EN 13675:2004+A1:2010

(Main)Safety of machinery - Safety requirements for tube forming and rolling mills and their finishing line equipment

Safety of machinery - Safety requirements for tube forming and rolling mills and their finishing line equipment

This European Standard describes the health and safety requirements of fully automated plant used in the process of tube forming, rolling and finishing (hereafter referred to as "plant"). It describes the foreseeable, significant hazards, hazardous situations, and events arising from plants and from particular machines integrated to form the plant; it does not describe the full health and safety requirements for each particular machine. It indicates preventive measures for avoiding the hazards and reducing the risks. It deals not only with circumstances where the machinery is used as intended, but also includes other conditions foreseen by the manufacturer, such as foreseeable faults, malfunctions or misuse.

This European Standard specifies the requirements to ensure the safety of persons which are to be met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment.

This standard assumes that installations are operated and maintained by adequately trained and competent personnel. Manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of these machines.

This standard assumes that the machinery is used with adequate workplace lighting conforming to

EN 12464-1 or to local regulations.

This standard applies to:

Automated plant and equipment operated for the production of metal seamless hot and cold finished tubes and welded tubes. A list of machines which could make up different plants is shown in Annex D (informative).

This standard covers:

For seamless hot-finished tubes: from material charging downstream of the heating furnace through the rolling process and up to, but not including any intermediate storage equipment or the downstream finishing lines.

For seamless cold-finished tubes: from material charging through the rolling process to the discharging equipment but not including any storage equipment.

For welded tubes: from coil charging through strip pr

Sicherheit von Maschinen - Sicherheitsanforderungen an Rohrform- und -walzwerke und ihre Adjustageanlagen

Dieses Dokument beschreibt die allgemeinen Sicherheitsanforderungen an automatisierte Anlagen für die

Herstellung von geformten und gewalzten Rohren und deren Adjustage (im nachfolgenden Text „Anlagen“

genannt). Es beschreibt vorhersehbare, signifikante Gefährdungen, Gefährdungssituationen und -ereignisse

für Anlagen und für Einzelmaschinen, aus denen die Anlage besteht. Es beschreibt nicht alle Gesundheitsund

Sicherheitsanforderungen an jede einzelne Maschine. Es zeigt vorbeugende Maßnahmen zur

Vermeidung der Gefährdungen und Reduzierung der Risiken auf. Es behandelt nicht nur die Gegebenheiten,

bei denen die Maschine bestimmungsgemäß genutzt wird, sondern beinhaltet auch andere Bedingungen, die

der Hersteller in Betracht gezogen hat, wie vorhersehbare Fehler, Fehlfunktionen oder fehlerhafte Nutzung.

Dieses Dokument spezifiziert die Anforderungen, die erfüllt werden müssen, um die Sicherheit von Personen

während der Konstruktion, des Baus, des Transports, der Inbetriebnahme, des Betriebs, der Instandhaltung

und der Außerbetriebnahme sicherzustellen.

Dieses Dokument geht davon aus, dass die Anlagen von entsprechend geschultem und fachkundigem

Personal bedient und gewartet werden. Das manuelle Eingreifen zum Einrichten, Einstellen und zur Wartung

wird als Teil des normalen Einsatzes dieser Maschinen akzeptiert.

Dieses Dokument geht davon aus, dass die Maschinen bei entsprechender Arbeitsplatzbeleuchtung nach

!EN 12464-1" oder gemäß lokalen Bestimmungen genutzt werden.

Dieses Dokument gilt für:

Automatisierte Anlagen und Ausrüstungen zur Herstellung von warm- und kaltgewalzten Nahtlosrohren sowie

geschweißten Rohren. Eine Liste von Maschinen mit denen verschiedene Anlagen zusammengesetzt werden

können, ist in Anhang D (informativ) aufgeführt.

