ASTM E2119-00

(Practice)Standard Practice for Quality Systems for Conducting In Situ Measurements of Lead Content in Paint or Other Coatings Using Field-Portable X-Ray Fluorescence (XRF) Devices (Withdrawn 2009)

Standard Practice for Quality Systems for Conducting In Situ Measurements of Lead Content in Paint or Other Coatings Using Field-Portable X-Ray Fluorescence (XRF) Devices (Withdrawn 2009)

SCOPE

1.1 This practice covers the collection and documentation of quality control (QC) measurements for determining acceptable levels of instrumental performance when using field-portable energy-dispersive x-ray fluorescence spectrometry devices (XRFs) for the purposes of generating lead classification results from measurements on paint and other coating films within buildings and related structures.

1.2 QC procedures covered in this provisional practice include the performance of calibration checks, substrate bias checks, and specific instructions for documenting the collected data for later use in reporting the results.

1.3 No detailed operating instructions are provided because of differences among the various makes and models of suitable instruments. Instead, the analyst is to follow the instructions provided by the manufacturer of the particular XRF device or other relevant sources of information on XRF operation.

1.4 This practice contains notes which are explanatory and are not part of the mandatory requirements of this provisional practice.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covers the collection and documentation of quality control (QC) measurements for determining acceptable levels of instrumental performance when using field-portable energy-dispersive x-ray fluorescence spectrometry devices (XRFs) for the purposes of generating lead classification results from measurements on paint and other coating films within buildings and related structures.

Formerly under the jurisdiction of Committee E06 on Performance of Buildings, this practice was withdrawn in January 2009 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 2119 – 00

Standard Practice for

Quality Systems for Conducting In Situ Measurements of

Lead Content in Paint or Other Coatings Using Field-

Portable X-Ray Fluorescence (XRF) Devices

This standard is issued under the fixed designation E 2119; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1605 Terminology Relating to Abatement of Hazards

from Lead-Based Paint in Buildings and Related Struc-

1.1 Thispracticecoversthecollectionanddocumentationof

tures

quality control (QC) measurements for determining acceptable

E 1613 Test Method for Analysis of Digested Samples for

levels of instrumental performance when using field-portable

Lead by Inductively Coupled Plasm Atomic Emissions

energy-dispersive x-ray fluorescence spectrometry devices

Spectrometry (ICP-AES), Flame Atomic Absorption

(XRFs) for the purposes of generating lead classification

(FAAS), or Graphite Furnace Atomic Absorption (GFA

results from measurements on paint and other coating films

AS) Techniques

within buildings and related structures.

E 1645 Practice for Preparation of Dried Paint Samples for

1.2 QC procedures covered in this provisional practice

Subsequent Lead Analysis by Atomic Spectrometry

include the performance of calibration checks, substrate bias

E 1729 Practice for Field Collection of Dried Paint Samples

checks, and specific instructions for documenting the collected

for Lead Determination by Atomic Spectrometry Tech-

data for later use in reporting the results.

niques

1.3 No detailed operating instructions are provided because

2.2 Other Document:

of differences among the various makes and models of suitable

Guidelines for the Evaluation and Control of Lead-Based

instruments. Instead, the analyst is to follow the instructions

Paint Hazards in Housing

provided by the manufacturer of the particular XRF device or

other relevant sources of information on XRF operation.

3. Terminology

1.4 This practice contains notes which are explanatory and

3.1 Definitions—For definition of terms not presented be-

are not part of the mandatory requirements of this provisional

low, refer to Terminology E 1605.

practice.

3.2 Definitions of Terms Specific to This Standard:

1.5 The values stated in SI units are to be regarded as the

3.2.1 building component, n—part or element of a building

standard.

that is made of an industry product that is manufactured as an

1.6 This standard does not purport to address all of the

independent unit and is capable of being joined with other

safety concerns, if any, associated with its use. It is the

elements. Examples include doors, walls, baseboard and exte-

responsibility of the user of this standard to establish appro-

rior siding.

priate safety and health practices and determine the applica-

3.2.2 calibration check, n—a procedure that generates a QC

bility of regulatory limitations prior to use.

measurement using a calibration test sample with one type of

2. Referenced Documents control block (usually wood).

3.2.3 calibration mode, n—a selected operating mode that

2.1 ASTM Standards:

permits adjustment of an instrument’s calibration.

