ASTM E1165-04(2010)

(Test Method)Standard Test Method for Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Imaging

Standard Test Method for Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Imaging

SIGNIFICANCE AND USE

One of the factors affecting the quality of a radiographic image is geometric unsharpness. The degree of geometric unsharpness is dependent upon the focal size of the radiation source, the distance between the source and the object to be radiographed, and the distance between the object to be radiographed and the film. This test method allows the user to determine the focal size of the X-ray source and to use this result to establish source to object and object to film distances appropriate for maintaining the desired degree of geometric unsharpness.

SCOPE

1.1 This test method provides instructions for determining the length and width dimensions of line focal spots in industrial X-ray tubes (see Note 1). This determination is based on the measurement of an image of a focal spot that has been radiographically recorded with a “pinhole” projection/imaging technique.

Note 1—Line focal spots are associated with vacuum X-ray tubes whose maximum voltage rating does not generally exceed 500 kV.

1.2 This test method may not yield meaningful results on focal spots whose nominal size is less than 0.3 mm (0.011 in.). (See Note 2.)

Note 2—The X-ray tube manufacturer may be contacted for nominal focal spot dimensions.

1.3 This test method may also be used to determine the presence or extent of focal spot damage or deterioration that may have occurred due to tube age, tube overloading, and the like. This would entail the production of a focal spot radiograph (with the pinhole method) and an evaluation of the resultant image for pitting, cracking, and the like.

1.4 Values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1165–04 (Reapproved 2010)

Standard Test Method for

Measurement of Focal Spots of Industrial X-Ray Tubes by

Pinhole Imaging

This standard is issued under the fixed designation E1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 2—The X-ray tube manufacturer may be contacted for nominal

1. Scope

focal spot dimensions.

1.1 This test method provides instructions for determining

1.3 This test method may also be used to determine the

thelengthandwidthdimensionsoflinefocalspotsinindustrial

presence or extent of focal spot damage or deterioration that

X-ray tubes (see Note 1). This determination is based on the

may have occurred due to tube age, tube overloading, and the

measurement of an image of a focal spot that has been

like. This would entail the production of a focal spot radio-

radiographically recorded with a “pinhole” projection/imaging

graph (with the pinhole method) and an evaluation of the

technique.

resultant image for pitting, cracking, and the like.

NOTE 1—Line focal spots are associated with vacuum X-ray tubes

1.4 Values stated in SI units are to be regarded as the

whose maximum voltage rating does not generally exceed 500 kV.

standard. Inch-pound units are provided for information only.

1.2 This test method may not yield meaningful results on

1.5 This standard does not purport to address all of the

focal spots whose nominal size is less than 0.3 mm (0.011 in.).

safety concerns, if any, associated with its use. It is the

(See Note 2.)

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1 bility of regulatory limitations prior to use.

This test method is under the jurisdiction of ASTM Committee E07 on

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on

Radiology (X and Gamma) Method.

Current edition approved June 1, 2010. Published November 2010. Originally

approved in 1987. Last previous edition approved in 2004 as E1165 – 04. DOI:

10.1520/E1165-04R10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1165–04 (2010)

