ASTM D6010-96(2001)

(Practice)Standard Practice for Closed Vessel Microwave Solvent Extraction of Organic Compounds from Solid Matrices

Standard Practice for Closed Vessel Microwave Solvent Extraction of Organic Compounds from Solid Matrices

SCOPE

1.1 This practice describes the closed vessel microwave extraction of soils, sediments, sludges, and wastes for subsequent determination of solvent extractable semivolatile and nonvolatile organic compounds by such techniques as gas chromatography and gas chromatography-mass spectrometry.

1.1.1 Compounds listed in Tables 1 - 5 can be extracted from the preceding materials.

1.2 This test method is applicable to samples that will pass through a 10-mesh (approximately 2-mm opening) screen.

1.3 The detection limit and linear concentration range for each compound is dependent on the gas chromatograph or gas chromatograph-mass spectrometer technique employed and may be found in the manual accompanying the instrument used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 8 for specific hazard statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6010–96 (Reapproved 2001)

Standard Practice for

Closed Vessel Microwave Solvent Extraction of Organic

Compounds from Solid Matrices

This standard is issued under the fixed designation D 6010; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Test Methods for Evaluating Solid Waste Volume 1A: L-

aboratory Manual Physical/Chemical Methods

1.1 This practice describes the closed vessel microwave

Title21, CodeofFederalRegulations(CFR),Part1030,and

extraction of soils, sediments, sludges, and wastes for subse-

Title 47, Part 18

quent determination of solvent extractable semivolatile and

nonvolatile organic compounds by such techniques as gas

3. Summary of Practice

chromatography and gas chromatography-mass spectrometry.

3.1 This procedure ensures intimate contact of the sample

1.1.1 Compounds listed inTables 1–5 can be extracted from

matrix with 115°C extraction solvent.

the preceding materials.

3.2 A 1 to 5-g portion of a solid sample is extracted in a

1.2 This test method is applicable to samples that will pass

sealed microwave transparent extraction vessel with 30 mL of

through a 10-mesh (approximately 2-mm opening) screen.

acetone-hexane (1 + 1).

1.3 The detection limit and linear concentration range for

3.3 Up to 12 samples may be extracted simultaneously.

each compound is dependent on the gas chromatograph or gas

3.4 After extraction the vessels are cooled to room tempera-

chromatograph-mass spectrometer technique employed and

ture, opened, and the solvent and sample are separated by

may be found in the manual accompanying the instrument

decanting, filtration, or centrifuging.

used.

3.5 This practice provides a sample suitable for analysis by

1.4 This standard does not purport to address all of the

gas chromatography or gas chromatography-mass spectrom-

safety concerns, if any, associated with its use. It is the

etry.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use. See Section 8 for

4.1 Extraction of organic pollutants from wastes can pro-

specific hazard statements.

vide information on the susceptibility of compounds to leech-

ing, water quality changes, or other site conditions.

2. Referenced Documents

2 4.2 Rapid heating, in combination with temperatures in

2.1 ASTM Standards:

excess of the atmospheric boiling point of organic solvents,

D 1193 Specification for Reagent Water

reduces sample extraction times.

D 3976 Practice for Preparation of Sediment Samples for

4.3 Small amounts of solvents (30 mL) are used resulting in

Chemical Analysis

reduced sample preparation cost and time.

D 5368 Test Method for the Gravimetric Determination of

Total Solvent Extractable Content (TSEC) of Solid Waste

5. Interferences

Samples

5.1 Method interferences may be caused by contaminants in

2.2 Other Standards:

solvents, labware, and other hardware used in sample process-

United States Environmental Protection Agency (USEPA),

ing that lead to discrete artifacts or elevated baselines in gas

chromatograms. The analyst must demonstrate, through the

This practice is under the jurisdiction of ASTM Committee D34 on Waste analysisofreagentblanks,thatthesystemandthematerialsare

Management and is the direct responsibility of Subcommittee D34.01.06 on

free from interferents.

Analytical Methods.

Current edition approved Oct. 10, 1996. Published December 1996.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from the Superintendent of Documents, U.S. Government Printing

the ASTM website. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6010–96 (2001)

5.2 The use of high-purity solvents helps to minimize

Spike Level, Average

interference problems.