E 1583 Practice for Evaluating Laboratories Engaged in the

3.2.4 calibration test sample, n—a test film sample of a

Determination of Lead in Paint, Dust, Airborne Particu-

known lead level in mg/cm , which must have a reported

lates,andSoilinAroundBuildingsandRelatedStructures

uncertainty of the lead level. Calibration test samples may be

separate from a substrate or adhered to a substrate. All

ThispracticeisunderthejurisdictionofASTMCommitteeE-6onPerformance

of Buildings and is the direct responsibility of Subcommittee E06.23 onAbatement

of Hazards from Lead in Buildings and Related Structures.

Current edition approved Nov. 10, 2000. Published March 2001. Originally Annual Book of ASTM Standards, Vol 04.11.

published as PS 95 – 98. Last previous edition PS 95 – 98. Available from the U.S. Department of Housing and Urban Development,

Discontinued 1998. See 1997 Annual Book of ASTM Standards, Vol 04.11. Washington, DC 20410, www.hud.gov/lea.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2119–00

calibration test samples shall be traceable to the National cause ionization of atoms in the sample, and subsequently a

Institute of Standards and Technology (NIST) standard refer- cascade of higher energy electrons into the vacated lower

ence materials and have a known specified uncertainty in the

energy shells. As these electrons fall into the lower energy

known lead level. orbitals, X rays characteristic of the atomic species, such as

3.2.5 continuing calibration check, n—a calibration check lead, are emitted from the test location.

performed during the testing day after the initial calibration

3.2.18 read time—a period of X ray data collection time. It

check. A continuing calibration check also can serve as a final

may be controlled manually or automatically depending on the

calibration check.

XRF instrument model. It begins with the opening of the XRF

3.2.6 control block, n—a small block of material of an

instrument shutter to expose the paint film surface to source

identifiable substrate type used to simulate a building material

gamma rays and X rays and ends when the source shutter is

during QC measurements.

closed and the XRF reading is complete.

3.2.7 display unit, n—an electronic device that presents the

3.2.19 sampling site—a local geographical area that con-

results of an XRF measurement to the user. Other parameters

tains at least one unit being tested.Asampling site generally is

such as total measurement time also may be presented.

limited to an area that is easily covered by walking.

3.2.8 final calibration check, n—the last calibration check

3.2.20 substrate, n—thebuildingmaterialthatliesunderthe

performed in a testing period.

coating.

3.2.9 inconclusive lead classification result, n—a lead clas-

3.2.21 substrate bias check (SBC), n—a procedure that

sification result that reliably cannot be expressed, for example,

generates a QC measurement using a calibration test sample

reported, as either containing lead (positive) or not containing

and a control block to determine the effect of that substrate on

lead (negative) at or above an appropriate local, state, or

the XRF measurement.

federal action level for lead in coatings. Such results com-

3.2.22 substrate-corrected XRF measurements—a proce-

monly are referred to and reported as “inconclusive” results,

dure that corrects an XRF measurement for substrate effects

for example, the XRF measurement that cannot determine

(see the HUD Guidelines for more information on substrate

whether lead is or is not present at or above an appropriate

local, state, or federal action level for lead in coatings. corrections).

3.2.10 initial calibration check, n—the first calibration

3.2.23 substrate type, n—the type of building material that

check of the testing period performed after the XRF instrument

lies under the coating. Examples include wood, plaster, gyp-

has been turned on and allowed to warm up.

sum wallboard, metal, brick, and concrete.

3.2.11 lead classification result, n—an XRF measurement

3.2.24 test location, n—an area on a building component

expressed,forexample,aseitherpositive-for-lead,ornegative-

where a lead measurement value is obtained.

for-lead, at or above and appropriate local, state, or federal

3.2.25 testing period, n—a block of time that defines the

actionlevelforleadincoatings.Anegative-for-leadresultdoes

continuous power-on operation of an XRF instrument. Any

not mean there is no lead present. For some makes and models

power-down of an XRF instrument terminates the testing

ofXRFinstruments,leadmeasurementvaluesobtainednearan

period.

appropriate local, state or federal action level for lead in

3.2.26 unit, n—all or a portion of a structure or facility that

coatings may generate inconclusive lead classification results.

isthetargetofaninvestigation.Testlocationsareconsideredto

3.2.12 nominal read time, n—a read time that results when

be within a unit. An example of a unit is a single family

the radioactive source normally provided by the manufacturer

dwelling including a detached garage that is part of the

for that XRF instrument is at its original source strength.

property.

