ASTM D5291-02(2007)

(Test Method)Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants

Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants

SIGNIFICANCE AND USE

This is the first ASTM standard covering the simultaneous determination of carbon, hydrogen, and nitrogen in petroleum products and lubricants.

Carbon, hydrogen, and particularly nitrogen analyses are useful in determining the complex nature of sample types covered by this test method. The CHN results can be used to estimate the processing and refining potentials and yields in the petrochemical industry.

The concentration of nitrogen is a measure of the presence of nitrogen containing additives. Knowledge of its concentration can be used to predict performance. Some petroleum products also contain naturally occurring nitrogen. Knowledge of hydrogen content in samples is helpful in addressing their performance characteristics. Hydrogen to carbon ratio is useful to assess the performance of upgrading processes.

SCOPE

1.1 These test methods cover the instrumental determination of carbon, hydrogen, and nitrogen in laboratory samples of petroleum products and lubricants. Values obtained represent the total carbon, the total hydrogen, and the total nitrogen.

1.2 These test methods are applicable to samples such as crude oils, fuel oils, additives, and residues for carbon and hydrogen and nitrogen analysis. These test methods were tested in the concentration range of at least 75 to 87 mass % for carbon, at least 9 to 16 mass % for hydrogen, and 0.1 to 2 mass % for nitrogen.

1.3 The nitrogen test method is not applicable to light materials or those containing 0.75 mass % nitrogen, or both, such as gasoline, jet fuel, naphtha, diesel fuel, or chemical solvents.

1.4 These test methods are not recommended for the analysis of volatile materials such as gasoline, gasoline-oxygenate blends, or gasoline type aviation turbine fuels.

1.5 The results of these tests can be expressed as mass % carbon, hydrogen or nitrogen.

1.6 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D5291–02 (Reapproved 2007)

Standard Test Methods for

Instrumental Determination of Carbon, Hydrogen, and

Nitrogen in Petroleum Products and Lubricants

This standard is issued under the fixed designation D5291; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 Thesetestmethodscovertheinstrumentaldetermination

D4177 Practice for Automatic Sampling of Petroleum and

of carbon, hydrogen, and nitrogen in laboratory samples of

Petroleum Products

petroleum products and lubricants. Values obtained represent

D6299 Practice for Applying Statistical Quality Assurance

the total carbon, the total hydrogen, and the total nitrogen.

and Control Charting Techniques to Evaluate Analytical

1.2 These test methods are applicable to samples such as

Measurement System Performance

crude oils, fuel oils, additives, and residues for carbon and

hydrogen and nitrogen analysis. These test methods were

3. Summary of Test Methods

testedintheconcentrationrangeofatleast75to87mass%for

3.1 In these test methods, carbon, hydrogen, and nitrogen

carbon, at least 9 to 16 mass % for hydrogen, and <0.1 to 2

aredeterminedconcurrentlyinasingleinstrumentalprocedure.

mass % for nitrogen.

With some systems, the procedure consists of simply weighing

1.3 The nitrogen test method is not applicable to light

a portion of the sample, placing the portion in the instrument,

materials or those containing <0.75 mass % nitrogen, or both,

and initiating the (subsequently automatic) analytical process.

such as gasoline, jet fuel, naphtha, diesel fuel, or chemical

In other systems, the analytical process, to some degree, is

solvents.

manually controlled.

1.4 These test methods are not recommended for the analy-

3.2 The actual process can vary substantially from instru-

sis of volatile materials such as gasoline, gasoline-oxygenate

ment to instrument, since a variety of means can be utilized to

blends, or gasoline type aviation turbine fuels.

effect the primary requirements of the test methods. All

1.5 The results of these tests can be expressed as mass %

satisfactory processes provide for the following:

carbon, hydrogen or nitrogen.

