ASTM E1165-12

(Test Method)Standard Test Method for Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Imaging

Standard Test Method for Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Imaging

SIGNIFICANCE AND USE

One of the factors affecting the quality of radiologic images is the geometric unsharpness. The degree of geometric unsharpness is dependent on the focal spot size of the radiation source, the distance between the source and the object to be radiographed, and the distance between the object to be radiographed and the detector (imaging plate, Digital Detector Array (DDA) or film). This test method allows the user to determine the effective focal size of the X-ray source. This result may then be used to establish source to object and object to detector distances appropriate for maintaining the desired degree of geometric unsharpness and/or maximum magnification for a given radiographic imaging application. Some ASTM standards require this value for calculation of a required magnification, for example, E1255, E2033, and E2698.

SCOPE

1.1 The image quality and the resolution of X-ray images highly depend on the characteristics of the focal spot. The imaging qualities of the focal spot are based on its two dimensional intensity distribution as seen from the detector plane.

1.2 This test method provides instructions for determining the effective size (dimensions) of standard and mini focal spots of industrial x-ray tubes. This determination is based on the measurement of an image of a focal spot that has been radiographically recorded with a “pinhole” technique.

1.3 This standard specifies a method for the measurement of focal spot dimensions from 50 μm up to several mm of X-ray sources up to 1000 kV tube voltage. Smaller focal spots should be measured using EN 12543-5 using the projection of an edge.

1.4 This test method may also be used to determine the presence or extent of focal spot damage or deterioration that may have occurred due to tube age, tube overloading, and the like. This would entail the production of a focal spot radiograph (with the pinhole method) and an evaluation of the resultant image for pitting, cracking, and the like.

1.5 Values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1165 − 12

Standard Test Method for

Measurement of Focal Spots of Industrial X-Ray Tubes by

1

Pinhole Imaging

This standard is issued under the fixed designation E1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1255Practice for Radioscopy

E2002PracticeforDeterminingTotalImageUnsharpnessin

1.1 The image quality and the resolution of X-ray images

Radiology

highly depend on the characteristics of the focal spot. The

E2033Practice for Computed Radiology (Photostimulable

imaging qualities of the focal spot are based on its two

Luminescence Method)

dimensional intensity distribution as seen from the detector

E2698Practice for Radiological Examination Using Digital

plane.

Detector Arrays

3

1.2 This test method provides instructions for determining

2.2 European Standards:

theeffectivesize(dimensions)ofstandardandminifocalspots

EN 12543-2Non-destructive testing—Characteristics of fo-

of industrial x-ray tubes. This determination is based on the

cal spots in industrial X-ray systems for use in non-

measurement of an image of a focal spot that has been

destructive testing—Part 2: Pinhole camera radiographic

radiographically recorded with a “pinhole” technique.

method

1.3 Thisstandardspecifiesamethodforthemeasurementof EN 12543-5Non-destructive testing—Characteristics of fo-

cal spots in industrial X-ray systems for use in non-

focal spot dimensions from 50 µm up to several mm of X-ray

sourcesupto1000kVtubevoltage.Smallerfocalspotsshould destructive testing—Part 5: Measurement of the effective

focal spot size of mini and micro focus X-ray tubes

bemeasuredusingEN12543-5usingtheprojectionofanedge.

2.3 Papers:

1.4 This test method may also be used to determine the

Klaus Bavendiek, Uwe Heike, Uwe Zscherpel, Uwe Ewert

presence or extent of focal spot damage or deterioration that

And Adrian Riedo,“New measurement methods of focal

may have occurred due to tube age, tube overloading, and the

spot size and shape of X-ray tubes in digital radiological

like. This would entail the production of a focal spot radio-

applications in comparison to current standards,” WC-

graph (with the pinhole method) and an evaluation of the

NDT 2012, Durban, South Africa

resultant image for pitting, cracking, and the like.

1.5 Values stated in SI units are to be regarded as the 3. Terminology

standard.

3.1 Definitions of Terms Specific to This Standard:

1.6 This standard does not purport to address all of the

3.1.1 actual focal spot—the X-ray producing area of the

safety concerns, if any, associated with its use. It is the

target as viewed from a position perpendicular to the target

responsibility of the user of this standard to establish appro-

surface (see Fig. 1).

priate safety and health practices and determine the applica-

3.1.2 effective focal spot—the X-ray producing area of the

bility of regulatory limitations prior to use.

target as viewed from a position perpendicular to the tube axis

in the center of the X-ray beam (see Fig. 1).