3.2.13 operating mode, n—one or more settings that define

3.2.27 x-ray detector, n—a device that results in an elec-

the operating parameters of an XRF instrument. Some XRF

tronic signal as a result of the interception of an x-ray.

instruments have multiple settings for use under different

Examples include gas proportional counters, for example, Xe,

testing situations, for example, substrates, time or testing

solid scintillation counters, for example, CsI, and semiconduc-

objectives.

tor devices of elemental composition, for example, Si or Ge, or

3.2.14 power-down, n—an event where the power to the

compound composition, for example, HgI , CdTe, or CdZnTe.

XRF instrument is turned off. The XRF instrument can not

3.2.28 XRF instrument, n—a field-portable XRF device or

collect and display any XRF measurements after a power-

analyzer with associated equipment designed and manufac-

down.

tured for use in measuring lead in paint or other coating films.

3.2.15 power-on, n—an event where the power to the XRF

XRF instruments, at minimum, include an excitation source,

instrument from the battery is turned on. The XRF instrument

such as a radioactive source, x-ray detector, probe, and a

can collect and display any XRF measurements after a power-

display unit.

on.

3.2.16 probe, n—a hand-held device containing a radioac- 3.2.29 XRFmeasurement,n—aprocedureusedtodetermine

tive source, x-ray detector and associated mechanical and

the lead content of a coating at a test location using an XRF

electronic components that is placed against a test location or instrument, or a lead result, expressed as mg of lead per cm of

calibration test sample to obtain an XRF measurement.

surface, that is, mg/cm , obtained from a coating at a test

3.2.17 radioactive source, n—a radioactive material (for location using an XRF instrument.An XRF measurement may

57 109

example, Co or Cd) that emits X rays or gamma rays that be one reading or the average of one or more XRF readings.