Dieses Dokument umfasst:

Sécurité des machines - Prescriptions de sécurité pour formeuses et laminoirs à tubes et leurs lignes de parachèvement

La présente Norme européenne spécifie les prescriptions d’hygiène et de sécurité générales pour les équipements automatisés utilisés pour les formeuses et les laminoirs à tubes ainsi que les ligne de parachèvement (ci-après dénommés «équipements»). Elle décrit les phénomènes, situations et événements dangereux prévisibles et significatifs pour ces installations y compris les machines particulières intégrées à celles-ci. Elle indique les mesures préventives possibles pour éliminer les phénomènes dangereux et réduire les risques. Elle ne prend pas seulement en compte les conditions liées à l'usage prévu de la machine, elle inclut aussi celles prévues par le fabricant comme les défauts, les dysfonctionnements ou les mauvais usages prévisibles.

La présente Norme européenne spécifie les prescriptions à satisfaire pour garantir la sécurité des personnes pendant la conception, la construction, le transport, la mise en service, le fonctionnement, la maintenance et la mise hors service de l’équipement.

La présente norme suppose que l'exploitation et la maintenance des installations soient réalisées par un personnel compétent et formé de façon adaptée. L’intervention manuelle pour l’installation, le réglage et la maintenance est considéré comme faisant partie de l’usage normal de ces machines.

Cette norme suppose que les installations sont utilisées avec un éclairage adéquat des postes de travail conforme à l’!EN 12464-1" ou à la réglementation locale.

Cette norme s'applique aux :

Installations et équipements automatiques destinés à la production de tubes en métal non soudés laminés à chaud et à froid et de tubes soudés. Une liste de machines pour installations différentes est présentée en Annexe D (informative).

Varnost strojev - Varnostne zahteve za cevarne, valjarne in opremo za pakiranje blaga

Ta evropski standard opisuje zdravstvene in varnostne zahteve za popolnoma avtomatiziran obrat, ki se uporablja v procesih cevarn, valjarn in pakiranja blaga (v nadaljevanju »obrat«). Opisuje predvidljive pomembne nevarnosti, nevarne situacije in dogodke, ki izhajajo iz obratov ter posameznih strojev, ki so del obrata; ne opisuje popolnih zdravstvenih in varnostnih zahtev za vsak posamezen stroj. Navaja preventivne ukrepe za preprečevanje nevarnosti in zmanjševanje tveganj. Obravnava ne le okoliščine, v katerih se stroji uporabljajo kot predvideno, pač pa vključuje tudi druge pogoje, ki jih predvidi proizvajalec, na primer predvidene napake, okvare ali napačno uporabo. Ta evropski standard določa zahteve za zagotavljanje varnosti oseb, ki so vključene v načrtovanje, sestavljanje, prevoz, usposobitev za zagon, delovanje, vzdrževanje in izločitev opreme iz uporabe. Ta standard predvideva, da inštalacije upravlja in vzdržuje primerno usposobljeno in pristojno osebje. Ročni posegi v nastavitve, prilagoditve in vzdrževanje so sprejemljivi kot del normalne uporabe teh strojev.

General Information

- Status

- Published

- Publication Date

- 06-Apr-2010

- Withdrawal Date

- 30-Oct-2010

- Drafting Committee

- CEN/TC 322/WG 3 - Rolling mills and finishing line equipment

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2017

- Completion Date

- 02-Dec-2017

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 30-Jan-2010

- Effective Date

- 30-Jan-2010

Overview

EN 13675:2004+A1:2010 is a CEN type‑C European standard specifying health and safety requirements for fully automated tube forming and rolling mills and their finishing line equipment. It covers foreseeable, significant hazards and indicates preventive measures to avoid hazards and reduce risks throughout the equipment lifecycle: design, assembly, transport, commissioning, operation, maintenance and decommissioning. The standard assumes use by adequately trained personnel and specifies lighting requirements (EN 12464‑1 or local regulations). It applies to automated plants producing seamless hot‑ and cold‑finished tubes and welded tubes, and to tube finishing lines - while excluding items such as furnaces, quenching, storage equipment and certain specialised welding and testing machines.

