ASTM D3888-07

(Terminology)Standard Terminology for Yarn Spinning Systems

Standard Terminology for Yarn Spinning Systems

SIGNIFICANCE AND USE

p>Terminology D 3888 was originally developed as a terminology standard for rotor spinning when it evolved as a new yarn spinning technology in the 1980’s. Ring spinning production had been the traditional spinning since the early 1800's when hand spinning became mechanized. Rotor spinning and other spinning technologies increased yarn production rates and formed yarns by different mechanical means that generated yarns with characteristics unlike traditional ring-spun yarns. The revision of this document is intended to compile terminology for current yarn spinning systems into one standard rather than individual standards, in that all yarn formation is generated by processing raw fiber into a spun yarn by using common preparation steps, such as opening, cleaning, carding, roving formation, and sometimes combing. Terminology in this standard is grouped by the type of spinning system and in chronological order of their development and production usage. It should be noted that the higher end of yarn number ranges cited with each spinning system are possible but are rare in actual production.

SCOPE

1.1 This terminology covers terms related to ring, rotor, and air jet yarn spinning systems.

1.1.1 This standard formerly only included terminology related to open-end spinning. It has been expanded to include terms relating to ring and air jet spinning systems.

1.1.2 While the term rotor spinning is technically correct, the terms rotor and open-end are used interchangeably in the textile industry.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3888–07

Standard Terminology for

1

Yarn Spinning Systems

This standard is issued under the fixed designation D3888; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope compile terminology for current yarn spinning systems into

one standard rather than individual standards, in that all yarn

1.1 This terminology covers terms related to ring, rotor, and

formation is generated by processing raw fiber into a spun yarn

air jet yarn spinning systems.

by using common preparation steps, such as opening, cleaning,

1.1.1 This standard formerly only included terminology

carding, roving formation, and sometimes combing. Terminol-

related to open-end spinning. It has been expanded to include

ogy in this standard is grouped by the type of spinning system

terms relating to ring and air jet spinning systems.

andinchronologicalorderoftheirdevelopmentandproduction

1.1.2 While the term rotor spinning is technically correct,

usage. It should be noted that the higher end of yarn number

the terms rotor and open-end are used interchangeably in the

rangescitedwitheachspinningsystemarepossiblebutarerare

textile industry.

in actual production.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Terminology

responsibility of the user of this standard to establish appro-

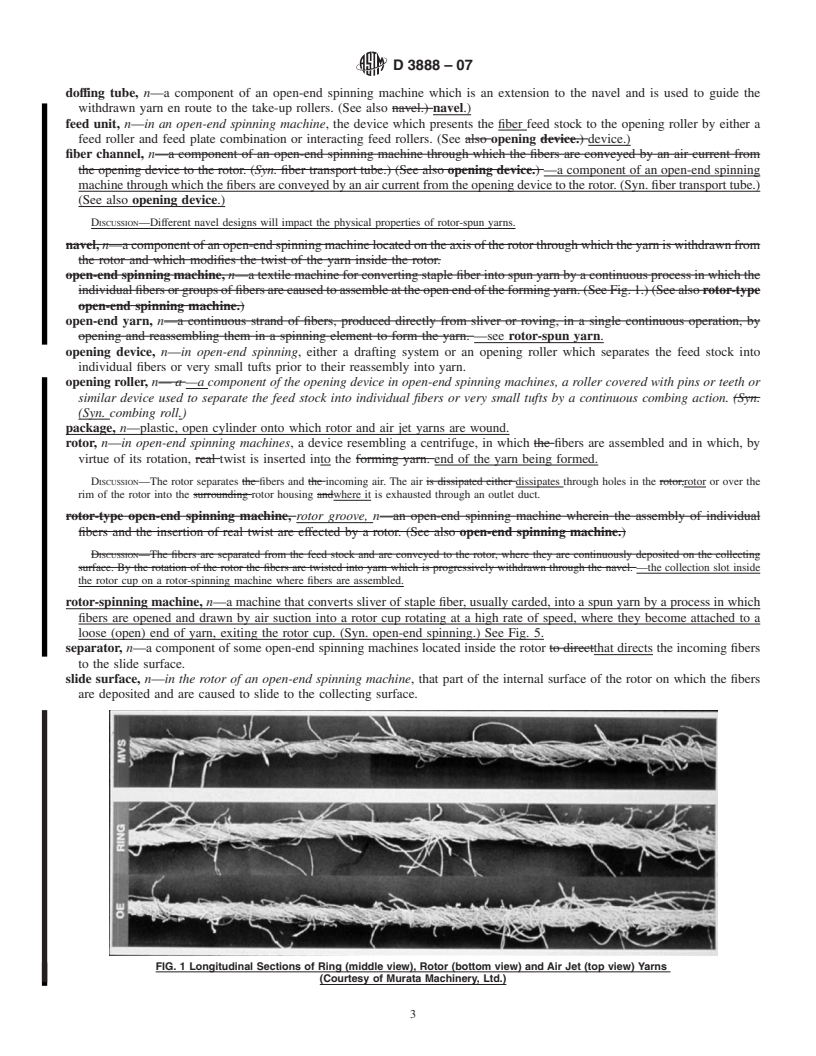

4.1 Ring Spinning—Ring spinning is the oldest spinning

priate safety and health practices and determine the applica-

system in use, therefore ring-spun yarns are the basis for

bility of regulatory limitations prior to use.

comparing yarns produced from other spinning systems. Pro-

2. Referenced Documents duction rates are low when compared to new spinning systems.

2

The production delivery capability of ring spinning is limited

2.1 ASTM Standards:

by traveler velocity and the twist limits of the yarn number

D123 Terminology Relating to Textiles

being made; the speed may range between 10 and 20 m/min.