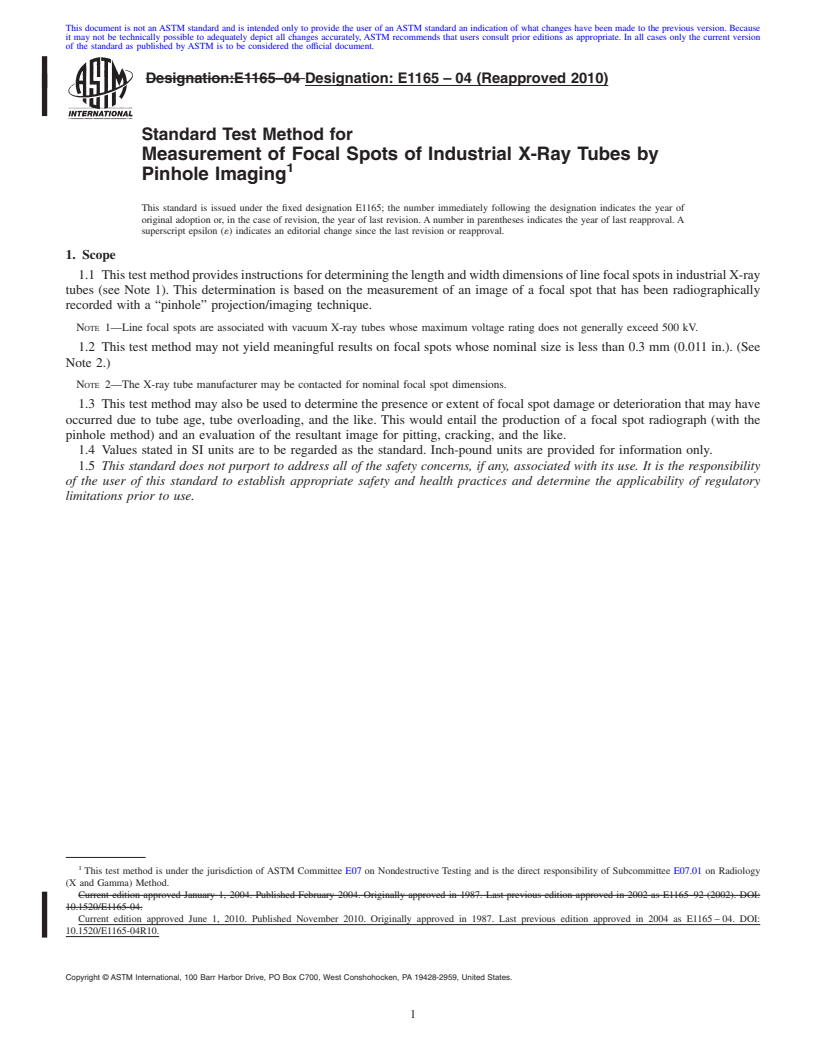

2. Referenced Documents 3.1.2 effective focal spot—the X-ray producing area of the

2 target as viewed from a position perpendicular to the tube axis

2.1 ASTM Standards:

in the center of the X-ray beam (see Fig. 2).

E999 Guide for Controlling the Quality of Industrial Radio-

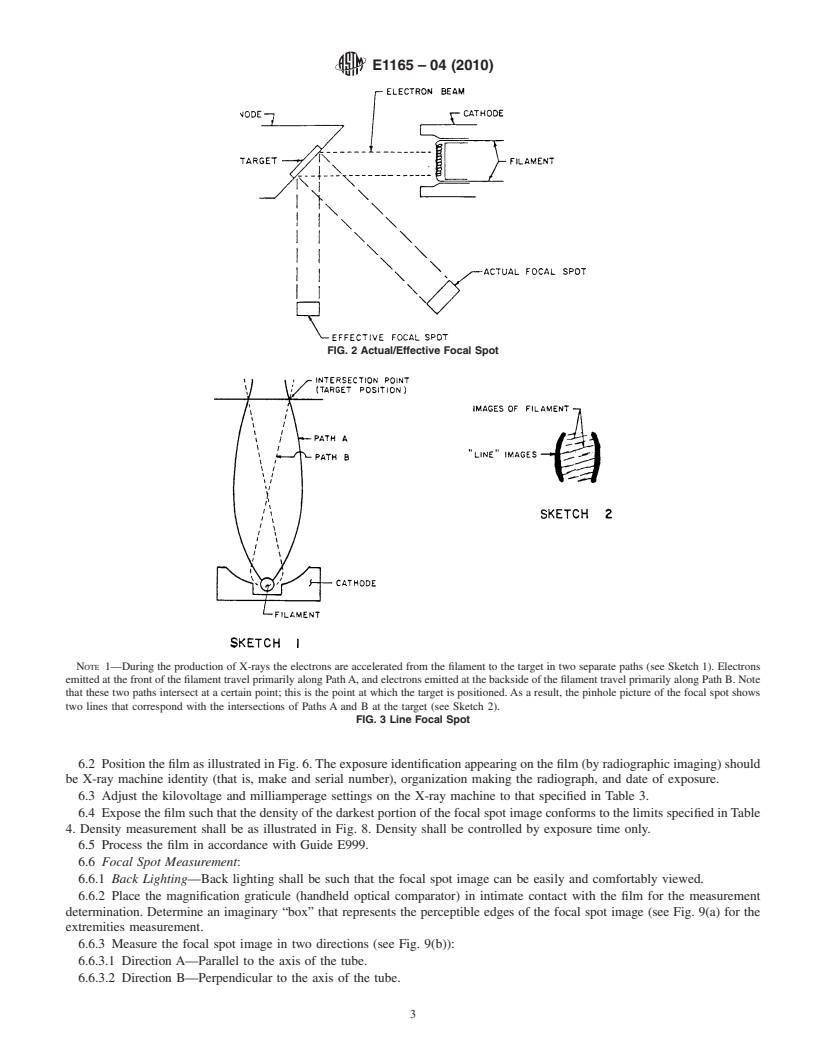

3.1.3 line focal spot—a focal spot whose projected pinhole

graphic Film Processing

image consists primarily of two curved lines (see Fig. 3).