3.2.1 The conversion of the subject materials (in their

1.6 The values stated in SI units are to be regarded as the

entirety) to carbon dioxide, water vapor, and elemental nitro-

standard.

gen, respectively, and

1.7 This standard does not purport to address all of the

3.2.2 The subsequent, quantitative determination of these

safety concerns, if any, associated with its use. It is the

gases in an appropriate gas stream.

responsibility of the user of this standard to establish appro-

3.3 The conversion of the subject materials to their corre-

priate safety and health practices and determine the applica-

sponding gases takes place largely during combustion of the

bility of regulatory limitations prior to use.

sample at an elevated temperature in an atmosphere of purified

2. Referenced Documents oxygen. Here, a variety of gaseous materials are produced,

2 including the following:

2.1 ASTM Standards:

3.3.1 Carbon dioxide from the oxidation of organic and

elemental carbon,

These test methods are under the jurisdiction of ASTM Committee D02 on

3.3.2 Hydrogen halides from organic halides (and organic

Petroleum Products and Lubricants and are the direct responsibility of Subcommit-

hydrogen, as required),

tee D02.03 on Elemental Analysis.

3.3.3 Water vapor from the oxidation of (the remaining)

CurrenteditionapprovedMay1,2007.PublishedJuly2007.Originallyapproved

in 1992. Last previous edition approved in 2002 as D5291–02. DOI: 10.1520/

organic hydrogen and the liberation of moisture,

D5291-02R07.

3.3.4 Nitrogen and nitrogen oxides from the oxidation of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

organic nitrogen, and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5291–02 (2007)

3.3.5 Sulfur oxides from the oxidation of organic sulfur. In 4.2 Carbon, hydrogen, and particularly nitrogen analyses

somesystems,sulfurousandsulfuricacidscanalsobeobtained are useful in determining the complex nature of sample types

from a combination of the sulfur oxides and the water vapor. covered by this test method. The CHN results can be used to

3.4 There are several accepted ways of isolating the desired estimatetheprocessingandrefiningpotentialsandyieldsinthe

gaseous products and quantitatively determining them. These petrochemical industry.

are as follows: 4.3 The concentration of nitrogen is a measure of the

3,4

3.4.1 Test Method A —From the combustion product gas presence of nitrogen containing additives. Knowledge of its

stream, oxides of sulfur are removed with calcium oxide in the concentration can be used to predict performance. Some

secondary combustion zone.Aportion of the remaining mixed petroleum products also contain naturally occurring nitrogen.

gasesiscarriedbyheliumgasoverahotcoppertraintoremove Knowledge of hydrogen content in samples is helpful in

oxygen, and reduce NO to N , over NaOH to remove CO , addressing their performance characteristics. Hydrogen to

x 2 2

and over magnesium perchlorate to remove H O. The remain- carbon ratio is useful to assess the performance of upgrading

ingelementalnitrogenismeasuredbythethermalconductivity processes.

cell.Simultaneously,butseparatelyfromthenitrogenmeasure-

ment, the carbon and hydrogen selective infrared cells measure 5. Apparatus

the CO and H O levels.

2 2 5.1 Sinceavarietyofinstrumentalcomponentsandconfigu-

4,5

3.4.2 Test Method B — From the combustion product gas

rations can be satisfactorily utilized for these test methods, no

stream (which is cleaned from sulfur oxides, excess oxygen,

specifications are given here with respect to overall system

etc. as in 3.4.1), the remaining CO , water vapor, and N are

2 2

design.

flushed into a mixing chamber and are thoroughly homog-

5.2 Functionally,however,thefollowingarespecifiedforall

enized at a precise volume, temperature, and pressure. After

instruments:

homogenization, the chamber is depressurized to allow the

5.2.1 The conditions for combustion of the sample must be

gases to pass through a heated column, where the gases

such that (for the full range of applicable samples) the subject

separate as a function of selective retention times. The sepa-

components are completely converted to carbon dioxide, water

ration occurs in a stepwise steady-state manner for nitrogen,

vapor(exceptforhydrogenassociatedwithvolatilehalidesand

carbon dioxide, and water.