Key topics and technical requirements

- Risk identification and reduction: Lists significant hazards, hazardous situations and events; prioritises prevention and risk‑reduction measures consistent with EN ISO 12100 principles.

- Machine and plant safety measures: General design requirements, guards, interlocks, emergency stop design and protective devices tailored to tube forming and rolling mills.

- Control systems and electrical safety: Normative provisions for electrical equipment and control systems (see Annex A) aligned with EN 60204‑1 and EN ISO 13849‑1 for safety‑related control parts.

- Ergonomics and human factors: Requirements for operator interfaces, access and maintenance tasks (referencing EN 614‑1/2, EN 894 series).

- Noise reduction: Noise considered a safety requirement with testing guidance in Annex B and references to EN ISO 4871, EN ISO 11202 and EN ISO 11688.

- Verification and information for use: Procedures for verification of safety measures, marking, warning devices and required documentation including maintenance manuals and manufacturer’s instructions.

- Scope boundaries and exclusions: Clearly defines where the standard applies within production flows and which equipment types are out of scope.

Applications and users

This standard is essential for:

- Manufacturers and OEMs designing tube forming, rolling and finishing plants

- System integrators assembling automated tube production lines

- Safety engineers and compliance officers performing risk assessments and CE‑marking work

- Plant operators and maintenance teams implementing safe operation and maintenance procedures

- Notified bodies and regulators assessing conformity with the Machinery Directive (see Annex ZA)

Related standards (selected)

- EN ISO 12100 (risk assessment principles)

- EN 60204‑1 (electrical equipment of machines)

- EN ISO 13849‑1 (safety‑related control systems)

- EN 12464‑1 (workplace lighting)

- EN ISO 4871 / EN ISO 11202 (noise)

Keywords: EN 13675, tube forming, rolling mills, finishing line equipment, safety of machinery, risk assessment, CEN standard, noise reduction, control systems, maintenance manual.

Frequently Asked Questions

EN 13675:2004+A1:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for tube forming and rolling mills and their finishing line equipment". This standard covers: This European Standard describes the health and safety requirements of fully automated plant used in the process of tube forming, rolling and finishing (hereafter referred to as "plant"). It describes the foreseeable, significant hazards, hazardous situations, and events arising from plants and from particular machines integrated to form the plant; it does not describe the full health and safety requirements for each particular machine. It indicates preventive measures for avoiding the hazards and reducing the risks. It deals not only with circumstances where the machinery is used as intended, but also includes other conditions foreseen by the manufacturer, such as foreseeable faults, malfunctions or misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This standard assumes that installations are operated and maintained by adequately trained and competent personnel. Manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of these machines. This standard assumes that the machinery is used with adequate workplace lighting conforming to EN 12464-1 or to local regulations. This standard applies to: Automated plant and equipment operated for the production of metal seamless hot and cold finished tubes and welded tubes. A list of machines which could make up different plants is shown in Annex D (informative). This standard covers: For seamless hot-finished tubes: from material charging downstream of the heating furnace through the rolling process and up to, but not including any intermediate storage equipment or the downstream finishing lines. For seamless cold-finished tubes: from material charging through the rolling process to the discharging equipment but not including any storage equipment. For welded tubes: from coil charging through strip pr

