EN 9102:2024

(Main)Aerospace series - Quality systems - First article inspection requirements

Aerospace series - Quality systems - First article inspection requirements

1.1 General

This document establishes the requirements for performing and documenting FAI. It is emphasized the requirements specified in this document are complementary (not alternative) to customer and applicable statutory and regulatory requirements.

1.2 Purpose

The primary purpose of FAI is to verify and validate product realization processes are capable of producing characteristics that meet engineering and design requirements. A well-planned and executed FAI by a multi-disciplinary team (e.g. members from responsible functions) provides objective evidence the manufacturer’s processes can produce compliant product; having effectively understood and incorporated the associated requirements.

NOTE A FAI is not a product acceptance document. While interrelated, FAI and product acceptance are separate activities. The focus of FAI is verification of production processes via assessment of product. FAI and supporting documentation do not provide assurance regarding conformance for product acceptance purposes; neither does the lack of a FAI necessarily imply product is nonconforming to engineering and design requirements.

FAI will:

- provide confidence, through objective evidence, the product realization processes are capable of producing conforming product;

- demonstrate the manufacturers and processors of the product have an understanding of the associated requirements;

- provide assurance of product conformance at the start of production and after changes, as outlined in this document.

A FAI is intended to:

- mitigate risks associated with production startup and process changes;

- reduce future escapes;

- help ensure product safety;

- improve quality, delivery, and customer satisfaction;

- reduce costs and production delays associated with product nonconformances;

- identify product realization processes not capable of producing conforming characteristics and initiate and/or validate associated corrective actions.

-

1.3 Application

This document applies to organizations and their suppliers responsible for product realization processes that produce the design characteristics of the product. The organization shall flow down the requirements of this document to suppliers who produce design characteristics.

This document also applies to suppliers performing special process(es). A certificate of conformance (CoC) provided by processors attests to satisfying the requirements. External suppliers providing special process(es) can satisfy this document's requirements by either:

- documenting the design characteristics and associated results on a first article inspection report (FAIR); or

- documenting the design characteristics and associated results on a detailed CoC.

This document applies to assemblies, sub-assemblies, and detail parts including castings, forgings, and modifications to standard catalogue or commercial-off-the-shelf (COTS) items. Each of these items have a separate FAI.

Unless contractually required, this document does not apply to:

- development and prototype parts that are not considered as part of the first production run;

- procured standard catalogue item, COTS, or deliverable software. When these items are included in an assembly, they shall be documented in the index of part numbers in an assembly FAIR.

1.4 Informative

If there is a conflict between the requirements of this document, and customer or applicable statutory/regulatory requirements, the latter takes precedence.

In this document, the following verbal forms are used:

- "shall" indicates a requirement;

- "should" indicates a recommendation;

- "may" indicates a permission;

- "can" indicates a possibility or a capability.

Information marked as "NOTE" is for guidance in understanding or clarifying the associated requirement .

Luft- und Raumfahrt - Qualitätsmanagementsysteme - Anforderungen an die Erstmusterprüfung

Série aérospatiale - Systèmes qualité - Exigences pour la revue premier article

1.1 Généralités

Le présent document établit les exigences pour réaliser et documenter la FAI. Il est à souligner que les exigences spécifiées dans le présent document viennent compléter (sans les remplacer) les exigences du client et les exigences légales et réglementaires applicables.

1.2 Objet

L'objet principal de la FAI est de vérifier et de valider que les procédés de réalisation du produit sont à même de produire des caractéristiques qui satisfont aux exigences d'ingénierie et de conception. Une FAI bien planifiée et effectuée par une équipe pluridisciplinaire (par exemple : dont les membres occupent des fonctions à responsabilité) apporte les preuves objectives que les procédés du fabricant permettent de produire des produits conformes, pour autant que les exigences associées aient été bien comprises et incluses à la FAI.

NOTE Une FAI n'est pas un document d'acceptation d'un produit. Si elles sont interdépendantes, la FAI et l'acceptation d'un produit sont toutefois des activités distinctes. L’objectif de la FAI est de vérifier les procédés de production via l'évaluation du produit. La FAI et la documentation associée ne fournissent aucune garantie quant à la conformité en vue de l'acceptation d'un produit. L'absence de FAI n'implique pas que le produit n'est pas conforme aux exigences d'ingénierie et de conception.

La FAI :

- donne confiance, grâce aux preuves objectives, dans la capacité des procédés de réalisation du produit à fournir un produit conforme ;

- démontre que les fabricants et les transformateurs du produit comprennent les exigences associées ;

- garantit la conformité du produit au début de la production et après les changements, comme décrit dans le présent document.

Une FAI est destinée à :

- réduire les risques associés au lancement de la production et aux modifications de procédé ;

- réduire les futures dérives ;

- garantir la sécurité du produit ;

- améliorer la qualité, la livraison et la satisfaction client ;

- réduire les coûts et les délais de production associés aux non-conformités du produit ;

- identifier les procédés de réalisation du produit ne permettant pas de produire des caractéristiques conformes, et lancer et/ou valider les actions correctives associées.

1.3 Application

Le présent document s'applique aux organismes et à leurs fournisseurs responsables des procédés de réalisation du produit qui élaborent les caractéristiques de conception du produit. L'organisme doit transmettre les exigences du présent document aux fournisseurs qui élaborent les caractéristiques de conception.

Le présent document s’applique également aux fournisseurs en charge d’un ou plusieurs procédés spéciaux. Un certificat de conformité (CC) fourni par les transformateurs atteste que les exigences sont satisfaites. Les fournisseurs externes chargés d’un ou plusieurs procédés spéciaux peuvent satisfaire aux exigences du présent document :

- en documentant les caractéristiques de conception et les résultats associés dans un rapport de revue premier article (FAIR) ; ou

- en documentant les caractéristiques de conception et les résultats associés dans un CC détaillé.

Le présent document s'applique aux ensembles, aux sous-ensembles et aux pièces élémentaires, y compris aux pièces forgées ou moulées et aux modifications des articles catalogue standards ou des produits sur étagère (COTS). Chacun de ces articles dispose d’une FAI distincte.

Sauf exigence contractuelle, le présent document ne s'applique pas :

- aux pièces prototypes et de développement qui ne sont pas considérées comme faisant partie de la première production de série ;

- aux articles catalogue standards, aux COTS ou aux logiciels livrables achetés. Lorsque ces articles sont inclus dans un ensemble, ils doivent être documentés dans l'index des références articles d'un FAIR de l’ensemble.