3. Terminology

4. Significance and Use

4.1 One of the factors affecting the quality of a radiographic

3.1 Definitions of Terms Specific to This Standard:

image is geometric unsharpness. The degree of geometric

3.1.1 actual focal spot—the X-ray producing area of the

unsharpness is dependent upon the focal size of the radiation

target as viewed from a position perpendicular to the target

source, the distance between the source and the object to be

surface (see Fig. 2).

radiographed, and the distance between the object to be

radiographed and the film. This test method allows the user to

determine the focal size of the X-ray source and to use this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

result to establish source to object and object to film distances

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

appropriate for maintaining the desired degree of geometric

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. unsharpness.

E1165–04 (2010)

should be X-ray machine identity (that is, make and serial

number), organization making the radiograph, and date of

exposure.

6.3 Adjustthekilovoltageandmilliamperagesettingsonthe

X-ray machine to that specified in Table 3.

6.4 Expose the film such that the density of the darkest

portion of the focal spot image conforms to the limits specified

in Table 4. Density measurement shall be as illustrated in Fig.

8. Density shall be controlled by exposure time only.

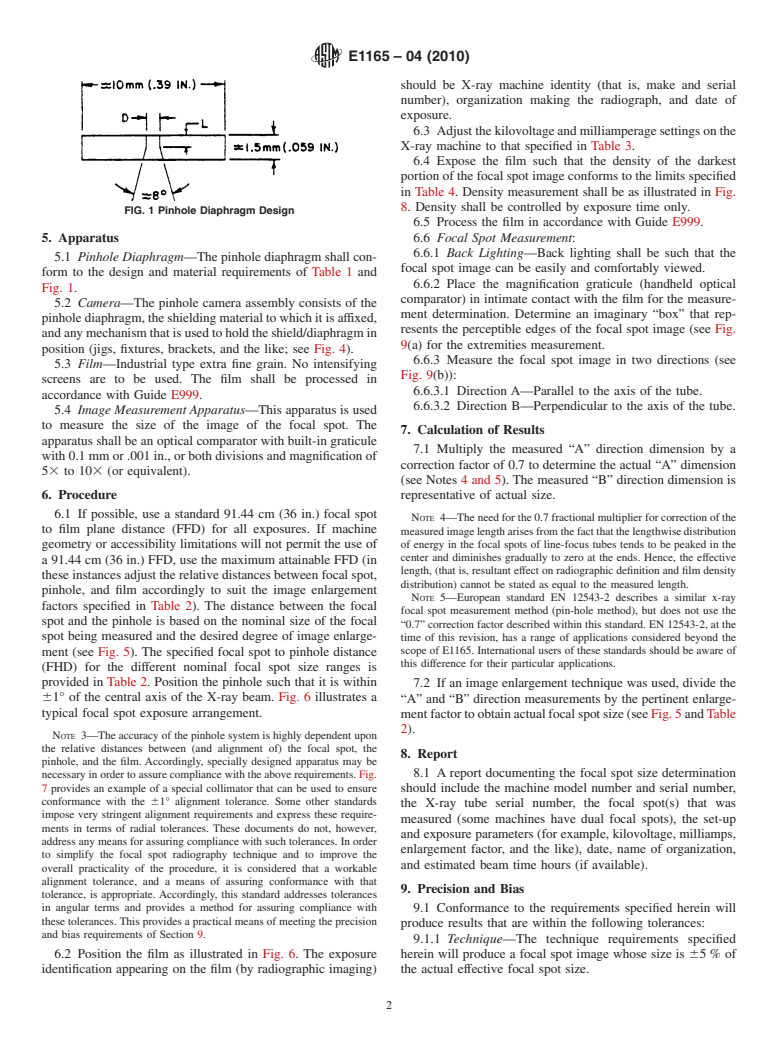

FIG. 1 Pinhole Diaphragm Design

6.5 Process the film in accordance with Guide E999.

5. Apparatus 6.6 Focal Spot Measurement:

6.6.1 Back Lighting—Back lighting shall be such that the

5.1 Pinhole Diaphragm—The pinhole diaphragm shall con-

focal spot image can be easily and comfortably viewed.