This European Standard describes the health and safety requirements of fully automated plant used in the process of tube forming, rolling and finishing (hereafter referred to as "plant"). It describes the foreseeable, significant hazards, hazardous situations, and events arising from plants and from particular machines integrated to form the plant; it does not describe the full health and safety requirements for each particular machine. It indicates preventive measures for avoiding the hazards and reducing the risks. It deals not only with circumstances where the machinery is used as intended, but also includes other conditions foreseen by the manufacturer, such as foreseeable faults, malfunctions or misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This standard assumes that installations are operated and maintained by adequately trained and competent personnel. Manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of these machines. This standard assumes that the machinery is used with adequate workplace lighting conforming to EN 12464-1 or to local regulations. This standard applies to: Automated plant and equipment operated for the production of metal seamless hot and cold finished tubes and welded tubes. A list of machines which could make up different plants is shown in Annex D (informative). This standard covers: For seamless hot-finished tubes: from material charging downstream of the heating furnace through the rolling process and up to, but not including any intermediate storage equipment or the downstream finishing lines. For seamless cold-finished tubes: from material charging through the rolling process to the discharging equipment but not including any storage equipment. For welded tubes: from coil charging through strip pr

EN 13675:2004+A1:2010 is classified under the following ICS (International Classification for Standards) categories: 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13675:2004+A1:2010 has the following relationships with other standards: It is inter standard links to EN 13675:2004/FprA1, EN 13675:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13675:2004+A1:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 13675:2004+A1:2010 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost strojev - Varnostne zahteve za cevarne, valjarne in opremo za pakiranje blagaSicherheit von Maschinen - Sicherheitsanforderungen an Rohrform- und -walzwerke und AdjustageanlagenSécurité des machines - Prescriptions de sécurité pour formeuses et laminoirs à tubes et de lignes de parachèvementSafety of machinery - Safety requirements for tube forming and rolling mills and their finishing line equipment77.180Oprema za metalurško industrijoEquipment for the metallurgical industry25.120.20Rolling, extruding and drawing equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 13675:2004+A1:2010SIST EN 13675:2004+A1:2010en,fr01-junij-2010SIST EN 13675:2004+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13675:2004+A1

April 2010 ICS 77.180 Supersedes EN 13675:2004English Version

Safety of machinery - Safety requirements for tube forming and rolling mills and their finishing line equipment

Sécurité des machines - Prescriptions de sécurité pour formeuses et laminoirs à tubes et de lignes de parachèvement

Sicherheit von Maschinen - Sicherheitsanforderungen an Rohrform- und -walzwerke und Adjustageanlagen This European Standard was approved by CEN on 1 April 2004 and includes Amendment 1 approved by CEN on 21 February 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13675:2004+A1:2010: ESIST EN 13675:2004+A1:2010

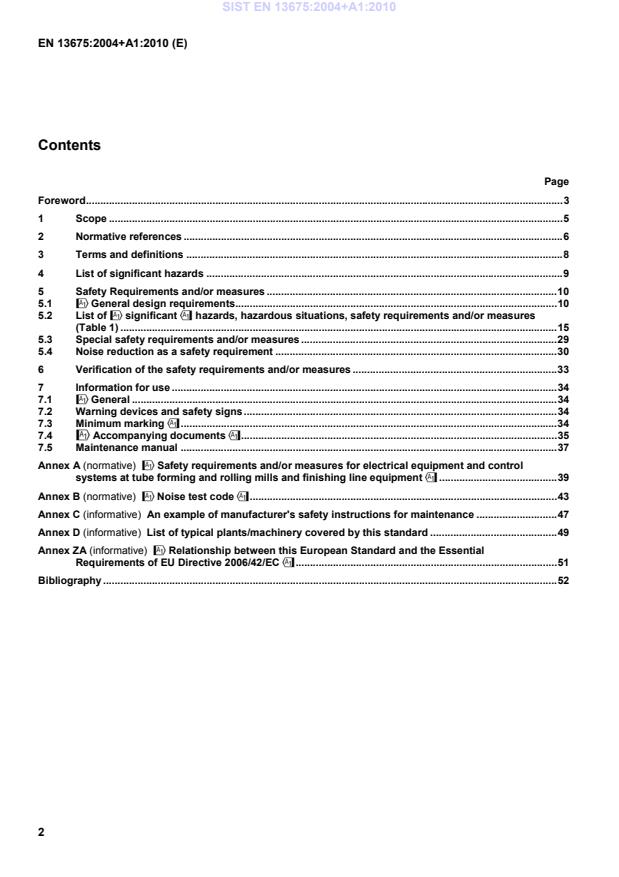

!Safety requirements and/or measures for electrical equipment and control systems at tube forming and rolling mills and finishing line equipment" . 39Annex B (normative)