2. Referenced Documents

2

3.1.3 effective size of focal spot—focalspotsizemeasuredin

2.1 ASTM Standards:

accordance with this standard.

E1000Guide for Radioscopy

4. Summary of Test Method

1

This test method is under the jurisdiction of ASTM Committee E07 on

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

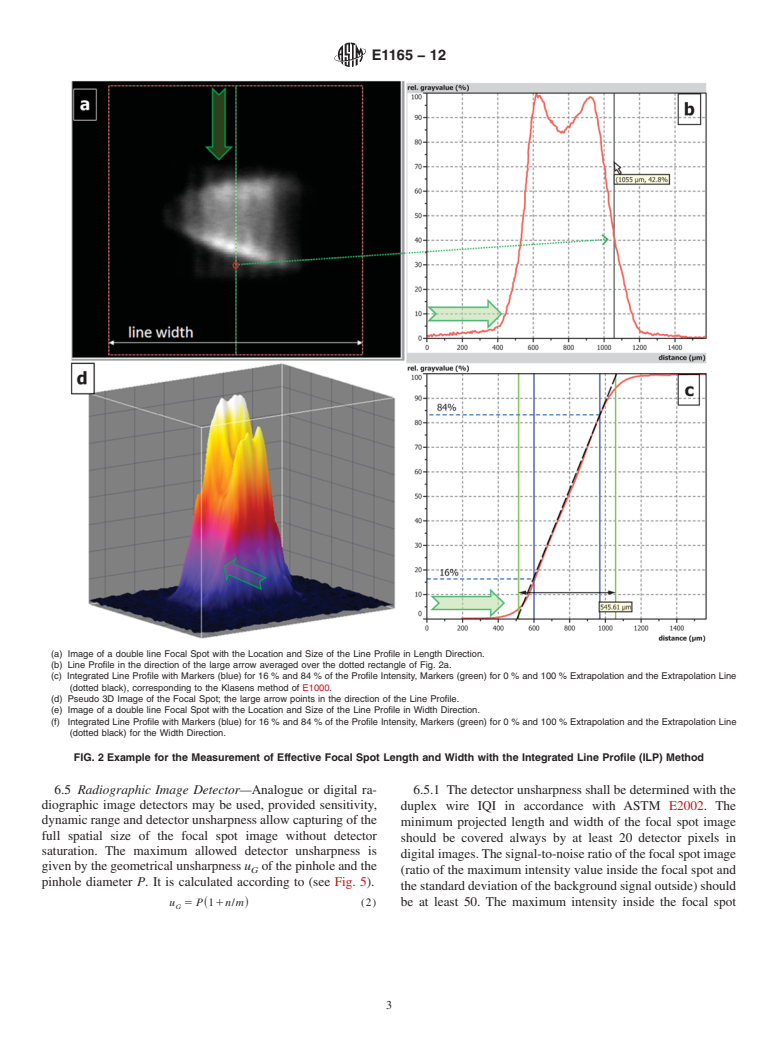

4.1 This method is based on a projection image of the focal

Radiology (X and Gamma) Method.

spot using a pinhole camera. This image shows the intensity

Current edition approved June 15, 2012. Published September 2012. Originally

distributionofthefocalspot.Fromthisimagetheeffectivesize

approved in 1987. Last previous edition approved in 2010 as E1165–04(2010).

of the focal spot is computed.Adouble integration of a profile

DOI: 10.1520/E1165-04R12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization (CEN), Avenue