[...]

Aeronavtika - Sistem vodenja kakovosti - Zahteve za prvi pregled vzorcev

1.1 Ta dokument postavlja zahteve za izvedbo in dokumentiranje za prvi pregled vzorcev (FAI). Poudariti je treba, da zahteve iz tega standarda dopolnjujejo (niso alternativna možnost) zahteve odjemalcev in ustrezne zakonske ter regulativne zahteve.

V primeru neskladnosti med zahtevami iz tega dokumenta in zahtevami odjemalcev ali ustreznimi zakonskimi ali regulativnimi zahtevami, imajo prednost ustrezne zakonske ali regulativne zahteve.

V tem dokumentu so uporabljene naslednje glagolske oblike:

– »treba je« ali »mora« označuje zahtevo;

– »naj« označuje priporočilo;

– »sme« označuje dovoljenje;

– »lahko« označuje možnost ali sposobnost.

Informacije, označene kot »OPOMBA«, so namenjene usmerjanju pri razumevanju ali pojasnjevanju pripadajoče zahteve.

1.2 Namen

Primarni namen prvega pregleda vzorcev je preveriti in potrditi, da procesi realizacije izdelka omogočajo ustvarjanje lastnosti, ki izpolnjujejo zahteve inženiringa in projektiranja. Prvi pregled vzorcev ni dokument o sprejemljivosti proizvoda. Dobro načrtovan in izveden prvi pregled vzorcev, ki ga izvede večdisciplinarna skupina (npr. člani z odgovornih funkcij), zagotovi objektivne dokaze, da proizvajalčevi procesi lahko proizvedejo skladen izdelek ob razumevanju in upoštevanju povezanih zahtev.

OPOMBA: Čeprav sta med seboj povezani, sta prvi pregled vzorcev in sprejemljivost izdelka ločeni dejavnosti. Prvi pregled vzorcev se osredotoča na preverjanje proizvodnih procesov z ocenjevanjem izdelka. Prvi pregled vzorcev in spremni dokumenti ne dajejo zagotovila glede skladnosti za namene sprejemljivosti izdelka; prav tako odsotnost prvega pregleda vzorcev ne pomeni nujno, da je izdelek neskladen z inženirskimi in projektantskimi zahtevami.

Prvi pregled vzorcev bo:

– zagotovil zaupanje, da procesi realizacije izdelka omogočajo proizvodnjo skladnega izdelka;

– pokazal, da proizvajalci in obdelovalci izdelka razumejo z izdelkom povezane zahteve;

– zagotovil objektivne dokaze o zmožnosti procesa;

– zmanjšal tveganja, povezana z začetkom proizvodnje in/ali spremembami procesa;

– zagotovil skladnost izdelka ob začetku proizvodnje in po spremembah, opredeljenih v tem dokumentu.

Prvi pregled vzorcev je namenjen:

– zmanjšanju prihodnjih napak, tveganj in skupnih stroškov;

– v pomoč pri zagotavljanju varnosti izdelka;

– izboljšanju kakovosti, dobave in zadovoljstva strank;

– zmanjšanju stroškov in zastojev proizvodnje, povezanih z neskladnostjo izdelka;

– ugotavljanju procesov realizacije izdelka, ki ne omogočajo proizvodnje skladnega izdelka, in sprejemanju in/ali potrjevanju povezanih korektivnih ukrepov.

1.3 Uporaba

Ta dokument se uporablja za organizacije in podrejene entitete, ki so odgovorne za proizvodnjo projektnih lastnosti izdelka (tj. za realizacijo izdelka). Organizacija bo zahteve tega dokumenta posredovala dobaviteljem, ki proizvajajo konstrukcijske lastnosti.

Ta dokument se uporablja za zunanje dobavitelje, ki izvajajo posebne procese. Potrdilo o skladnosti, ki ga zagotovijo obdelovalci, dokazuje skladnost z zahtevami specifikacij pristojnega organa za projektiranje. Zunanji dobavitelji, ki zagotavljajo posebne procese, lahko izpolnijo zahteve iz tega dokumenta:

– z dokumentiranjem konstrukcijskih lastnosti in povezanih rezultatov pri prvem pregledu vzorcev;

– z dokumentiranjem konstrukcijskih lastnosti in povezanih rezultatov na potrdilu o skladnosti, ki ga določi stranka.

Ta dokument se uporablja za sestave, podsestave in posamezne dele, vključno z ulitki, izkovki, in spremembami izdelkov iz kataloga dokumenta ali standardnih izdelkov (COTS). Za vsakega od teh elementov je treba izvesti ločen prvi pregled vzorcev.

Če ni pogodbeno dogovorjeno drugače, se ta dokument ne uporablja za:

– razvijanje delov in prototipov, ki ne spadajo v prvo proizvodno serijo;

– izdelke, dobavljene iz standardnega kataloga, standardne izdelke ali dobavljivo programsko opremo. Te elemente je treba dokumentirati v kazalu številk delov pri pripravi poročila o prv

General Information

- Status

- Published

- Publication Date

- 12-Mar-2024

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 6/S 1 - EAQG European Aerospace Quality Group

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 13-Mar-2024

- Completion Date

- 13-Mar-2024

Relations

- Effective Date

- 19-Jan-2023

Overview

EN 9102:2024 - "Aerospace series - Quality systems - First article inspection requirements" (CEN) specifies requirements for planning, performing and documenting First Article Inspection (FAI). Approved March 2024 and superseding EN 9102:2015, the standard clarifies how manufacturers and suppliers demonstrate that product realization processes can produce parts that meet engineering and design requirements. EN 9102:2024 emphasizes FAI planning, evaluation, re-accomplishment and alignment with EN 9100, and it reinforces that FAI requirements are complementary to customer and statutory/regulatory requirements.

Key topics and requirements

- Purpose of FAI: Verify and validate that production processes produce characteristics conforming to engineering/digital product definition (DPD) and design requirements.

- Scope & application: Applies to assemblies, sub‑assemblies and detail parts (castings, forgings, modified COTS). Each item requires a separate FAI unless contractually excluded (e.g., certain prototypes or off‑the‑shelf items documented in an assembly index).

