting occurs in repeat tests, these test rods should be

7.6 IP 60/80 Petroleum Spirit, as specified by IP Standard

discarded.

Reference Liquids, Appendix B. (Warning—Flammable.

9.3 Preliminary Grinding—If the test rod has been used

Health hazard.)

previously and is free of rust or other irregularities, the

7.7 Steel Test Rod, as specified in Section 9.

preliminary grinding may be omitted, and it may be subjected

onlytofinalpolishingasprescribedin9.4.Ifthetestrodisnew

8. Sampling

or if any part of its surface shows rust or other irregularities,

8.1 Sample for this test can come from tanks, drums, small

clean it with ASTM precipitation naphtha or isooctane or IP

containers, or even operating equipment, and they should be

60/80 petroleum spirit and grind with medium 150 grit

truly representative of the entire quantity. Therefore, use the

aluminum oxide cloth to remove all irregularities, pits, and

applicable apparatus and techniques described in Practice

scratches, as determined by visual inspection (Note 10).

D4057, or other comparable standard practice.

Perform the grindings by mounting the test rod in the chuck of

the grinding and polishing apparatus, and turning it at a speed

9. Test Rod and Its Preparation

of 1700 r⁄min to 1800 r/min while applying the 150 grit

9.1 For each test oil, prepare two steel test rods. These may

aluminum oxide cloth. Old 150 grit aluminum oxide cloth may

either be new or from a previous test (see Note 9) and shall be

be used to remove rust or major irregularities, but complete the

prepared in accordance with 9.2 and 9.3.

grinding with new cloth. Proceed at once with the final

polishing with 240 grit aluminum oxide cloth, or remove the

9.2 The test rod assembly shall consist of a round steel test

test rod from the chuck and store

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D665 − 12 D665 − 14

Designation: 135/06

Standard Test Method for

Rust-Preventing Characteristics of Inhibited Mineral Oil in

the Presence of Water

This standard is issued under the fixed designation D665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the evaluation of the ability of inhibited mineral oils, particularly steam-turbine oils, to aid in

preventing the rusting of ferrous parts should water become mixed with the oil. This test method is also used for testing other oils,

such as hydraulic oils and circulating oils. Provision is made in the procedure for testing heavier-than-water fluids.

NOTE 1—For synthetic fluids, such as phosphate ester types, the plastic holder and beaker cover should be made of a chemically resistant material,

such as polytetrafluoroethylene (PTFE).chemically resistant material suitable for the type of fluid tested.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 6.47.4 – 6.67.6.

2. Referenced Documents

2.1 ASTM Standards:

A108 Specification for Steel Bar, Carbon and Alloy, Cold-Finished

A240/A240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and

for General Applications

D91 Test Method for Precipitation Number of Lubricating Oils

D1193 Specification for Reagent Water

D2422 Classification of Industrial Fluid Lubricants by Viscosity System

D3603 Test Method for Rust-Preventing Characteristics of Steam Turbine Oil in the Presence of Water (Horizontal Disk Method)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

2.2 Other Documents:

Motor Fuels, Section I, Annex A2, Table 32, Reference Materials and Blending Accessories

Specifications-IP Standard Thermometers, Vol 2, Appendix A

Specifications for IP Standard Reference Liquids, Appendix B

SAE Standard J405 Chemical Composition of SAE Wrought Stainless Steels

BS 871 Specification for abrasive papers and cloths

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.C0.02 on Corrosion and Water/Air Separability.

Current edition approved Nov. 1, 2012Oct. 1, 2014. Published March 2013November 2014. Originally approved in 1942. Last previous edition approved in 20062012 as

D665D665 – 12.-06. DOI: 10.1520/D0665-12.10.1520/D0665-14.

This standard has been developed through the cooperative effort between ASTM International and the Energy Institute, London. The EI and ASTM International logos

imply that the ASTM International and EI standards are technically equivalent, but does not imply that both standards are editorially identical.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

See 1996 Annual Book of ASTM Standards, Vol 05.04.

Annual Book of IP Standard Methods for Analysis and Testing of Petroleum and Related Products, Vol 2. Available from Energy Institute, 61 New Cavendish St., London,

WIG 7AR, U.K.

1995 SAE Handbook, Vol 1. Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D665 − 14

BS 970 Part 1: Carbon and Carbon Manganese Steels Including Free Cutting Steels

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 rust, n—a special case of corrosion that can be visually observed on the surface of round steel test rods as reddish-brown

discoloration or small black spots.