!Noise test code" . 43Annex C (informative)

An example of manufacturer's safety instructions for maintenance . 47Annex D (informative)

List of typical plants/machinery covered by this standard . 49Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 51Bibliography . 52

Annexes C and D are informative. An assessment of the foreseeable risks arising from the use of the plant/machinery was carried out when this standard was drafted by CEN/TC 322/WG 3, comprising experts from the following countries: Denmark, Germany, Italy, Sweden and the United Kingdom. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

!EN 12464-1" or to local regulations. This standard applies to: Automated plant and equipment operated for the production of metal seamless hot and cold finished tubes and welded tubes. A list of machines which could make up different plants is shown in Annex D (informative). This standard covers: For seamless hot-finished tubes: from material charging downstream of the heating furnace through the rolling process and up to, but not including any intermediate storage equipment or the downstream finishing lines. For seamless cold-finished tubes: from material charging through the rolling process to the discharging equipment but not including any storage equipment. For welded tubes: from coil charging through strip preparation, forming and welding equipment up to, but not including any intermediate storage equipment or the downstream finishing lines. For the tube finishing line: from tube charging to the discharging equipment to the storage. The following items are outside the scope of this standard: complete risk assessment of single machines which are used to form a plant furnaces; quenching equipment; spiral tube manufacture; large diameter tube welding manufacture using three-roll bending machines, U-ing and O-ing press lines and their finishing lines; butt welding machinery for the manufacture of endless strips; irradiation units (material testing by e. g., ultrasonic and X-ray testing units); centrifugal casting machines; machine tools used for e. g., threading, chamfering, stamping and marking machines; SIST EN 13675:2004+A1:2010

Part 1: General principles for human interactions with displays and control actuators EN 894-2, Safety of machinery — Ergonomics requirements for the design of displays and control actuators —

Part 2: Displays EN 894-3, Safety of machinery — Ergonomics requirements for the design of displays and control actuators —

Part 3: Control actuators EN 953:1997, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards EN 981:1996, Safety of machinery — System of auditory and visual danger and information signals EN 982:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics EN 983:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Pneumatics EN 999:1998, Safety of machinery — The positioning of protective equipment in respect of approach speeds of parts of the human body SIST EN 13675:2004+A1:2010

(IEC 60825-1:2007) EN 61310-1, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual, acoustic and tactile signals (IEC 61310-1:2007) EN 61310-2, Safety of machinery — Indication, marking and actuation — Part 2: Requirements for marking

(IEC 61310-2:2007) EN 61496-1, Safety of machinery — Electro- sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) EN 60529:1991, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 7731:2005, Ergonomics — Danger signals for public and work areas — Auditory danger signals (ISO 7731:2003) EN ISO 9692-2, Welding and allied processes — Joint preparation — Part 2: Submerged arc welding of steels (ISO 9692-2:1998) EN ISO 11064-1, Ergonomic design of control centres — Part 1: Principles for the design of control centres