- FAI execution: Requires a planned, multidisciplinary approach to provide objective evidence of process capability. A FAI is a verification of processes via product assessment - not a product acceptance certificate.

- Documentation: Use of First Article Inspection Report (FAIR) forms and retained documented information, with options for external processors to use a detailed Certificate of Conformance (CoC) for special processes.

- Digital product definition (DPD): Recognizes digital drawings and 3D models as part of the design baseline; DPD characteristics must be included in the FAI.

- Nonconformance & re-accomplishment: Defines evaluation activities, nonconformance handling and when partial or full re-accomplishment of FAI is required.

- Terminology & normative references: Uses ISO 9000 vocabulary and IAQG definitions; conventions for “shall/should/may/can” are specified.

Practical applications

- Use EN 9102:2024 to establish or improve a standardized FAI process across aerospace supply chains.

- Employ FAIRs to demonstrate process readiness at production start or after design/process changes.

- Suppliers performing special processes can either submit FAIRs or detailed CoCs to satisfy requirements.

- Integrate with quality management systems (e.g., EN 9100/ISO 9001) to reduce escapes, lower rework costs, and improve product safety and delivery.

Who should use this standard

- Aerospace manufacturers, OEMs and tiered suppliers responsible for product realization.

- Quality, engineering, inspection, and procurement teams planning FAIs.

- External processors and special‑process providers needing to demonstrate conformance via FAIR or CoC.

Related standards

- EN 9100 (aerospace quality management) - alignment noted in EN 9102:2024

- ISO 9000 - normative reference for quality vocabulary

- IAQG Internal Dictionary - terminology used by the industry

Keywords: EN 9102:2024, First Article Inspection (FAI), FAIR, DPD, aerospace quality, certificate of conformance, EN 9100, product realization.

Frequently Asked Questions

EN 9102:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Quality systems - First article inspection requirements". This standard covers: 1.1 General This document establishes the requirements for performing and documenting FAI. It is emphasized the requirements specified in this document are complementary (not alternative) to customer and applicable statutory and regulatory requirements. 1.2 Purpose The primary purpose of FAI is to verify and validate product realization processes are capable of producing characteristics that meet engineering and design requirements. A well-planned and executed FAI by a multi-disciplinary team (e.g. members from responsible functions) provides objective evidence the manufacturer’s processes can produce compliant product; having effectively understood and incorporated the associated requirements. NOTE A FAI is not a product acceptance document. While interrelated, FAI and product acceptance are separate activities. The focus of FAI is verification of production processes via assessment of product. FAI and supporting documentation do not provide assurance regarding conformance for product acceptance purposes; neither does the lack of a FAI necessarily imply product is nonconforming to engineering and design requirements. FAI will: - provide confidence, through objective evidence, the product realization processes are capable of producing conforming product; - demonstrate the manufacturers and processors of the product have an understanding of the associated requirements; - provide assurance of product conformance at the start of production and after changes, as outlined in this document. A FAI is intended to: - mitigate risks associated with production startup and process changes; - reduce future escapes; - help ensure product safety; - improve quality, delivery, and customer satisfaction; - reduce costs and production delays associated with product nonconformances; - identify product realization processes not capable of producing conforming characteristics and initiate and/or validate associated corrective actions. - 1.3 Application This document applies to organizations and their suppliers responsible for product realization processes that produce the design characteristics of the product. The organization shall flow down the requirements of this document to suppliers who produce design characteristics. This document also applies to suppliers performing special process(es). A certificate of conformance (CoC) provided by processors attests to satisfying the requirements. External suppliers providing special process(es) can satisfy this document's requirements by either: - documenting the design characteristics and associated results on a first article inspection report (FAIR); or - documenting the design characteristics and associated results on a detailed CoC. This document applies to assemblies, sub-assemblies, and detail parts including castings, forgings, and modifications to standard catalogue or commercial-off-the-shelf (COTS) items. Each of these items have a separate FAI. Unless contractually required, this document does not apply to: - development and prototype parts that are not considered as part of the first production run; - procured standard catalogue item, COTS, or deliverable software. When these items are included in an assembly, they shall be documented in the index of part numbers in an assembly FAIR. 1.4 Informative If there is a conflict between the requirements of this document, and customer or applicable statutory/regulatory requirements, the latter takes precedence. In this document, the following verbal forms are used: - "shall" indicates a requirement; - "should" indicates a recommendation; - "may" indicates a permission; - "can" indicates a possibility or a capability. Information marked as "NOTE" is for guidance in understanding or clarifying the associated requirement .

1.1 General This document establishes the requirements for performing and documenting FAI. It is emphasized the requirements specified in this document are complementary (not alternative) to customer and applicable statutory and regulatory requirements. 1.2 Purpose The primary purpose of FAI is to verify and validate product realization processes are capable of producing characteristics that meet engineering and design requirements. A well-planned and executed FAI by a multi-disciplinary team (e.g. members from responsible functions) provides objective evidence the manufacturer’s processes can produce compliant product; having effectively understood and incorporated the associated requirements. NOTE A FAI is not a product acceptance document. While interrelated, FAI and product acceptance are separate activities. The focus of FAI is verification of production processes via assessment of product. FAI and supporting documentation do not provide assurance regarding conformance for product acceptance purposes; neither does the lack of a FAI necessarily imply product is nonconforming to engineering and design requirements. FAI will: - provide confidence, through objective evidence, the product realization processes are capable of producing conforming product; - demonstrate the manufacturers and processors of the product have an understanding of the associated requirements; - provide assurance of product conformance at the start of production and after changes, as outlined in this document. A FAI is intended to: - mitigate risks associated with production startup and process changes; - reduce future escapes; - help ensure product safety; - improve quality, delivery, and customer satisfaction; - reduce costs and production delays associated with product nonconformances; - identify product realization processes not capable of producing conforming characteristics and initiate and/or validate associated corrective actions. - 1.3 Application This document applies to organizations and their suppliers responsible for product realization processes that produce the design characteristics of the product. The organization shall flow down the requirements of this document to suppliers who produce design characteristics. This document also applies to suppliers performing special process(es). A certificate of conformance (CoC) provided by processors attests to satisfying the requirements. External suppliers providing special process(es) can satisfy this document's requirements by either: - documenting the design characteristics and associated results on a first article inspection report (FAIR); or - documenting the design characteristics and associated results on a detailed CoC. This document applies to assemblies, sub-assemblies, and detail parts including castings, forgings, and modifications to standard catalogue or commercial-off-the-shelf (COTS) items. Each of these items have a separate FAI. Unless contractually required, this document does not apply to: - development and prototype parts that are not considered as part of the first production run; - procured standard catalogue item, COTS, or deliverable software. When these items are included in an assembly, they shall be documented in the index of part numbers in an assembly FAIR. 1.4 Informative If there is a conflict between the requirements of this document, and customer or applicable statutory/regulatory requirements, the latter takes precedence. In this document, the following verbal forms are used: - "shall" indicates a requirement; - "should" indicates a recommendation; - "may" indicates a permission; - "can" indicates a possibility or a capability. Information marked as "NOTE" is for guidance in understanding or clarifying the associated requirement .