4. Summary of Test Method

4.1 A mixture of 300 mL of the oil under test is stirred with 30 mL of distilled water or synthetic sea water, as required, at a

temperature of 60 °C 6 1°C1 °C with a cylindrical steel test rod completely immersed therein. It is recommended to run the test

for 4 h; however, the test period may, at the discretion of the contracting parties, be for a shorter or longer period. The test rod

is observed for signs of rusting and, if desired, degree of rusting.

NOTE 2—Until 1999 it was customary to run the test for 24 h. A round robin with comparisons of different test times showed that no statistically

significant differences in rating were found for any sample, between the 44 h and 24 h results.

5. Significance and Use

5.1 In many instances, such as in the gears of a steam turbine, water can become mixed with the lubricant, and rusting of ferrous

parts can occur. This test indicates how well inhibited mineral oils aid in preventing this type of rusting. This test method is also

used for testing hydraulic and circulating oils, including heavier-than-water fluids. It is used for specification of new oils and

monitoring of in-service oils.

NOTE 3—This test method was used as a basis for Test Method D3603. Test Method D3603 is used to test the oil on separate horizontal and vertical

test rod surfaces, and can provide a more discriminating evaluation.

6. Apparatus

6.1 Oil Bath—A thermostatically controlled liquid bath capable of maintaining the test sample at a temperature of 6060 °C 6

1°C1 °C (see Note 4). An oil having a viscosity of approximately ISO VG 32 (see Classification D2422) is suitable for the bath.

The bath shall have a cover with holes to accommodate the test beakers.

NOTE 4—ASTM Thermometer 9C, as prescribed in Specification E1, or IP Thermometer 21C in accordance with IP Standard Thermometers, Volume

2, Appendix A, is suitable to indicate the temperature. Alternatively, calibrated thermocouples may be used.

6.2 Beaker—A 400-mL, Berzelius-type, tall-form heat-resistant glass beaker without pourout,pour-out, as shown in Fig. 1,

approximately 127 mm in height measured from the inside bottom center and approximately 70 mm) in mm inside diameter

measured at the middle.

6.3 Beaker Cover—A flat beaker cover of glass or poly (methyl methacrylate) (PMMA) (Note 5), kept in position by suitable

means such as a rim or groove. Two holes shall be provided on any diameter of the cover; one for a stirrer 12 mm in diameter

with its center 6.4 mm from the center of the cover; and the other, on the opposite side of the center of the cover, for the test rod

assembly (see Section 89), 18 mm in diameter with its center 16 mm from the center of the cover. In addition, a third hole 12 mm

in diameter shall be provided for a temperature measuring device, with its center 22.5 mm from the center of the cover and on a

diameter of the cover at right angles to the diameter through the other two holes.

NOTE 5—An inverted petri dish makes a suitable cover, as the sides of the dish aid in keeping it in position. Fig. 2 shows a PMMA resin cover for

the beaker which has been found to be suitable. An optional feature is shown, consisting of a slot, 1.6 mm by 27 mm, which is centered on a diameter

of the stirrer hole at right angles to the cover diameter through the test rod hole and stirrer hole. This feature allows withdrawal of the stirrer while the

beaker cover is in place. When the test method test is used for other fluids such as synthetics, the beaker cover should be made from chemically resistant

material such as polymonochlorotrifluoroethylene (PCTFE).

6.4 The plastic holder shall be made of PMMA resin in accordance with the dimensions shown in Fig. 3 (two types of holders

are illustrated). When testing synthetic fluids, the plastic holder should be made from chemically resistant material such as

polytetrafluoroethylene (PTFE).

6.5 Stirrer—A stirrer constructed entirely from stainless steel (Note 6 and Note 7) in the form of an inverted T. A flat blade 25(25

by 6 6) mm by 0.6 mm shall be attached to a 6-mm rod rod with a diameter of 6 mm in such a way that the blade is symmetrical

with the rod and has its flat surface in the vertical plane.

NOTE 6—A suitable material is an 18 % chromium, 8 % nickel alloy steel conforming to Type 304, of Specification A240/A240M, or SAE No. 30304

(see SAE J405), or BS 970: Part 1: 1983: 302S31.

NOTE 7—If stainless steel is not obtainable, stirrers made of heat-resistant glass and having approximately the same dimensions as the stainless steel

stirrers specified can be used.

Supporting data (results of the cooperative test program with modified test duration) have been filed at ASTM International Headquarters and may be obtained by

requesting Research Report RR:D02-1474.