(ISO 11064-1:2000) EN ISO 11202, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Survey method in situ (ISO 11202:1995) SIST EN 13675:2004+A1:2010

control stand free standing control desk (usually situated adjacent to the machine or equipment) SIST EN 13675:2004+A1:2010

mandrels a) tools to form seamless tubes b) the centre on which the strips are coiled 3.5

custom-made equipment equipment made to the customers specification 3.6

large plant/equipment interconnected equipment (size > 15 m) in which several items of machinery or forming stages are linked by dedicated transport facilities (e. g., roller conveyors, cross-transfer systems). Excluded are overhead cranes, fork lifts, trucks and railway trucks and other vehicles 3.7

cobbling product/material leaving its intended path 3.8

competent person person with the knowledge of systems, background, experience and ability to operate and/or maintain the equipment in the way intended 3.9

unauthorized person person not permitted to enter certain areas, or to perform certain actions in relation with the operation and/or maintenance of the equipment, because not having the required specific knowledge and skill and for not being properly equipped in order to avoid the related hazards 3.10 automated operation access to a danger zone where automated processes take place shall be prevented, because there are dangerous movements, which cannot be influenced by the operator in a pulpit or at a control stand. Manual operations such as loading, unloading, maintenance or repairs are forbidden in the dangerous zone of the automatic operation 4 List of significant hazards An assessment of the hazards and risks arising from the use of machines which form a plant, and falling within the scope of this standard, was carried out when this standard was prepared. This risk identification then formed the basis for determining: a) potentially hazardous situations having significant risks; b) the safety requirements and/or measures which shall be incorporated into the machinery/equipment; c) any special instructions which shall be communicated to the user. The significant hazards and hazardous situations identified are listed in columns 1 and 2 of clause 5, Table 1. !Before using this European Standard it is important for the manufacturer to carry out a risk assessment of the machines which form a plant to identify any other relevant hazards (see EN ISO 14121-1)." SIST EN 13675:2004+A1:2010

Clause 5 and those set out in Clause 7 and Annex A and B. Relevant hazards identified in the risk assessment carried out by the manufacturer but not dealt with in this European Standard shall be reduced by applying the principle of EN ISO 12100-2. For hazards which are to be reduced by the application of a B standard such as e.g. EN ISO 13857, EN ISO 13850, EN ISO 13732-1 the risk assessment carried out by the manufacturer shall establish the requirements of the B standard which are to be applied. This specific risk assessment shall be part of the general risk assessment of the machine. Where the means of reducing the risk is by the physical arrangement or positioning of the installed machines, the manufacturer shall include in the Information for use a reference to these specific reduction means. Where the means of reducing the risk is by a safe system of working the plant, the manufacturer shall include in the information for use details of the system and of the elements of information required by the operating personnel. This shall include arrangements to run a machine for essential operating reasons or in special mode with safety devices suspended or temporarily modified. This clause specifies and explains the preventative measures given in Table 1 and it also describes additional safety features, procedures and techniques which shall be considered by the designer and the manufacturer of the equipment." 5.1.2 !Site inspection The manufacturer shall undertake sufficient site inspection to establish all requirements of the plant design for: a) accessibility; b) maintenance and clearance gaps for cleaning; c) movement of machinery and material; d) safe operation; e) health and safety at the workplace; f) prevention of emissions hazardous to health at the workplace. 5.1.3 Structural assembly The manufacturer shall undertake and record design calculations to show that the structural assembly, e.g. steel sections, auxiliaries, lifting points and fixtures, which form part of the equipment are adequate for safety functions under intended use. 5.1.4 Safety layout The manufacturer shall prepare a safety layout document of the plant. The aim of the safety layout is to give information (normally by means of one or more drawings) about the physical position of safety related elements like, e.g.: a) isolators according to EN 60204-1; b) emergency stop buttons, according to the requirements of EN ISO 13850; SIST EN 13675:2004+A1:2010

Vibration Vibration reduction at source or !See 5.1.18" D

Positioning equipment at a distance from vibration sources to eliminate vibration damage or !See 5.1.6" V, D

Provision of isolation/dampening measures and/or !See 5.1.6" V, D

Dimensioning taking into account the vibration load and See 5.3.4 D

Cutting ring connections shall be used only on pipework having working pressures p < 160 bar

D

Reversed bending stress Selection of material and dimensioning, taking into account the fatigue strength of pipework and hoses See 5.3.4 D