Analyte RSD, %

A

mg/kg Recovery, %

5.3 Matrixinterferencesarecausedbycontaminantsthatare

Methyl methanesulfonate 5.0 48.5 28

coextracted from the sample. The extent of matrix interfer-

2-Methylnaphthalene 5.0 104 9.3

ences may vary considerably from sample to sample.

2-Methylphenol 5.0 95.1 8.5

5.4 After cleaning, vessel liners and covers should be stored 4-Methylphenol 5.0 92.4 11

Naphthalene 5.0 95.0 12

in a clean environment to prevent accumulation of contami-

1-Naphthylamine 5.0 57.8 8.7

nants.

2-Naphthylamine 5.0 73.5 9.0

2-Nitroaniline 5.0 100 7.7

3-Nitroaniline 5.0 96.8 8.5

TABLE 1 Semivolatile Analyte Recovery from Freshly Spiked

4-Nitroaniline 5.0 99.0 8.5

Topsoil

Nitrobenzene 5.0 88.4 19

2-Nitrophenol 5.0 85.3 10

Spike Level, Average

4-Nitrophenol 5.0 104 6.0

Analyte RSD, %

A

mg/kg Recovery, %

N-nitroso-di-n-butylamine 5.0 97.5 9.3

N-nitroso-di-n-propylamine 5.0 87.5 20

Acenaphthene 5.0 97.6 9.8

N-nitrosopiperidine 5.0 90.8 7.6

Acenaphthylene 5.0 100 10

Pentachlorobenzene 5.0 101 9.1

Acetophenone 5.0 92.2 12

Pentachloronitrobenzene 5.0 109 9.7

4-Aminobiphenyl 5.0 77.3 9.5

Pentachlorophenol 5.0 86.2 8.1

Aniline 5.0 68.1 7.5

Phenacetin 5.0 97.0 12

Anthracene 5.0 108 9.2

Phenanthrene 5.0 109 8.5

Benzidine 5.0 0

Phenol 5.0 97.3 9.2

Benzoic acid 5.0 42.3 13

2-Picoline 5.0 7.7 30

Benzo(a)anthracene 5.0 113 9.4

Pronamid 5.0 120 11

Benzo(b)fluoranthene 5.0

Pyrene 5.0 113 8.4

Benzo(k)fluoranthene 5.0 116 9.3

1,2,4,5-Tetrachlorobenzene 5.0 91.2 8.6

Benzo(g,h,i)perylene 5.0 111 4.7

2,3,4,6-Tetrachlorophenol 5.0 104 7.3

Benzo(a)pyrene 5.0 110 8.6

1,2,4-Trichlorobenzene 5.0 89.3 11

Benzyl alcohol 5.0 96.1 9.0

2,4,5-Trichlorophenol 5.0 95.1 12

Bis(2-chloroethoxy)methane 5.0 92.4 9.8

2,3,6-Trichlorophenol 5.0 96.4 6.7

Bis(2-chloroethyl)ether 5.0 96.0 11

2-Fluorobipenyl 2.5 92.9 8.0

Bis(2-chloroisopropyl)ether 5.0 95.2 12

2-Fluorophenol 5.0 95.4 7.7

Bis(2-ethylhexyl)phthalate 5.0 116 9.3

Nitrobenzene-d 2.5 92.2 9.8

4-Bromophenylphenyl ether 5.0 108 9.0

Phenol-d 5.0 98.9 9.7

Butyl benzyl phthalate 5.0 116 9.8

Terphenyl-d 2.5 112 10

4-Chloroaniline 5.0 97.0 9.2

2,4,6-Tribromophenol 5.0 92.3 7.7

1-Chloronaphthalene 5.0 104 12

A

The topsoil was dry when spiked. The number of determinations was three.

2-Chloronaphthalene 5.0 91.8 7.3

Determinations were made by gas chromatography-mass spectrometry.All recov-

4-Chloro-3-methylphenol 5.0 107 12

eries were corrected for analyte losses incurred during blowdown evaporation of

2-Chlorophenol 5.0 94.5 7.8

solvent to determine, specifically, recoveries by microwave extraction.