D665 − 14

FIG. 1 Rusting Test Apparatus

6.6 Stirring Apparatus—Any convenient form of stirring apparatus capable of maintaining a speed of 1000 r/min 6 50

50 r rpm.⁄min.

6.7 Grinding and Polishing Equipment —Equipment—A CAMI 150-grit (99-μm) 150 grit (99 μm) and a CAMI 240-grit

(53.5-μm) 240 grit (53.5 μm) in accordance with BS 871 or its equivalent, metalworking aluminum oxide abrasive cloth coat on

a jeans backing (the corresponding European grades (FEPA) are P150J and P280J, respectively), a suitable chuck (see Fig. 4) for

holding the test rod, and a means of rotating the test rod at a speed of 1700 r/min to 1800 rpm.r/min.

NOTE 8—CAMI (Coated Abrasives Manufacturers Institute) is a United States organization and FEPA (Federation of European Producers of Abrasives)

is a European organization.

D665 − 14

FIG. 2 Beaker Cover

6.8 Oven, capable of maintaining a temperature of 65°C.65 °C.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such

specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity

to permit its use without lessening the accuracy of the determination.

7.2 Purity of Water— Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type II of Specification D1193.

Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D665 − 14

FIG. 3 Test Rod and Holders

D665 − 14

FIG. 4 Chuck for Polishing Test Rods

7.3 The synthetic sea water shall have the following composition:

Salt g/L

Salt

NaCl 24.54 g/L

MgCl ·6H O 11.10 g/L

2 2

Na SO 4.09 g/L

2 4

CaCl 1.16

CaCl ·2H O 1.54 g/L

2 2

KCl 0.69 g/L

NaHCO 0.20 g/L

KBr 0.10 g/L

H BO 0.03 g/L

3 3

SrCl ·6H O 0.04 g/L

2 2

NaF 0.003

NaF 0.04 g/L

7.3.1 The solution can be conveniently prepared as follows. This procedure avoids any precipitation in concentrated solutions

with subsequent uncertainty of complete resolution. Using certified pure (cp) chemicals and distilled water, prepare the following

stock solutions:

Stock Solution No. 1:

MgCl ·6H O 3885 g

2 2

CaCl (anhydrous) 406 g

CaCl ·2H O 538 g

2 2

SrCl ·6H O 14 g

2 2

Dissolve and dilute to 7 L

Stock Solution No. 2:

KCl 483 g

NaHCO 140 g

KBr 70 g

H BO 21 g

3 3

NaF 2.1 g

Dissolve and dilute to 7 L

7.3.2 To prepare the synthetic sea water, dissolve 245.4 g of NaCl and 40.94 g of Na SO in a few litres of distilled water, add

2 4

200 mL of Stock Solution No. 1 and 100 mL of Stock Solution No. 2 and dilute to 10 L. Stir the 10-L batch L, stir and add 0.1

N Na CO solution until the pH is between 7.8 and 8.2. One or two millilitres of the carbonate solution will be required.

2 3

D665 − 14

7.4 Precipitation Naphtha, as specified in Test Method D91. (Warning—Flammable. Health hazard.)

7.5 Isooctane, as specified in Motor Fuels, Section I, Annex A2, Table 32, Reference Materials and Blending Accessories.

(Warning—Flammable. Health hazard.)

7.6 IP 60/80 Petroleum Spirit, as specified by IP Standard Reference Liquids, Appendix B. (Warning—Flammable. Health

hazard.)

7.7 Steel Test Rod, as specified in Section 89.

8. Sampling

8.1 Sample for this test can come from tanks, drums, small containers, or even operating equipment, and they should be truly

representative of the entire quantity. Therefore, use the applicable apparatus and techniques described in Practice D4057, or other

comparable standard practice.

9. Test Rod and Its Preparation

9.1 For each test oil, prepare two steel test rods. These may either be new or from a previous test (see Note 9) and shall be

prepared in accordance with 8.29.2 and 8.39.3.

9.2 The test rod assembly shall consist of a round steel test rod fitted to a plastic holder. The round steel test rod, when new,

shall be 12.7 mm in diameter and approximately 68 mm in length exclusive of the threaded portion which screws into the plastic

holder and shall be tapered at one end as shown in Fig. 3. It shall be made of steel conforming to Grade 10180 of Specification

A108 or to BS 970 Part I: 1983-070M20. If these steels are not available, other equivalent steels may be used, provided they are

found to be satisfactory by comparative test using this Test Method D665 – IP 135.

NOTE 9—When making a check test, the steel test rod that showed rus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.