EN 9102:2024 is classified under the following ICS (International Classification for Standards) categories: 03.120.10 - Quality management and quality assurance; 49.020 - Aircraft and space vehicles in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 9102:2024 has the following relationships with other standards: It is inter standard links to EN 9102:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 9102:2024 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2024

Aeronavtika - Sistem vodenja kakovosti - Zahteve za prvi pregled vzorcev

Aerospace series - Quality systems - First Article Inspection Requirement

Luft- und Raumfahrt - Qualitätsmanagementsysteme - Anforderungen an die

Erstmusterprüfung

Série aérospatiale - Systèmes qualité - Exigences pour la revue premier article

Ta slovenski standard je istoveten z: EN 9102:2024

ICS:

03.120.10 Vodenje in zagotavljanje Quality management and

kakovosti quality assurance

49.020 Letala in vesoljska vozila na Aircraft and space vehicles in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 9102

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2024

EUROPÄISCHE NORM

ICS 03.120.10; 49.020 Supersedes EN 9102:2015

English Version

Aerospace series - Quality systems - First article inspection

requirements

Série aérospatiale - Systèmes qualité - Exigences pour Luft- und Raumfahrt - Qualitätsmanagementsysteme -

la revue premier article Anforderungen an die Erstmusterprüfung

This European Standard was approved by CEN on 29 January 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 9102:2024 E

worldwide for CEN national Members.

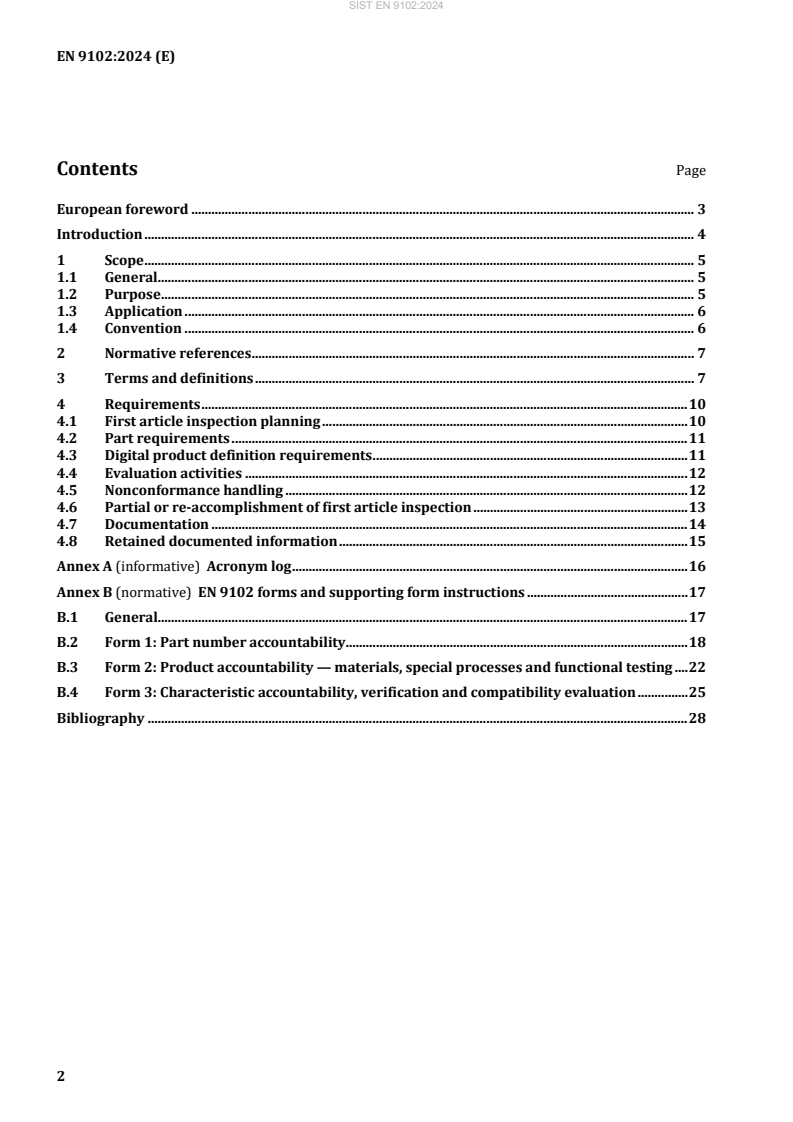

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

1.1 General. 5

1.2 Purpose . 5

1.3 Application . 6

1.4 Convention . 6

2 Normative references . 7

3 Terms and definitions . 7

4 Requirements . 10

4.1 First article inspection planning . 10

4.2 Part requirements . 11

4.3 Digital product definition requirements . 11

4.4 Evaluation activities . 12

4.5 Nonconformance handling . 12

4.6 Partial or re-accomplishment of first article inspection . 13

4.7 Documentation . 14

4.8 Retained documented information . 15

Annex A (informative) Acronym log . 16

Annex B (normative) EN 9102 forms and supporting form instructions . 17

B.1 General. 17

B.2 Form 1: Part number accountability . 18

B.3 Form 2: Product accountability — materials, special processes and functional testing . 22

B.4 Form 3: Characteristic accountability, verification and compatibility evaluation . 25

Bibliography . 28

European foreword

This document (EN 9102:2024) has been prepared by ASD-STAN.

After enquiries and votes carried out in accordance with the rules of this Association, this document has

received the approval of the National Associations and the Official Services of the member countries of

ASD-STAN, prior to its presentation to CEN.