the ASTM website. Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1165 − 12

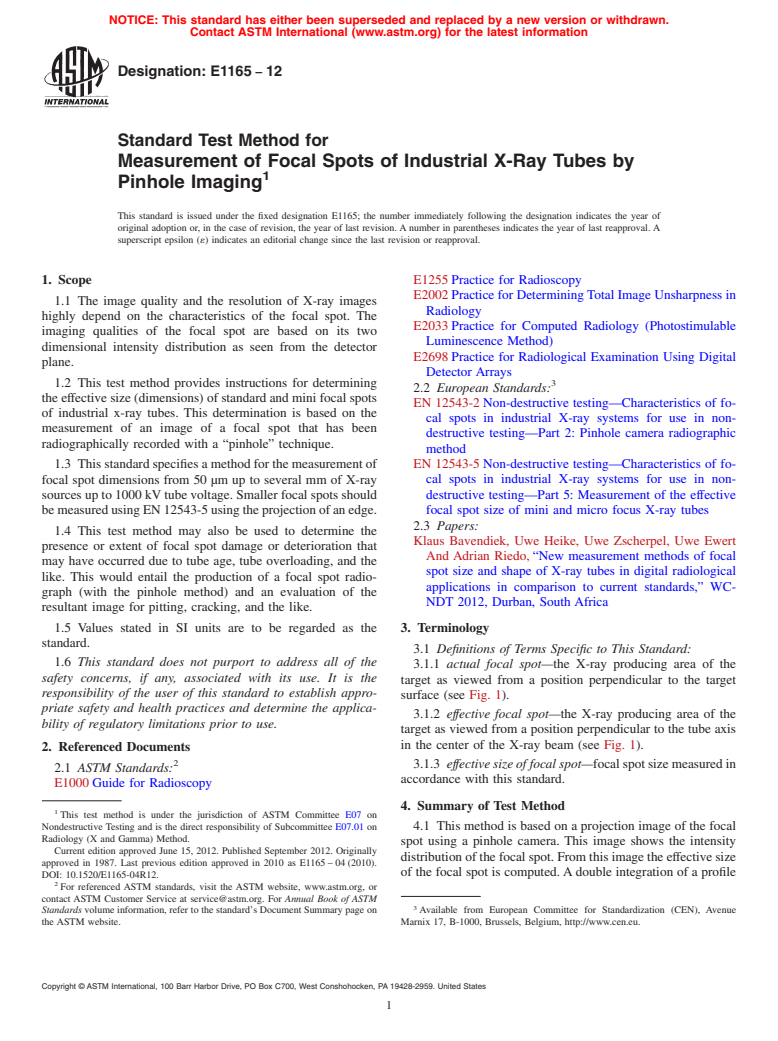

FIG. 1 Actual/Effective Focal Spot

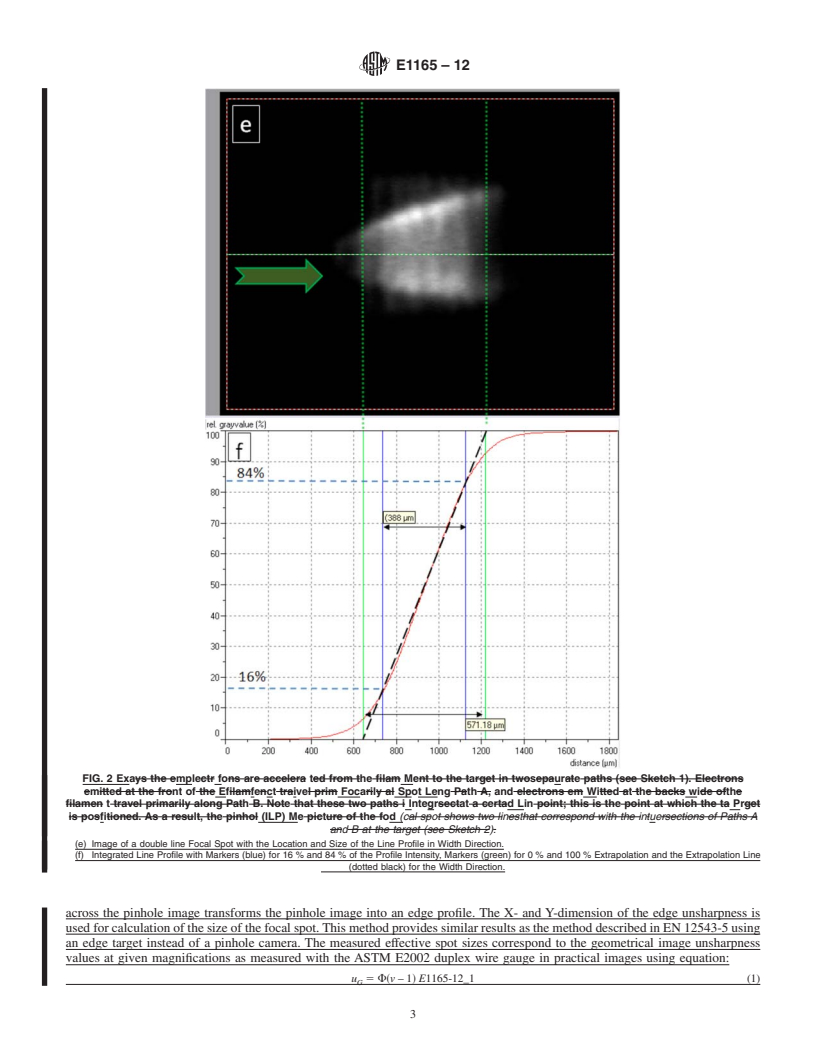

across the pinhole image transforms the pinhole image into an 6. Apparatus

edge profile.The X- andY-dimension of the edge unsharpness

6.1 Pinhole Diaphragm—The pinhole diaphragm shall con-

isusedforcalculationofthesizeofthef

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1165–04 (Reapproved 2010) Designation: E1165 – 12

Standard Test Method for

Measurement of Focal Spots of Industrial X-Ray Tubes by

1

Pinhole Imaging

This standard is issued under the fixed designation E1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method provides instructions for determining the length and width dimensions of line focal spots in industrial X-ray

tubes (see Note 1). This determination is based on the measurement of an image of a focal spot that has been radiographically

recorded with a “pinhole” projection/imaging technique.

NOTE1—Line focal spots are associated with vacuum X-ray tubes whose maximum voltage rating does not generally exceed 500 kV.

1.2This test method may not yield meaningful results on focal spots whose nominal size is less than 0.3 mm (0.011 in.). (See

Note 2.)

NOTE2—The X-ray tube manufacturer may be contacted for nominal focal spot dimensions.

1.3This test method may also be used to determine the presence or extent of focal spot damage or deterioration that may have

occurred due to tube age, tube overloading, and the like. This would entail the production of a focal spot radiograph (with the

pinhole method) and an evaluation of the resultant image for pitting, cracking, and the like.

1.4Values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.5

1.1 The image quality and the resolution of X-ray images highly depend on the characteristics of the focal spot. The imaging

qualities of the focal spot are based on its two dimensional intensity distribution as seen from the detector plane.

1.2 This test method provides instructions for determining the effective size (dimensions) of standard and mini focal spots of