sulfur oxides), and nitrogen or nitrogen oxides. Generally,

,

4 6

3.4.3 Test Method C —The combustion product gas

instrumental conditions that affect complete combustion in-

stream, after full oxidation of component gases, is passed over

clude availability of the oxidant, temperature, and time.

heated copper to remove excess oxygen and reduce NO to N

x 2 5.2.2 Representative aliquots of the combustion gases must

gas. The gases are then passed through a heated chromato-

then be treated:

graphic column to separate and elute N ,CO , and H O in that

2 2 2 5.2.2.1 To liberate (as water vapor) hydrogen present as

order. The individual eluted gases are measured by a thermal

hydrogen halides and sulfur oxyacids, and

conductivity detector.

5.2.2.2 To reduce (to the element) nitrogen present as

3.5 In all cases, the concentrations of carbon, hydrogen and

nitrogen oxides.

nitrogen are calculated as functions of the following:

5.2.3 The water vapor and nitrogen so obtained must be

3.5.1 The measured instrumental responses,

included with the materials originally present in these aliquots.

3.5.2 The values for response per unit mass for the elements

5.2.4 Additional treatment of the aliquots (prior to detec-

(established via instrument calibration), and

tion) depends on the detection scheme utilized for the instru-

3.5.3 The mass of the sample.

ment (see Note 1).

3.6 A capability for performing these computations auto-

NOTE 1—These additional treatments can be provided by the instru-

matically can be included in the instrumentation utilized for

mental components utilized to satisfy 5.2.2.

these test methods.

5.2.5 The detection system (in its full scope) must deter-

4. Significance and Use minetheanalyticalgasesindividuallyandwithoutinterference.

Additionally, for each analyte, either:

4.1 This is the first ASTM standard covering the simulta-

5.2.5.1 The detectors must provide linear responses with

neous determination of carbon, hydrogen, and nitrogen in

respect to concentration over the full range of possible con-

petroleum products and lubricants.

centrations from the applicable samples, or

5.2.5.2 The system must include provisions for appropri-

ately evaluating nonlinear responses so that they can be

The sole source of supply of the Leco CHN-600 instrument known to the

accurately correlated with these concentrations.

committee at this time is Leco Corporation, 3000 Lakeview Ave., St. Joseph, MI

49085.

5.2.6 Suchprovisionscanbeintegraltotheinstrumentation,

If you are aware of alternative suppliers, please provide this information to

or they can be provided by (auxiliary) computation schemes.

ASTM International Headquarters. Your comments will receive careful consider-

5.2.7 Lastly, except for those systems where the concentra-

ation at a meeting of the responsible technical committee , which you may attend.

tion data are output directly, the instrument must include an

The sole source of supply of the Perkin Elmer 240C, 2400 series and CEC

240XA and 440 instruments known to the committee at this time is Perkin Elmer

appropriate readout device for the detector responses.

Corporation, Main Ave., Norwalk, CT 06856.

5.3 Additionally consumables needed for the analyses in-

The sole source of supply of the Carlo Erba 1106, 1108, and 1500 instruments

clude:

knowntothecommitteeatthistimeisCarloErbaStrumentazione,StradaRivoltana,

20090 Rodano, Milan, Italy. 5.3.1 Tin Capsules, large and small,

D5291–02 (2007)