This document shall be given the status of a national standard, either by publication of an identical text

or by endorsement, at the latest by September 2024, and conflicting national standards shall be

withdrawn at the latest by September 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 9102:2015.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this document: Austria, Belgium, Bulgaria, Croatia, Cyprus,

Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document was revised to emphasize and enhance the first article inspection (FAI) planning,

evaluation, and re-accomplishment activities; aligning requirements to EN 9100. Additional changes to

the document requirements, definitions, and associated notes were incorporated in response to

stakeholder needs.

To ensure customer satisfaction, the aviation, space, and defence industry organizations must produce

and continually improve safe, reliable products that meet or exceed customer and regulatory

requirements. The globalization of the industry and the resulting diversity of regional/national

requirements and expectations have complicated this objective. End product organizations face the

challenge of assuring the quality and integration of products purchased from suppliers throughout the

world and at all levels of the supply chain. Industry suppliers face the challenge of delivering products

to multiple customers having varying quality requirements and expectations.

The aviation, space, and defence industry established the International Aerospace Quality Group (IAQG)

for the purpose of achieving significant improvements in quality, delivery, safety, and reductions in cost

throughout the value stream. This organization includes representation from companies in the

Americas, Asia/Pacific, and Europe.

This document standardizes FAI process requirements to the greatest extent possible. While primarily

developed for the aviation, space, and defence industry, this document can also be used in other

industry sectors where a standardized FAI process is needed.

1 Scope

1.1 General

This document establishes the requirements for performing and documenting FAI. It is emphasized the

requirements specified in this document are complementary (not alternative) to customer and

applicable statutory and regulatory requirements.

1.2 Purpose

The primary purpose of FAI is to verify and validate product realization processes are capable of

producing characteristics that meet engineering and design requirements. A well-planned and executed

FAI by a multi-disciplinary team (e.g. members from responsible functions) provides objective evidence

the manufacturer’s processes can produce compliant product; having effectively understood and

incorporated the associated requirements.

NOTE A FAI is not a product acceptance document. While interrelated, FAI and product acceptance are separate

activities. The focus of FAI is verification of production processes via assessment of product. FAI and supporting

documentation do not provide assurance regarding conformance for product acceptance purposes; neither does

the lack of a FAI necessarily imply product is nonconforming to engineering and design requirements.

FAI will:

— provide confidence, through objective evidence, the product realization processes are capable of

producing conforming product;

— demonstrate the manufacturers and processors of the product have an understanding of the

associated requirements;

— provide assurance of product conformance at the start of production and after changes, as outlined

in this document.

A FAI is intended to:

— mitigate risks associated with production startup and process changes;

— reduce future escapes;

— help ensure product safety;

— improve quality, delivery, and customer satisfaction;

— reduce costs and production delays associated with product nonconformances;

— identify product realization processes not capable of producing conforming characteristics and

initiate and/or validate associated corrective actions.

1.3 Application

This document applies to organizations and their suppliers responsible for product realization

processes that produce the design characteristics of the product. The organization shall flow down the

requirements of this document to suppliers who produce design characteristics.

This document also applies to suppliers performing special process(es). A certificate of conformance

(CoC) provided by processors attests to satisfying the requirements. External suppliers providing

special process(es) can satisfy this document's requirements by either:

— documenting the design characteristics and associated results on a first article inspection report

(FAIR); or

— documenting the design characteristics and associated results on a detailed CoC.

This document applies to assemblies, sub-assemblies, and detail parts including castings, forgings, and

modifications to standard catalogue or commercial-off-the-shelf (COTS) items. Each of these items have

a separate FAI.

Unless contractually required, this document does not apply to:

— development and prototype parts that are not considered as part of the first production run;

— procured standard catalogue item, COTS, or deliverable software. When these items are included in

an assembly, they shall be documented in the index of part numbers in an assembly FAIR.

1.4 Convention

If there is a conflict between the requirements of this document, and customer or applicable

statutory/regulatory requirements, the latter takes precedence.

In this document, the following verbal forms are used:

— “shall” indicates a requirement;

— “should” indicates a recommendation;

— “may” indicates a permission;

— “can” indicates a possibility or a capability.

Information marked as “NOTE” is for guidance in understanding or clarifying the associated

requirement .

Notes to entry used in definitions, however, are considered normative and will provide additional information

that supplements the terminological data such as statements, instructions, recommendations, or requirements

relating to the use of a term.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 9000, Quality management systems — Fundamentals and vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 9000, the IAQG Internal

Dictionary and the following apply.

An acronym log for this document is presented in Annex A.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

assembly

product that is produced by joining two or more detail parts, COTS, standard catalogue items, or sub-

assemblies into one item

3.2

attribute data

result from a characteristic or property that is appraised only as to whether it does or does not conform

to a given requirement

3.3

ballooned design characteristic

clear and uniquely identified design characteristic indicated on a ballooned document

Note 1 to entry: the unique identifier may be circled or highlighted for easy visual identification.

3.4

ballooned document

aid used in FAI to identify all the design characteristics, including all documents [e.g., drawings,

purchase order, digital product definition (DPD)]; typically sequentially numbering the design

characteristics and putting a circle around or highlighting the numbered design characteristics

3.5

baseline part number

part number from the previous FAI or approved configuration, including revision level, to which a

partial FAI is performed

Note 1 to entry: an example of an approved configuration is a part produced and verified as conforming product

prior to the requirements of this document.

Published by: ISO International Organization for Standardization http://www.iso.ch/.

Located on the IAQG website: https://iaqg.org/tools/dictionary/.

3.6

commercial-off-the-shelf (COTS) item

commercially available item intended by design to be procured and utilized without modification (e.g.,

common electronic components)

Note 1 to entry: any item or assembly meeting all of the following requirements:

a) defined by industry, manufacturer, military, or recognized specifications or standards;

b) without design modification, specifically for a customer;

c) customarily used by the public or industries; and

d) offered for sale to the public, though catalogues, price list, brochures, stores, or websites.