E2119–00

A

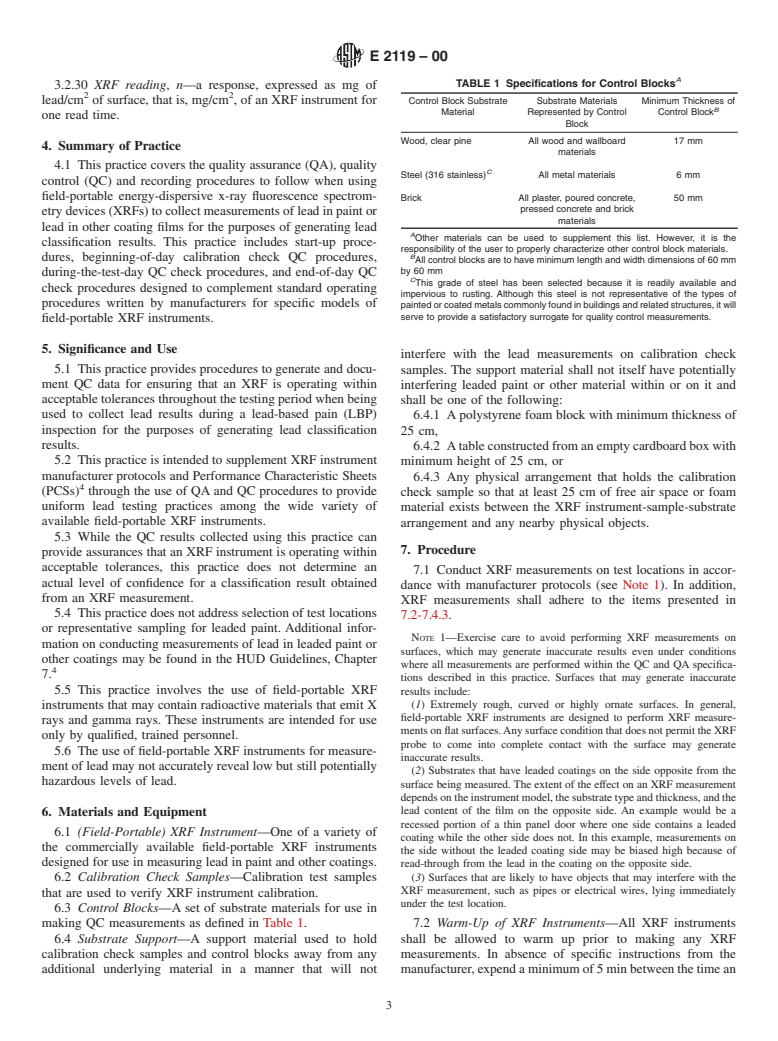

TABLE 1 Specifications for Control Blocks

3.2.30 XRF reading, n—a response, expressed as mg of

2 2

lead/cm of surface, that is, mg/cm , of an XRF instrument for Control Block Substrate Substrate Materials Minimum Thickness of

B

Material Represented by Control Control Block

one read time.

Block

Wood, clear pine All wood and wallboard 17 mm

4. Summary of Practice

materials

4.1 This practice covers the quality assurance (QA), quality

C

Steel (316 stainless) All metal materials 6 mm

control (QC) and recording procedures to follow when using

field-portable energy-dispersive x-ray fluorescence spectrom-

Brick All plaster, poured concrete, 50 mm

pressed concrete and brick

etry devices (XRFs) to collect measurements of lead in paint or

materials

lead in other coating films for the purposes of generating lead

A

Other materials can be used to supplement this list. However, it is the

classification results. This practice includes start-up proce-

responsibility of the user to properly characterize other control block materials.

B

dures, beginning-of-day calibration check QC procedures,

All control blocks are to have minimum length and width dimensions of 60 mm

by 60 mm

during-the-test-day QC check procedures, and end-of-day QC

C

This grade of steel has been selected because it is readily available and

check procedures designed to complement standard operating

impervious to rusting. Although this steel is not representative of the types of

procedures written by manufacturers for specific models of

paintedorcoatedmetalscommonlyfoundinbuildingsandrelatedstructures,itwill

serve to provide a satisfactory surrogate for quality control measurements.

field-portable XRF instruments.

5. Significance and Use

interfere with the lead measurements on calibration check

5.1 This practice provides procedures to generate and docu-

samples. The support material shall not itself have potentially

ment QC data for ensuring that an XRF is operating within

interfering leaded paint or other material within or on it and

acceptable tolerances throughout the testing period when being

shall be one of the following:

used to collect lead results during a lead-based pain (LBP)

6.4.1 Apolystyrene foam block with minimum thickness of

inspection for the purposes of generating lead classification

25 cm,

results.

6.4.2 Atableconstructedfromanemptycardboardboxwith

5.2 This practice is intended to supplement XRF instrument

minimum height of 25 cm, or

manufacturer protocols and Performance Characteristic Sheets 6.4.3 Any physical arrangement that holds the calibration

(PCSs) through the use of QA and QC procedures to provide

check sample so that at least 25 cm of free air space or foam

uniform lead testing practices among the wide variety of material exists between the XRF instrument-sample-substrate

available field-portable XRF instruments.

arrangement and any nearby physical objects.

5.3 While the QC results collected using this practice can

7. Procedure

provide assurances that an XRF instrument is operating within

acceptable tolerances, this practice does not determine an

7.1 Conduct XRF measurements on test locations in accor-

actual level of confidence for a classification result obtained

dance with manufacturer protocols (see Note 1). In addition,

from an XRF measurement.

XRF measurements shall adhere to the items presented in

5.4 This practice does not address selection of test locations

7.2-7.4.3.

or representative sampling for leaded paint. Additional infor-

NOTE 1—Exercise care to avoid performing XRF measurements on

mation on conducting measurements of lead in leaded paint or

surfaces, which may generate inaccurate results even under conditions

other coatings may be found in the HUD Guidelines, Chapter

where all measurements are performed within the QC and QA specifica-

7.

tions described in this practice. Surfaces that may generate inaccurate

5.5 This practice involves the use of field-portable XRF

results include:

(1) Extremely rough, curved or highly ornate surfaces. In general,

instruments that may contain radioactive materials that emit X

field-portable XRF instruments are designed to perform XRF measure-

rays and gamma rays. These i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.