A,B

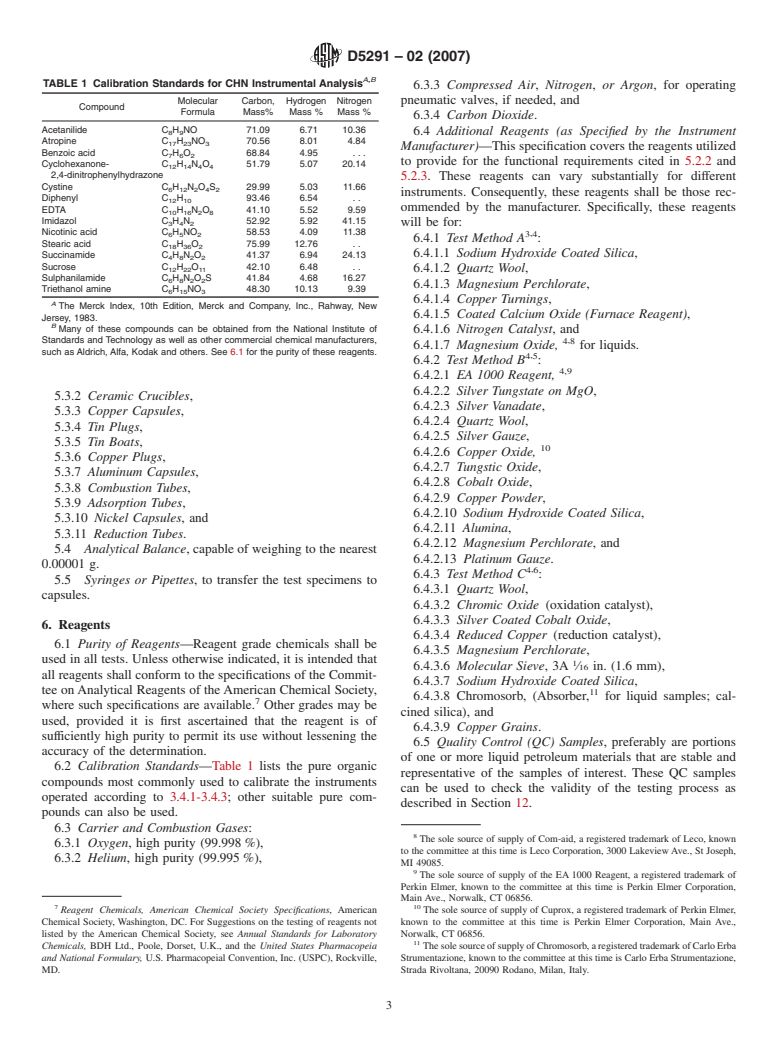

TABLE 1 Calibration Standards for CHN Instrumental Analysis

6.3.3 Compressed Air, Nitrogen, or Argon, for operating

Molecular Carbon, Hydrogen Nitrogen pneumatic valves, if needed, and

Compound

Formula Mass% Mass % Mass %

6.3.4 Carbon Dioxide.

Acetanilide C H NO 71.09 6.71 10.36

8 9 6.4 Additional Reagents (as Specified by the Instrument

Atropine C H NO 70.56 8.01 4.84

17 23 3

Manufacturer)—This specification covers the reagents utilized

Benzoic acid C H O 68.84 4.95 . . .

7 6 2

to provide for the functional requirements cited in 5.2.2 and

Cyclohexanone- C H N O 51.79 5.07 20.14

12 14 4 4

2,4-dinitrophenylhydrazone

5.2.3. These reagents can vary substantially for different

Cystine C H N O S 29.99 5.03 11.66

6 12 2 4 2

instruments. Consequently, these reagents shall be those rec-

Diphenyl C H 93.46 6.54 . .

12 10

ommended by the manufacturer. Specifically, these reagents

EDTA C H N O 41.10 5.52 9.59

10 16 2 8

Imidazol C H N 52.92 5.92 41.15

3 4 2

will be for:

Nicotinic acid C H NO 58.53 4.09 11.38

3,4

6 5 2

6.4.1 Test Method A :

Stearic acid C H O 75.99 12.76 . .

18 36 2

6.4.1.1 Sodium Hydroxide Coated Silica,

Succinamide C H N O 41.37 6.94 24.13

4 8 2 2

Sucrose C H O 42.10 6.48 . .