3.7

deliverable software

embedded or loadable airborne, spaceborne, or ground support software or firmware components

which are part of an aircraft type design, weapon system, missile, or spacecraft

3.8

design characteristic

dimensional, visual, functional, mechanical, and material features or properties, which describe and

constitute the design of the product

Note 1 to entry: these characteristics can be measured, inspected, tested, or verified to determine conformance to

the design requirements as specified on the parts list, purchasing document, drawing, or DPD, to which the

product is to be produced:

— dimensional design characteristics include in-process locating features (e.g. additive manufacturing, target-

machined or forged/cast dimensions on forgings and castings, weld/braze joint preparation necessary for

acceptance of finished joint);

— material design characteristics include processing output variable (e.g. plating or coating thickness/runout,

material hardness/conductivity). These provide assurance of intended characteristics that could not be

otherwise defined.

3.9

designed tooling

product specific tooling [e.g. check fixtures, coordinate measurement machine (CMM) program]

specifically made to validate the design characteristics of a product

3.10

detail part

article/part produced to engineering definition that does not include assembly processes (i.e. processes

that join two or more parts together)

Note 1 to entry: detail parts may include processing, finishes, and/or special processes.

3.11

digital product definition

DPD

digital data file(s) that disclose, directly or by reference, the physical or functional requirements,

including data files that disclose the design or acceptance criteria of a product

Note 1 to entry: examples of DPD include the following:

— digital data file(s) and fully dimensioned two-dimensional (2D) drawing sheets;

— three-dimensional (3D) data model, and simplified or reduced content 2D drawing sheets;

— 3D data model with design characteristics displayed as text;

— any other data files containing design characteristics that define a product in its entirety.

3.12

first article inspection

FAI

planned, complete, independent, and documented inspection and verification process to ensure that

prescribed production processes have produced an item conforming to engineering drawings, DPD,

planning, purchase order, engineering specifications, and/or other applicable design documents

Note 1 to entry: the intent of independent as referenced above is to mitigate the effect of measurement error.

This includes ensuring the person that verifies the characteristic for the first article not be the same person that

generated the characteristic. Self-inspection (i.e. operator self-verification) is not considered independent. The

equipment used to verify the characteristic should be different from the equipment used to produce the

characteristic.

3.13

first article inspection report

FAIR

comprised of the forms identified in Annex B, all ballooned design characteristics, and the supporting

documentation determined by FAI planning for a part number (e.g., detail, sub-assembly, or assembly)

3.14

first production run

initial group of one or more parts that are the result of a planned process designed to be used for

production of these same parts

3.15

modified commercial-off-the-shelf (COTS)/standard catalogue item

COTS or standard catalogue item that has a change made to it from its original designed configuration

Note 1 to entry: Once modified, these items are categorized as detail parts for the purpose of assembly.

3.16

multiple characteristics

identical characteristics that occur at more than one location (e.g. “4 places”), but are identified by a

single set of drawing or DPD requirements (e.g. rivet hole size, dovetail slots, corner radii, chemical

milling pocket thickness)

3.17

product

any intended output resulting from the product realization process, which in the context of this

document includes finished detail parts, sub-assemblies, assemblies, forgings, and castings

3.18

qualified tooling

universal (not part specific) calibrated monitoring and measuring equipment (e.g. go/no go gauges,

thread gauges, radius gauges) used to validate product design characteristics using attribute data

3.19

reference characteristic

characteristic (including reference and basic dimensions) that are used for “information only” or to

show relationship; these are dimensions without tolerances and refer to other dimensions on the

drawing or in the DPD

3.20

special process

any process for production and service provision where the resulting output cannot be verified by

subsequent monitoring or measurement and, as a consequence, deficiencies become apparent only after

the product is in use or the service has been delivered

3.21

standard catalogue item

part or material that conforms to an established industry or national authority published specification,

having all characteristics identified by written description or an industry/national/military standard

drawing

3.22

variable data

quantitative measurements taken on a continuous scale (e.g. the diameter of a cylinder, the gap

between mating parts)

4 Requirements

4.1 First article inspection planning

a. The organization shall have a documented process to plan for FAI. This process shall identify the

responsible functions and address the activities to be performed, prior to the first production run.

b. The organization shall verify the revision for embedded or deliverable software as defined by the

bill of materials (BOM), drawing/DPD, specification, or purchase order requirements.

c. The organization shall consider the following activities during FAI planning and, if required by

contract, coordinate planning with the customer:

1. determine design characteristic inspection and sequencing for inspection of characteristics not

measurable in the final product and provisions to carry out those activities at the appropriate

stage of the manufacturing process;

2. evaluate DPD design characteristics required for product realization which are not fully

defined on 2D drawings, including tolerances for nominal dimensions;

3. determine the required objective evidence to be included in the FAIR for each design

characteristic, including supporting documentation;

NOTE This includes bubbled or ballooned document(s), and can also include certifications, inspection

reports, test reports, manufacturing plans, purchase orders, etc.

4. identify the approved special process, laboratory, material, and customer required sources, as

applicable, and confirm the manufacturing planning, routing, and purchase document identify

the correct specification and relevant sources;

5. identify key characteristic and critical item requirements, as applicable (see IAQG standards

EN 9100 and EN 9103 for supporting guidance/direction);

6. determine suitable monitoring and measuring equipment of appropriate resolution and

accuracy. Ensure part specific gauges and tooling are identified, qualified, and traceable.

Metrology principles (e.g. accuracy ratio, measurement uncertainty) should be taken into

consideration when selecting a measurement method;

7. coordinate customer FAI review(s) at any stage;

8. identify events requiring an updated FAI (see subclause 4.6).

d. The organization shall verify FAI planning activities have been completed.

4.2 Part requirements

a. The organization shall perform a FAI on new product representative of the first production run.

The first production product delivery requires a FAI.

b. The organization shall use one or more representative items from the first production run of a new

product to verify that the production processes, production documentation, and tooling have the

ability to produce products that meet established requirements.

c. For assemblies, the assembly level FAI shall be performed on those characteristics specified on the

assembly drawing or DPD.

d. Detail part characteristics created or modified during assembly may be accounted for at the

assembly level FAI, all other detail part characteristics shall be accounted for on the detail part FAI.

4.3 Digital product definition requirements

a. When design requirements are in a DPD format and traditional 2D drawing information is not

available for all applicable design requirements, DPD design characteristics required for product

realization shall be extracted, verified, and included in the FAIR.

b. The organization shall:

1. establish a process to extract the applicable DPD design characteristics;

2. extract the DPD design characteristics required for product realization;

3. ensure the production, inspection, and operations requiring verification have been completed

as planned to achieve DPD design characteristics.