industrial x-ray tubes. This determination is based on the measurement of an image of a focal spot that has been radiographically

recorded with a “pinhole” technique.

1.3 This standard specifies a method for the measurement of focal spot dimensions from 50 µm up to several mm of X-ray

sources up to 1000 kV tube voltage. Smaller focal spots should be measured using EN 12543-5 using the projection of an edge.

1.4 This test method may also be used to determine the presence or extent of focal spot damage or deterioration that may have

occurred due to tube age, tube overloading, and the like. This would entail the production of a focal spot radiograph (with the

pinhole method) and an evaluation of the resultant image for pitting, cracking, and the like.

1.5 Values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1

This test method is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

(X and Gamma) Method.

Current edition approved June 1, 2010.15, 2012. Published November 2010.September 2012. Originally approved in 1987. Last previous edition approved in 20042010

as E1165 – 04 (2010). DOI: 10.1520/E1165-04R102.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1165 – 12

2. Referenced Documents

2

2.1 ASTM Standards:

E999Guide for Controlling the Quality of Industrial Radiographic Film Processing 1000 Guide for Radioscopy

E1255 Practice for Radioscopy

E2002 Practice for Determining Total Image Unsharpness in Radiology

E2033 Practice for Computed Radiology (Photostimulable Luminescence Method)

E2698 Practice for Radiological Examination Using Digital Detector Arrays

3

2.2 European Standards:

EN 12543-2 Non-destructive testing—Characteristics of focal spots in industrial X-ray systems for use in non-destructive

testing—Part 2: Pinhole camera radiographic method

EN 12543-5 Non-destructive testing—Characteristics of focal spots in industrial X-ray systems for use in non-destructive

testing—Part 5: Measurement of the effective focal spot size of mini and micro focus X-ray tubes

2.3 Papers:

Klaus Bavendie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.