12 22 11 6.4.1.2 Quartz Wool,

Sulphanilamide C H N O S 41.84 4.68 16.27

6 8 2 2

6.4.1.3 Magnesium Perchlorate,

Triethanol amine C H NO 48.30 10.13 9.39

6 15 3

6.4.1.4 Copper Turnings,

A

The Merck Index, 10th Edition, Merck and Company, Inc., Rahway, New

6.4.1.5 Coated Calcium Oxide (Furnace Reagent),

Jersey, 1983.

B

Many of these compounds can be obtained from the National Institute of

6.4.1.6 Nitrogen Catalyst, and

Standards and Technology as well as other commercial chemical manufacturers, ,

4 8

6.4.1.7 Magnesium Oxide, for liquids.

such as Aldrich, Alfa, Kodak and others. See 6.1 for the purity of these reagents.

4,5

6.4.2 Test Method B :

,

4 9

6.4.2.1 EA 1000 Reagent,

6.4.2.2 Silver Tungstate on MgO,

5.3.2 Ceramic Crucibles,

6.4.2.3 Silver Vanadate,

5.3.3 Copper Capsules,

6.4.2.4 Quartz Wool,

5.3.4 Tin Plugs,

6.4.2.5 Silver Gauze,

5.3.5 Tin Boats,

6.4.2.6 Copper Oxide,

5.3.6 Copper Plugs,

6.4.2.7 Tungstic Oxide,

5.3.7 Aluminum Capsules,

6.4.2.8 Cobalt Oxide,

5.3.8 Combustion Tubes,

6.4.2.9 Copper Powder,

5.3.9 Adsorption Tubes,

6.4.2.10 Sodium Hydroxide Coated Silica,

5.3.10 Nickel Capsules, and

6.4.2.11 Alumina,

5.3.11 Reduction Tubes.

6.4.2.12 Magnesium Perchlorate, and

5.4 Analytical Balance, capable of weighing to the nearest

6.4.2.13 Platinum Gauze.

0.00001 g.

,

4 6

6.4.3 Test Method C :

5.5 Syringes or Pipettes, to transfer the test specimens to

6.4.3.1 Quartz Wool,

capsules.

6.4.3.2 Chromic Oxide (oxidation catalyst),

6.4.3.3 Silver Coated Cobalt Oxide,

6. Reagents

6.4.3.4 Reduced Copper (reduction catalyst),

6.1 Purity of Reagents—Reagent grade chemicals shall be

6.4.3.5 Magnesium Perchlorate,

used in all tests. Unless otherwise indicated, it is intended that

6.4.3.6 Molecular Sieve,3A ⁄16 in. (1.6 mm),

all reagents shall conform to the specifications of the Commit-

6.4.3.7 Sodium Hydroxide Coated Silica,

tee onAnalytical Reagents of theAmerican Chemical Society,

6.4.3.8 Chromosorb, (Absorber, for liquid samples; cal-

where such specifications are available. Other grades may be

cined silica), and

used, provided it is first ascertained that the reagent is of

6.4.3.9 Copper Grains.

sufficiently high purity to permit its use without lessening the

6.5 Quality Control (QC) Samples, preferably are portions

accuracy of the determination.

of one or more liquid petroleum materials that are stable and

6.2 Calibration Standards—Table 1 lists the pure organic

representative of the samples of interest. These QC samples

compounds most commonly used to calibrate the instruments

can be used to check the validity of the testing process as

operated according to 3.4.1-3.4.3; other suitable pure com-

described in Section 12.

pounds can also be used.

6.3 Carrier and Combustion Gases:

The sole source of supply of Com-aid, a registered trademark of Leco, known

6.3.1 Oxygen, high purity (99.998 %),

to the committee at this time is Leco Corporation, 3000 Lakeview Ave., St Joseph,

6.3.2 Helium,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.