NOTE For additional information on DPD, refer to ASME Y14.41 and/or ISO 16792.

4.4 Evaluation activities

The organization shall conduct the following activities during product realization in support of FAI to

ensure conformance with design characteristics:

a. review the manufacturing process documentation (e.g. routing sheets, risk analysis, manufacturing

or quality plans, manufacturing work instructions) to ensure all operations are complete as

planned and call out the correct specification, material types, conditions, and approvals;

b. review supporting documentation for completeness;

c. verify the raw material and special process certifications (e.g. CoC, special process completion

certification, raw material test report number, modified standard catalogue item compliance report

number, traceability number) call out the correct specification, material types, conditions, and

approvals;

d. verify that required customer approved sources are utilized (e.g. directed source, approved

suppliers list);

e. review nonconformance documentation for completeness;

f. verify that required designed tooling (e.g. part specific gauges) is used;

g. verify that every design characteristic requirement, including DPD characteristics as required per

4.3b, is accounted for, uniquely identified, and has inspection results traceable to each unique

identifier (e.g. ballooned design characteristic);

h. verify the design characteristics resulting from the output of the manufacturing process are

measured, inspected, tested, or verified to determine conformance, including DPD characteristics as

required per 4.3b.;

i. verify part marking has met defined requirements, such as legibility (i.e. human/machine

readable), method, material, content, size, and location.

4.5 Nonconformance handling

a. When processing a FAIR with documented nonconformances, the organization shall:

1. record the nonconfor

...

SIST EN 9102:2024는 항공우주 산업에서 요구되는 품질 시스템 및 최초 제품 검사(FAI) 요구 사항을 규정하는 중요한 문서입니다. 이 표준의 범위는 FAI 수행과 문서화에 관한 요구 사항을 명확히 하며, 고객 및 해당 법적 또는 규제 요건과 상호 보완적인 관계로 설정되어 있습니다. 이 문서의 강점 중 하나는 FAI의 목적이 명확하게 정의되어 있다는 점입니다. FAI는 제품 실현 과정이 엔지니어링 및 설계 요건을 충족하는 특성을 생산할 수 있는지를 검증하고 유효성을 확인하는 데 초점을 맞추고 있습니다. 다학제 팀이 잘 계획하고 실행한 FAI는 제조 과정이 준수하는 제품을 생산할 수 있다는 객관적인 증거를 제공합니다. 이러한 객관성을 통해 발생할 수 있는 위험을 완화하고, 품질, 납기, 고객 만족도를 향상시키며, 향후 결함 발생을 감소시킬 수 있는 기회를 제공합니다. 또한, 이 표준은 제조업체와 프로세서가 관련 요구 사항을 충분히 이해하고 있음을 보여주는 역할도 합니다. 생산 시작 시 및 변경 사항 발생 후 제품의 적합성을 보장하는 데 중점을 두어, 기업이 품질 관리 체계를 강화할 수 있는 기반을 제공합니다. SIST EN 9102:2024는 제품 설계 특성을 생산하는 조직과 그 공급업체에 적용되며, 각기 다른 경우의 FAI가 필요하다는 점이 강조됩니다. 이 표준은 조립품, 하위 조립품, 주조 및 단조품을 포함한 세부 부품에 광범위하게 적용되어, 복잡한 제품 설계의 품질 관리 체계를 체계적으로 지원합니다. 전체적으로 SIST EN 9102:2024는 품질 시스템 확보 및 최초 제품 검사와 관련된 과정을 표준화하고, 항공우주 산업의 규정을 준수하게 하며, 제조업체가 더 높은 품질의 제품을 설계하고 생산할 수 있도록 돕는 중요한 문서입니다. 이는 항공우주 산업에서 제품 안전성을 높이고 비즈니스 프로세스의 효율성을 증대시키는 데 기여합니다.

EN 9102:2024は、航空宇宙産業における品質システムのための第一記事検査(FAI)要件を定めた重要な標準であり、その内容は非常に包括的です。この文書は、製品実現プロセスがエンジニアリングおよび設計要件を満たす特性を生産できることを検証・確認するための要件を確立しています。特に、顧客や適用される法令・規制の要件に補完的であることが強調されており、深い関連性を持っています。 この標準の強みは、FAIプロセスの計画と実行に対する明確なガイダンスを提供する点にあります。多様な専門家からなるチームによる計画的なFAIは、製造プロセスが適合した製品を生産する能力を客観的な証拠で示すことができます。これにより、製造業者は関連する要件を効果的に理解し、組み込む必要性が理解されます。 FAIの目的は、リスクを軽減し、将来の不具合の発生を防ぎ、製品の安全性を確保することにあります。さらに、品質、納期、顧客満足度の向上、コスト削減にも寄与し、製品の適合性を確認するための重要な手段となります。この文書に従い、FAIは製品の生産開始や変更後における適合性の保証を提供します。 また、EN 9102:2024は、製品の設計特性を生産するプロセスを担当する組織やそのサプライヤーに適用される点も重要です。サプライヤーへの適切な要件の流通が求められるため、品質管理の全体的な向上が期待できます。特に、特別プロセスを行うサプライヤーに対する要求も含まれており、これにより外部供給者が標準をどのように満たすかの柔軟性も提供されています。 この文書は、組み立て品やサブアセンブリ、詳細部品などに明確に適用され、それぞれのアイテムに対して別々のFAIが必要とされることで、実践的な適応性も示しています。特に、契約上の要件がなければ開発・試作部品には適用されないという明確なガイダンスも、適切な適用範囲を定義しており、効率的な運用が可能です。 結果として、EN 9102:2024は、航空宇宙産業での製品品質を向上させるための有力な基準となっており、その適用は製品の信頼性と安全性を確保する上で不可欠です。この標準は、現代の厳しい製品要件に対して非常に関連性が高く、必要不可欠なフレームワークを提供しています。