D861 Practice for Use of the Tex System to Designate

Ring spinning allows for the production of the widest range of

Linear Density of Fibers, Yarn Intermediates, and Yarns

yarn numbers from 200 to 2 tex (Ne 3/1 to 300/1). Ring-spun

c

D1244 Practice for Designation of Yarn Construction

yarnsareproducedbydraftingrovingsbetweenpairsofrollers,

D2260 Tables of Conversion Factors and Equivalent Yarn

twisting the drafted roving by passing it under a traveler that

Numbers Measured in Various Numbering Systems

rotates around a fixed ring on the frame of the spinning

3. Significance and Use

machine, and winding the twisted strand on a removable

bobbin mounted on a rotating spindle. Ring spun yarns are

3.1 Terminology D3888 was originally developed as a

characterized by a uniform fiber orientation around the yarn

terminology standard for rotor spinning when it evolved as a

axis. See Fig. 1.

new yarn spinning technology in the 1980’s. Ring spinning

production had been the traditional spinning since the early

bobbin, n—a slightly tapered plastic cylinder, mounted on a

1800’s when hand spinning became mechanized. Rotor spin-

spindle of a ring spinning frame on which yarn produced

ningandotherspinningtechnologiesincreasedyarnproduction

from drafting and twisting is wound.

rates and formed yarns by different mechanical means that

DISCUSSION—Yarn from several ring frame bobbins is wound onto a

generated yarns with characteristics unlike traditional ring-

cone or cheese to create a larger package from which it can be easily

spun yarns. The revision of this document is intended to

unwound for use in weaving, knitting, or other processes.

carding, v—a mechanical preparation, utilized by staple fiber

1

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles

spinning systems, that cleans, straightens, and aligns fibers

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

using wire-covered rolls (or cylinders) that converts fibers

Current edition approved Dec. 1, 2007. Published January 2008. Originally

approved in 1980. Last previous edition approved in 2001 as D3888 – 95 (2001).

into a sliver.

DOI: 10.1520/D3888-07.

carded yarn, n—an organized, continuous strand of staple

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fibers produced by carding, drawing, roving formation, and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

spinning. (Compare with combed yarn.)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3888–95 (Reapproved 2001)

Standard Terminology Relating to Open-End

SpinningDesignation:D3888–07

Standard Terminology for

1

Yarn Spinning Systems

This standard is issued under the fixed designation D 3888; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This terminology covers those parts of a spinning machine which are specific to open-end yarn production.

1.1 This terminology covers terms related to ring, rotor, and air jet yarn spinning systems.

1.1.1 This standard formerly only included terminology related to open-end spinning. It has been expanded to include terms

relating to ring and air jet spinning systems.

1.1.2 While the term rotor spinning is technically correct, the terms rotor and open-end are used interchangeably in the textile

industry.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D123Terminology Relating to Textiles

2.2 Other Standards:

ISO2205 Terminology of Drafting Arrangements

ISO447Terminology Relative to Cone and Cheese Winders 123 Terminology Relating to Textiles

D 861 Practice for Use of the Tex System to Designate Linear Density of Fibers, Yarn Intermediates, and Yarns

D 1244 Practice for Designation of Yarn Construction

D 2260 Tables of Conversion Factors and Equivalent Yarn Numbers Measured in Various Numbering Systems

3. Significance and Use

3.1 Terminology D 3888 was originally developed as a terminology standard for rotor spinning when it evolved as a new yarn

spinning technology in the 1980’s. Ring spinning production had been the traditional spinning since the early 1800’s when hand

spinning became mechanized. Rotor spinning and other spinning technologies increased yarn production rates and formed yarns

by different mechanical means that generated yarns with characteristics unlike traditional ring-spun yarns. The revision of this

document is intended to compile terminology for current yarn spinning systems into one standard rather than individual standards,

in that all yarn formation is generated by processing raw fiber into a spun yarn by using common preparation steps, such as

opening, cleaning, carding, roving formation, and sometimes combing. Terminology in this standard is grouped by the type of

spinning system and in chronological order of their development and production usage. It should be noted that the higher end of

yarn number ranges cited with each spinning system are possible but are rare in actual production.

4. Terminology

3.1Definitions:

1

This terminology is under the jurisdiction ofASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.58 onYarn Test Methods, General.

Current edition approved May 15, 1995. Published July 1995. Originally published as D3888–80. Last previous edition D3888–90.

1

This terminology is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers .

Current edition approved Dec. 1, 2007. Published January 2008. Originally approved in 1980. Last previous edition approved in 2001 as D 3888 – 95 (2001).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3888–07

4.1 Ring Spinning—Ring spinning is the oldest spinning system in use, therefore ring-spun yarns are the basis for comparing

yarns produced from other spinning systems. Production rates are low when compared to new spinning systems. The production

delivery capability of ring spinning is limited by traveler velocity and the twist limits of the yarn number being made; the speed

may range between 10 and 20 m/min. Ring spinning allows for the production of the widest range of yarn numbers from 200 to

2 tex (Ne 3/1 to 300/1). Ring-spun y

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.