4-Chlorophenyl phenyl ether 5.0 106 9.7

B

Chrysene 5.0 111 8.8 Determined as azobenzene.

Dibenzo(a,j)acridine 5.0 10.6 34

Dibenzo(a,h)anthracene 5.0 110 5.9

6. Apparatus

Dibenzofuran 5.0 98.8 9.9

Di-n-butyl phthalate 5.0 113 9.4

6.1 Microwave Heating System—A laboratory microwave

1,2-Dichlorobenzene 5.0 89.9 12

heating system capable of delivering a minimum of 900 W of

1,3-Dichlorobenzene 5.0 87.6 13

1,4-Dichlorobenzene 5.0 87.3 13 microwave energy. The system should be capable of 1 %

3,3-Dichlorobenzidine 5.0 96.8 12

power adjustments and 1-s time adjustments. The microwave

2,4-Dichlorophenol 5.0 97.5 8.0

unit must be capable of measuring and controlling solvent

2,6-Dichlorophenol 5.0 93.1 12

Diethyl phthalate 5.0 111 8.0

temperature within an extraction vessel. The microwave cavity

Dimethylaminoazobenzene 5.0 116 11

should be constructed so as to prevent any possible metal to

7,12-Dimethylbenz(a)anthracene 5.0 128 7.0

metal arcing from occurring within the cavity. The oven cavity

aa-Dimethylphenethylamine 5.0 7.0 4.1

2,4-Dimenthylphenol 5.0 107 9.4 should be equipped with an exhaust ventilation sufficient to

Dimethyl phthalate 5.0 106 8.4

provide ten chamber exchanges/min. The ventilation exhaust

4,6-Dinitro-2-methylphenol 5.0 57.6 9.3

should contain an air flow sensor and a solvent sensor capable

2,4-Dinitrophenol 5.0 17.2 39

2,4-Dinitrotoluene 5.0 98.2 6.2 of detecting no air flow and solvent concentrations below their

2,6-Dinitrotoluene 5.0 98.5 9.9

lower explosive limits and shutting the microwave source off.

B

1,2-Diphenylhydrazine 5.0 108 11

The cavity shall have a 360° oscillating turntable to ensure

Di-n-octyl phthalate 5.0 117 12

Ethyl methanesulfonate 5.0 77.9 10

even sample heating and be capable of removing contained

Fluoranthene 5.0 110 8.7

vessel-vented solvents. Safety interlocks to shut off magnetron

Fluorene 5.0 101 10

power output shall be contained in the cavity door opening

Hexachlorobenzene 5.0 108 8.9

Hexachlorobutadiene 5.0 89.5 11

mechanism. The system shall comply with the Department of

Hexachlorocyclopentadiene 5.0 60.9 14

Health and Human Services Standards under the CFR, Part

Hexachloroethane 5.0 83.7 13

1030.10, Subpart (c)(1), (c)(2), and (c)(3), for microwave

Indeno(1,2,3-cd)pyrene 5.0 99.2 6.2

Isophorone 5.0 88.7 8.5

leakage. The system should have Federal Communication

3-Methylcholanthrene 5.0 117 8.6

Commission (FCC) type approval for operations under FCC

D6010–96 (2001)