form to the design and material requirements of Table 1 and

6.6.2 Place the magnification graticule (handheld optical

Fig. 1.

comparator) in intimate contact with the film for the measure-

5.2 Camera—The pinhole camera assembly consists of the

ment determination. Determine an imaginary “box” that rep-

pinholediaphragm,theshieldingmaterialtowhichitisaffixed,

resents the perceptible edges of the focal spot image (see Fig.

andanymechanismthatisusedtoholdtheshield/diaphragmin

9(a) for the extremities measurement.

position (jigs, fixtures, brackets, and the like; see Fig. 4).

6.6.3 Measure the focal spot image in two directions (see

5.3 Film—Industrial type extra fine grain. No intensifying

Fig. 9(b)):

screens are to be used. The film shall be processed in

6.6.3.1 Direction A—Parallel to the axis of the tube.

accordance with Guide E999.

6.6.3.2 Direction B—Perpendicular to the axis of the tube.

5.4 Image Measurement Apparatus—This apparatus is used

to measure the size of the image of the focal spot. The

7. Calculation of Results

apparatus shall be an optical comparator with built-in graticule

7.1 Multiply the measured “A” direction dimension by a

with 0.1 mm or .001 in., or both divisions and magnification of

correction factor of 0.7 to determine the actual “A” dimension

53 to 103 (or equivalent).

(see Notes 4 and 5). The measured “B” direction dimension is

6. Procedure representative of actual size.

6.1 If possible, use a standard 91.44 cm (36 in.) focal spot

NOTE 4—The need for the 0.7 fractional multiplier for correction of the

to film plane distance (FFD) for all exposures. If machine

measuredimagelengtharisesfromthefactthatthelengthwisedistribution

geometry or accessibility limitations will not permit the use of of energy in the focal spots of line-focus tubes tends to be peaked in the

center and diminishes gradually to zero at the ends. Hence, the effective

a 91.44 cm (36 in.) FFD, use the maximum attainable FFD (in

length, (that is, resultant effect on radiographic definition and film density

these instances adjust the relative distances between focal spot,

distribution) cannot be stated as equal to the measured length.

pinhole, and film accordingly to suit the image enlargement

NOTE 5—European standard EN 12543-2 describes a similar x-ray

factors specified in Table 2). The distance between the focal

focal spot measurement method (pin-hole method), but does not use the

spot and the pinhole is based on the nominal size of the focal

“0.7” correction factor described within this standard. EN 12543-2, at the

spot being measured and the desired degree of image enlarge-

time of this revision, has a range of applications considered beyond the

scope of E1165. International users of these standards should be aware of

ment (see Fig. 5). The specified focal spot to pinhole distance

this difference for their particular applications.

(FHD) for the different nominal focal spot size ranges is

provided in Table 2. Position the pinhole such that it is within

7.2 If an image enlargement technique was used, divide the

61° of the central axis of the X-ray beam. Fig. 6 illustrates a

“A” and “B” di

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1165–04 Designation:E1165–04 (Reapproved 2010)

Standard Test Method for

Measurement of Focal Spots of Industrial X-Ray Tubes by

Pinhole Imaging

This standard is issued under the fixed designation E1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 ThistestmethodprovidesinstructionsfordeterminingthelengthandwidthdimensionsoflinefocalspotsinindustrialX-ray

tubes (see Note 1). This determination is based on the measurement of an image of a focal spot that has been radiographically

recorded with a “pinhole” projection/imaging technique.

NOTE 1—Line focal spots are associated with vacuum X-ray tubes whose maximum voltage rating does not generally exceed 500 kV.

1.2 This test method may not yield meaningful results on focal spots whose nominal size is less than 0.3 mm (0.011 in.). (See

Note 2.)

NOTE 2—The X-ray tube manufacturer may be contacted for nominal focal spot dimensions.

1.3 This test method may also be used to determine the presence or extent of focal spot damage or deterioration that may have

occurred due to tube age, tube overloading, and the like. This would entail the production of a focal spot radiograph (with the

pinhole method) and an evaluation of the resultant image for pitting, cracking, and the like.

1.4 Values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This test method is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

(X and Gamma) Method.

Current edition approved January 1, 2004. Published February 2004. Originally approved in 1987. Last previous edition approved in 2002 as E1165–92 (2002). DOI:

10.1520/E1165-04.