EN 9102:2024 establishes a comprehensive framework for Quality Systems in the aerospace sector, focusing specifically on First Article Inspection (FAI) requirements. The document delineates clear guidelines for performing and documenting FAI, which serves as a vital process to verify that product realization processes can consistently yield products meeting engineering and design specifications. One of the standard's key strengths is its emphasis on the complementary nature of FAI in relation to customer and statutory requirements, ensuring that this process enriches compliance rather than acting as a substitute. The clarity in defining FAI as a verification tool, distinct from product acceptance, allows organizations to implement robust quality assurance mechanisms without confusion. The scope of the standard is notably extensive, applying to organizations and their suppliers involved in the product realization processes for various components, including assemblies, sub-assemblies, and detail parts. This inclusivity ensures that all relevant entities can effectively respond to the requirements laid out in EN 9102:2024. The requirement for external suppliers to document design characteristics through First Article Inspection Reports (FAIR) or Certificates of Conformance (CoC) reinforces the standard's commitment to traceability and accountability. Moreover, the potential for FAI to mitigate risks associated with production setups and process changes highlights its relevance in enhancing product safety and quality. This proactive approach can lead to significant reductions in production costs, delays, and nonconformances, ultimately driving customer satisfaction. The focus on evidence-based assessment facilitates a culture of continuous improvement across the manufacturing spectrum. Overall, EN 9102:2024 plays a crucial role in the aerospace industry's quality management landscape by providing a structured approach to First Article Inspection that enhances compliance, safety, and manufacturing efficiency. Its detailed requirements empower organizations to adopt best practices in quality assurance while adapting to evolving regulatory landscapes.

Die Norm EN 9102:2024 stellt einen wesentlichen Bestandteil in der Luft- und Raumfahrtindustrie dar, da sie die Anforderungen für die Durchführung und Dokumentation der Erstartikelprüfung (FAI) festlegt. Sie bietet eine umfassende Grundlage, um sicherzustellen, dass die Realisationsprozesse von Produkten in der Lage sind, Merkmale zu erzeugen, die den technischen und entwicklungseitigen Anforderungen entsprechen. Die Stärken dieser Norm liegen vor allem in ihrer Fähigkeit, objektive Nachweise zu liefern, die belegen, dass die Herstellungsprozesse konform sind, und dass die Hersteller die damit verbundenen Anforderungen gekonnt verstanden und integriert haben. Ein weiterer wichtiger Aspekt dieser Norm ist die Risikominderung, die sie bei Produktionsstarts und Prozessänderungen bietet. Durch die Minimierung zukünftiger Abweichungen trägt die FAI dazu bei, die Produktqualität und -sicherheit zu gewährleisten, was letztlich die Kundenzufriedenheit erhöht. Darüber hinaus unterstützt die Norm Unternehmen dabei, Kosten und Produktionsverzögerungen zu reduzieren, die mit Produktabweichungen verbunden sein können, indem sie nicht konforme Produktionsprozesse identifiziert und erforderliche Korrekturmaßnahmen einleitet oder validiert. Die Anwendbarkeit dieser Norm erstreckt sich nicht nur auf Organisationen, sondern auch auf deren Lieferanten, die für die Realisation von Produktmerkmalen verantwortlich sind. Dies zeigt die Relevanz von EN 9102:2024, da sie sicherstellt, dass die Anforderungen bis zu den Zulieferern durchgereicht werden, um Konsistenz und Qualität in der gesamten Lieferkette zu fördern. Außerdem verlangt die Norm von externen Lieferanten, besondere Prozesse dokumentiert darzustellen, sei es in Form eines Erstartikelprüfberichts oder eines detaillierten Konformitätszertifikats (CoC). Trotz ihrer umfassenden Anforderungen bleibt die Norm klar und prägnant, indem sie Aussagen wie "shall", "should", "may" und "can" verwendet, um die jeweiligen Verbindlichkeiten und Empfehlungen deutlich zu kennzeichnen. Dies erleichtert das Verständnis der Anforderungen und fördert die korrekte Implementierung. Zusammengefasst stellt die EN 9102:2024 eine grundlegende Norm dar, die die Luft- und Raumfahrtindustrie in ihren Bemühungen um Qualitätssicherung und Risiko-Management unterstützt. Ihre umfassenden und klar definierten Anforderungen sind unverzichtbar für die Gewährleistung der Konformität und die Steigerung der Effizienz innerhalb der Produktionsprozesse.

La norme EN 9102:2024, intitulée "Série aéronautique - Systèmes de qualité - Exigences de l'inspection du premier article", établit des exigences essentielles pour la réalisation et la documentation de l'inspection du premier article (FAI). Cette norme offre des directives claires qui complètent les exigences des clients ainsi que celles légales et réglementaires, soulignant son caractère complémentaire plutôt qu'alternatif. L'une des forces majeures de cette norme réside dans son objectif principal, qui est de vérifier et valider les processus de réalisation des produits afin de garantir qu'ils peuvent produire des caractéristiques conformes aux exigences d'ingénierie et de conception. L'engagement d'une équipe pluridisciplinaire dans la réalisation du FAI apporte une preuve objective que les processus du fabricant sont en mesure de produire un produit conforme, démontrant ainsi une compréhension approfondie des exigences associées. La norme EN 9102:2024 est particulièrement pertinente pour réduire les risques liés au démarrage de la production et aux changements de processus. Elle vise à réduire les non-conformités futures, à améliorer la sécurité des produits, la qualité, la livraison et la satisfaction client. Les bénéfices économiques sont également évidents, avec une réduction des coûts et des retards de production associés aux non-conformités. Applicables aux organisations et à leurs fournisseurs impliqués dans les processus de réalisation de produits, les exigences de cette norme s'étendent notamment à la documentation des caractéristiques de conception et des résultats dans un rapport d'inspection de premier article (FAIR) ou dans un certificat de conformité (CoC). Par ailleurs, EN 9102:2024 précise que chaque élément assemblé doit faire l'objet d'un FAI distinct, garantissant ainsi une approche rigoureuse et systématique. Une autre force importante de cette norme est son approche à la gestion des conflits potentiels entre ses exigences et celles des clients ou des exigences réglementaires. En précisant que les exigences des clients et celles légales prennent priorité, elle assure une flexibilité et une adaptabilité nécessaires dans un environnement complexe. En somme, la norme EN 9102:2024 constitue un cadre robuste pour l'inspection du premier article, jouant un rôle crucial dans l'assurance qualité au sein de l'industrie aéronautique, tout en soulignant l'importance d'une documentation rigoureuse pour la conformité des produits. L'approche méthodique proposée par la norme favorise une meilleure organisation des processus de production et promet une amélioration continue des pratiques de qualité.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...