Mechanical stress, kinking, damage Dimensioning taking into account mechanical stress and kinking pipework and hoses and See 5.3.4 D

Protected location (e. g., by distance) or covering !See 5.1.6" D

Thermal degradation Position of hoses and pipe work at a distance from heat source where thermal exposure does not occur or !See 5.1.6" M, D

Covering against thermal radiation (e.g., heat shields) See 5.1.15 V, D

Chemical reaction Taking corrosion/chemical reactions into account when selecting materials and fluids and dimensioning wall thickness !See 5.3.4.2" D

Use of inhibitors in fluids See 5.3.4 M, D

Table 1 — (continued) Column 1 Column 2 Column 3 Column 4 Column 5 !Significant hazards" Hazardous Situation

Safety Requirements and/or Measures Reference

Verifi-cation

Mechanical damage by (cobbling) product/material or during scrap removal (e. g., welding or gas cutting) Protected location or !See 5.1.6" D

Protection against mechanical damage by covering or See 5.1.15 V, D

Use of deflectors See 5.1.15 V, D

Unexpected start-up Automatic pressure reduction in the pressure system (vessels) when the mill is switched off and !See 5.1.6" !EN ISO 13849-1" P, D

Measures to prevent start-up by third parties (e. g., key-operated switch or key transfer system) shall be implemented EN 1037 !EN 60204-1:2006"; 5.4; 5.5; 5.6 See Annex A; A.2 P, D Acoustic and visual warning device for restart EN 981:1996; Table 3 P, D

Dismantling and repair operations Attachment of measuring points with pressure relief facility and

D

Hoselines with quick-dies connecting couplings which are not automatically shutting-off at both ends shall be disconnected only in the de-pressurised state and − !See 5.1.6" D

Warning signs and − !See 5.1.11" V

Operating/maintenance instructions − !See 5.1.6" V

Measurement and operational checks Safe access for testing and inspection purposes − EN ISO 12100-2:2003; 5.5.6 − !See 5.1.12" and Annex A; A.2 V, D 5.2.1.2 Burns, fire, explosion Combustion of fluids may cause − Release of substances hazardous to health − Poisoning caused by fumes Use of low-toxicity and PCB-free fluids in the hydraulic equipment and/or − EN 626-1 − !See 5.1.7" D Position at a distance from heat source so combustion of fluids does not occur or − !See 5.1.6" D Covering against thermal radiation by heat shields − See 5.1.15 V, D − Hazard of asphyxiation by CO2 Acoustic warning device and Warning signs and − !EN ISO 7731" − EN 61310 P, D V Facility to manually override the automatic CO2 deployment

D 5.2.1.3 Release of stored energy − Maintenance work on high pressure vessels − Depressurising valve and − EN 982:1996; 5.1 − EN 983:1996; 5.1 D − Warning signs − !See 5.1.11" V − Maint

...

The article discusses the safety requirements for tube forming and rolling mills and their finishing line equipment. It focuses on fully automated plants used in the process and describes the hazards, situations, and events that can arise from the machines integrated into the plant. It provides preventive measures to avoid hazards and reduce risks. The standard applies to the design, assembly, transport, commissioning, operation, maintenance, and decommissioning of the equipment. It assumes that the machinery is operated and maintained by trained and competent personnel. The standard also mentions the requirement for adequate workplace lighting. It covers automated plants and equipment used for the production of metal seamless hot and cold finished tubes, as well as welded tubes. The scope of coverage for each type of tube is specified.