Current edition approved June 1, 2010. Published November 2010. Originally approved in 1987. Last previous edition approved in 2004 as E1165 – 04. DOI:

10.1520/E1165-04R10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1165–04 (2010)

2. Referenced Documents

2.1 ASTM Standards:

E999 Guide for Controlling the Quality of Industrial Radiographic Film Processing

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 actual focal spot—theX-rayproducingareaofthetargetasviewedfromapositionperpendiculartothetargetsurface(see

Fig. 2).

3.1.2 effective focal spot—the X-ray producing area of the target as viewed from a position perpendicular to the tube axis in

the center of the X-ray beam (see Fig. 2).

3.1.3 line focal spot—a focal spot whose projected pinhole image consists primarily of two curved lines (see Fig. 3).

4. Significance and Use

4.1 One of the factors affecting the quality of a radiographic image is geometric unsharpness. The degree of geometric

unsharpness is dependent upon the focal size of the radiation source, the distance between the source and the object to be

radiographed, and the distance between the object to be radiographed and the film. This test method allows the user to determine

the focal size of the X-ray source and to use this result to establish source to object and object to film distances appropriate for

maintaining the desired degree of geometric unsharpness.

5. Apparatus

5.1 Pinhole Diaphragm—The pinhole diaphragm shall conform to the design and material requirements of Table 1 and Fig. 1.

5.2 Camera—The pinhole camera assembly consists of the pinhole diaphragm, the shielding material to which it is affixed, and

any mechanism that is used to hold the shield/diaphragm in position (jigs, fixtures, brackets, and the like; see Fig. 4).

5.3 Film—Industrialtypeextrafinegrain.Nointensifyingscreensaretobeused.Thefilmshallbeprocessedinaccordancewith

Guide E999.

5.4 Image Measurement Apparatus —This apparatus is used to measure the size of the image of the focal spot. The apparatus

shall be an optical comparator with built-in graticule with 0.1 mm or .001 in., or both divisions and magnification of 53 to 103

(or equivalent).

6. Procedure

6.1 If possible, use a standard 91.44 cm (36 in.) focal spot to film plane distance (FFD) for all exposures. If machine geometry

or accessibility limitations will not permit the use of a 91.44 cm (36 in.) FFD, use the maximum attainable FFD (in these instances

adjust the relative distances between focal spot, pinhole, and film accordingly to suit the image enlargement factors specified in

Table 2). The distance between the focal spot and the pinhole is based on the nominal size of the focal spot being measured and

the desired degree of image enlargement (see Fig. 5). The specified focal spot to pinhole distance (FHD) for the different nominal

focal spot size ranges is provided in Table 2. Position the pinhole such that it is within 61° of the central axis of the X-ray beam.

Fig. 6 illustrates a typical focal spot exposure arrangement.

NOTE 3—The accuracy of the pinhole system is highly dependent upon the relative distances between (and alignment of) the focal spot, the pinhole,

and the film.Accordingly, specially designed apparatus may be necessary in order to assure compliance with the above requirements. Fig. 7 provides an

example of a special collimator that can be used to ensure conformance with the 61° alignment tolerance. Some other standards impose very stringent

alignment requirements and express these requirements in terms of radial tolerances. These documents do not, however, address any means for assuring

compliance with such tolerances. In order to simplify the focal spot radiography technique and to improve the overall practicality of the procedure, it

is considered that a workable alignment tolerance, and a means of assuring conformance with that tolerance, is appropriate. Accordingly, this standard

addresses tolerances in angular terms and provides a method for assuring compliance with these tolerances. This provides a practical means of meeting

the precision and bias requirements of Section 9.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

FIG. 1 Pinhole Diaphragm Design

E1165–04 (2010)

FIG. 2 Actual/Effective Focal Spot

NOTE 1—During the production of X-rays the electrons are accelerated from the filament to the target in two separate paths (see Sketch 1). Electrons

emitted at the front of the filament travel primarily along PathA, and electrons emitted at the backside of the filament travel primarily along Path B. Note

that these two paths intersect at a certain point; this is the point at which the target is positioned.As a result, the pinhole picture of the focal spot shows

two lines that correspond with the intersections of Paths A and B at the target (see Sketch 2).

FIG. 3 Line Focal Spot

6.2 Position the film as illustrated in Fig. 6. The exposure identification appearing on the film (by radiographic imaging) should

be X-ray machine identity (that is, make and serial number), organization making the radiograph, and date of exposure.

6.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.