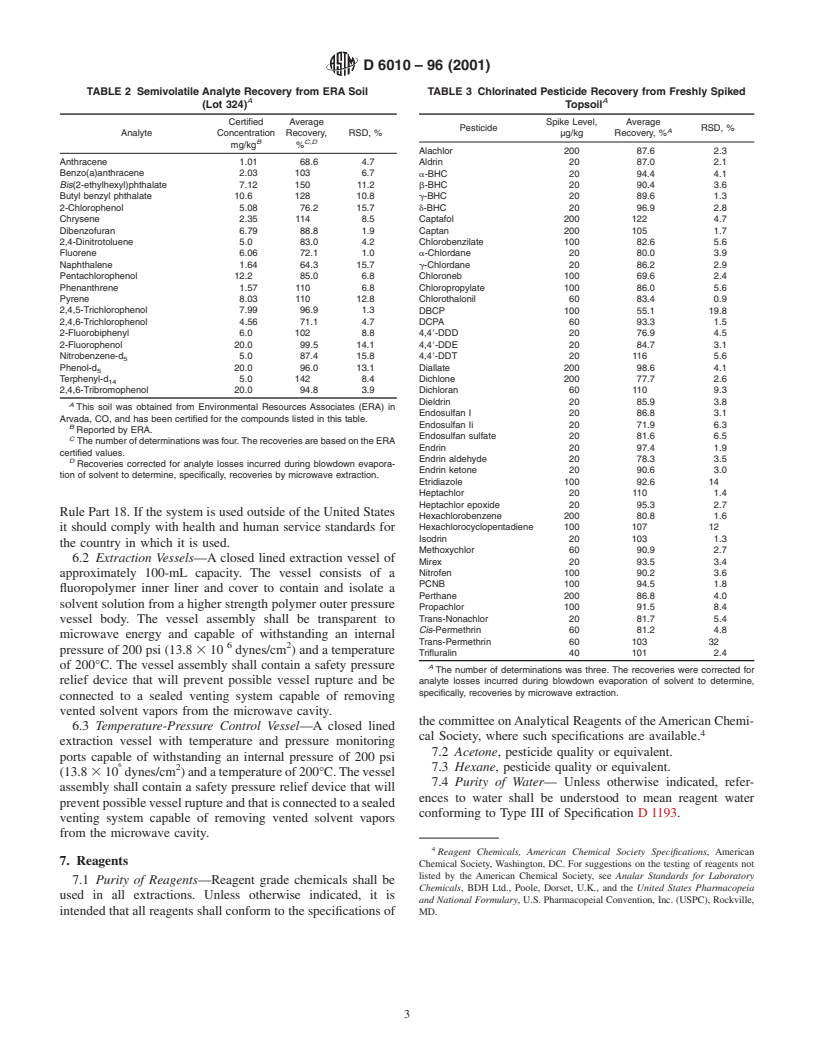

TABLE 2 Semivolatile Analyte Recovery from ERA Soil TABLE 3 Chlorinated Pesticide Recovery from Freshly Spiked

A A

(Lot 324) Topsoil

Certified Average Spike Level, Average

Pesticide RSD, %

A

Analyte Concentration Recovery, RSD, % µg/kg Recovery, %

B C,D

mg/kg %

Alachlor 200 87.6 2.3

Anthracene 1.01 68.6 4.7 Aldrin 20 87.0 2.1

Benzo(a)anthracene 2.03 103 6.7 a-BHC 20 94.4 4.1

Bis(2-ethylhexyl)phthalate 7.12 150 11.2

b-BHC 20 90.4 3.6

Butyl benzyl phthalate 10.6 128 10.8 g-BHC 20 89.6 1.3

2-Chlorophenol 5.08 76.2 15.7 d-BHC 20 96.9 2.8

Chrysene 2.35 114 8.5 Captafol 200 122 4.7

Dibenzofuran 6.79 88.8 1.9 Captan 200 105 1.7

2,4-Dinitrotoluene 5.0 83.0 4.2 Chlorobenzilate 100 82.6 5.6

Fluorene 6.06 72.1 1.0 a-Chlordane 20 80.0 3.9

Naphthalene 1.64 64.3 15.7 g-Chlordane 20 86.2 2.9

Pentachlorophenol 12.2 85.0 6.8 Chloroneb 100 69.6 2.4

Phenanthrene 1.57 110 6.8

Chloropropylate 100 86.0 5.6

Pyrene 8.03 110 12.8 Chlorothalonil 60 83.4 0.9

2,4,5-Trichlorophenol 7.99 96.9 1.3 DBCP 100 55.1 19.8

2,4,6-Trichlorophenol 4.56 71.1 4.7 DCPA 60 93.3 1.5

2-Fluorobiphenyl 6.0 102 8.8 4,48-DDD 20 76.9 4.5

2-Fluorophenol 20.0 99.5 14.1 4,48-DDE 20 84.7 3.1

Nitrobenzene-d 5.0 8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.