記事タイトル: EN 13675:2004+A1:2010 - 機械の安全 - チューブ成形およびロールミルとその仕上げライン装置の安全要件 記事内容: このヨーロッパ規格は、チューブ成形、ロール、仕上げの過程で使用される完全自動プラントの健康と安全の要件を説明しています(以下、「プラント」と呼びます)。プラントおよびプラントを形成する特定の機械から予見可能な重大な危険、危険な状況、およびイベントが発生することを説明し、各特定の機械のすべての健康と安全の要件を説明していません。危険を回避し、リスクを減らす予防策を示しています。機械が意図した通りに使用される状況だけでなく、製造業者が予見した異常、機能障害、または誤用などの他の条件も含まれます。 このヨーロッパ規格は、設計、組み立て、輸送、立ち上げ、運用、保守、廃棄の過程で満たす必要がある人の安全を確保する要件を指定しています。 この規格は、設備が適切に訓練された有能な人員によって運用および保守されていると想定しています。機械の設定、調整、および保守による手動介入は、これらの機械の正常な使用の一部として受け入れられます。 この規格は、EN 12464-1または現地の規制に準拠した適切な作業場照明が使用されていると想定しています。 この規格は以下に適用されます: 金属シームレスな熱間および冷間仕上げパイプおよび溶接パイプの生産に使用される自動化されたプラントおよび装置。異なるプラントを形成するための機械のリストは付録Dに示されています(情報提供)。 この規格は以下をカバーしています: シームレスな熱間仕上げパイプの場合:加熱炉の下流からロール工程を経由して中間保管装置や下流の仕上げラインを除くプロセスまで。 シームレスな冷間仕上げパイプの場合:材料供給からロール工程まで排出装置だけを含みますが、保管装置は含まれません。 溶接パイプの場合:コイルの供給からストリップまでです。

기사 제목: EN 13675:2004+A1:2010 - 기계의 안전 - 튜브 형성 및 압연 밀 및 마무리 라인 장비의 안전 요구 사항 기사 내용: 이 유럽 표준은 튜브 형성, 압연 및 마무리 공정에서 사용되는 완전 자동화 설비의 건강 및 안전 요구 사항을 기술합니다 (이하 "설비"로 통칭됨). 이는 설비와 설비를 형성하는 특정 기계로부터 발생하는 예견 가능한 중요한 위험, 위험 상황 및 사건을 설명하며, 각 특정 기계에 대한 전체 건강 및 안전 요구 사항을 설명하지는 않습니다. 이는 위험을 피하는 예방 조치와 위험을 줄이기 위한 조치를 나타냅니다. 이는 기계가 의도한대로 사용되는 상황뿐만 아니라 제조업자가 예견한 기타 조건, 예를 들어 예견 가능한 결함, 기능 장애 또는 오용까지 포함합니다. 이 유럽 표준은 장비의 설계, 조립, 운송, 도입, 운영, 유지 보수 및 폐기 과정에서 충족해야 하는 사람들의 안전을 보장하기 위한 요구 사항을 명시합니다. 이 표준은 설치가 적절하게 훈련받고 유능한 인력에 의해 운영 및 유지 보수되고 있다고 가정합니다. 기계의 설정, 조정 및 유지 관리를 위한 수동 개입은 이러한 기계의 정상 사용의 일부로 수용됩니다. 이 표준은 EN 12464-1 또는 현지 규정에 준하는 적당한 작업장 조명이 충분히 사용된다고 가정합니다. 이 표준은 다음에 적용됩니다: 금속 신발 열간 및 열간 마무리 튜브 및 용접 튜브 생산을 위해 운영되는 자동화 설비 및 장비. 각기 다른 설비를 구성할 수 있는 기계 목록은 부록 D에 나와 있습니다 (정보 제공). 이 표준은 다음을 다룹니다: 금속 신발 열간 완성 튜브의 경우: 가열로 하류에서 재료 공급으로부터 압연 공정을 거쳐 중간 저장 장비 또는 하류 마무리 라인을 포함하지 않고까지의 과정. 금속 신발 냉간 완성 튜브의 경우: 재료 공급을 통해 압연 공정에서 배출 장비로 이동하지만 저장 장비는 포함하지 않습니다. 용접 튜브의 경우: 봉지 충전부터 스트립으로부터 출발합니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...